Infrared heating of industrial premises

Another way to create good working conditions for workers is to use infrared radiation. Devices generate ray energy, which is transmitted to surrounding objects, heating them. This heat is then released into the air. The method has a significant drawback: a uniform distribution of energy is not always possible. Under the ceiling it is much warmer than at lower levels.

The heating element for infrared heating can be different:

- halogen - if an impact or a fall occurs, the tube may break;

- carbon fiber - energy consumption is reduced by almost 2.5 times;

- ceramic - a gas-air mixture burns inside the heater, which causes the device to heat up and give off heat to the environment.

Every year it is necessary to prepare the boiler room for the heating season. In this case, in winter there will definitely not be any problems.

Do not forget about the ceiling heating system, which is often used to heat industrial buildings. With the help of special devices, it is not the air that is heated, but the walls, ceiling, floor. There is no circulation, therefore, the risk of getting a cold or sore throat is reduced by the workers of the department or workshop. In the ceiling heating system, a number of advantages are distinguished, such as: long service life, takes up little space, is easy and quick to install, and is light in weight.

SNiP norms for heating industrial premises

Before you start designing a particular system, think about which industrial heating boiler to choose, you need to study the following rules and follow them. Be sure to take into account heat loss, because not only the air in the room heats up, but also equipment and objects. The maximum temperature of the coolant (water, steam) is 90 degrees, and the pressure is 1 MPa.

When drawing up a project for heating, landings are not taken into account. The use of boilers and other gas-fired equipment is permitted only if the oxidation products are removed in a closed manner and there is no danger of an explosion or fire in the workplace.

After completion of work, the heating system is filled with water and a control check is carried out.

Each of these heating methods has its own advantages and disadvantages. It is necessary to choose the best of the methods on the basis of the technological processes that are carried out in a particular workshop. Workers cannot stay indoors if the air temperature there is below 10 degrees. Warehouses usually store finished products. To maintain its quality, you need to maintain an optimal microclimate.

Interesting on the topic:

-

Preparing the system for the heating season

-

Pipes for different heating systems

-

Polypropylene pipes for heating: pros and cons.

-

Heating pipe insulation

Calculation of materials for heating

It will be difficult for a person who is far from the design of the heating system to correctly calculate the materials for heating - at a minimum, it is necessary to at least visualize the entire heating system assembly and know the component parts of the pipe intended for use. That is why, in order to correctly calculate the amount of materials, you will have to study the whole ins and outs of the heating system.

Doubt? Then contact the experts you know and ask them, if not to assemble the entire system for you, then at least draw it with an indication of all the necessary elements. A good friend over a bottle of tea will be happy to help you solve this problem. Well, I, for my part, will try to at least roughly describe what components and what you need.

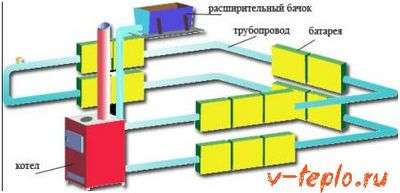

Let's start with a boiler - as an example, consider a double-circuit boiler, which is most often used in small houses and apartments. Installing a heating boiler and connecting it to the heating system will require you to have at least four ball valves with detachable connections, two mechanical filters and four threaded adapters for connecting pipelines.

To tie one heating battery, you will need 2 radiator valves (regulating and shut-off), a Mayevsky valve, a plug, again, two threaded adapters for connecting batteries to pipelines and two tees installed directly on the heating line.

Approximately calculate the footage of the pipe, I think no one will have problems - for this you need to clearly understand the installation locations of the batteries. The resulting footage is multiplied by two, because two pipes are usually laid (supply and return). Pipe diameters are another matter - as a rule, all wall-mounted double-circuit boilers are equipped with ø3 / 4 ″ connections. In principle, for houses and apartments up to 100 sq.m. this is quite enough, but for more extensive systems, larger pipe diameters will be needed. But if only small heating systems are concerned, then for their installation you will need ø3/4″ pipes for laying pipelines and ø1/2″ pipes directly for connecting batteries.

To be honest, such complex work as the calculation and installation of a heating system. an exceptionally competent person who knows how to handle modern tools and possesses a large amount of knowledge in the field of heat engineering can independently perform. Of course, you can try everything else, but for this you will have to learn a little and master a considerable amount of information.

(Votes: 8 )

Installation and start-up notes

For long-term operation of the equipment and its high efficiency, some rules should be observed:

- The pump is mounted so that its shaft is horizontal. For equipment with a "wet" rotor, this requirement is mandatory! The orientation of the pipelines (vertical, horizontal or inclined run) does not matter.

- The terminal box must be at the top. This will ensure safety even in case of possible leaks.

