ChK pipes

Cast iron sewer pipes of the Cheka are used in the construction of modern heating systems, water supply systems and systems for the removal of household and fecal effluents - both residential and industrial buildings (sewerage).

SML pipe

The company "SEVER" provides its customers with a wide range of products used in plumbing and other industries. It is better to get acquainted with the assortment on the page of the site "cast iron pipes price", which contains complete information about the products, their sizes, prices, quantities. Cast iron pipes are classified into several types. These include VChShG pipe, ChK pipe, ChNR pipe, SML pipe.

Cast iron pipes are popular among consumers due to their advantages over pipes made from other materials. This product has a long service life, is quite reliable, and its cost is much lower than the price of alternative pipes made of metal-polymer or high-quality alloy steel. Cast iron pipes, the price of which can be viewed on the company's website, are incredibly popular. They can be used as sewer pipes and not only. They are easily mounted on site, and have a large margin of reliability and durability, which is an important condition for operation in extreme conditions.

- An indicator such as tensile strength increases;

- The probability of internal stresses is greatly reduced;

- Pipes are easy to process and cut into finished products of the desired length.

For additional protection of the inner surface of the pipe from chemical or mechanical impact, an environmentally neutral coating is applied to it. The basis of this layer is epoxy, which adds elasticity and smoothness to the inner surface and prevents the formation of sediment and deposits. Thus, the probability of stagnation or blockage in the pipe is practically zero. The layer thickness is about 130 microns. The outer surface of the pipe is covered with a layer of red-brown primer. Drying, this type of primer forms a thin (15-20 microns), smooth, even surface. This pipe adds additional strength, resistance to environmental influences and temperature fluctuations from -45 to +60 degrees Celsius.

SML sewerage

Cast iron has proven itself as a material and can be used in SML systems (sewage of residential, multi-storey, commercial, industrial buildings), which are cast iron systems that meet international and European standards. SML pipes meet all the necessary requirements that are imposed by modern construction. This product has an outer coating of applied red-brown primer, and an epoxy layer is applied to the inner layer of the pipe, which is highly resistant to various influences (chemical or mechanical).

- SML pipes do not need additional treatment with flame retardant materials and agents;

- Compared to other types, SML sewerage is lighter, more versatile and easier to assemble due to the fact that, in addition to clamps, it does not need additional fasteners. Butt-to-butt joints provide excellent tightness;

- Anti-corrosion SML pipes provide a long life of the sewer without repairs and replacements;

- SML sewerage does not need additional noise reduction systems;

- The technical features of the cast iron from which SML pipes are made make it possible to embed SML sewers into concrete.

- SML sewerage with its long-term use significantly saves money on maintenance and repair.

Due to the fact that this type of sewage has such high technical characteristics, it is usually carried out in buildings with special requirements for noise and fire safety, such as hotels, universities, airports and train stations, hospitals, supermarkets and other places of large crowds of people.

Types of connection of cast iron pipes

There are the following types of connection of VSHCHG pipes:

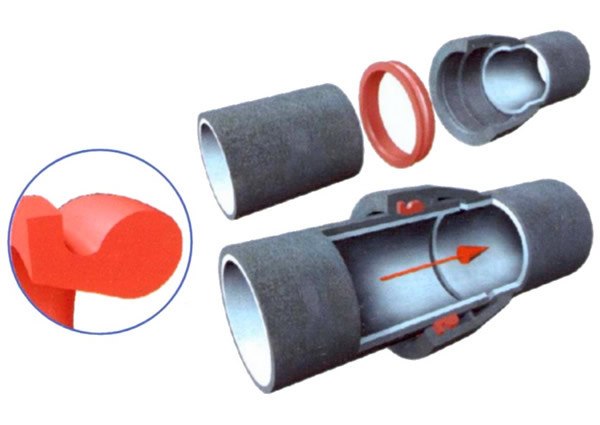

- Socket connection "Tyton". This type of pipe connection at the joint under the annular two-layer seal is mainly used for cold water supply pipes operating under pressure up to 1.6 MPa.

