Features of welding zinc pipes

Deciding which electrodes to cook galvanizing with, choose the desired brand based on the operating conditions of the welded product during further use. Welding is no different from conventional welding, with the exception of some nuances:

- The temperature effect on the zinc layer leads to its burnout with the formation of toxic gases, therefore, in the process of welding, safety precautions must be observed - use flow ventilation and protect the respiratory organs from gases.

- Before carrying out work, test welding should be carried out on short sections of pipes for the selection of electrodes and the optimal mode of the power supply.

- To burn out zinc, additional energy is needed, so the current on the welding machine is set 10% more than when welding uncoated steel.

- A better seam is obtained when using rutile electrodes (this is well known), when welding with electrodes with a basic coating, zinc further degrades the quality of the seam, making the edges of its edges torn and uneven. Therefore, it is recommended that before welding with electrodes with the main coating, prepare the place of the future joint - remove the zinc coating with acid or abrasive materials.

Rice. 13 Surface treatment with zinc paint for corrosion protection

Features of welding

The direct technological map for welding galvanized pipes provides for certain parameters of the work and the workflow, which must comply with the regulations. The welding process must provide for certain characteristics, the purpose of which is to prevent damage to the surface of the galvanized coating during technological welding. Thus, electric welding of galvanized pipes involves the application of a special flux to the surface of the galvanized coating. This will prevent burnout of zinc at the time of welding.

According to the procedure for welding galvanized pipes, the joint venture provides for the following steps:

- At the place of welding, a flux compound is applied, which has a liquid-viscous technological state.

- In the process of welding, the flux connection passes into a different structure, while melting occurs, and the flux does not emit combustion products, nor does it evaporate, but welding galvanized pipes is harmful to health, without the use of special protective devices for the operator of welding equipment.

- At the end of technological welding, a perfectly even and strong seam is obtained at the junction. The surface is completely protected from the appearance of corrosion processes in the future.

https://youtube.com/watch?v=QFoiF2vXzVE

How to weld pipes by electric welding correctly step by step guide

Selection of electrodesVarieties of welds and pipe jointsPreliminary work with partsWelding processSubtleties of electric weldingAssembling jointsWorking with rotary and fixed jointsChecking the reliability of jointsSafety rules when working with a welding machine

In the process of housekeeping, there are often cases when it is required to build some kind of structure from ordinary pipes or profiles. Often, light and easy-to-install plastic pipes, as well as steel products with threaded fasteners, are used for these purposes. However, in this article we will look at how to properly weld a pipe for heating or other necessary systems in your home, because the options mentioned above are not always acceptable and appropriate.

Selection of electrodes

The first thing you need to perform welding work on heating pipes or other structures is electrodes. Not only the reliability of the obtained welds and the tightness of the system, but also the process of performing work will depend on the quality of this consumable.

An electrode is understood as a thin steel rod with a special coating, which allows for a stable arc in the process of electric welding of pipes, and is involved in the formation of a weld, and also prevents metal oxidation.

According to the type of core, there are such electrodes:

- With non-melting center. The material for such products is graphite, electrical coal or tungsten.

- With melting center. In this case, the core is a wire, the thickness of which depends on the type of welding.

As for the outer shell, the many electrodes that are found on the market should be divided into several groups.

So, the coverage can be:

- Cellulose (grade C). These products are mainly used for welding work with pipes of large sections. For example, for the installation of pipelines for transporting gas or water.

- Rutile acid (RA). Such electrodes are optimal for welding metal pipes for heating or plumbing. In this case, the weld is covered with a small layer of slag, which is easily removed by tapping.

- Rutile (RR). This type of electrode makes it possible to obtain very accurate welding seams, and the slag formed during operation is very easily removed. Mostly such electrodes are used in places of corner joints or when welding the second or third layer.

- Rutile cellulose (RC). Such electrodes can perform welding in absolutely any plane. In particular, they are very actively used to create a long vertical seam.

- Basic (B)

Varieties of welds and joints

Welding of steel pipes is carried out by a welding machine using the melting method. The welding machine forms a direct current from alternating current and, by means of an electric arc, heats a local area of \u200b\u200bthe product to the desired temperature. The formation of an electric arc occurs on a metal rod (electrode). Where the arc works, a special atmosphere is formed, which, when the metal melts, does not allow it to oxidize. Thanks to the high-quality welded seam, leaks are completely excluded, since the connection is sealed.

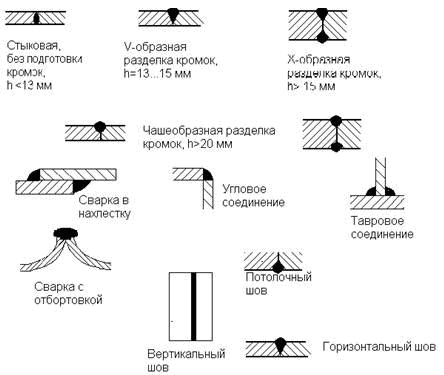

There are many ways to suture. Which method to choose depends on the thickness of the pipes and the material from which they are made. The main types of seams:

- in Taurus;

- butt;

- overlap;

- angular.

It is also important to consider the location of the pipes in relation to each other:

- bottom seam. During welding, the electrode is placed over the elements to be joined. With this method, the welder can clearly see all the welded areas, so this method is the most convenient.

- Ceiling seam. The electrode is placed under the element to be welded. In this case, the operator raises his hand up and holds it above his head, so this method is used only during repairs or when replacing a deformed pipe section. When arranging a new system, it is not used.

- vertical seam. This connection method is used if 2 pipes are located horizontally. The welder moves the electrode up and down and from bottom to top (in the vertical direction).

- Horizontal seam. Often, horizontal connections make the installation of heating and plumbing systems. In this case, the two pipes are in a vertical position.

Is it possible to weld galvanized pipes

The rules for assembling pipelines are determined by GOSTs. However, the standard requirements are not suitable for working with galvanized pipes. The protective layer of zinc boils at a temperature of 906 degrees Celsius. However, the base must be heated to 1200 degrees.Because of this, innovations were introduced, according to which two possible ways to solve the problem were indicated:

- Welding using flux. The composition should not contain components that dissolve in water.

- Reduced welding time. So zinc does not have time to evaporate. To complete the work faster, you need to increase the temperature using the current regulator.

The welder chooses the method depending on the situation, technical requirements.