Instrument installation and maintenance

So, we found out that Kiturami heat generators have excellent characteristics, but it is worth remembering that during their operation the relevant requirements should be followed, otherwise the most reliable device in the world will require a major overhaul.

The very first thing that many boiler users encounter is installing an already purchased model. During installation, it is necessary to adhere to all the requirements of the manufacturer, for this reason it is much better if qualified specialists take over the work - in this case, there will be no risk of having to repair the device immediately after the installation work is completed. Indeed, in most cases, the cause of an early breakdown of the device is just its incorrect installation. And to avoid all this, you have to pay a little extra.

Due to the fact that the diesel heat generator is equipped with a fuel tank, certain operational requirements are also imposed on it. So, you can pour exceptionally clean fuel into the tank, in addition, it should be cleaned regularly, as well as the boiler itself.

For this reason, when buying, you should pay attention to whether the tank is equipped with a sediment outlet pipe and a fix bag.

Note! Before turning on the boiler itself, fill it with fuel and let it stand for at least twenty minutes. Only after that you can proceed to the device settings.

If voltage drops often occur in your area, then do not spare the money and also buy a stabilizer that can save the functionality of the control unit and various sensors present in the device. But proper installation and competent operation is not all, because Kiturami diesel boilers need periodic preventive measures. Such activities consist of:

- mechanical cleaning;

- checking all nodes is not a matter of operability and the presence of leaks.

Some of these works can be done with your own hands - for example, connect the device itself - but it is advisable to entrust the rest to professionals. And always remember the need to care for the heat generator, so carry out all these activities in advance. So you can avoid a number of minor problems, as well as prevent more serious ones.

What is the peculiarity of heating equipment from Kiturami

The Kiturami concern is engaged in the production of various types of heating equipment, which includes biofuel and gas installations. But it was Kiturami's diesel heating equipment that brought the concern such great fame and a high rating. The name diesel speaks about the type of fuel on which it runs.

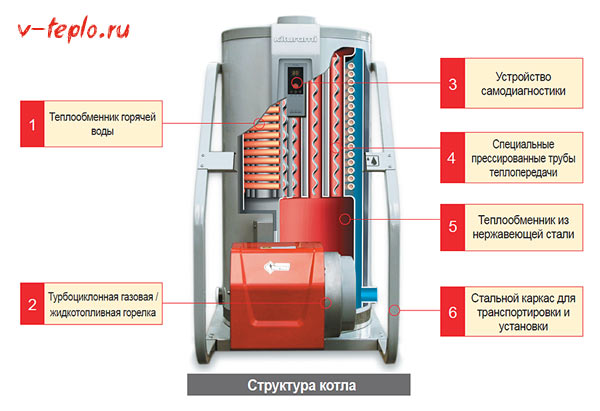

Rice. one

The most popular model in the line of this manufacturer is the Kiturami Turbo 17 diesel boiler, the purpose of which is hot water supply and heating of industrial and residential premises. Boilers from the manufacturer Kiturami are very convenient for use in country houses, when the need for hot water does not arise daily, and heating is required only during the presence of the owners there. In addition, with proper operation, repair of such equipment is very rarely necessary.

The main advantages of Kiturami diesel heating equipment include:

- the diesel copper of Kiturami is convenient in operation. The control panel allows you to set any control function. Kiturami's work on the coolant and room temperature is regulated by a thermostat built into the remote control. The boilers are independent of the size of the chimney and the presence of draft due to the presence of a turbo blowing effect, which forcibly sends the exhaust gases to the chimney;

- diesel Kiturami is highly economical. Thanks to the aerodynamic flow in the combustion chamber, maximum efficiency is achieved in terms of the amount of fuel consumed;

- setting up the equipment is absolutely simple, and you can do it yourself;

- The house has hot water all year round. Boilers of the Kiturami brand are also used at a time when the room is not heated;

- The Kiturami diesel boiler has a self-diagnosis system that informs on the display about its operation and the malfunctions that have occurred, showing the real state of the system. If you constantly monitor the display readings, then the need for repairs will be minimal.

