Types of materials of the bowl and/or toilet bowl

Both materials are made from a mixture of quartz sand, koalin and white clay, but different production technologies and proportions. As a result, faience comes out lighter and, accordingly, porous, which affects its fragility for the worse. The most common plumbing products are porcelain in a more expensive price category, and faience - in a cheap one.

Such toilets are used in public places, but there are exclusive models for the home interior, made in different versions. As a rule, steel is used, but older models made of cast iron also have a place to be.

Feature - impact resistance compared to ceramics, even if made from the highest quality porcelain. The disadvantage is that the same blow can easily chip off the enamel and thus lead to an emergency state of operation of the toilet bowl.

Fiberglass acts as a reinforcing material: one or more of its layers, with successive impregnation and a front, thicker layer of acrylic, creates a crack-resistant coating.

The advantage is that such a toilet bowl: firstly, its light weight; secondly, the cost; thirdly, the smallest pore coefficient. Although, the last parameter is controversial, because the enamel and glaze of high-quality porcelain / faience products will not yield to plastic.

Here it is very difficult to judge the performance and hygiene of products made from such materials, because the materials themselves are very diverse in physical properties. It can be answered that glass has better hygiene, stone - strength; tree somewhere in the middle.

If you have money, then you can order such an exclusive toilet bowl from anything, be it a precious stone or metal (how many rumors are there about a golden toilet bowl then?).

Or you can order a copy of the exclusive from cheaper, artificial substitutes for expensive materials, and then the indistinguishable dummy of the “golden toilet” will please the eye?

Features of drain tanks

Separately, it should be noted and various types of drain cisterns, which can be located directly on the toilet or mounted separately. There are such cisterns for the toilet:

- Compact. The most popular type of tank. It is installed directly on the back of the toilet. Such a tank can be solid or attached to the toilet with bolts.

- Separate tank. This type of design is also popular due to the ability to reduce the space needed to install the toilet. The tank in this case is located separately and is attached to the toilet with a pipe. It can be wall-mounted, ceiling-mounted, or even hidden. The benefits also include a better pressure when flushing.

- Tank in the installation system. Some types of toilets use cisterns that are hidden by the installation system.This is a frame on which the tank is installed along with water and sewer pipes, after which it is closed with drywall or other material. Thus, only the toilet itself and the flush button are visible to the user.

- A toilet without a cistern. Toilet bowls are also used, in which flushing occurs directly from the plumbing system. However, due to the small pressure, such designs are not very popular.

When choosing a cistern for a toilet bowl, it is necessary to take into account the convenience of its use, appearance and the availability of free space in the room.

We change the details of how to install and adjust

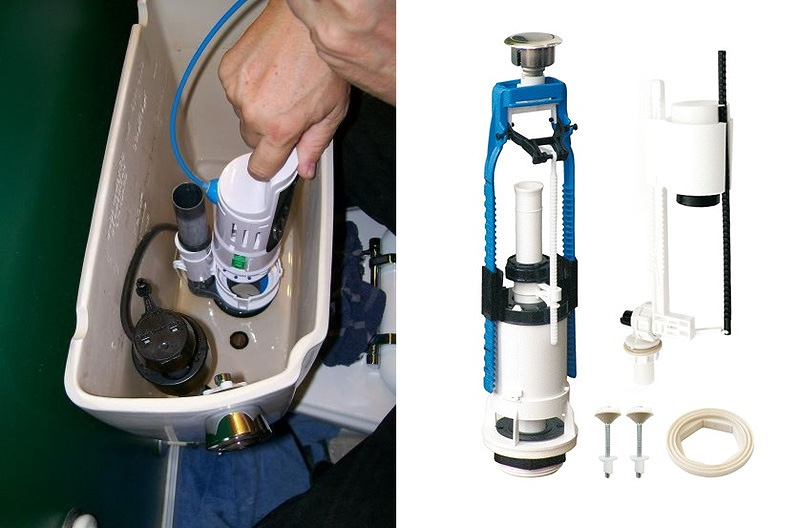

Sometimes there is no other choice but to replace the cistern parts. First, turn off the water, remove the cover and inspect the mechanism to detect defects. In expensive tanks we see several (possibly one) holes of small diameter through which water flows. The valve diaphragm is installed in one hole. Its condition is very dependent on the quality of the water. To prolong its life, a filter is installed: the better, the longer it will last. If the water supply does not have a filter, we change the expensive mechanism to a simple domestic one.

