Operation of infrared heaters

Operation of infrared heaters - the order of operation of heat-generating devices that convert the consumed energy into heat, which is transferred to objects through infrared radiation.color>

Principle of operationcolor>

The principles of operation of infrared heaters differ significantly from any other types of heating devices. Its functioning is associated with the formation of thermal energy in a wide spectrum of infrared radiation. Moreover, the maximum value of the radiation intensity in this spectrum falls on a wavelength proportional to the heating temperature of the radiating body. Thermal energy is delivered to the required place by electromagnetic waves at a speed of about 300,000 km / s.

In this respect, infrared heating differs from other types in that the delivery of infrared heat

occurs almost immediately after turning on the heater. And, conversely, the effect of heat rays ceases when turned off. There is no fundamental difference: turn on or off the light source or the heat source in the room.

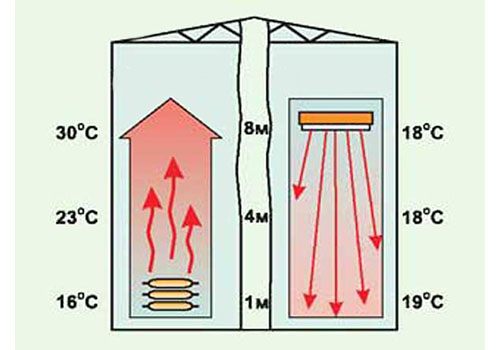

The work of infrared heaters is based on the fact that infrared radiation heats primarily objects that are in its path. Air directly practically does not receive heat from the infrared beam, it passes it through itself. Objects, gradually heated by convection, transfer heat to the air. With this method of heating, objects located in the zone of functioning of infrared radiation will always be 2 - 3 ° C warmer than air.

The effect of infrared heaters lies in the fact that the thermal energy generated by them is used by 90% to heat objects and only 10% is directly absorbed by the air mass, so they have a high efficiency. All other types of heaters spend the bulk of the energy consumed on air heating, and all other objects are heated only from it. Due to the fact that the infrared beam is almost not absorbed by the air and does not reduce the oxygen content in it, comfortable conditions are created for a person to stay. At the same time, he does not experience such sensations as a lack of oxygen, headache, general malaise and fatigue, which are inherent in staying in a room heated by convection heaters.

Application featurescolor>

This type of heaters is widely used in the creation of local zones.

heating of workplaces at industrial enterprises and is the only way to heat a person in rooms with large ceilings and heat losses.

The use of infrared heaters makes it possible to create a local heating zone with a spot diameter approximately equal to (2 * h), that is, equal to two heights of the emitter suspension. At the same time, the heat transfer area is much larger than that of conventional heaters, which means that the heating time is reduced. Reducing the operating time of the heater leads to energy savings. Therefore, infrared heaters are by far the most efficient electric heaters that allow you to save electricity by about 50% of the calculated power.

They have found wide application in heating houses, cottages, garages, industrial premises, etc.

Types of infrared heaters for large rooms

The most common infrared heating heaters are gas and electric, each of which has several types. The main advantage of all infrared heaters is efficiency.

In comparison with a conventional heating system, infrared heaters will be twice as economical, and when installing a new IR

equipment, it pays off in 1-2 heating seasons.

Gas infrared heaters

Infrared gas heaters are mounted on the ceiling and run on gas. They are divided into two types: light and dark. The selection and calculation of power is based on the volume of the heated room, the presence of air flows and the required heating temperature. Disadvantages for gas infrared heaters are: the presence of a gas pipeline system, additional installation of an air vent, a ceiling height of at least 4 meters.

Electric infrared heaters

Infrared heaters with ceramic emitters can be installed both on the wall and on the ceiling. They can be used in any type of premises, including outdoors, which is convenient for short-term outdoor work. IK heaters fasten in any convenient place and are connected to the power supply network.

The advantages of IR heaters are that they can be used in rooms with a high fire hazard, in dusty and damp rooms, they are mobile and can be reconnected within 5-10 minutes. Infrared heating is safe and economical. IR type heaters can be found in hospitals and educational institutions. They are economical and multifunctional.

The calculation of the power of infrared heaters can be done independently or with the help of a heating specialist from Infragorg.

