Assembly technology

To assemble an electric sauna heater with your own hands, you must perform the following steps:

- First, a drawing of the future furnace is drawn up, which depends on such data: the area of \u200b\u200bthe furnace, the required heating power, maximum and minimum dimensions, location. Usually electric furnaces are made small, the main space of their design is a stone cage.

- Calculation of the number of heating elements for the furnace. Their number depends on the power of the future design, the size of the furnace, the power of one heating element to be used.

- After that, you can start assembling the stove for baths. To do this, the heating elements are fixed on the frame, connected by jumpers. A sheet of steel with a thickness of 3 mm is used as a base, the rest of the parts are attached to it using bolts and welding.

- If the frame is ready, it is necessary to lay the stones as tightly as possible on top, there should be almost no gaps between them.

- Next, a protective casing is placed, which can also be made of steel sheet, like the main structure. Additionally, you can put a brick wall, providing for this the construction of a small pedestal under the stove.

- The connection of the electric furnace is carried out using serial, parallel connections of heating elements, it is necessary to have a thermostat, with the help of which the heating of stones will be controlled. In this case, it is recommended to use rotary or drum switches, the control element itself must be positioned in such a way that it is in a convenient place for use. Usually, the regulator is placed in the steam room so that you can independently set a comfortable temperature in the room without leaving it.

- The last step is to check the operation of the furnace, the safety and comfort of its use.

Today, for small home saunas, it is best to use not massive brick stoves that take up a lot of space, but small and compact, but convenient electric ones. The cost of such structures can be quite high, but you can save money by installing an electric furnace to heat stones with your own hands. The technology of its manufacture is available. This is a stone cage, in which heating elements are used for heating.

Connecting an electric furnace

There are no specific requirements for the cable used to connect to the control panel. For a three-phase network, a cable of five cores is needed, for a single-phase network, of three cores of the NYM or VVG-ng type.

There must be a protective earth conductor. As a rule, the oven can be connected using plastic boxes.

Vinyl-insulated cables should not be used in saunas. You can use a cable insulated with heat-resistant rubber, or single-core RKGM. To protect the wiring from negative factors, it is better to use a pre-grounded metal pipe or metal hose.

As an alternative to expensive heat-resistant wires, it is possible to offer the use of a junction box installed one meter from the electric furnace. The height from the floor should be at least half a meter. Wires are drawn to it, to which heating elements and a steam generator are connected. Heat-resistant wires are installed directly from the box.

The cables supplied with the oven are used to connect the sensors. They must not be extended, twisted or used for intermediate connection. Sensors are mounted in accordance with the instructions, which must be followed unquestioningly. Most often, sensors are installed above the shelves, the exit from the sauna and directly above the electric furnace.

Advantages of an electric furnace

Vertical oven.

Choosing an electric sauna stove, you get a whole list of advantages:

Fast heating while maintaining a predetermined comfortable temperature throughout the entire period of use, which is simply not possible with wood-burning stoves.

Dirt during use is completely absent, since the stove runs on electricity, no fuel is burned. In this regard, an electric furnace does not need a chimney to remove combustion products, in a special separate ventilation system. The air in the room does not dry out that much.

Caring for the stove is extremely simple, it does not need to be constantly cleaned from traces of soot, residues of unburned fuel, soot. To start heating, it is enough just to turn on the structure, providing the supply of electric current, setting the required temperature.

Unlike other types, the electric furnace is regulated and controlled very simply. The thermostat is installed directly in the steam room. The temperature during the entire use is maintained exactly at the level that is set, which is a huge plus

The thermostat has protection against overheating, which is very important when installing a do-it-yourself sauna stove.

The stove is safe, no carbon monoxide is emitted during its use, there is no open flame, which does not pose a danger to the wooden furnishings of the sauna.

The dimensions of the furnace are compact, its weight is small. You can install such a structure in any convenient place, there is no need to pre-install a massive foundation, a small pedestal for equipment is enough, in some cases a small protective brick wall is required, which ensures the safety of use during rest.

What is the difficulty of installing an electric stove in a sauna

The circuit diagram for connecting an electric furnace in a sauna is simple. Since it is based on a typical circuit tied to the controller and incorporating a control panel, assembling the oven is quite simple.

The difficulty lies in providing the necessary conditions, since a sauna, like a bath, is a place where the risk of electric shock is very high due to high temperature and humidity.

As you know, these two factors have a negative impact on wires and cables. Therefore, during the installation process, you need to consider the following:

- the control panel must be outside the sauna. Most often, it is mounted next to the entrance to the sauna, which eliminates the effects of high temperatures;

- to connect the remote control, there must be a circuit breaker in the switchboard, the rating of which corresponds to the current load that the furnace consumes. It is better to use a differential type auto switch with a rating of 30 mA. Or you can install an RCD on the line immediately after the circuit breaker.

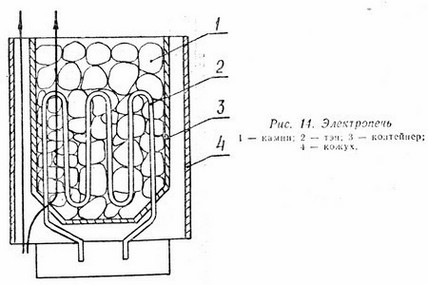

The design of the electric furnace installed in the sauna

An electric stove that can be installed in a sauna consists of three components:

- a stove equipped with a heater, heating elements and terminals designed to connect other elements (from a wide range of heating equipment, you can choose devices with steam generators and tanks, either with automatic or manual filling with water);

- Remote Control;

- sensors (as a rule, a temperature sensor is installed in all electric furnaces, but models with a humidity sensor can also be found).

Each of these structural elements is connected by wires or cables. Electric current is supplied to the terminals of the control panel, and from there energy is supplied to the heating elements.

If the stove is provided with a steam generator, then it is also connected to the control panel via low-current terminals. Each of the elements must be connected to the terminals intended for this, including the sensors. If something is done wrong during the connection process, then the operation of the electric furnace will not be safe. And the oven itself will not work.

It is also worth noting that most electric sauna heaters are designed to be connected to a three-phase network, the voltage of which is 380 volts. But there are furnaces that can be connected to a single-phase network.However, it must be remembered that in this case, the electric current load will increase three times, which must be taken into account when choosing the cable cross-section and the automatic control parameters of the furnace.

Also, when choosing an electric sauna heater, you need to determine the required power. When calculating it, you need to keep in mind that one kilowatt of power is needed for every cubic meter of sauna area.