The drain tank is easy to repair by replacing parts. To repair expensive models, it is enough to buy a repair kit consisting of a bushing and a membrane. These are the parts that fail, the rest serve for many years. To change the drain mechanism in the tank of cheap models, it is better to replace all the parts at the same time, they are not very expensive. The main thing is not to make a mistake with the diameter of the pipe, to know which one is suitable for a particular tank. Pipes are available in metric or inch sizes.

After replacing parts, we check the supply and discharge of water, its quantity. If necessary, adjust the mechanism. The tank of the old system with a side entrance is simple: it is equipped with a float, the lever of which is an ordinary wire. We change the water level by simply bending the lever. We bend upwards - the amount of incoming fluid increases, downwards - decreases.

Modern side-feed systems use plastic instead of wire for the lever. It will not work to bend it, so we carry out level control by moving the float along the lever. It is fastened with a thread or a latch, which we press out before adjusting. To increase the volume, move closer to the valve.

Bottom-feed designs are easier to adjust. There is a limiter in the tank - a plastic rod that goes from the float to the lever. We lengthen it or shorten it by unscrewing the plastic nut on the limiter.

Toilet flush device

Scheme of an economical flush tank.

When installing a toilet bowl in an apartment or a well-maintained house, it is important to know the principle of operation of the cistern

The first step when buying a toilet bowl is to pay attention to all the components, you need to evaluate the bowl itself. One of the most important elements is the drain tank.

It must be assembled, rationally installed and adjusted to work. The device of the drain tank is quite simple. The tank can be made of ceramic material or plastic. There are several mechanisms for the operation of the drain tank: with a stop button, a dual-mode drain and with two buttons.

The last option is the most economical and modern. In this way, water can be saved.

There is a big button and a small button. The large one drains all the water from the tank, and the small one only part of it. Flushing water can also be different: direct and reverse. In the first case, water flows directly from the tank into the toilet in one direction. In the second, the direction can change, which is more optimal. Of great importance is knowledge of the technology of installing a drain tank. The first step is to assemble it together, according to the attached instructions. The next stage of work is strengthening the tank. This largely depends on the model.The most important part of the installation is connecting it to the sewerage system and the water pipe so that there is a possibility of a constant supply of water. With the help of a special float, you need to learn how to regulate the water level in the drain tank. All this is in the instructions. Before you start using it, you need to check its operation. If there are leaks or other defects, it is recommended to replace it with a new one.

Common breakdowns and solutions

Malfunctions are externally manifested by continuous filling or leakage of water. The reasons lie in the misalignment of the float, the failure of its mechanism, the shut-off valve, in which the seal has become unusable, or it does not fit snugly into the nest. A skewed float is enough to correct. Do the same with the valve when it does not fall into place.

There may be a problem with constant overflow, when the shut-off valve does not shut off the water, often due to the fault of the float. To check the mechanism, we raise it to the very top. If the flow has not stopped, you will have to change the float assembly. The reason may lie in the valve seal. Over time, the rubber ages, cracks and no longer blocks the entrance. To check, we press it with our hand, if the water stops flowing, we change the seal.

Over time, the float wears out, the tightness is broken, and it can no longer stay afloat. Then there is not enough water in the tank. In this case, you can replace the fittings or use another method. Places of leaks in the float are sealed with any available material. You can heat the plastic, apply a sealant, or seal the leak with a suitable adhesive.

There are times when water does not enter the tank. Most likely, the narrowest part of the valve is clogged. We act as follows. We release the water and remove all the insides. A narrow passage for water to enter becomes available. We clean it with a wire or a needle. At the inlet, open the valve and rinse from the remnants of clogging. After the start of the normal flow of water, we block it and put the mechanism back.

Constant water leakage is caused by a loose fit of the pear to the saddle, repair is required. To check, press it with your hand. If the leak has stopped, the cause is identified correctly. To eliminate the malfunction, we attach a small load on top of the pear so that it provides a snug fit. But if the pear is worn out, even pressing with your hand does not block the leak, you need to replace it. After fixing the float at the top, unscrew the nut connecting the tank and the drain pipe, remove the mechanism. We remove the pear and install a new one.

Mounting methods

Depending on how the toilets are attached, they are divided into floor and hanging. Floor structures can be separately divided into wall and simple.

