Exploitation

Installation of foam plastic and mineral wool is almost the same. The only exception is loose mineral wool (glass wool) when it is mounted in piers.

If we talk about the very life cycle of these materials, then the difference is already significant. Let's compare polystyrene and mineral wool in several respects.

- fire resistance;

- Operational shrinkage;

- Environmental friendliness;

- Rodent protection.

Fire resistance. Mineral and basalt wool belongs to the category NG - non-combustible material. The temperature can reach 750 degrees Celsius during operation. Chimneys are insulated with wool.

Polyfoam belongs to the flammability class G3 and G4. This is if we talk about the majority of goods on the market. If the composition includes flame retardant additives, the flammability class is reduced to G1. But at the same time, when burning, it also continues to emit a lot of caustic smoke hazardous to health, containing carcinogens, although this class guarantees the temperature of the flue gases emitted during combustion below 135 degrees Celsius.

Polyfoam belongs to the flammability class G3 and G4. This is if we talk about the majority of goods on the market. If the composition includes flame retardant additives, the flammability class is reduced to G1. But at the same time, when burning, it also continues to emit a lot of caustic smoke hazardous to health, containing carcinogens, although this class guarantees the temperature of the flue gases emitted during combustion below 135 degrees Celsius.

Operational shrinkage. When using mineral wool with a density of 85 kg/m. cube issue with shrinkage disappears

It is important that the opening into which the mineral wool roll is laid does not exceed 3 meters in height. Proper installation, the use of properly selected fasteners allows you to minimize shrinkage

Styrofoam due to its density practically does not shrink. In particular, expanded polystyrene or basalt wool, their purpose is to withstand high pressure without losing shape. Therefore, basically, EPPS is used to insulate the foundation.

Environmental friendliness. The conclusion of the Moscow Research Institute of Hygiene. F.F. Erisman No. 03 / PM8 shows that when using polystyrene foam boards in the construction of residential buildings, styrene, harmful to health, is not detected in air samples. The environmental safety of polystyrene can be judged simply by looking at where it is used - disposable tableware, food containers, product packaging.

Mineral wool contains phenols and formaldehyde. Both of these components adversely affect human health. In case of violation of the production technology, the release of formaldehyde may exceed the maximum permissible concentration in the air (0.05 mg / m3) several times

Therefore, it is essential to ask the manufacturer for a quality certificate, which should indicate that the mineral or stone wool complies with accepted standards.

Moisture accumulation

Ordinary expanded polystyrene foam (styrofoam) is able to moisten and accumulate moisture. It cannot just be in the ground or in a damp basement. On the wall, it must be protected from sunlight and precipitation with a continuous plaster layer.

But mineral wool is able to absorb water like a sponge. A prerequisite for its use is constant ventilation with external dry air. Those. it is closed either with hinged panels, under which the air stream moves, or with a particularly vapor-transparent thin plaster layer. Embed cotton wool in concrete (heavy) structures without vents. a gap with a jet is always doubtful and is not a recommended option here.

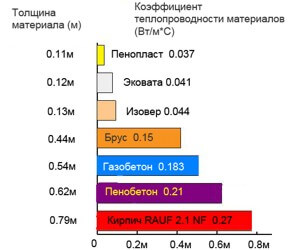

Thermal conductivity

So, what is better to use, mineral wool or polystyrene, if we compare their thermal conductivity coefficients?

| Material | Thermal conductivity, W/m*K |

| Styrofoam | 0,033 — 0,037 |

| EPS (extruded polystyrene foam) | 0,029 — 0,034 |

| Mineral wool | 0,036 — 0,045 |

It is obvious that the difference is small in terms of characteristics. But in this case, the behavior of the material during deformation will be the decisive factor. If you compress the mineral wool, then it will lose its properties. For EPPS, compression is generally provided, because it is used to insulate the foundation by laying at depth.

So, which is warmer than 50 mm polystyrene or 50 mm mineral wool? If we compare the numbers, we can conclude that ordinary foam does not lag behind in terms of thermal conductivity (polystyrene foam is not taken into account, given the specifics of its use).

There are no better heaters

Each building material has certain technical characteristics. All heaters have their own areas of application. Usually, where one material is good, the second turns out to be “bad”, i.e. not suitable. But in other conditions, the first one cannot be applied, and the second one will turn out to be the best.

What is more suitable - foam or mineral wool, will have to be decided based on the specific conditions of use. Most often, in private houses, developers are concerned about large-scale insulation of foundations, walls, roofs or ceilings, as well as floors. The areas of insulation are large, the volume of materials is “not cheap”

Therefore, the importance of choosing and correctly using heat insulators is very significant.