"Tyton" connection diagram

"Tyton" connection diagram

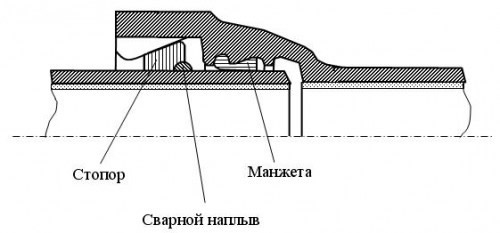

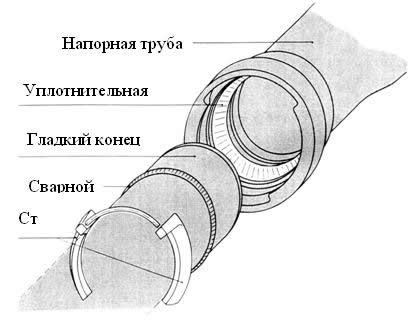

- Connection "VRS". Connection socket-stop, fixed. The seal is a two-layer ring. Cast iron pressure pipes VChShG, fixed by the VRS method, as a rule, are used when laying on terrain with difficult terrain.

Scheme of connection type "VRS"

Scheme of connection type "VRS"

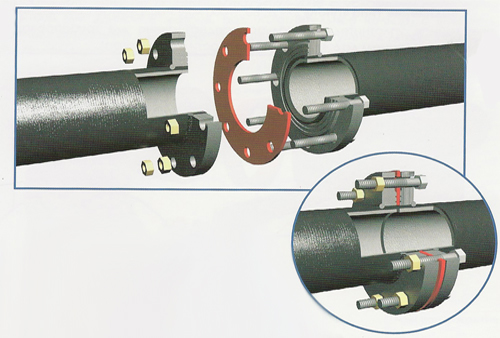

- Flange connection. Socketless pipes are connected using various flanges, depending on the working pressure of the liquid transported through the pipeline - from 1.6 to 2.0 and 2.5 MPa.

Flange Connection Diagram

Flange Connection Diagram

- The connection is welded. Socket pipes with a welded joint are used for the installation of networks providing hot and cold water supply, heating networks. The working pressure in the system is no more than 1.6 MPa.

Scheme of a welded joint

- Pile shells. Cast iron pipes ChShG can be used as a shell filled with concrete, to install piles in the construction of buildings, port facilities, to strengthen weak soil.

Pile shell scheme

Obtaining ductile iron

Since the growth in the production of castings from ductile iron is due to an exceptionally favorable combination of physical, mechanical, operational

and mechanical properties of this material, as well as economic considerations, the volume of production and consumption of castings

from ductile iron with nodular graphite

increases continuously.

Obtaining graphite in the structure of cast iron is based on separate or joint processing

liquid cast iron with magnesium, REM, calcium and other additives containing in one quantity or another the indicated

(spheroidizing graphite) substances, additives.

Magnesium iron is the most common method for producing high-strength cast iron in world practice.

a process based on the introduction of metallic magnesium, magnesium ligatures into the melt

and complex modifiers containing magnesium.

A very large number of works have been published on the theory and practice of using high-strength cast iron in the manufacture of castings, like ours,

and foreign scientists. As well as on the study of the mechanisms for obtaining high-strength cast irons. As an example of such work

we suggest that you familiarize yourself with the list of literature in this review (see below), as well as with the section Literature

website www.site.

Despite the abundance of works on this topic, such important issues as the optimal composition of the modifier,

conditions and technologies of modification, the mechanism of graphite formation, heat treatment modes and others.

See additionally: Castings from ductile iron of austenitic-bainitic class (article).

Literature:

Bublikov V.B. Ductile iron - 60. - // M .: Foundry, 2008, No. 11. - With. 2-8.

Ductile Iron Data // Ductile Iron Society. Promoting the production and application of ductile iron castings. , 2010 - Access mode: http://www.ductile.org, free. — Zagl. from the screen.

Keith D. Millis: the father of ductile iron Online Library

Kornienko E.N., Panov A.G., Khalfin D.F. Prospects for the production of castings from ChGG of the austenitic-bainitic class // M: Foundry worker of Russia, 2006 No. 2.

GOST 7293-85. Nodular cast iron for castings. Marks. — Spheroidal graphite iron for casting. grades. (Ductile iron. Ductile iron)

US2485760.Cast ferrous alloy. K.D. MILLIS AT AL.

High-quality cast irons for castings / V.S. Shumikhin, V.P. Kutuzov, A.I. Khramchenkov et al.; Ed. N.N. Aleksandrova - M .: Mashinostroenie, 1982. - 222 p., ill.