Types of toilet bowls depending on the method of attachment:

- Floor toilets. This type of construction is distinguished by affordable cost, as well as ease of installation. Installation of floor toilets is recommended in spacious toilets. Anchor bolts are used for installation. The design feature allows installation without harm to the floor covering. For small rooms, it is recommended to use wall models. Separately, you can highlight the corner floor structures that allow you to organize the space of even a small bathroom in an original way.

- Hanging toilets. Wall hung toilets are recommended for installation in small toilets. High-quality fastening system allows you to withstand loads up to 400 kg. The benefits also include the ability to carry out more thorough cleaning indoors. Fastening can be done by frame or block method. Block fastening involves mounting the frame to a load-bearing wall. Frame fastening provides rigid fastening of a toilet bowl to a wall and a floor.

When choosing a floor-mounted or wall-mounted design, consider the size of the room, the design of the toilet and the room as a whole.

Materials for creating toilet bowls

Today, toilet bowls are made from a variety of materials: in addition to standard porcelain and faience types, there are steel, plastic, glass, cast iron and even gold.

. The main variations of sanitary ceramics are presented in the form of porcelain and faience, which are made on the basis of the same raw materials. The main difference between them is the ratio of different raw materials and their processing technology, which leads to a variety of physical qualities of the manufactured materials.

Faience is familiar to many, since it was he who was often produced during the Soviet era. The disadvantages of this material include a large percentage of porosity and significant water absorption (in the region of 9-12%). In view of this substance, it is usually covered on top with a layer of glaze, which not only performs a decorative function, but also provides protection to the shell walls from aggressive cleaning solutions. The result is more efficient cleaning when flushing. The service life of toilet bowls made on the basis of earthenware is approximately 30 years.

Porcelain is created only from the best clay grades. Thus, the material is denser and less porous. Moreover, it practically does not absorb water (0.8%). High-quality porcelain products keep the glaze smooth for an order of magnitude longer, so it is much easier to keep them clean. It is porcelain that is given the greatest preference today. In the case of sufficiently careful operation, porcelain products will be able to serve their owners in the region of 50 years.

Structures created using other materials (glass, marble, wood, not to mention semi-precious and precious stones) are almost impossible to find on the world market in everyday sales. These items are made to order.

Feeding and draining system device and operation

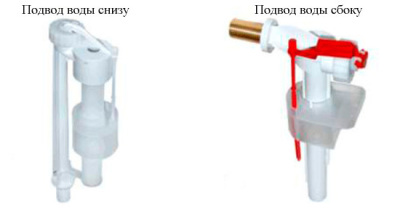

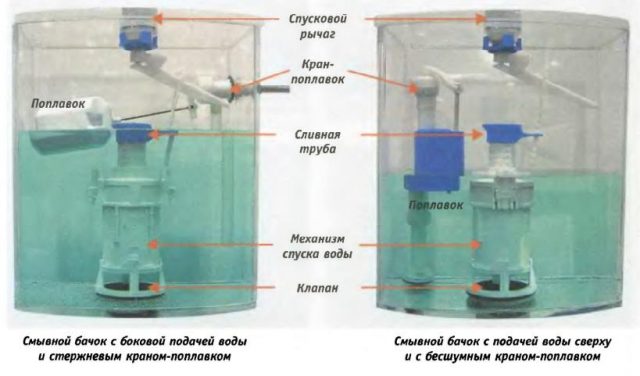

Water is supplied to the tank according to one of the schemes: side supply or bottom. For tanks with lateral water supply, a simple mechanism of two units is used: a membrane in the body, the purpose of which is to let water into the tank and block its flow, and a float connected by means of a lever to the body. It lowers and rises along with the level, the lever drives the membrane rod, which regulates the flow of water.

The device is simple and reliable, mostly of domestic production, but the water makes a lot of noise when typing. In more expensive models that operate on the same principle, in order to reduce noise, a pipe is used through which water is supplied to the bottom.

In tanks with a lower intake, the system is somewhat more complicated, but less noisy. The movement of the float does not occur freely in the tank, but along the rod, but the principle of operation is the same. In an empty tank, it descends, and water begins to flow. When a certain level is reached, the valve closes the hole, and the flow stops. The fittings are adjusted to a volume of 5-7 liters.