This is interesting: Floor-to-ceiling windows in a country house: all the nuances

Heat loss resistance

What is the best way to insulate a balcony - polystyrene foam or mineral wool? Having considered the heat-insulating properties of the two materials, we come to the conclusion that polystyrene foam has no equal in this characteristic.

Many heaters lose to him, including mineral wool. And this is despite the fact that the thermal conductivity values of the two materials we are considering have almost the same values. The fact is that the internal structure of the foam is a huge number of closed cells filled with air.

This structure contributes to good heat retention. The mineral wool has no closed cells. This helps warm air to escape from it.

So what keeps heat better - mineral wool or polystyrene? The conclusion is clear. Styrofoam, even one that is not of the highest quality and price, is better used as a heat insulator than mineral wool.

Optimum application of each type of thermal insulation

Depending on the purpose and design features, certain options for thermal insulation are appropriate. So, for example, in low-rise brick houses, as well as in three-layer concrete panels, it is better to use mineral stone wool as the middle heat-insulating layer.

Also, the insulator will be appropriate for thermal insulation in wooden houses, where it is important to use "breathable" materials. In addition, to keep warm with the help of mineral wool will turn out:

- in attics and pitched roofs;

- in attics and ceilings;

- in rooms with very hot appliances and the risk of fire;

- in pipeline systems and heating mains;

- frame structures of any type.

Expanded polystyrene plates are used for insulation and sound insulation:

- in brick and block structures to eliminate the risk of dew point;

- foundations and underground engineering structures in contact with wet soil;

- horizontal part of foundations with a layer of waterproofing under operating conditions at low temperatures;

- floors and areas between floors with a concrete screed;

- roofs of non-ventilated type with a layer of waterproofing;

- freezers, isothermal vans and refrigerators.

Having studied the characteristics of expanded polystyrene and mineral stone wool as heaters, certain conclusions can be drawn. In terms of thermal conductivity, foam plastic is definitely better in all respects, while only stone wool can compete for the title of a material that removes moisture and steam. However, in a humid environment, foam plastic retains its functionality better than mineral wool, although it is not able to remove moisture to the outside.

In terms of fire safety, both materials are dangerous, while polystyrene foam as a heater is always a risk of ignition, while mineral heat insulators burn and melt only at the highest temperatures and the inclusion of additional synthetic components. High-quality basalt wool with the most natural composition is able to withstand temperatures up to 1000 degrees Celsius.

Mineral wool weighs more than foam, so it is more difficult to install. Expanded polystyrene is lighter, more convenient to cut and simply attached to the surface. The disadvantage of the latter is the joints and possible cold bridges, which are excluded when choosing in favor of mineral wool.

One way or another, you need to choose expanded polystyrene or stone mineral wool for insulation from trusted manufacturers, taking into account the purpose of the structure. High-quality foam plastic is plates with uniform polyhedrons, securely fixed to each other, while low-quality insulation is easy to distinguish by balls interlocked with each other.

Mineral heaters should have relatively high density indicators, a special arrangement of fibers that excludes increased friability of the material, indicating a low level of quality.

Compare materials

To decide which material to use, you need to understand what is the advantage of one of them over the second and vice versa.

- Fire resistance. Mineral wool wins the fire resistance comparison. It does not burn even at high temperatures. Therefore, in those places where the risk of fire is increased, it is best to use mineral wool. For example, this may relate to the insulation of the boiler room.

- The quality of thermal insulation (thermal conductivity). What will be warmer - foam or mineral wool. If we compare both of these materials, we can say that 8 cm of polystyrene replace 10 cm of mineral wool. Therefore, for maximum insulation efficiency, it is worth using expanded polystyrene. It keeps warm better. In addition, due to its lighter weight, it will not create a large load on the foundation of the structure.

- Ease of installation. It is much easier to work with foam, as this material is safer. When working with mineral wool, it is necessary to use all protective equipment: gloves, goggles, a respirator. It is also necessary to work in trousers and clothes with long sleeves. Mineral wool fibers entering the body through the respiratory tract cause severe irritation, foam does not have such a drawback.

Facade insulation

- Ease of plastering. If we are talking about wet insulation of the facade, then it is better to use polystyrene foam, since the adhesion of glue to polystyrene foam is much better than with mineral wool, this will allow plastering to be done quickly enough. Also, foam sheets are easier to glue evenly, and this will affect the quality of the facade.

- Susceptibility to the influence of rodents. Here mineral wool has an advantage. Mice can gnaw on polystyrene, and in rural areas, geese also pose a threat to the material - they just eat it. Therefore, in order to protect the insulation, it must be plastered.

