Tool types

The tool for mounting polypropylene pipes can be divided into:

- welders;

- glue guns;

- pipe cutters;

- stripping.

Welders

Welders are of two types:

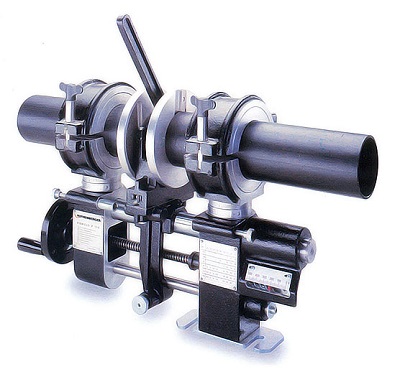

- Mechanical apparatus. It is used if it is necessary to connect pipes of large diameter or a large force is required to align the joints. Device:

- support frame;

- instrument block;

- hydraulic drive.

Half-ring grips are located on the left and right. Between them, for pressure distribution and alignment, inserts are installed, the inner diameter of which corresponds to the outer diameter of the pipes being welded.

Mechanical welding machine

- Manual welding machine. Serves for welding pipes of small diameter up to 125 mm. Device:

- thermostat;

- a heating plate with holes in which nozzles with a non-stick coating are installed;

- a set of nozzles for installing the elements to be welded (in pairs), the Teflon coating prevents polypropylene from sticking to the heated nozzle.

Connecting with a handheld device

Glue guns

The use of a gun simplifies the installation work. A socket connection using couplings of connecting or other elements can be made using glue for polypropylene pipes. Advantages of a hot glue gun:

- setting speed - from 1 to 3 minutes;

-

the reliability of the seam is practically not inferior to other types of connections.

Surfaces to be bonded must be free of dirt and grease.

Pipe cutters

Types of pipe cutters:

Precision scissors with a ratchet mechanism (for pipes up to 42 mm in diameter) have a steel blade with a gear rack.

Scissors for polypropylene pipes

Roller pipe cutter with ratchet mechanism. The pipe is inserted into a C-shaped recess and, when the handles are closed, it is cut off with a blade located opposite. The cutting must be carried out strictly at an angle of 90o. Deviation in the cutting process leads to deformation of the cutting line or even breakage of the scissors.

Roller pipe cutter for polypropylene pipes

- Cordless pipe cutter with a small electric motor that provides high cutting speed.

- Guillotine pipe cutter, which is used for cutting pipes of large diameter.

In the absence of a pipe cutter, you can use an ordinary hacksaw for metal or wood, but then the ends must be carefully cleaned of burrs. Also, when cutting, the pipe must not be deformed.

Cleanups

For hot water and heating systems, it is recommended to use reinforced polypropylene pipes. Pipes reinforced with fiberglass do not need to be stripped, since the mesh is located between the layers of polypropylene, it is not afraid of water and does not come into contact with the fitting. Aluminum foil used for reinforcement must be removed from the joint prior to welding. Aluminum in contact with water can cause electrochemical processes, which will lead to the destruction of the reinforcing film. In the case of external reinforcement, aluminum will interfere with the welding process of polypropylene elements. Therefore, pipes reinforced with aluminum foil need to be stripped. Types of cleaning tools:

- manual - with removable, non-removable handles or corrugation;

- drill bits.

Hand strippers and drill attachment

With small amounts of cleaning work and lack of experience, it is better to use a hand tool.

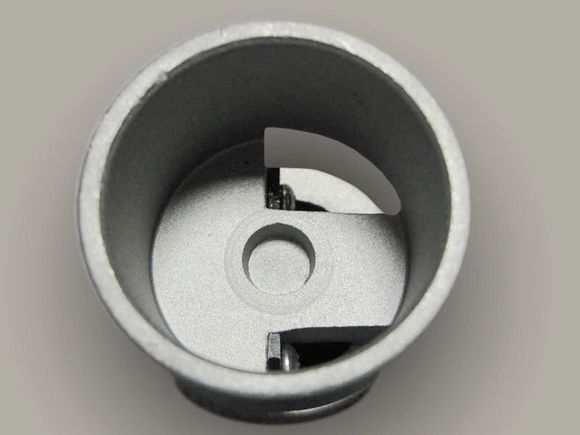

- For the outer layer, couplings with knives from the inside (material - tool steel), the so-called shavers, are used. The diameter of the tool is selected according to the diameter of the cleaned pipe. Double-sided couplings are often used, allowing work with pipes of two different diameters.

Shaver for polypropylene pipes

- For the inner layer, trimmers are used. Knives are located from the inner end. You just need to insert the pipe into the tool, turn it several times and you can weld.

Trimmer for polypropylene pipes

It is faster to remove the inner layer, because about 2 mm of foil is required to be removed. When removing the outer layer, it is necessary to remove about 2 cm.

Drill nozzle

Nozzles on a drill differ from manual strippers with a steel rod for installation in a drill, screwdriver or puncher. Serve to remove both the outer and inner reinforcing layer (the location of the knives determines the type of layer to be removed).

Mounting methods

There are two options for installing pipelines - hidden, outdoor. The second option is simple, but pipes don't always look pretty. The first option is more laborious, but the pipeline will be hidden from view.

External mount

To perform outdoor installation of the pipeline, you need to prepare a minimum set of tools. Regardless of the fastener type, the workflow is the same. Dowels are used to secure clips or clamps.