Lyubchenko A.P. High-strength cast irons. M: Metallurgy, 1982. - 120 p. /UDC 669.131.7 Abstract

Litovka V.I. Improving the quality of ductile iron in castings. Kiev: Nauk. Dumka, 1987. - 208 p. /UDK 621.74: 668.131.7: 621.746.58 Abstract

Zakharchenko E.V., Levchenko Yu.N., Gorenko V.G., Varenik P.A. Cast iron with nodular and vermicular graphite. Kiev: Nauk. Dumka, 1986. - 248 p. /UDC 621.74.04: 669.131.7 Abstract

Obtaining and properties of cast iron with nodular graphite. Edited by Girshovich N.G. - M., L.: Leningrad branch of Mashgiz, 1962, - 351 p. annotation

Business ideas

Obtaining ductile iron

Since the growth in the production of castings from ductile iron is due to an exceptionally favorable combination of physical, mechanical, operational

and mechanical properties of this material, as well as economic considerations, the volume of production and consumption of castings

from ductile iron with nodular graphite

increases continuously.

Obtaining graphite in the structure of cast iron is based on separate or joint processing

liquid cast iron with magnesium, REM, calcium and other additives containing in one quantity or another the indicated

(spheroidizing graphite) substances, additives.

Magnesium iron is the most common method for producing high-strength cast iron in world practice.

a process based on the introduction of metallic magnesium, magnesium ligatures into the melt

and complex modifiers containing magnesium.

A very large number of works have been published on the theory and practice of using high-strength cast iron in the manufacture of castings, like ours,

and foreign scientists. As well as on the study of the mechanisms for obtaining high-strength cast irons. As an example of such work

we suggest that you familiarize yourself with the list of literature in this review (see below), as well as with the section Literature

website www.site.

Despite the abundance of works on this topic, such important issues as the optimal composition of the modifier,

conditions and technologies of modification, the mechanism of graphite formation, heat treatment modes and others.

See additionally: Castings from ductile iron of austenitic-bainitic class (article).

Literature:

Bublikov V.B. Ductile iron - 60. - // M .: Foundry, 2008, No. 11. - With. 2-8.

Ductile Iron Data // Ductile Iron Society. Promoting the production and application of ductile iron castings. , 2010 - Access mode: http://www.ductile.org, free. — Zagl. from the screen.

Keith D. Millis: the father of ductile iron Online Library

Kornienko E.N., Panov A.G., Khalfin D.F. Prospects for the production of castings from ChGG of the austenitic-bainitic class // M: Foundry worker of Russia, 2006 No. 2.

GOST 7293-85. Nodular cast iron for castings. Marks. — Spheroidal graphite iron for casting. grades. (Ductile iron. Ductile iron)

US2485760. Cast ferrous alloy. K.D. MILLIS AT AL.

High-quality cast irons for castings / V.S. Shumikhin, V.P. Kutuzov, A.I. Khramchenkov et al.; Ed. N.N. Aleksandrova - M .: Mashinostroenie, 1982. - 222 p., ill.

Lyubchenko A.P. High-strength cast irons. M: Metallurgy, 1982. - 120 p. /UDC 669.131.7 Abstract

Litovka V.I. Improving the quality of ductile iron in castings. Kiev: Nauk. Dumka, 1987. - 208 p. /UDK 621.74: 668.131.7: 621.746.58 Abstract

Zakharchenko E.V., Levchenko Yu.N., Gorenko V.G., Varenik P.A. Cast iron with nodular and vermicular graphite. Kiev: Nauk. Dumka, 1986. - 248 p. /UDC 621.74.04: 669.131.7 Abstract

Obtaining and properties of cast iron with nodular graphite. Edited by Girshovich N.G. - M., L.: Leningrad branch of Mashgiz, 1962, - 351 p. annotation

When a water pipe is being installed, the attention of engineers and builders is riveted to the laying technology and the choice of materials. A worthy alternative to steel products

Its base is cast iron. The material does not at all limit the scope of such pipes only for sewage. On the contrary, some features of the production process make it possible to create a product that is in demand in the construction of residential, public and highly specialized facilities.

Characteristics of ductile iron pipes in a case weight, dimensions, etc.