The drain mechanism is implemented in different versions. It is triggered after a person touches the handle, presses a button or jerks the chain. Expensive toilet models are equipped with two buttons. One can drain part of the water, saving it in this way. In the event of a malfunction of the float mechanism, the tank has an overflow. The drain device consists of a siphon and a manual drive. When a person activates the drain, the locking device opens. The toilet is flushed with incoming water and drained into the sewer.

Most modern toilets use top flush. The most common option is with a rubber pear. It works very simply: we press the button on the tank, under its influence the pear rises with the lever, the water drains. Instead of a button, a handle or chain can be installed.The system is even simpler: just pull, and the pear will open the drain.

Bowl and siphon device

The toilet device includes such parts as a siphon and a bowl. The bowl is the visible part of the toilet, where the departures directly take place. As it descends, it smoothly turns into a siphon. The latter is needed as a hydraulic seal for gases accumulating in the system. The siphon goes into the main pipe, which goes directly to the sewer system. The siphon has a curved shape. Various impurities very often accumulate in this place: garbage, hair, etc. Because of all this, the toilet bowl must be periodically cleaned using various methods. You can use chemicals such as "Mole", "Mr. Muscle", "Tiret".

A good effect is given by some folk remedies containing acids and alkalis in their composition. You can remove blockages with the help of a bypass, it is in every apartment.

Thus, we can conclude that the device of such a device as a toilet is not very difficult. Its main components are a drain tank and a bowl. The tank is the most complex. Its device is distinguished by the presence of valves, buttons, a float.

The toilet cistern breaks down quite often, but not everyone wants to repair it and call a plumber. Meanwhile, the device of the tank is very simple, and it will not be difficult to repair it, having the simplest set of tools in the house.

Types of toilet bowls

The shape of the toilet bowl should provide functionality, hygiene and, of course, comfort. There are several main types of bowls:

- Funnel-shaped. In this case, the funnel is located in the very center of the bowl, which guarantees a high level of hygiene. Defecation products are instantly removed without leaving marks on the toilet. The disadvantage of this design is the likelihood of a surge.

- Dish-shaped. This design is a platform on which defecation products accumulate. Its purification occurs only under the influence of water. Such bowls are considered obsolete and are practically not produced. Their only advantage is the lack of spatter.

- Visor. Most often, this is the shape of the bowls. The design is a special ledge that prevents the occurrence of a splash, but at the same time they have a sufficient slope to allow the products of defecation to be removed from the walls of the toilet on their own.

Water supply to the tank

To select a suitable water supply, be guided by how convenient it will be to bring communication - from the side or from below. In this case, everything again depends on how the pipes are located in the toilet.

Side supply - the design implies that when filling the tank, water is drained from above. Many note this option as noisier, although this problem is solved: it is enough to put a piece of plastic or rubber tube of the same length on the branch pipe of the locking mechanism.

In the case of the lower inlet valve, it is located on the bottom of the tank, in the immediate vicinity of the drain siphon. The fundamental difference is the noise level emitted when water is drawn from below - it is much lower.

Types of flush toilets

Types of toilet bowls by drain can be divided depending on the direction of water flow. They are divided into direct and circular drain designs, and each of them has a number of disadvantages and advantages.

Types of flush toilets:

- Direct flush. In this case, the drain is carried out by a stream of water on one side of the bowl. This type is durable, but cannot guarantee thorough cleaning of the entire surface of the toilet bowl. Advantages include affordable cost. The disadvantages include noise and splashing of water during flushing, as well as insufficient cleaning of the bowl.

- Circular flush. Such a drain ensures the movement of a jet of water at different angles to the inner surface of the bowl.Thanks to this, the surface of the toilet bowl is processed very carefully and efficiently. In addition, this drain design guarantees a low noise level.

- Non-standard drain. It is used extremely rarely due to the strong overspending of water. It consists in the initial filling of the bowl with water, after which a quick descent is carried out. The advantage of such a drain is the complete coverage of the entire inner surface of the bowl with water.

You can also divide the drain mechanisms by the presence of one and two drain modes. The standard system consumes about 6 liters of water per drain. However, in order to save water, it is recommended to choose a toilet equipped with two drain modes - standard and economical. The second one uses half as much water as a standard flush.

The mechanism of the drain tank in the design of the toilet bowl general information

Scheme of the structure and connection of the toilet bowl.