Equipment characteristics

-

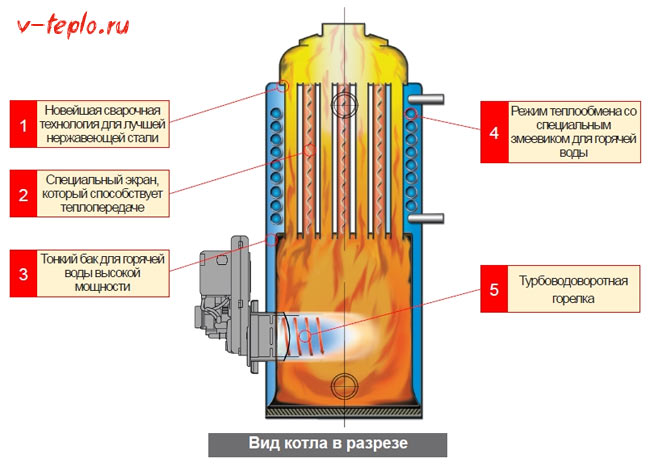

The design, equipped with high-quality elements and blocks, is different from other brands.

The heat exchanger is made of highly alloyed steel, superior in physical and technical qualities to other metals, which increases its cost, offset by high quality. -

The equipment is made of copper, which does not react with water and increases its heat resistance.

The presence of internal and external control units, which contributes to the regulation and control of the operating mode of the system from various places in the boiler room. -

Coverage of the power range of floor-standing 2-loop units –

from 10 to 35 kW, sufficient for heating 250-275 sq. m. -

The dependence of the actual fuel consumption on personal settings.

The nozzle is selected from the manufacturer for the actual power parameters. -

Heating power, fuel consumption and its combustion mode are set independently.

With power parameters up to 15 kW, the expected fuel consumption is 8 liters per day, while the burner will work with a certain frequency to create the optimal room temperature. By choosing the right heating mode and installing a variable temperature controller, you can significantly reduce fuel consumption. - Boilers for gas, diesel fuel, floor or mounted on the wall are mainly equipped with a closed-type combustion chamber and a forced gas exhaust system.

A steel or ceramic chimney is coaxial so that the supply of street air flow and gas exhaust are carried out at the same time. -

It is possible to build a chimney with a slightly larger diameter - up to 120 mm.

Reducing its size and cross section is unacceptable.

Specifications

The operational characteristics, dimensions and parameters of the Turbo series boilers are presented in the table below. It is clearly seen that a series of floor-standing diesel boilers covers a power range from 10 to 35 kW, which is quite enough for heating houses up to 250-275 square meters. Part of the heat will go to the preparation of hot water, which must be taken into account in the calculations.

All Kuturami boilers are double-circuit and heat exchangers, by the way, are ideally designed specifically for these tasks.

| Boiler model | Unit ism | TURBO-9R | TURBO-13R | TURBO-17R | TURBO-21R | TURBO-30R | |

| Power | kcal/hour | 9000 | 13000 | 17000 | 21000 | 30000 | |

| Power | kW | 10,5 | 15,1 | 19,8 | 24,4 | 34,9 | |

| Fuel consumption | liter/hour | 1,13÷1,5 | 1,6÷1,97 | 1,87÷2,15 | 2,28÷2,80 | 3,75÷4,30 | |

| efficiency | % | 92 | 92 | 92.2 | 92.4 | 91.8 | |

| DHW consumption | ∆t=25ºC | 6,0 | 9,7 | 11,3 | 14,0 | 23,3 | |

| ∆t=40ºC | 3,8 | 6,1 | 7,1 | 8,7 | 14,6 | ||

| Heating supply and return | mm | 25 | 25 | 25 | 25 | 25 | |

| Hot water inlet/outlet | mm | 15 | 15 | 15 | 15 | 15 | |

| Chimney diameter | mm | 80 | |||||

| Power supply | V/Hz | 220/50(60) | |||||

| Power consumption | Tue | 80 | 160 | ||||

| External size | w×d×h | 325×600×835 | 365×650×930 | ||||

| Weight | kg | 60 | 79 | 85 | 85 | 85 |

Fuel consumption

Fuel consumption is specified in the table with technical requirements. However, please note that the actual flow rate depends on individual settings. Under the actual power required for heating the house, the appropriate nozzle is selected from the set proposed by the manufacturer.

The thermal power, fuel consumption and fuel combustion mode are set. The parameter indicated in the table displays factory presets sufficient to ensure proper performance if only high-quality fuel is used, more often it means diesel fuel already with winter additives that do not allow it to thicken or stand out paraffin in excess.