- Water absorption. Mineral wool absorbs moisture well and at the same time its heat-insulating properties are lost.When insulating open areas with mineral wool, they must be protected with a layer of glue or film until the first rain. Getting a large amount of wool on the material will significantly reduce its quality. Therefore, thinking about this moment, it is worth choosing polystyrene foam.

- Vapor permeability. Mineral wool is able to maintain a good microclimate in the room, while polystyrene practically does not let air through.

- Price. If you choose the same thermal insulation parameters, it turns out that the foam is more expensive than mineral wool, so it is better to give preference to the latter.

Having considered in comparison the advantages and disadvantages of both materials, we can conclude that there is no unequivocal answer to the question of which is better. Each one is good in its own way. Therefore, it is worth deciding which material to use based on which part of the building is planned to be insulated.

What is better to insulate with foam

This material proved to be very good, in those places where the humidity of the air is quite high, but insulation is required.

- Styrofoam will not be affected by contact with wet ground, so they can perfectly insulate foundations, as well as various engineering structures underground. Dozens of years will pass, and the insulation will remain the same as in the very beginning. It is often used in the construction of multi-layer foundations as a middle layer. It turns out a very reliable and high-quality foundation.

- When building houses, without basements, on a monolithic foundation, it is also convenient to use expanded polystyrene. Slabs of this material are laid on a leveled area, and then a layer of concrete is poured on top of them. The plates themselves can be either one row or several. After the concrete has hardened, the walls of the house begin to be erected.

- So that the foundation of the house does not freeze, it is very effective to insulate with foam plastic not only its vertical, but also its horizontal part. Styrofoam plates are placed along the foundation. Then they fall asleep, if necessary, additionally laying a waterproofing layer. This method of insulation reliably protects the foundation from frost.

- The walls of houses (both inside and outside) can also be effectively insulated with polystyrene foam. It is best if these walls are block or brick. A high heat-insulating effect is achieved when using expanded polystyrene for insulation of interior spaces, while the formation of a dew point is not observed.

- For roofs of non-ventilated type (warm, flat roofs), the brand of expanded polystyrene PSBS is used. A waterproofing layer must be placed on top. For cold roofs that are ventilated, thermal insulation is carried out differently. Styrofoam isolate the inside of the roof, without fail leaving space for ventilation. This prevents water vapor from condensing.

- Floors and ceilings between floors are also well insulated with foam boards. A layer of insulating material is placed under them, and on top they are poured with concrete.

- A variety of packaging is also produced from expanded polystyrene, and it is also used for thermal insulation of refrigerators, freezers and special isothermal vans.

What is the best insulator

Comparing the thermal conductivity coefficients of heaters indicated in various sources, one can notice that for foam plastics it is indicated approximately the same - about 0.037 W / m? C. And for mineral wool, you can find a significant spread - literally from 0.03 W / mS to 0.06 W / mS.

This is due to the desire of producers to sell more mineral wool, and to play on the possibility of indicating not operational, but laboratory values.

It is necessary to take into account the moisture content of the layer in the structure, shrinkage-compaction of the material or the use of denser samples - for calculations, the mineral wool coefficient is taken as 0.45 - 0.55 W / mS ....

Thus, the foam is on average 17% better insulating. But this is not so significant when choosing a heater, and does not at all determine which one is better. The choice is something else entirely.

1 About the characteristics of materials

First of all, you should figure out which is warmer - foam or mineral wool. To do this, you should compare the general qualitative characteristics of these materials and understand what exactly they are.

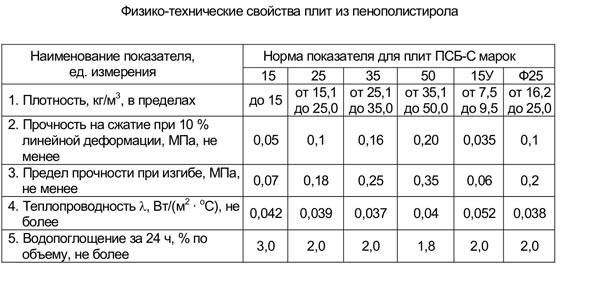

Here are the characteristics of this material:

- thermal conductivity coefficient: about 0.037-0.041 W / mK;

- compressive strength: from 0.05 MPa;

- density: from 12-15 kg / m³ and above (depending on the brand, it can reach 35 kg / m³);

- moisture absorption coefficient: about 1%;

- vapor permeability coefficient: about 0.03 mg / mchPa;

- average cost: about 140-150 rubles per "square" (sheet 10 cm thick).