The functioning of the toilet cistern directly depends on the valves that are located inside it. The various types of construction of this element in the cistern largely affect the features of the toilet bowl.

Contains 2 main fittings:

- Responsible for the collection of water in the drain tank (complex for the collection of water in the drain tank).

- Responsible for flushing water directly into the toilet (drain).

The fittings that are responsible for collecting water in the tank can be of 2 types:

- For collecting water in the upper area of the tank. A similar method of placing valves can be found in the cheapest domestic-style toilet bowls. This option of filling the tank creates a decent amount of noise.

- An armature that draws water into the lower area of the toilet flush tank. This tank filling complex can be found in the line of toilet bowls, both imported and domestic. This arrangement of valves creates much less noise.

The principle of operation of the drain tank

The mechanism for draining water is very simple. When the water release button is pressed, a valve opens that connects the toilet to the tank, and water flows out into the mouth. In case if the water level in the tank has dropped, then the float is switched on, which allows it to fill up again. In order to ensure the desired volume of water in the tank, you need to monitor the position of the float. If there is a lot of water, then the float needs to be raised. Adjustment is carried out using special devices that are located on the float.

If there is an automatic drain system, the valve will close after the tank is completely empty. The oldest types of toilets have the installation of valves with a float valve. There are wall models of toilet bowls, which are made of durable plastic. They look like a wide, flat canister. The built-in cistern must be equipped with a flush panel with 2 buttons. If you click on the right of them, then 6 liters of water will pour out, if on the left - 9 liters. In the first case, there is an opportunity to save water.

Types by location and method of connecting toilets

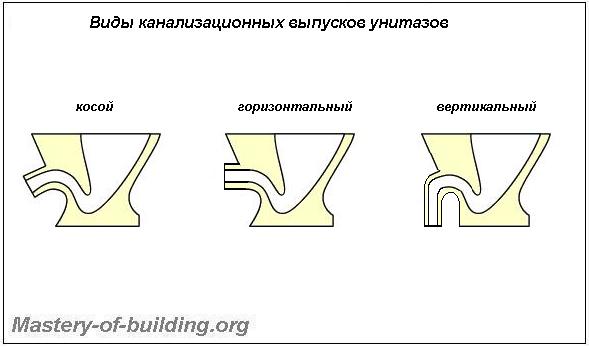

It should be understood that the toilet is not one thing, it is a complex of equipment connected to each other by removable or non-removable (as in a “monoblock”) connections, as well as to centralized networks - sewerage and water supply. In turn, one of the components is a bowl that has an outlet - a process of ceramics in the form of a bell, which connects to the sewer sewer pipe. And according to this criterion, that is, according to the release to the sewer, the toilet bowl is divided into:

- with horizontal outlet;

- with vertical outlet;

- with oblique release (45 degrees).

Horizontal outlet bowls are most common in European countries, the US and other Western countries. They perfectly adapt to both vertical (using a corrugated pipe) and horizontal sewer outlet. Today (2016), in most cases, sewers are designed for just this type of outlet.

Bowls with a vertical outlet are practically no longer used, and earlier they were popular in the buildings of the Stalin era. They cannot be adapted to vertical and horizontal sewer outlets. On the face of it, it might seem that there is an advantage that the pipe is not visible, as in the next (corner) outlet, and plus, it goes vertically down through the slab, so it does not take up space at all.

Bowls with an oblique outlet at an angle of 45 degrees were common in the 70-80s, especially in apartment buildings, Khrushchev. Allegedly, this type of issue saves more space than horizontal, but this is a moot point. Such a toilet bowl can be connected both to the oblique and to the vertical outlet of the sewer pipe using corrugated pipes.

The floor-standing type of installation involves transferring the entire weight to the floor, fixing it accordingly to the floor with an anchor / dowel method, plus shrinkage on a special adhesive solution for better stability. The resulting thin seam between the floor and the “sole” of the toilet bowl can be sealed with grout or sealant, just like tile seams. There are the most compact varieties - floor wall and corner, which are made with the expectation of being pressed against the wall as much as possible. These types of installation of toilet bowls, as well as the classic floor version, are made with all three of the above types of outlets for sewerage.