- Modern units allow installation both for supply and return, but location on the return section will reduce thermal loads and increase equipment life.

- When installing, be sure to bypass for circulation pump. This will allow you to use the heating system in natural circulation mode in the event of a power failure.

- The average speed of the equipment is chosen as the working one. The system is started at the highest speed (in systems with automatic blocking is disabled).

- After starting, the accumulated air should be removed through the special valves provided in the design.

Heating scheme

Despite the above, we will not use radiant heating for our scheme. The fact is that most of the industrial buildings are still Soviet-style, with large heat losses. They need the most inexpensive heating option, preferably using alternative fuels.

So, the average volume of such buildings is 5760 cubic meters, and in order to make up for the losses, a power of 108 kilowatts per hour is required. These are very approximate figures, which depend on a number of factors. We only note that we should have another 30% power reserve. Our fuel is wood and pellets.

In order to get the power we need, about 40 kilograms of fuel per hour are required, and if the production has an eight-hour working day (plus an hour break), then 360 kilograms of fuel will be required per day. On average, the heating season is 150 days, which means that in total we will need 54 tons of firewood. But this value is maximum.

Now let's calculate the cost. (see table)

Since competition in the domestic market is growing every day, manufacturers are forced to pay attention to all cost items. If you look at this list, then far from the closing position will be the cost of heating various industrial premises.

Since the cost of energy carriers has increased, their percentage of prime cost has also increased.

Air heating of the production room

If earlier such a question as the choice of the most economical option was not yet so acute, now it is positioned in the category of the most relevant. Air heating of a production facility in such a situation is often considered the most efficient and at the same time the most economical option.

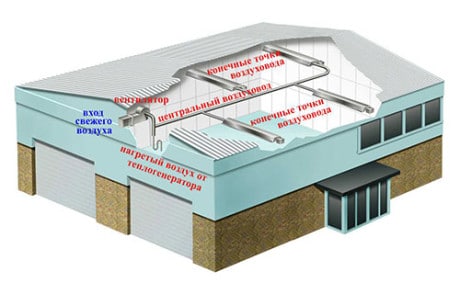

Air heating of industrial premises

Through the system of air ducts, heat is distributed throughout the territory of the production workshop

The air heating system at each specific industrial enterprise can be used as the main one, or as an auxiliary one. In any case, the installation of air heating in the workshop is cheaper than water heating, since it is not necessary to install expensive boilers for heating industrial premises, lay pipelines and mount radiators.

Advantages of the air heating system of the industrial premises:

- saving the area of the working area;

- energy efficient consumption of resources;

- simultaneous heating and air purification;

- uniform heating of the room;

- safety for the well-being of employees;

- no risk of leaks and freezing of the system.

Air heating of a production facility can be:

- central - with a single heating unit and an extensive network of air ducts through which heated air is distributed throughout the workshop;

- local - air heaters (air-heating units, heat guns, air-heat curtains) are located directly in the room.

In the centralized air heating system, to reduce energy costs, a recuperator is used, which partially uses the heat of the internal air to heat the fresh air coming from outside. Local systems do not carry out recovery, they only warm the internal air, but do not provide an inflow of external air. Wall-ceiling air heaters can be used for heating individual workplaces, as well as for drying any materials and surfaces.

By giving preference to air heating of industrial premises, business leaders achieve savings due to a significant reduction in capital costs.

Easy Ways to Calculate Heat Load

Any calculation of the heat load is needed to optimize the parameters of the heating system or improve the thermal insulation characteristics of the house. After its implementation, certain methods of regulating the heating load of heating are selected. Consider non-labor-intensive methods for calculating this parameter of the heating system.

The dependence of heating power on the area

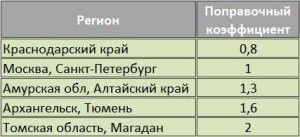

Table of correction factors for various climatic zones of Russia

For a house with standard room sizes, ceiling heights and good thermal insulation, a known ratio of room area to required heat output can be applied. In this case, 1 kW of heat will be required per 10 m². To the result obtained, it is necessary to apply a correction factor depending on the climatic zone.

Let's assume that the house is located in the Moscow region. Its total area is 150 m². In this case, the hourly heat load on heating will be equal to:

The main disadvantage of this method is the large error. The calculation does not take into account changes in weather factors, as well as building features - heat transfer resistance of walls and windows. Therefore, it is not recommended to use it in practice.

Enlarged calculation of the thermal load of the building

The enlarged calculation of the heating load is characterized by more accurate results. Initially, it was used to pre-calculate this parameter when it was impossible to determine the exact characteristics of the building. The general formula for determining the heat load on heating is presented below:

Where q ° is the specific thermal characteristic of the structure. The values must be taken from the corresponding table, and - the correction factor mentioned above, Vn - the external volume of the building, m³, Tvn and Tnro - the temperature values inside the house and on the street.

