Sink restoration, crack masking

Ceramics tend to crack, impacts are especially dangerous for it, or such a process occurs over time. That's when the question arises, how to close a crack in a ceramic sink and give it a neat look.

Often used for such work are specially designed sealants that are water resistant. You should purchase a good quality composition suitable for a ceramic sink in a store and simply cover the cracks with it.

Naturally, you should first clean the place of repair from rust, mold and grease, and dry it. Now you know exactly how to close the crack and you can safely go to the store for materials.

Advantages and disadvantages of stone sinks

There are practically no drawbacks to a sink made of artificial stone - except for their huge weight and high cost, then we can safely say that these products have no drawbacks. There are, however, a couple of minor points, but, as a rule, they are not taken into account: firstly, overheated dishes should not be placed on an artificial stone sink, since a frying pan just removed from the stove can leave an irreparable mark on the material. And, secondly, such products are afraid of strong blows - for example, if a sledgehammer falls from a height of half a meter onto a sink, then a crack will probably remain on it. Although in most cases this moment primarily depends on the quality of the product - and it is unlikely that anyone will throw specially heavy objects at the sink.

Integrated sink made of artificial stone photo

Now, as for the advantages of a cast stone sink, there are a lot of them, but we will focus only on the main advantages. These include the following points:

- Very long service life. Almost all manufacturers of such sinks install a guarantee of 10 years or more on their products - if we talk about the actual service life, then we can safely guarantee 50 years or more. Such a sink can be safely passed on to children and grandchildren. Naturally, all this depends primarily on the quality of workmanship, and it is for this reason that you need to purchase such products from trusted manufacturers.

- Hygiene or, as they say, antiseptic - thanks to special additives, various pathogenic microbes do not breed in such sinks. In these sinks, a putrefactive smell and similar unpleasant moments never appear.

- A well-made mortise sink made of artificial stone has a huge margin of safety, which exceeds the similar characteristics of products made of natural stone by two or even three times. It is even stronger than concrete. So a dropped pot or even a cast-iron skillet will not cause her any harm.

-

High degree of maintainability. Scratches and even chips are removed very simply - the first ones are polished, and the second ones are simply sealed with a special acrylic-based adhesive.

There are other advantages that have made modern sinks made of artificial stone widespread, for example, the lack of restrictions in production. By casting, a sink of any shape and any color can be made.

Bonding a marble sink

Pipe bonding.

In order to manage to break a marble sink or toilet bowl into several pieces, these items must at least be dropped on a hard surface. But more often it turns out that a solid heavy object falls on them, in this case the marble, although it will not split into pieces, will definitely have small chips. Sometimes this results in cracks.

For the restoration of such objects, gruel from pounded alabaster in glue water is used, which is suitable for white marble.And if necessary, add crushed slate, ocher or other fillers to give the mixture the desired shade. After such a putty on the seams or cracks hardens, it should be polished.

Recipe five. Crushed gypsum in 4 parts is mixed with 1 part of powdered gum arabic. A strong solution of borax in cold water is added to the resulting mixture to the state of batter. The object glued in this way is left for 5-7 days in a cool place.

If you need to make the seam almost invisible, then a cracked marble toilet or sink can be glued together using a mixture based on the same marble, but ground into powder.

Recipe six. Powdered marble is mixed with rubber and wax in the following proportion: 2 parts of wax and 1 part of natural rubber go to 2 parts of marble powder. The mixture is heated in a water bath, then it is applied to the well-prepared surfaces to be glued, squeezed and excess glue is removed.

Another recipe for gluing faience and glass looks like this: 100 g of slaked lime and 100 g of sugar are dissolved in 1 liter of water. All this is cooked on low heat for 3 hours without boiling. Then the mixture settles and the water is drained. 0.5 kg of crushed tile adhesive is added, the mass is stirred and aged for half a day. Next, excess water is drained from the swollen glue, and it is put on a slow fire for complete dissolution. Such glue is used in a chilled state.

This adhesive is still inferior to synthetic in terms of water resistance and susceptibility to microorganisms. But in the absence of a synthetic adhesive, this one will do, until it becomes possible to use a more durable one.