The wall-mounted toilet bowl is mounted to the wall using special anchors designed for at least a load of 400 kg. There are several mounting methods: to the frame and to the supporting wall. In the first case, a solid frame is erected from thick metal profiles / corners, which is the carrier for the toilet bowl. As a rule, in order to hide the frame itself, as well as communications, the whole thing is sewn up with moisture-resistant drywall (a false wall is erected). The second case is easier in terms of the toilet bowl itself: a massive frame is not required, but here it becomes difficult to hide the cistern and the installation system as a whole. It is good if a niche is provided in advance in the load-bearing wall, in the volume of which the entire drain system with its mounting elements can be placed. The release of the suspended models of the toilet bowl is horizontal.

Bottom supply some features of the models

Tanks with a side supply are more common, but in some cases it is more expedient to use a bottom supply. It looks more aesthetically pleasing, requires less space. Breakdowns are common, like all tanks, but the methods of elimination are somewhat different. Water can continuously flow into the tank due to low pressure in the water supply. The diaphragm valve does not work, and the solution is to replace it with a stem valve, which is independent of pressure.

Incorrectly working drain, insufficient or excessive filling of the tank are more often due to the incorrect position of the fittings when it touches the walls. We adjust the position so that the reinforcement moves without touching the walls. If the water is drained through the overflow, the float must be adjusted by tightening the screw.

The most common problem with bottom lined cisterns is leakage at the connections. When the tightness is broken, we restore it by applying plumbing sealant or changing the gasket.

Main varieties

Toilet and cistern installation.

The toilet can be of several types, depending on the design and installation technique. Allocate floor toilet and hanging. In turn, among the floor there are toilet bowls with a cistern, free-standing, attached and Turkish. The difference between the suspended ones is that their device requires a drain system and a special tank on the wall. In this case, the drain goes directly. Depending on the type of drain, devices with a horizontal, vertical, inclined or siphon drain are distinguished.Some varieties are partially made with the addition of silver, which provides an antibacterial effect. Others are water repellent.

The most modern toilets (automated) allow you to get rid of an unpleasant smell, have heated seats and other functions. There are certain requirements for them. Toilets are part of the drainage system. Installation height must be 400 mm. To avoid breakage, the toilet bowl must withstand a load of 200 kg, some of them are able to withstand a load of 400 and even 800 kg. There are several types of water drain systems: simple, double (3 and 6 liters each) and interrupted. Drainage systems can be electronic and mechanical.

The drain tank is optional.

Material for the manufacture of toilet bowls

The first relatively modern toilet bowl was made of faience and fitted with a wooden seat. Since that time, this plumbing item has been made from other materials:

- Porcelain. It has a sufficiently high degree of durability and strength, so they can be used both for arranging a home toilet and a public one. Another advantage is the ease of cleaning the surface. The disadvantages include the rather high cost of products. To reduce production costs, ceramic toilet bowls are more often produced. However, they are characterized by less strength, greater weight and a lower degree of surface smoothness.

- Metal. Metal toilet bowls are most often produced from cast iron and steel. As a rule, this material is used for the production of products for public toilets. Metal toilet bowls are distinguished by a good indicator of strength and durability, but their price is quite high. Cast iron products are not very popular due to their large weight, as well as the poor resistance of the coating to mechanical damage.

- Faience. Faience toilet bowls are distinguished by a low indicator of strength and durability. In addition, their surface has a high porosity, so cleaning such a product can be difficult. Modern manufacturers practically do not use this material for the manufacture of sanitary ware. These toilets are fragile and prone to cracking. And even despite modern technologies that improve the characteristics of the material, faience is much inferior to other materials for the production of toilets.

- Plastic. Modern technologies make it possible to make toilet bowls even from plastic. In this case, reinforced acrylic is used. Such toilets are characterized by a high strength index and a non-porous structure, which simplifies cleaning and maintenance. The disadvantages include a low rate of resistance to high temperatures and mechanical stress.

- Glass and stone. Toilet bowls made of artificial and natural stone, as well as glass, are luxury products. They have a high cost, but at the same time they have a beautiful design and fit perfectly into the interior in modern style. Artificial stone and glass have low strength, but during the production of toilet bowls, special additives are introduced into these materials that improve their performance.

Choosing a toilet bowl is a crucial step, because it should not only fit well into the interior and have the necessary performance characteristics, but also be convenient and comfortable.

https://youtube.com/watch?v=MQpz6qNWNTw

Types of toilet bowls for release into the sewer

Separately, it is necessary to distinguish the types of toilet bowls with different ways of release into the sewer system. According to this parameter, they can be horizontal, vertical or have an oblique outlet. The choice of toilet bowls for this parameter depends on the location of the sewer inlet.