Table of specific thermal characteristics of buildings

Suppose that it is necessary to calculate the maximum hourly heating load in a house with an external volume of 480 m³ (area 160 m², two-story house). In this case, the thermal characteristic will be equal to 0.49 W / m³ * C. Correction factor a = 1 (for the Moscow region). The optimum temperature inside the dwelling (Tvn) should be + 22 ° С. The outside temperature will be -15°C. We use the formula to calculate the hourly heating load:

Compared to the previous calculation, the resulting value is less. However, it takes into account important factors - the temperature inside the room, on the street, the total volume of the building. Similar calculations can be made for each room. The method of calculating the heating load according to aggregated indicators makes it possible to determine the optimal power for each radiator in a particular room. For a more accurate calculation, you need to know the average temperature values \u200b\u200bfor a particular region.

This calculation method can be used to calculate the hourly heat load for heating. But the results obtained will not give the optimally accurate value of the heat loss of the building.

Calculation corrections and advice

The above methods for calculating the number of radiator sections are perfect for rooms whose height reaches 3 meters. If this indicator is greater, it is necessary to increase the thermal power in direct proportion to the increase in height.

If the whole house is equipped with modern plastic windows, in which the heat loss coefficient is as low as possible, it becomes possible to save money and reduce the result obtained by up to 20%.

It is believed that the standard temperature of the coolant circulating through the heating system is 70 degrees. If it is below this value, it is necessary to increase the result by 15% for every 10 degrees. If it is higher, on the contrary, decrease it.

Premises with an area of more than 25 square meters. m. to heat with one radiator, even consisting of two dozen sections, will be extremely problematic. To solve this problem, it is necessary to divide the calculated number of sections into two equal parts and install two batteries. Heat in this case will be distributed throughout the room more evenly.

If there are two window openings in the room, heating radiators should be placed under each of them. They should be 1.7 times more than the nominal power determined in the calculations.

Having bought stamped radiators, in which sections cannot be divided, it is necessary to take into account the total power of the product. If it is not enough, you should consider buying a second battery of the same or slightly less heat capacity.

Correction factors

Many factors can influence the final result. Consider in what situations it is necessary to make correction factors:

- Windows with conventional glazing - magnification factor 1.27

- Insufficient thermal insulation of the walls - increasing factor 1.27

- More than two window openings per room - increasing factor 1.75

- Bottom-wired manifolds - multiplying factor 1.2

- Reserve in case of unforeseen situations - increasing factor 1.2

- Use of improved thermal insulation materials - reduction factor 0.85

- Installation of high-quality heat-insulating double-glazed windows - reducing factor 0.85

The number of adjustments to be made to the calculation can be huge and depends on each specific situation. However, it should be remembered that it is much easier to reduce the heat transfer of a heating radiator than to increase it. Therefore, all rounding is done up.

Summing up

If you need to make the most accurate calculation of the number of radiator sections in a complex room, do not be afraid to contact specialists. The most accurate methods, which are described in specialized literature, take into account not only the volume or area of the room, but also the temperature outside and inside, the thermal conductivity of the various materials from which the house box is built, and many other factors.

Of course, you can not be afraid and throw a few edges to the result. But an excessive increase in all indicators can lead to unjustified expenses, which are not immediately, sometimes and not always, possible to recoup.

Air heating of industrial premises

This method of heating production areas became popular back in the 70s. The principle of operation is based on air heating by heat generators, water or steam heaters. Air through the collectors enters those areas where it is necessary to maintain the desired temperature. To distribute air flows, special distribution heads or blinds are installed. This is far from an ideal method of heating, it has significant drawbacks, but it is used quite widely.

Central and zonal systems

Depending on the needs of building owners, uniform heating of the entire room or individual zones can be equipped. Central air heating is a device that takes air from outside, heats it up and delivers it to the premises. The main disadvantage of this type of system is the inability to control the temperature in individual rooms of the building.

Zone heating allows you to create the desired temperature in each room. To do this, a separate heating device (most often a gas convector) is installed in each room, which maintains the desired temperature. The zonal system is cost-effective, as it uses only as much energy as is needed for heating, and wasteful costs are minimized. During installation, there is no need to lay air ducts.

An experienced specialist should determine the appropriate type of system and calculate the air heating of the production room. The following factors are taken into account:

- heat losses;

- the required temperature regime;

- the amount of heated air;

- power and type of air heater.