The use of spheroidal graphite cast iron for casting pipes allows you to get quality products at an affordable price.

Welded or socket type connections form a sealed structure.

Cast iron ductile iron pipes are endowed with the following qualities:

- corrosion resistance,

- breaking strength,

- resistance to deformation and damage,

- plastic,

- low cost.

Description of ductile iron pipes is impossible without mentioning the scope of their application. They are in demand when creating:

- outdoor heating networks, where the water t reaches 150 ° C;

- pipelines for the chemical and oil refining industries;

- water supply networks;

- non-pressure and pressure sewerage;

- fire pipelines.

This list is not final and is constantly updated.

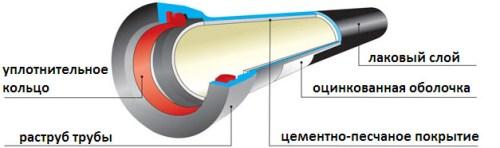

Description and purpose of external and internal coating connection of cast-iron pipes with CPP cement-sand coating

Ductile iron products are sometimes referred to as: VSHCHG 300 pipe with CPP. The numbers indicate the size, and the abbreviation stands for cement-sand coating. It is applied for additional protection against corrosion and improves the hydraulic characteristics of products. The thickness of the layer, its composition and method of application are different, but it always helps to keep the water flow coefficient in. The ductile iron pipe is a guarantor of the strength of communications.

Outside, a zinc layer coated with bituminous varnish is applied. With such processing, the pipeline is able to function even in difficult conditions. The scope of ductile iron pipes is quite large.

Vchshg decoding

ductile iron with nodular graphite

Dictionary of abbreviations and abbreviations. Academician. 2015 .

See what "VChShG" is in other dictionaries:

ductile iron with nodular graphite, ductile iron — The volume of production and consumption of castings from ductile iron with nodular graphite is continuously increasing. The growth in the production of castings from ChShG is due to an exceptionally favorable combination of physical, mechanical, operational and ... ... Metallurgical Dictionary

Ural Standard — CJSC Trading House Ural Standard is one of the leading Russian suppliers of new generation pipes for water supply and drainage systems made of ductile iron with nodular graphite (ductile iron) and fiberglass with a diameter of up to 4000 mm. "Ural ... ... Wikipedia

Saint-Gobain - Saint Gobain Type Open Stock ... Wikipedia

Water supply - Monument to the water supply in Mytishchi, installed in honor of the 200th anniversary of the first Russian water supply Water supply system of continuous water supply to consumers, intended ... Wikipedia

Free falcon (factory) - This term has other meanings, see Free falcon. "Lipetsk Metallurgical Plant" Svobodny Sokol "Type Open Joint Stock Company Founded 1900 Location ... Wikipedia

Water supply - A monument to the water supply in Mytishchi, erected in honor of the 200th anniversary of the first Russian water supply Water supply system of continuous water supply to consumers, designed to carry water for drinking and technical purposes from one place ... ... Wikipedia

XinXing Ductile Iron Pipes Co., Ltd - Type Ltd Founded 1971 Location ... Wikipedia

IRON - (Turkic) an alloy of iron with carbon (C is usually more than 2%, mass fraction), which also contains permanent impurities (Si, M, P and S), and sometimes alloying elements. Cast iron is the most important primary product of ferrous metallurgy (see Domain production), ... ... Metallurgical Dictionary

Specifications

Naturally, the pipe from this most durable and inexpensive material became one of the first products that were made. The process of creating pipes is quite simple and cheap, it consists in the technological method of casting.

The current improved ductile iron pipes are produced both for connection work with welding equipment and for connection with expansion. Of course, cast iron products are connected by a welding machine with special electrode elements.The properties of tightness in such a situation are acquired using seals, rubber rings.

It must be remembered that, nevertheless, for laying a sewer system in a private house, the choice should be stopped on polymer pipes, in particular on pipes made of polyethylene or polyvinyl chloride, and not to consider the option of using cast iron pipes. Two main nuances that can influence the choice are that polymer pipes are much lighter than cast iron pipes, in addition, the assembly process is much simpler. For cast iron material, there are much more acceptable and acceptable areas.

Specifications

Naturally, the pipe from this most durable and inexpensive material became one of the first products that were made. The process of creating pipes is quite simple and cheap, it consists in the technological method of casting.