On this basis, toilet bowls differ in the following types of outlet:

- Horizontal. Widely used in modern construction.The retraction angle is almost equal to 180 degrees. It is used when laying sewerage in the plane of floors, which are combined with a system of vertical risers.

- oblique. The retraction angle in this case is 140-145 degrees. This type of toilet was common in apartment buildings 40-50 years ago.

- Vertical. Widely used in the first half of the last century. Nowadays, such a system is used in the countries of South and North America due to the structural features of the sewage system.

Pushbutton drive most common problems

To remove the top of the tank with one button, unscrew the retaining ring around it. Do not press hard, they are often plastic and can break. In addition to the problems with the membrane and the pear, which we have already talked about, the destruction of the bolts holding the pear seat is possible. We unscrew the nut between the valve and the liner, the bolts that attract the shelf to the toilet. Slightly tilt the tank forward and take out the cuff. We change the bolts in pairs, even if one is in good condition. The material for them is brass or stainless steel.

We remove faience from under the saddle of the pear, carefully clean it, and also clean the surfaces of the shelf and tank. If we do not change the pear, we lubricate with sealant so that it sticks to the saddle. We assemble the tank and tighten it with new bolts without distortions

We check the work, paying special attention to places of possible leakage

If the buttons do not work, they either sink or the lever mechanism is disconnected. In this case, the cover is removed, and the mechanism is installed in the desired position.

Add site to bookmarks

- Kinds

- Choice

- Installation

- Finishing

- Repair

- Installation

- Device

- Cleaning

Toilet device

The design of the toilet should be both comfortable (suitable for all family members in height) and easy to clean.

Each of these parameters will be described in more detail below.

Among the designs of toilet bowls, the following features can be conditionally distinguished:

- toilet cistern mechanism;

- toilet flush complex;

- release device;

- toilet bowl decor.

Toilet cistern how it works

The device of the toilet cistern is not too different in different designs. They operate on the same principle, they consist of two main elements: a mechanism that provides water supply, and a device for flushing. Tanks at the installation site are available in three types:

- compact, mounted on the bowl itself (Fig. 1);

- built into the wall - used mainly with suspended structures (Fig. 2);

- suspended, fixed at a certain height and connected to the bowl by a drain pipe (Fig. 3).

The compact cistern is located on the rear shelf of the toilet and is activated by pressing a lever or button. The self-contained tank is hung on the wall and connected to the bowl with a pipe. The drain has a chain that you need to pull. The hanging toilet is attached to the wall, and the tank is hidden behind it. It differs from the usual in appearance and design. It is carried out as a high-strength polymer container of a flat shape. There is a button on the wall that is pressed to flush.

Sink diagram

Diagram of a typical toilet bowl.

The device of the tank is quite simple. The scheme resembles a water seal. It has a float, a seal and levers. With a button or lever, you can direct the water from top to bottom to clean and remove the contents. The tank has visible and invisible parts. The visible ones include the lid, tank, button. The invisible part is located inside. The drain tank incorporates a float valve (it is needed in order to fill the tank with water and regulate its amount), a button for flushing water, a plug with a side type of water supply and drain fittings.

Installation of a hanging tank is carried out according to the following technology. Before installing the tank, it is required to turn off the water. First you need to attach the flush pipe to the tank. Pipe size 32 mm. The drain tank is raised so that the lower end of the pipe is located at the desired level.Before that, a mark is made in the wall for the pipe. Using a marker or pencil, mark the points where the holes for attaching the tank will be drilled. To do this, you can use screws or dowels. The tank is fixed in a horizontal position. Then cold water joins it, and it fills up. It is advisable to make gaskets at the junctions of the pipe and the tank to prevent leaks.

If it is supposed to place the tank low, then it is mounted on the toilet shelf. In this case, the gasket is laid first. After that, the drain tank is attached to the shelf using bolts with gaskets located inside the tank. After that, you need to tighten the nuts and cover the through hole in the tank. Then the tank is installed on the toilet. To do this, the bolts located on the tank are aligned with the holes in the shelf and the nuts are screwed on. At the end, you need to connect the water supply through the hose.