Advantages and disadvantages

Important advantages can be considered a quick heating of the air, the possibility of combining heating with ventilation. The disadvantage is associated with a well-known law of physics: warm air rises. A warmer zone is created under the ceiling than at the level of human growth. The difference can be several degrees. For example, in workshops with ceilings 10 m high below, the temperature can be 16 degrees, and in the upper part of the room - up to 26. To maintain the desired thermal regime, the system must work constantly. Such inappropriate energy consumption forces owners to look for other methods of heating buildings.

Scheme of air heating of industrial premises

How to correctly calculate the power of the heating system

SanPiN norms are taken as the basis, which clearly regulate the temperature limit in residential premises from 18 to 24 ° C, but this applies to district heating, although of course, any owner of an autonomous heating system has the right to move the limit in any direction. It is not recommended to do this, as these values are the most optimal for creating a comfortable environment and fuel consumption.Do not forget that the highest efficiency of a boiler or other unit, and of the entire system as a whole, is achieved precisely when operating in the “normal” mode, when regulating in the direction of decreasing or increasing, the efficiency will always decrease.

To calculate the power of the heating system, the following data are used:

- The average annual temperature for a given region during the heating period - data from the corresponding directory;

- Wind rose in the same period for this region - data from the directory;

- Heat loss through building envelope - data from the reference book for each type of material (adobe, brick, concrete, wood, etc.), including losses through window and door openings;

— The area of heated premises;

- Power of the heat generator and heating devices;

– The energy carrier used is gas, electricity, coal, wood, etc.

- It should be remembered that it is advisable to carry out the calculation of the heating system only after all energy saving measures have been taken and possible heat leaks have been eliminated. If you calculate the required power, and perform the insulation later, it turns out that even at minimum power, the room will be quite hot, but this will become especially noticeable during thaws and transition periods.

According to the available reference data, you can see how much heat in kilowatts is lost through the fences at low outside temperatures in each of the rooms per unit of time, and, therefore, the heating system should compensate for this loss on average. Based on the data obtained, the choice of a heat generator and heating appliances of the appropriate power is carried out.

Water heating of industrial facilities

Water heating is appropriate if there is a private boiler room nearby or if there is a central water supply. The main component in this case will be an industrial heating boiler, which can run on gas, electricity or solid fuel.

Water will be supplied under high pressure and temperature. Usually with its help it is impossible to heat large workshops with high quality, therefore the method is called "on duty". But there are a number of advantages:

- air circulates freely throughout the room;

- heat is distributed evenly;

- a person can actively work in conditions with water heating, it is absolutely safe.

The heated air enters the room, where it mixes with the environment and the temperature is balanced. Sometimes it is necessary to reduce energy costs. To do this, the air is cleaned with the help of filters and reused for heating industrial buildings.

Calculation of heating radiators by area

The easiest way. Calculate the amount of heat required for heating, based on the area of \u200b\u200bthe room in which radiators will be installed. You know the area of \u200b\u200beach room, and the need for heat can be determined according to the building codes of SNiP:

- for an average climatic zone, 60-100W is required for heating 1m 2 of a dwelling;

- for areas above 60 o, 150-200W is required.

Based on these norms, you can calculate how much heat your room will require. If the apartment / house is located in the middle climatic zone, 1600W of heat (16 * 100 = 1600) will be required to heat an area of 16m 2. Since the norms are average, and the weather does not indulge in constancy, we believe that 100W is required. Although, if you live in the south of the middle climatic zone and your winters are mild, consider 60W.

Calculation of heating radiators can be done according to the norms of SNiP

A power reserve in heating is needed, but not very large: with an increase in the amount of power required, the number of radiators increases. And the more radiators, the more coolant in the system. If for those who are connected to central heating this is not critical, then for those who have or plan individual heating, a large volume of the system means large (extra) costs for heating the coolant and a large inertia of the system (the set temperature is maintained less accurately). And the logical question arises: “Why pay more?”

Having calculated the need for heat in the room, we can find out how many sections are required. Each of the heaters can emit a certain amount of heat, which is indicated in the passport.The found heat demand is taken and divided by the radiator power. The result is the required number of sections to make up for losses.

Let's count the number of radiators for the same room. We have determined that we need to allocate 1600W. Let the power of one section be 170W. It turns out 1600/170 \u003d 9.411 pieces. You can round up or down as you wish. You can round it into a smaller one, for example, in the kitchen - there are enough additional heat sources, and into a larger one - it is better in a room with a balcony, a large window or in a corner room.

The system is simple, but the disadvantages are obvious: the height of the ceilings can be different, the material of the walls, windows, insulation and a number of other factors are not taken into account. So the calculation of the number of sections of heating radiators according to SNiP is indicative. You need to make adjustments for accurate results.