What is an infrared heatercolor

Infrared heater - - a heater that uses infrared radiation in its work and is used for the main or additional heating of premises, as well as local areas of street space or workplaces in the workshop.color>

Heaters are usually used for space heating. Depending on the method of heat transfer, they can be convective or radiant.

Convective ones work on the principle of mixing cold and hot air, while the temperature difference between the air mixture on the ceiling and the floor can reach large values.

Radiant ones transfer heat mainly due to infrared radiation, place them above the heated area or on the ceilings and walls of the room.

Air, if it is not saturated with water vapor, almost completely transmits radiant energy. This energy directly heats any objects in its path, and they in turn give off heat to the air.

That gives a significant economic effect compared to convection heating, which consumes part of the generated heat to heat the subceiling space where it is not needed.

In addition, infrared radiation is felt by a person immediately after it is turned on, which eliminates the need for preliminary heating of the room and can significantly reduce heating costs.

Infrared heater devicecolor>

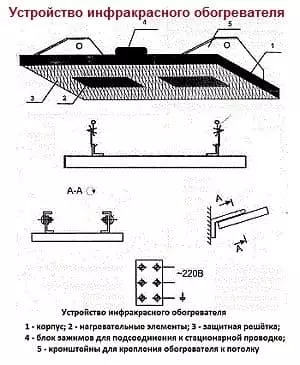

The main structural element of an infrared heater is an emitter that generates infrared radiation. In order to provide directional radiation and protect the body from overheating, a reflector made of a heat-resistant element is placed behind the radiator.

The reflector on the reverse side is covered with a heat-insulating material, which further protects the body from exposure to high temperatures.

If the heater is used in places where people or animals are located, the emitter is covered with a metal mesh to prevent involuntary burns or electric shock.

Infrared Wave Rangecolor>

Infrared Wave Range represents an electromagnetic wave located in the range of radiation from 0.74 microns. up to 2000 microns.color>

Infrared heaters are heating devices that provide heat transfer from a radiator with a high temperature to bodies with a lower temperature by means of electromagnetic (infrared) radiation.

Infrared radiation is absorbed by surfaces encountered in its path, turning into

thermal energycolor>,

and air is heated from these surfaces. This allows you to significantly save energy for space heating compared to convection heating. The wavelength of the infrared range of radiation depends on the heating temperature of the emitters installed in infrared heaters. It is in the range from 0.74 µm. up to 2000 microns. The dependence of the infrared wavelength on temperature expresses Wien's displacement law. A graphical representation of this law for various temperatures is shown in the figure. It can be seen from the graph that the surface area under the curve corresponding to a certain temperature is proportional to the amount of radiant energy, and it increases greatly with increasing temperature. In addition, it can be concluded that the wavelength λ at which the maximum value of the curve is determined, it shifts with increasing temperature by smaller values.

Infrared heating systems system on infrared emitters

Infrared heaters form the basis of an infrared heating system. The principle of their operation is based on the fact that the energy of the burned gas or electricity is converted into the energy of thermal radiation.

Advantages: the ability to direct heat directly to the desired area and heat individual local areas in large volumes.

Disadvantages: if it is necessary to warm up the entire volume of air in the room, the efficiency of the devices is greatly reduced; radiating surfaces heated to high temperatures are located directly in the heated room, which can lead to a fire; emitters operating on natural gas require a complex and extensive gas supply system, which greatly increases the cost of the entire project; gas emitters burn out oxygen from the room, which leads to the need for ventilation; emitters powered by electricity consume a lot of electricity, which is uneconomical; possible deterioration of the well-being of personnel exposed to direct radiation.

Radiators are effective only when several local working areas need to be heated pointwise in a large volumetric room, the efficiency of their use for heating the entire volume of the room as a whole is extremely low.

Industrial infrared heaters IkoLine.

Infrared heaters IkoLine with a power of 2.0 to 4.0 kW are conventionally called industrial. because most often they are used in various industrial premises, in workshops, in car services, in warehouses and other premises with a ceiling height of 3.3 to 12.0 meters.

Of course, there are living quarters with high shelves where it is advisable to use more powerful industrial infrared heaters, but such cases are rather an exception.

If you want to create a comfortable and cost-effective heating for production, workshop or warehouse, then IcoLine industrial infrared heaters are the best choice for you. IkoLine industrial infrared heaters are also successfully used in sports halls, indoor tennis courts, in concert halls and stages, at railway stations. In addition to being very efficient and economical, IcoLine heaters are also very user-friendly and durable. And of course, an important factor is the low cost of these heaters with high quality. The warranty period for IcoLine industrial infrared heaters is 5 years! Service life 25 - 30 years!