In a real situation, for a boiler model with a power of up to 15 kW, one can expect fuel consumption at the level of 8 liters per day

taking into account the frequency of the burner and the optimal temperature in the house. However, this is not the limit.

The right approach to choosing the heating mode, as well as installing a controller with a variable temperature regime, for example, depending on the time of day and day of the week, can reduce consumption even more.

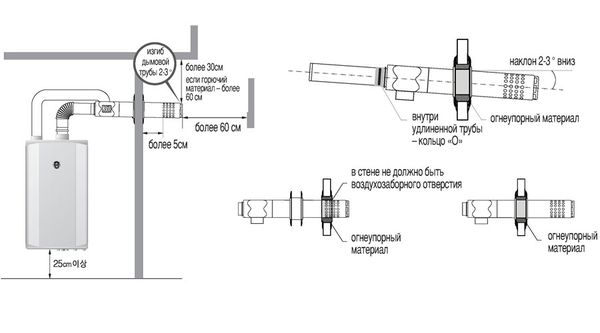

Chimney

Boilers Kuturami, gas, diesel, floor or wall-mounted, for the most part, are equipped with a closed combustion chamber and, accordingly, a forced exhaust gas system. The Turbo series, which we are currently reviewing, is no exception.

The chimney for boilers is used coaxial for the simultaneous supply of fresh air from the street and the removal of exhaust gases. Since the exhaust temperature after passing through the heat exchangers is no longer high, the requirements for the heat resistance of the chimney are reduced, and the list of acceptable materials is expanding.

In the best case, a steel coaxial chimney is still used, however, a ceramic vertical chimney with a group of internal separate channels for air supply, exhaust gases from the combustion chamber and ventilation of the boiler room can be effectively used in the same capacity.

The size of the chimney is strictly specified in the boiler specification and operating instructions. For the entire Turbo series, this is 80 mm.

It is possible, if desired, to make a chimney of a slightly larger diameter, but not more than 50% in excess of the specified value, that is, up to 120 mm.

In no case can the size and cross section be reduced.

Even though the removal of combustion products is forced, the resistance of the chimney will greatly affect the combustion mode and the quality of the fuel burnout.

Strengths and weaknesses of diesel units

So, we found out that all boilers from this Korean manufacturer embody excellent quality, functionality, affordable cost and modern design. The fuel in this case can be both light oil and kerosene. If the burner is replaced, it is also possible to switch to natural gas.

Other advantages of the devices include the presence of security sensors with which you can control the main work processes. Tellingly, when creating these sensors, a unique technology was used regarding the removal of fuel combustion products.

A distinctive feature of the models of the Turbo series is that they include floor-mounted diesel heat generators that can not only heat the room, but also heat water for domestic needs. Therefore, there is no need to purchase an expensive boiler, because all models of this series already belong to boiler-type devices.

Another advantage is the high degree of protection provided by the fact that the boilers are built in:

- sensors;

- forced removal of flue gases;

- control bullets;

- thermostat.

The common advantages of all boilers of this manufacturer include the fact that they are quite capable of functioning in any conditions, and this is quite relevant for our country. And buying spare parts for Kiturami boilers is also not difficult, since the company has many dealerships.

When compared with boilers made by other manufacturers, Korean models are distinguished by one of the most economical fuel consumption. And if we talk about the performance of hot water, then this figure can reach twenty liters per minute.

And now let's talk about the main advantage of the described boilers - this, of course, is their affordable cost. To date, Kiturami diesel boilers can be purchased for the amount from 20-30 thousand rubles

. Moreover, this equipment is distinguished by the widest model range, due to which the requirements of not only the owners of country houses, but also the management of industrial facilities will be satisfied.

Description of Kiturami malfunctions and repair

The Kiturami diesel boiler belongs to the economy option and has a rather long service life. But there are situations when the boilers fail prematurely. The reason for the need to repair Kiturami is their untimely service or the use of poor quality fuel.

A simple repair of Turbo boilers can be carried out independently, but it is more rational to contact service organizations in case of malfunctions.