The current improved ductile iron pipes are produced both for connection work with welding equipment and for connection with expansion. Of course, cast iron products are connected by a welding machine with special electrode elements. The properties of tightness in such a situation are acquired using seals, rubber rings.

It must be remembered that, nevertheless, for laying a sewer system in a private house, the choice should be stopped on polymer pipes, in particular on pipes made of polyethylene or polyvinyl chloride, and not to consider the option of using cast iron pipes. Two main nuances that can influence the choice are that polymer pipes are much lighter than cast iron pipes, in addition, the assembly process is much simpler. For cast iron material, there are much more acceptable and acceptable areas.

Application of ductile iron

From high-strength cast iron with nodular graphite, castings are made by weight from tenths of a kilogram to several tens of tons.

The properties of ductile iron are very diverse, so ductile iron is used:

- instead of gray cast iron - to extend the service life of castings (moulds, rolls, pistons, piston rings, etc.);

- instead of steel - in order to simplify and reduce the cost of production, reduce the amount of metal and rationalize the design of castings

(crankshafts, traverses, gears, etc.); - instead of non-ferrous alloys - with the aim of reducing the consumption of scarce metals and reducing the cost of machines.

Along with structural high-strength cast irons, high-strength cast irons with special properties are used: heat-resistant and

growth-resistant (for example, see Niresist), resistant to various aggressive environments,

anti-friction ductile iron with low coefficient of friction, etc.

The most famous to date scope of ductile iron

is the production of pipes from ductile iron.

ICM (www.website)

Application of ductile iron

From high-strength cast iron with nodular graphite, castings are made by weight from tenths of a kilogram to several tens of tons.

The properties of ductile iron are very diverse, so ductile iron is used:

- instead of gray cast iron - to extend the service life of castings (moulds, rolls, pistons, piston rings, etc.);

- instead of steel - in order to simplify and reduce the cost of production, reduce the amount of metal and rationalize the design of castings

(crankshafts, traverses, gears, etc.); - instead of non-ferrous alloys - with the aim of reducing the consumption of scarce metals and reducing the cost of machines.

Along with structural high-strength cast irons, high-strength cast irons with special properties are used: heat-resistant and

growth-resistant (for example, see Niresist), resistant to various aggressive environments,

anti-friction ductile iron with low coefficient of friction, etc.

The most famous to date scope of ductile iron

is the production of pipes from ductile iron.

ICM (www.website)

Application of ductile iron

From high-strength cast iron with nodular graphite, castings are made by weight from tenths of a kilogram to several tens of tons.

The properties of ductile iron are very diverse, so ductile iron is used:

- instead of gray cast iron - to extend the service life of castings (moulds, rolls, pistons, piston rings, etc.);

- instead of steel - in order to simplify and reduce the cost of production, reduce the amount of metal and rationalize the design of castings

(crankshafts, traverses, gears, etc.); - instead of non-ferrous alloys - with the aim of reducing the consumption of scarce metals and reducing the cost of machines.

Along with structural high-strength cast irons, high-strength cast irons with special properties are used: heat-resistant and

growth-resistant (for example, see Niresist), resistant to various aggressive environments,

anti-friction ductile iron with low coefficient of friction, etc.

The most famous to date scope of ductile iron

is the production of pipes from ductile iron.

ICM (www.website)

Manufacturing

In general, the process is known: cast iron is made from ore and has a higher carbon content than steel. To reduce the excess of this element, the material is boiled in converter furnaces. Air is blown through the melt, carbon atoms are bound, and carbon dioxide is formed. The result is steel. However, this material is significantly susceptible to corrosion, which at one time opened up great prospects for the use of cast iron pipes in sewers.

Cast iron pipe socket

Of course, there are methods to increase the corrosion resistance of steel, but all this affects the economic feasibility of all manipulations.

As a result, the Americans invented cast iron, which was inexpensive to produce, but at the same time it had the qualities of steel, in particular, it was not afraid of rust.

This modification involved changing the shape of the carbon particles. They became not flat, but spherical. And for this it was only necessary to add a little magnesium.

The resulting material had many advantages:

- Cheap.

- Stainless.

- Resistant to deformation and shock.

- Tear resistant.

- Plastic.