Mineral wool is a collective class of heat insulators, which include materials of three variations:

- Fiberglass.

- Slag.

- Stone wool.

Each of the three materials has a number of differences, consisting both in quality characteristics, and in the method and raw materials for production. Most often, glass wool is used as a heater - as the most effective (of the listed items) material. For this reason, the characteristics will be given specifically for him:

- thermal conductivity coefficient: about 0.04 to 0.05 W/mK;

- compressive strength: from 0.08 MPa;

- density: from 40 kg / m³ (depending on the brand, it can reach 200 kg / m³);

- moisture absorption coefficient: from 1 to 2%;

- vapor permeability coefficient: about 0.3 mg / mchPa;

- average cost: about 110-130 rubles per "square" (10 cm thick).

The material is produced in two types: in rolls and in plates. The first option is best suited for warming a horizontal surface - floors, attics. The second one is universal.

The question of the use of the material will be considered in more detail further, so for now we will not focus on technology.

Thus, even based on the characteristics, it can be determined that the foam plastic holds heat better and is more resistant to moisture, and it is much more effective to protect the house from the cold with it.

Fiberglass or mineral wool

Fiberglass is made from molten glass. It has a high strength, does not break and even bends without violating integrity.

The following characteristics of fiberglass can be distinguished:

- Moisture resistant.

- Average degree of flammability.

- Easy to work.

- High level of heat retention.

- Low price.

Drawing an analogy between mineral wool and fiberglass, we can say the following. Fiberglass has a low degree of hygroscopicity and does not pass steam well, unlike mineral wool. Fiberglass refers to non-combustible materials, however, it has a rather low melting point, due to which, in the event of a fire, fiberglass will easily melt and let the fire go further.

Mineral wool does not melt and burns poorly, this is its great advantage. Fiberglass is easy to work with due to its strength and elasticity. It will also do a good job of keeping warm, but mineral wool is better for soundproofing. The great advantage of fiberglass is the price, which is much lower than even the price of such an inexpensive material as mineral wool.

So, having considered the main types of materials for insulation and sound insulation and comparing their characteristics, we can highlight the strengths and weaknesses of each of them.

The most budgetary heaters are foam plastic, glass wool and fiberglass. Mineral wool is a little more expensive, and expanded polystyrene will be the most expensive. Here everyone should choose based on their budget.

But it is necessary to take into account the safety factors for human health and life. For example, mineral wool is the most fireproof insulation material discussed above. If the foam burns instantly, then the mineral wool is able to keep the fire from further spreading for a long time.

Do not forget about such an important point as working with materials

If with polystyrene foam and expanded polystyrene, however, as well as fiberglass, there will be no difficulties during installation, then glass wool requires certain knowledge and skills, as well as protection from small harmful particles of glass. Mineral wool occupies a middle position in terms of ease of use, and it depends on the substances that are used in its manufacture.

It should be noted that all of the listed characteristics of insulating building materials largely depend on the integrity of the manufacturers. Sometimes, for the sake of cheaper, harmful components are added, so you need to buy only from trusted companies, carefully reading the label. It will not be superfluous to additionally ask the seller about the properties of the selected product.

Of course, everyone should choose based on the specific situation, because different materials may be suitable for different insulation purposes.

But the most important thing is to take this issue seriously, carefully study all the characteristics, positive and negative consequences of using each of them, so that the people in the house are healthy and the house is happy.

- Mineral wool, technical specifications

- Technology of wall insulation with mineral wool

- Mineral wool Rockwool, Ursa, Knauf and TechnoNIKOL: comparison and characteristics

Mineral wool

Mineral wool is a fibrous material. By melting rocks, metallurgical slags and various mixtures, manufacturers get mineral wool. It is precisely because rocks are used that the material is of high quality and has good operational durability properties.

Table of properties of mineral wool.

There is also a blast-furnace production of mineral wool. It is obtained from slag, but it is not suitable for thermal insulation of large industrial premises. It is used only for insulation of residential buildings or apartment walls.

The positive aspects of mineral wool include the following:

- fire resistance;

- stability;

- no deformation;

- vapor permeability and resistance to moisture penetration;

- excellent sound insulation;

- anti-corrosion properties;

- high thermal resistance;

- simple installation;

- durability.

Mineral wool has good fire resistance, because non-combustible silicate melts of igneous rocks are used in its production. High temperatures do not cause deformation processes, and mineral wool is not destroyed. Premises in which it is planned to find various flammable substances, experts recommend insulating only with mineral wool boards. The material does not allow the spread of fire and the source of ignition in case of fire.