Below are the main error codes that the Kiturami Turbo 17 diesel boiler is more often exposed to:

- when the lights on the display flash “01”, “02” or “03”, it means that there are problems in the flame detector and ignition does not occur. The Turbo boiler in this case should be restarted according to the instructions;

- error "04" indicates that the water temperature sensor is faulty in the Kiturami heating system, and repair in this case becomes inevitable;

- error "08" warns that the route between the boiler and the temperature sensor is very long or a wire break has occurred in some place. Repairs will be required to identify the immediate cause of the failure;

- error "95" means too low pressure in the heating circuit. The Turbo boiler must be energized and the entire heating system must be examined for the possibility of leaks;

- error "96" - the mechanism that protects the Turbo system from overheating has worked;

- error "98" - indicates that there is a lack of fuel in the supply line.

Of all the errors described above, “01” flashes most often on the display, but this does not pose a great danger to the operation of the equipment. The diesel boiler Kiturami Turbo 17 is characterized by maximum efficiency. Thanks to the control panel, the boiler control functionality is achieved and room heating is possible in any temperature regime.

In Turbo it is possible to regulate temperature parameters step by step from 45 to 75°С. All information about the operation of the diesel Kiturami Turbo on the thermostat screen is displayed by the self-diagnosis mechanism.

Most often, the Kiturami diesel boiler gives error 01. This happens when there is no stable ignition in the Turbo.

The reasons may be as follows:

- when the screw jams, which serves as a fuel level limiter. The repair consists in the need to replace the locking element or check the injection motor;

- when the blower motor fails. It is necessary to check the working condition of the Kiturami motor. If the motor is faulty, then the repair consists in replacing it with a new one;

- when there is a lack of incoming fuel, then its level should be checked in the tank, in this case repairs will not be needed;

- when a third-party object accidentally appears in the screw gate, then it must be removed during the repair process;

- when the photosensor fails, the Turbo repair consists in checking this element for its operability.

When the error code “01” periodically appears on the display, then in such cases it is necessary to seek help from the relevant specialists in order to avoid major costly repairs.

Carrying out regular maintenance and repair of Kiturami is a guarantee that Turbo boilers will work efficiently and reliably. If irreparable damage occurs in the diesel boiler during the warranty period, then it is repaired without the need to pay for such work.

The Kiturami Turbo diesel boiler has excellent performance, but it must always be remembered that non-compliance with the established installation scheme, correct settings and elementary rules for handling it in many cases ends with a total repair. When all requirements for use and operation are met, modern technologies for the production of Kiturami heating equipment guarantee each user stable operation of the boiler without the need for repair and a long service life.

Even at the heating design stage in the house, one has to operate with the generalized technical characteristics of the boiler, but in the end it is still necessary to go to the store and choose a very specific model from the huge range on the market.

It will be useful to find out in more detail what the Kiturami diesel boiler is, what models are in the line, and how they can be better than other offers on the market.

Setting

It is better to entrust the initial start-up and configuration of Kiturami boilers to a specialist who can correctly determine the optimal operating mode, select the desired type of nozzle and calibrate fuel consumption depending on its characteristics and even the connection method and location of the fuel tank.

For self-installation, complete with the boiler, a detailed instruction is attached, according to which you can determine the operating mode closest to the design value.

The main thing is to follow the sequence of actions defined in the technical documentation and visual aids for putting the equipment into operation.

It is necessary to adjust and adjust the boiler settings not only at the first start-up, but also during maintenance before each new season and for switching to summer mode, in which only the DHW circuit will be used.

turbo 13r

The model number of the boiler corresponds to the amount of heat generated per hour - 13000 kcal/hour. In terms of the usual kilowatts, the values \u200b\u200bare obtained are 15.1 kW.

The declared power is enough to heat a house up to 150 m2. Naturally, one should take into account the heat costs for the preparation of hot water supply. If a significant consumption of hot water is predicted, moreover, regularly, then the heat output for the heating circuit will naturally be lower.

Reliability and balanced operation, combined with the affordable cost of the boiler, gives a clear advantage in the case of using several boilers simultaneously in one building, for example, when dividing the heating circuit for each floor separately or when covering a large area in two more wings, directions.

Faults

Kuturami boiler equipment is equipped with a full-fledged self-diagnosis system built on the work of a number of sensors. The controller is able to evaluate the condition of the equipment, as well as the current mode of operation, and respond to any deviations or problems that arise during operation.

In any emergency situation, the main action determined by the boiler controller is to stop the burner in order to prevent significant consequences.