Pipes

Cast iron pipes of pressure type with a socket

Of course, pipes are one of the very first products that should be made from such a material. As a result, modern ductile iron pipes are manufactured for socket or welded joints.

Pipes made of such material are an excellent solution for many areas, although it would be more appropriate to use plastic for domestic use.

Standards

Standardization of ductile iron pipes depends on the area in which the product is used. After all, they differ for gravity sewerage and the oil and gas industry, for example.

If you take areas close to construction, then you need to be guided by TU 14-161-183-2000 and SP 40-106-202.

As for the assortment, it is described in GOST 9583-75.

Given the wall thickness, according to GOST, three classes of such pressure pipes are distinguished: B, A and LA.

Application

Such material does not spread under mechanical loads, significant deformations and high pressures, therefore, ductile iron pipes are used:

- When drilling wells as casing pipes.

- For the construction of high pressure oil and gas pipelines.

- For heating systems.

- For heating mains and water pipes.

- For pressure or gravity sewerage.

Component pipes made of HSCG

Ductile iron is an excellent material that does not corrode, but at the same time has no worse characteristics than carbon steel. All this opens up great opportunities for the use of ductile iron pipes in various fields.

Pipes for different types of connection

Pipes for "Tyton"

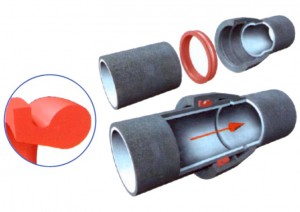

Installation of pipes intended for this connection should be carried out as follows:

- Clean the outer surface of the pipe from its smooth end from contamination.

- Make a mark that defines the boundary of the connection of the pipe to the socket of another pipe.

- Apply up to the mark the special grease supplied by the pipe manufacturer to the outer surface of the pipe.

- It is good to clean the inner surface of the socket from dirt and foreign objects.

Connection preparation

Connection preparation

To clean the internal and external surfaces of pipes, use brushes, scrapers, spatulas. The groove for the rubber seal should be cleaned especially carefully.

- Insert a rubber seal into the tube. Check the accuracy of the ring ridge placement.

- Lubricate the inner surface of the O-ring with grease.

Try not to allow smudges of grease under the outer surface of the rubber seal.

- Bring the pipe to the previously laid one, observing the centering.

- Connect the pipes using the installation device.

This is how the Tyton connection is made

Pipes for connection "VRS"

The socket-lock connection (VRS-Tiroflex) provides a strong fastening of the pipes to each other, which does not allow them to separate spontaneously under the action of shock loads or the movement of unstable soil. Stoppers that are inserted into special recesses of the socket and fixed with a rubber retainer, as well as a welded influx of the smooth end of the ductile iron pipe, ensure the strength of the connection.

The reliability of the "VRS" connection does not exclude the displacement of the joined pipes along the axis from 1.5 to 5 degrees, which does not lead to depressurization.

A strong one-piece connection allows you to use it:

- when installing a pipeline in a mountainous area;

- when laying in complex, unstable soils;

- when installing a vertical pipeline.

BPC is performed similarly to the Tyton connection

This connection is used for cold and hot water supply, sewerage, heating networks with a working pressure above 2.5 MPa.

Pipes for flange connection

Ease of installation and dismantling of the flange connection determine the range of its application. Flanged pipe cast iron VChShG is used in the device:

- elevated pipelines;

- viewing channels;

- valve service chambers;

- pumping stations.

The tight connection of flanged pipes is ensured by the use of two flanges that tightly compress the rubber seal. The dimensions and number of fixing bolts are determined by the nominal pressure and the nominal bore of the pipeline.

Flange connection technology

As you can see, the choice of pipes produced for various mounting methods is quite wide. All of them are produced by a well-known manufacturer in Russia, the Svobodny Sokol plant.

Obtaining ductile iron

Since the growth in the production of castings from ductile iron is due to an exceptionally favorable combination of physical, mechanical, operational

and mechanical properties of this material, as well as economic considerations, the volume of production and consumption of castings

from ductile iron with nodular graphite increases continuously.

Obtaining graphite in the structure of cast iron is based on separate or joint processing

liquid cast iron with magnesium, REM, calcium and other additives containing in one quantity or another the indicated

(spheroidizing graphite) substances, additives.