The figure shows that the greatest heat loss occurs through the walls, so they should be insulated.

When the question is what is better to choose for warming a room, a warehouse or a residential building, one should not forget that if a mouse starts up in a private house, which will have access to foam sheets, then most likely the rodent will ruin the material in several places. With mineral wool, this will never happen: rodents are not able to damage even a centimeter of this resistant and strong material. Mineral wool has a high biological and chemical resistance to various chemicals. Mineral wool is resistant to temperature extremes, sunlight and moisture. Having insulated his house with these materials, the owner will definitely not worry that mold or fungus will ever appear on the walls.

Mineral wool is not able to deform after shrinkage at home.

The performance properties of the foam are good, but sometimes it happens that it starts to let cold air through at the joints. Using mineral wool, the occurrence of "cold" cracks is excluded.

The level of humidity inside the building is very important in the construction of any room. In order to remove water vapor and condensate, it is necessary that the heat-insulating material has good vapor permeability properties.Mineral wool is just the material that has a high rate of vapor permeability.

Mineral wool has a high thermal resistance. This means that it has the ability to resist external changes and maintain a certain temperature in the room. Different geometry and direction of mineral wool fibers have different thermal conductivity. Randomly directed fibers are considered ideal.

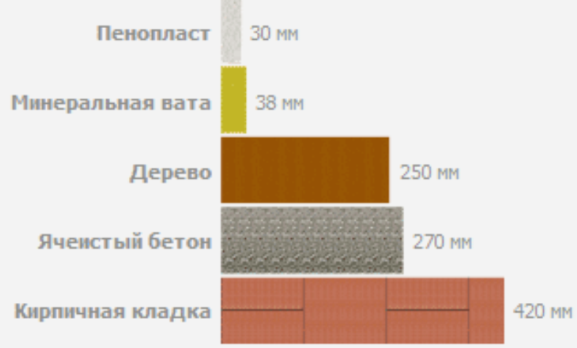

Comparison of materials by thickness

Mineral wool has excellent sound insulation. Styrofoam also prevents the penetration of sound waves, but mineral wool has this ability much higher.

Mineral wool has high strength and is an anti-corrosion material. When metal objects come into contact with wool, the process of corrosion is guaranteed not to occur.

Mineral wool is an environmentally friendly material and does not affect human health. Of course, cotton wool emits some substances, but they are absolutely not harmful to humans.

Installation of mineral wool is quite easy to carry out. The material is easily cut with a regular knife or hacksaw, easily takes the shape of any surface.

Mineral wool is a durable and strong material that will last for hundreds of years with proper installation. During production, basalt stone is added to mineral wool - this explains the long service life.

The only drawback of mineral wool is the cost. If we compare which is cheaper, mineral wool or polystyrene, then, of course, polystyrene will win.

What is insulated with mineral wool and foam

How to choose material for construction work? To do this, you need to know some rules.

So, if you are deciding whether it is better to insulate a house - with foam plastic or mineral wool, you need to pay attention to the material from which the building is made. Wooden walls are "breathable"

In no case can you insulate them with foam.

Otherwise, the tree will lose its useful properties. In buildings built of brick or reinforced concrete, fibrous material is used for insulation of partitions, ceilings, floors and ceilings. What is the best way to insulate the facade - foam plastic or mineral wool in this case?

Special requirements exist for the insulation of external walls. Brick and wooden houses are insulated with a ventilated suspended facade. An integral part of this design are vapor barrier membranes.

But polystyrene as a heater shows itself very well where there is a sufficiently high humidity. These are the foundations and walls of block and brick houses, non-ventilated roofs and interfloor ceilings.

Expanded polystyrene is widely used for the production of various packaging. They lay out the walls of freezers and refrigerators. In these cases, the foam serves as an excellent thermal insulator.

So, we considered what is better - mineral wool or polystyrene foam, if it is planned to insulate the balcony.

https://youtube.com/watch?v=TASJ4LqeaeMrel%3D0%26controls%3D0%26showinfo%3D0

- karkasdom.info

- teplodom1.ru

- fb.ru

Other characteristics

What other abilities of materials should be considered when buying them? When choosing a heater, you should pay attention to its hygroscopicity. If the environment in the room is humid, then in this case foam should be used.

During operation, it will not lose its consumer properties. Stone wool in such rooms will serve little. It is critical to the action of moisture.

As for weight, the undoubted leader in this matter is foam. Its weight is much lower than that of mineral wool.

Important parameters are the chemical and biological immunity of materials. Mineral wool is resistant to all fungi and organic substances. Polyfoam in this regard has the worst characteristics.