A well-developed self-diagnosis algorithm allows you to identify the problem and indicate the error code on the display so that the user can take all the necessary actions to repair and restore performance as quickly as possible.

Among the frequent breakdowns of diesel boilers Kiturami:

- No ignition (error code 01);

- Does not start, no messages on the display.;

- Coolant leakage (depressurization of the heat exchanger or one of the pipeline connections);

- The flame goes out periodically with an emergency stop of the boiler;

- There is no draft, the operation of the boiler is accompanied by the flow of smoke and exhaust into the room.

Error 01 and solution

If error code 01 appears on the boiler display screen, it means that for some reason the fuel did not ignite, there is no torch, the controller forcibly stops the fuel supply, issues an error message, and signals the problem to the user.

Solving the problem requires the exact implementation of a procedure that can identify the source of the problem and eliminate the obstacle in the boiler as efficiently as possible.

Briefly, the procedure looks like this:

Quite often, the fuel-air mixture is supplied under too much pressure into the chamber and therefore does not have time to ignite from the electrode. The problem is solved even at the 5th step of the algorithm by adjusting the air damper, which causes a mixture with a changed concentration to enter the chamber.

Doesn't start

The most unpleasant situation is when the boiler simply does not turn on. There are no signals on the display, and accordingly there is no error code by which it would be possible to determine the malfunction.

In such a situation, it would be adequate to call a service center specialist who will be able to understand the situation and issue the correct verdict, as well as determine the repair procedure. On your own, you can only check the presence of voltage in the network, as well as the fuses in the boiler.

leak

Most often, a leak means that a gasket seal has been damaged in some connection of the pipeline inside the boiler.It is enough to inspect the equipment and determine the place of leakage, replace the gasket.

The heat exchanger in Kiturami boilers is made of alloyed steel and copper, so it does not leak without obvious errors in the selection of the coolant or mechanical damage.

Burner goes out intermittently

The most common cause is a burner setting failure.

It is important to adjust it in terms of power and, using a gas analyzer, determine the optimal air / fuel ratio for proper combustion. Such work cannot be done on your own, so it is better to contact the service center

No draft, smoke and exhaust enters the room

It is most likely that the burner fan is not working for some reason.

It is important first of all to check that the impeller is intact and scrolls normally

It is possible that debris has accumulated inside the fan, or the impeller shaft is jammed. Next, the electrical part and the control unit are checked.

The work of the Kiturami concern is aimed at the production of heating devices for biofuels and gas. But it was diesel-fueled equipment that made this manufacturer popular.

Advantages of diesel fuel installations:

-

Ease of use due to the ability to control any function using the remote control.

The thermostat built into it determines the operating and temperature conditions. The operation of the boiler does not depend on the size and presence of draft, since the existing effect of turbocharging contributes to the forced direction of exhaust gases into the chimney; -

High economic efficiency is achieved through

aerodynamic flow during fuel combustion; - Possibility of self-configuration;

- Year-round hot water supply;

-

The presence of a self-diagnosis system

with information about the operation and malfunctions of the system; - Acceptable price;

- Variety of lineup.

The only negative is the type of fuel, which creates a negative environmental situation when it is burned.

Diesel boilers from the manufacturer

All diesel fuel boilers from Kiturami are double-circuit and are manufactured in several series, let's get acquainted with them.