Magnesium iron is the most common method for producing high-strength cast iron in the world practice.

a process based on the introduction of metallic magnesium, magnesium ligatures into the melt

and complex modifiers containing magnesium.

A very large number of works have been published on the theory and practice of using high-strength cast iron in the manufacture of castings, like ours,

and foreign scientists. As well as on the study of the mechanisms for obtaining high-strength cast irons. As an example of such work

we suggest that you familiarize yourself with the list of literature in this review (see below), as well as with the section Literature

site www.modificator.ru.

Despite the abundance of works on this topic, such important issues as the optimal composition of the modifier,

conditions and technologies of modification, the mechanism of graphite formation, heat treatment modes and others.

Cm.additionally: Castings from ductile iron of austenitic-bainitic class (article).

Literature:

Bublikov V.B. Ductile iron - 60. - // M .: Foundry, 2008, No. 11. - With. 2-8.

Ductile Iron Data // Ductile Iron Society. Promoting the production and application of ductile iron castings. , 2010 - Access mode: http://www.ductile.org, free. — Zagl. from the screen.

Keith D. Millis: the father of ductile iron Online Library

Kornienko E.N., Panov A.G., Khalfin D.F. Prospects for the production of castings from ChGG of the austenitic-bainitic class // M: Foundry worker of Russia, 2006 No. 2.

GOST 7293-85. Nodular cast iron for castings. Marks. — Spheroidal graphite iron for casting. grades. (Ductile iron. Ductile iron)

US2485760. Cast ferrous alloy. K.D. MILLIS AT AL.

High-quality cast irons for castings / V.S. Shumikhin, V.P. Kutuzov, A.I. Khramchenkov et al.; Ed. N.N. Aleksandrova - M .: Mashinostroenie, 1982. - 222 p., ill.

Lyubchenko A.P. High-strength cast irons. M: Metallurgy, 1982. - 120 p. /UDC 669.131.7 Abstract

Litovka V.I. Improving the quality of ductile iron in castings. Kiev: Nauk. Dumka, 1987. - 208 p. /UDK 621.74 : 668.131.7 : 621.746.58 Abstract

Zakharchenko E.V., Levchenko Yu.N., Gorenko V.G., Varenik P.A. Cast iron with nodular and vermicular graphite. Kiev: Nauk. Dumka, 1986. - 248 p. /UDK 621.74.04 : 669.131.7 Abstract

Obtaining and properties of cast iron with nodular graphite. Edited by Girshovich N.G. - M., L.: Leningrad branch of Mashgiz, 1962, - 351 p. annotation

Conclusion

Do not be afraid, at first glance, abstruse and confusing documents. In any case, it is better to familiarize yourself with them. It can be concluded that cast iron products still have their own consumer, which means that there will always be new offers from manufacturers. And with these proposals it is already worth understanding which are high-quality and which are not.

Ductile iron with nodular graphite or ductile iron is a structural material with high strength properties.

and good performance. As is known, in cast irons, the shape of the graphite grain has a decisive influence on

strength characteristics of the material. In high-strength ductile iron, graphite inclusions have a spherical shape *. As a result

VChShG significantly surpasses gray cast iron in mechanical properties and successfully competes with steel.

Ductile iron with nodular graphite favorably differs from steel in its good casting properties (high fluidity,

a low tendency to form hot cracks, less shrinkage, etc.), the relative simplicity of the smelting process and lower cost.

*Nodular graphite is also called spheroidal or globular graphite.

Conclusion

Do not be afraid, at first glance, abstruse and confusing documents. In any case, it is better to familiarize yourself with them. It can be concluded that cast iron products still have their own consumer, which means that there will always be new offers from manufacturers. And with these proposals it is already worth understanding which are high-quality and which are not.

Ductile iron with nodular graphite or ductile iron is a structural material with high strength properties.

and good performance. As is known, in cast irons, the shape of the graphite grain has a decisive influence on

strength characteristics of the material. In high-strength ductile iron, graphite inclusions have a spherical shape *. As a result

VChShG significantly surpasses gray cast iron in mechanical properties and successfully competes with steel.

Ductile iron with nodular graphite favorably differs from steel in its good casting properties (high fluidity,

a low tendency to form hot cracks, less shrinkage, etc.), the relative simplicity of the smelting process and lower cost.

*Nodular graphite is also called spheroidal or globular graphite.