Of course, the list of synthetic ready-made and self-made adhesives provided is not exhaustive. In our time of constant development and innovation, other brands can be found in specialized stores.

Adhesive compositions of self-preparation

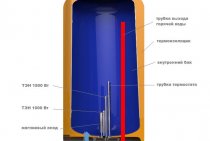

Sink device: 1 - wall mount; 2 - bracket, 3 - drain, 4 - wide nut, 5 - locking nut, 6 - glass, 7 - cement, 8 - sewer.

It is possible to make glue with your own hands. For example, for gluing a ceramic or faience toilet, you can prepare an adhesive based on casein.

Recipe one. 10 parts of casein and 1 part of borax are kneaded in 2 parts of water, later 2 more parts of water are added. To make a waterproof joint, add a few drops of a solution of aluminum alum or formalin to the finished solution. Such glue hardens in 2-3 hours - during this time it should be used for its intended purpose.

In order to glue large porcelain or faience items (toilet or cistern for example), you can prepare the following adhesive composition:

- 1 part crushed glass;

- 2 parts of river sifted sand;

- 6 parts of liquid glass or silicate glue.

This glue is strong enough, but it is not easy to make a seam with it hardly noticeable.

Second recipe:

- 1 part quicklime;

- 10 parts of chalk;

- 2.5 parts of liquid glass.

This composition should be prepared immediately before use, when the surfaces are fully prepared for bonding, as it quickly hardens.

Recipe three. For the manufacture of future use, a different composition of glue is suitable. It needs 1 part turpentine (by weight) and 2 parts light shellac. Turpentine and shellac are melted over low heat, mixed well and cooled. Further, the resulting mass can be divided into small tiles and left for storage.

Such glue is stored for a long time, before use it should be warmed up and applied in a thin layer on the surfaces to be glued, which then will need to be strongly compressed. The protruding excess glue is immediately removed.

Fourth recipe.A porcelain toilet bowl or other items made of this material can be glued together with a gypsum-based composition. To prepare such glue, you will also need ordinary alum. This glue is prepared as follows: burnt gypsum is soaked in a saturated solution of alum for 24 hours, then it is dried, calcined and crushed, then diluted with water to the consistency of sour cream.

How to drill a hole

Very often, ceramic sinks are made without a special tap hole. This happens because most modern faucets are installed on the wall near the sink.

But there are situations when the faucet needs to be built into the side of the ceramic sink, then it is advisable to watch a video on how to drill the sink.

But when it is not possible to see the whole process on the screen, we suggest that you familiarize yourself with the written version of how to drill a hole in a ceramic sink yourself.

The first step is to decide how to drill a ceramic sink, the answer is simple - with a drill. This is done not with an ordinary drill, but with a special nozzle for ceramic products.

A drill bit with a diamond core is suitable for such a case, which will allow drilling without adding water and cooling the drill itself.

The sales consultants in the store will help you choose the right crown. If everything is done correctly, then the problem will be solved. how to drill or seal a hole.

Now it’s important not to radically change everything during repairs, but to breathe new life into old objects that have an attractive appearance. Therefore, the question may arise how to seal a ceramic sink for restoration.

There are such adhesive materials for ceramics:

- waterproof glue;

- silicone sealant;

- cold welding.

Use a hair dryer first to get rid of unwanted moisture. Now you can seal the crack (for example, with waterproof glue), leave to dry for at least four hours.

Then you should apply epoxy putty at the joints and grind the repair site with a fine-grained sandpaper.

Also watch the video with an example of the restoration of a marble sink.

Repair of a chipped ceramic sink

It is possible to independently repair the chip on the sink using specialized sealants or putties. For a reliable result, you should perform the following actions:

- clean the damaged surface;

- dry the repair site;

- dilute the putty for ceramics in accordance with the instructions on the package;

- apply a bonding material (putty) to the place of the chip so that it protrudes beyond the edges (the putty will dry out);

- let the putty dry;

- clean with fine-grained sandpaper to an even and smooth state;

- paint the seam with the appropriate color, and remove excess paint from the surface with acetone.