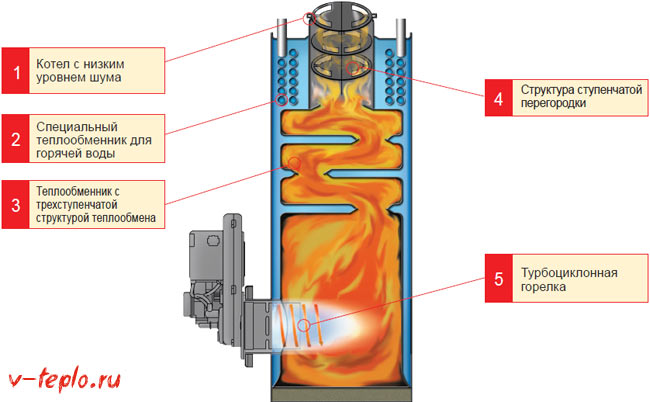

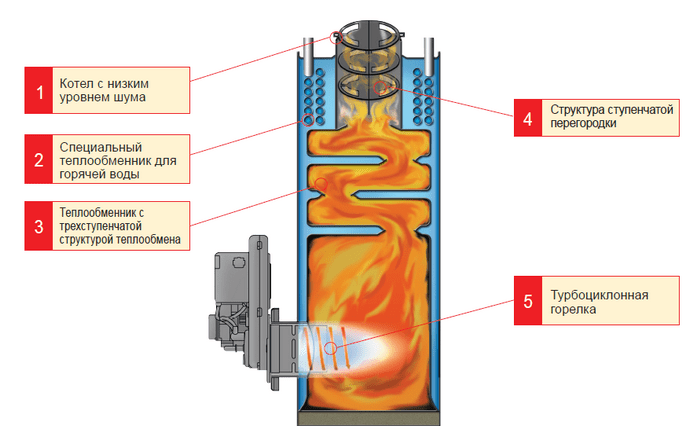

- - These are devices whose power can reach 35 kilowatts. The power, as we see, is insignificant, but there is a turbocyclone burner, and the cost is low. All models are designed for use in private houses or cottages, the area of which does not exceed 350 square meters.

|

Specifications |

Unit rev. |

||||

| Power | kWh | 15 | 19.8 | 24.5 | 35 |

| Heated area | m2 | up to 150 | up to 200 | up to 250 | up to 350 |

| efficiency | % | 92.8 | 92.9 | 92.8 | 92.7 |

| Average heat consumption | l/day | 4.9-6.8 | 6.1-8.6 | 7.3-10.4 | 10.0-14.5 |

| DHW capacity | l/min at T=40C | 5.2 | 6.5 | 8.2 | 13.0 |

| Heat exchanger area | m2 | 0.78 | 0.92 | 1.03 | 1.03 |

| Heat exchanger capacity | l | 23 | 32 | 29 | 29 |

| Boiler dimensions WxDxH | mm | 310x580x835 | 360x640x920 | 360x640x920 | 360x640x920 |

| Boiler weight | kg | 64 | 75 | 85 | 88 |

| Electricity consumption energy | W/h | 120 | 170 | 200 | 280 |

Table of technical characteristics of boilers of the Kiturami Turbo model

Kiturami STS

- similar devices, differing in that they are made of stainless steel.

|

Model |

Power | Heating area |

DHW at dT 25 C |

HxWxD-mm |

Weight |

| Kiturami STS 13 OIL | 16.9 kW | 160 sq.m | 6.2 l/min | 700x325x602 | 30 kg |

| Kiturami STS 17 OIL | 19.8 kW | 190 sq.m | 6.7 l/min | 700x325x602 | 30 kg |

| Kiturami STS 21 OIL | 24.4 kW | 240 sq.m | 8.3 l/min | 700x325x602 | 32 kg |

| Kiturami STS 25 OIL | 29.1 kW | 290 sq.m | 10.4 l/min | 930x365x650 | 48 kg |

| Kiturami STS 30 OIL | 34.9 kW | 340 sq.m | 12.5 l/min | 930x365x650 | 48 kg |

Table of technical characteristics of boilers of the Kiturami STS model

Kiturami KSOG

- high-power devices (up to 465 kilowatts) of a two-coil type, also consuming diesel fuel. These Kiturami diesel boilers have a built-in turbocyclone burner and are intended for operation at industrial facilities up to 4650 square meters, as well as for supplying hot water.

Note! All mentioned boilers have an electronic control unit, which is equipped with numerous functions. In addition, the manufacturer provides for the possibility of installing a room thermostat, which allows you to control the temperature in the room directly on site.

Table - Comparison of models and prices of Kiturami heat generators

|

The lineup |

Name |

Power, in kilowatts |

Cost, in rubles |

| Kiturami KSOG | 50R | 58 | 95.5 thousand |

| 200R | 230 | 304 thousand | |

| 150R | 175 | 246 thousand | |

| 100R | 116 | 166.6 thousand | |

| 70R | 81 | 104 thousand | |

| Kiturami STS | 30R | 35 | 63 thousand |

| 25R | 29 | 55 thousand | |

| 21R | 24 | 50 thousand | |

| 17R | 19 | 42 thousand | |

| 13R | 16 | 41 thousand | |

| 30R | 34 | 52 thousand | |

| 21R | 24 | 50 thousand | |

| 17R | 19 | 40.6 thousand | |

| 13R | 15 | 38 thousand |