External fixing of pipes to the wall

Hidden mount

To hide the tubes in the walls, it is necessary to use high-quality materials, to comply with all technologies. Polypropylene withstands high loads, exposure to chemicals. Due to this, the material will last a long time without deformation. More tools are needed to perform the installation than with an open fixing of the pipeline.

System masking

In order to independently hide the pipes in the wall, you need to understand the stages of the work, find out some features.

Preparing for installation

Before installing a pipeline made of polypropylene, you need to draw up a drawing of the mains, mark on it the connection points, the connection of household appliances, stopcocks. With it, it will be possible to calculate the number of pipes, fittings.

After drawing up the drawing, it is required to prepare tools, consumables:

- grinder with a disc for concrete;

- spatula, trowel, container for mixing mortar, cement;

- special scissors;

- perforator, hammer, chisel;

- soldering iron for plastic with a set of heads of different diameters.

After preparing the tools, you need to mark the walls along the path of laying the pipeline.

Preparation for the installation of polypropylene pipes

Installation

Step-by-step instructions for installing polypropylene pipes in the wall:

- After marking, you need to pierce the wall. To do this, with the help of a grinder, recesses in concrete are cut. The gates must be larger than the width of the pipes in order to be able to lay a shock-absorbing material, cover the holes with cement, and apply a decorative coating.

- Using a perforator, clean the strobes from concrete to the desired depth.

- Connect pipes.

- Lay the pipeline in strobes, wrap them in advance with energy flex.

It remains to check the system for leaks, cover the holes with cement mortar. If the plumbing was originally fixed to the wall, it can be hidden with a drywall box.

Not every home owner likes the outdoor location of the water supply. To remove it from your eyes, you can brick the pipes into the wall. To do this, you will need to dismantle the old system, make strobes, lay the assembled water supply, seal the recesses with cement

It is important to select in advance the installation locations for detachable connections, fittings, valves, in order to leave free access to these parts.

How NOT to install pipes when renovating a bathroom. Errors in the installation of pipes by plumbers

Watch this video on YouTube

Determination of the optimal diameter

The installation of the line is always preceded by a preliminary calculation of polypropylene pipes. It is carried out in order to determine the number and optimal diameter of products for a particular pipeline system, based on its purpose.

Properly selected diameter ensures minimum losses and necessary pressure in the system even during the hours of maximum (peak) water consumption. Calculation is especially important when designing a water supply system for an apartment building with a large number of plumbing fixtures.

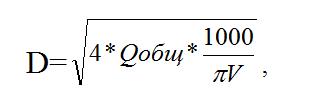

You can calculate the internal diameter of the pipe yourself using the formula:

- where Qtotal is the maximum (total) water consumption,

- V is the speed at which water is transported through the pipes.

For thick pipes, the velocity value is taken equal to 2 m / s, and for thinner pipes - 0.8 - 1.2 m / s.

But, owners of apartments and small country houses should not waste time on complex calculations. Considering that the overall permeability of the pipeline system depends on the throughput of the narrowest point, it is sufficient to purchase pipes with a diameter of 20.0 mm, provided that the length of the water supply system does not exceed 10 meters. With a standard number of sanitary appliances (sinks, toilet bowls, washbasins), the throughput of pipes of this diameter will be sufficient.

With a total length of the pipeline up to 30 meters, it is necessary to use 25 mm products in diameter, and with a length of more than 30 meters - 32 mm.

Installation requirements

Before laying the water pipe inside the wall structures, you need to study some rules for the work:

- Before immuring the pipe inside the strobe, it is necessary to make a layer of shock-absorbing material between the pipeline and the base. It is needed so that the elements expanding when heated do not put pressure on the concrete.

- The fewer connections, the higher the reliability of the system.

- Access to pipes should be in those places where measuring instruments, detachable fittings, and shutoff valves are located.

Parts made of polypropylene have different markings:

- PN 10 - used for the manufacture of pipelines for cold water. Can't withstand high pressure.

- PN 16, PN 20 - designed for assembly of pipelines withstanding pressure up to 1.5 MPa.

- PN 25 - have a reinforcing layer of fiberglass, aluminum. Withstand pressure from 1.5 to 2.5 MPa.

The choice of tubes depends on the required specifications.

Features of PP pipes

Polypropylene products have qualities that distinguish them from alternative products:

- Light weight, thanks to which the pipes are convenient to transport and work with them.

- Ease of installation. Operations for connecting pipelines to each other, as well as with fittings, do not cause difficulties even for novice craftsmen.

- Non-susceptibility to corrosion, as well as lime deposits on the inner surface, significantly increase the service life of the product.

- High strength allows the use of polypropylene products both in low-pressure systems and for pipelines operating under pressure in a bathroom, boiler room and other premises.

- Resistance to low temperatures and freezing of water makes it possible to use products for laying external highways.

- Good throughput and low degree of thermal conductivity provide high efficiency of PP products.

Features of polypropylene

To make a durable pipeline, you need to choose high-quality material. Previously, systems were made of galvanized steel, stainless steel, and cast iron. Over time, these materials were replaced by polypropylene. It combined the strengths of metals, but the price of products became lower.

This material is suitable for the manufacture of hot and cold water pipes.

It is important to take into account the fact that the system should not operate at high temperatures for a long time. Otherwise, it will lead to the destruction of the structure.

Polypropylene tubes can be laid in concrete screeds, mounted outside the walls.