“Does the fireplace heat in your house? No, our host saves on buying firewood.

. take a blanket and sit by the window on the sunny side"

A production building is a building with an area that can rarely be indicated in square meters by a three-digit number. Usually, this is a four, and sometimes a five-digit indicator. The height of industrial premises usually starts at 6 meters, reaching 25 meters or more. How to heat an industrial building.with this question, we are usually interested in the heat in the lower part of the room. That is, where people work and production equipment is located. Conclusion: in most cases, thermal comfort is needed at a height of 2-3 m from the floor level.

Installation of air heating

Heating of production halls

Having a clear plan for the location of components and assemblies of the system, it is very easy to carry out installation work by the employees of the enterprise. However, if you wish, you can contact specialized companies.

With self-installation, attention, first of all, must be paid to the completeness of the delivery. Under the order, manufacturers supply air ducts, dampers, tie-ins and other standard elements

In addition, you can additionally purchase the following materials:

- flexible lines

- aluminum tape

- insulation and mounting tape

Warming some areas is very important because it helps prevent condensation. For this purpose, a layer of foil insulation on a self-adhesive basis is laid over the walls of the pipelines.

Its thickness may vary. The most demanded materials are 3-5 millimeters thick.

Depending on the geometry of the premises and the design solution, rigid or flexible lines are installed. Separate sections are connected to each other using reinforced tape, plastic or metal clamps. All installation work is reduced to the following set of actions:

- installation of hot air lines

- installation of distribution pipes

- installation of a heat generating unit

- laying a thermal insulation layer

- installation of additional equipment

Air heating in warehouses. production and utility rooms is a complete system of heat supply. It is characterized by economy and high efficiency.

Criteria for selecting contractors for the development of a heating system for industrial premises

The right choice of a contractor capable of quickly and efficiently coping with such a difficult task as organizing optimal heating of production facilities is 99% of success.

Such non-profit partnerships were created within the framework of the legislation in 2009. Prior to this, the obligatory basis for carrying out work was the availability of the appropriate Rostekhnadzor License.

Now such a criterion is membership in one of the SROs

If the Contractor is included in it, it means that he has the appropriate legal framework, personnel, material resources and production base necessary to carry out contract work even on such a scale as heating plants professionally and on time. Often this factor is not given attention, and yet an organization that is not a member of the SRO does not have the right to take on such contracts

The second criterion is the experience of the company, both in the engineering market in general and in the segment under consideration, in particular. Even the presence of all permits and qualified specialists does not guarantee a high quality result.

As we have already mentioned, this topic has many specific nuances. Inexperienced companies may simply not know about them or imagine them by hearsay, and have a superficial knowledge of the topic.

Everyone once “stuffs bumps” ... But you want them to “stuff” not on you, right?

Another important parameter is the number and structure of the company, as well as the qualifications of its employees. If the company is a member of the SRO, it meets the minimum requirements

But when it comes to such an important and large-scale project as industrial heating, the minimum allowable level, as a rule, is not enough. Therefore, it is advisable to familiarize yourself with the potential opportunities of the future Contractor in advance.

The next significant criterion is the presence of a well-established system of work performance and a model for managing them. Its influence on the result, it would seem, is less obvious than the parameters indicated above, but, nevertheless, many cases are known when experienced firms with competent technical workers who quite conscientiously approached the task, “failed” the Object.

The main reason is the lack of a systematic approach to the implementation of these works, insufficiently effective business process management, and the lack of a quality control system.

In addition, the possibility of further service maintenance also plays an important role, which also depends on the level of relations between the contractor and suppliers and manufacturers of thermal equipment.

The level of equipment prices for a company with established business connections will always be lower than for a newcomer to this business. This is due to the size of discounts provided by manufacturers and distributors. Accordingly, a company with large discounts can offer better conditions to its customers.

We, being a member of a specialized SRO, have been working in this area since 1999. Our structure has a powerful engineering staff, a qualified design department, as well as experienced installation teams. The staff of specialists is divided into those who work in the industrial segment and those who are engaged in the household segment - heating country houses.

An experienced manager-coordinator is assigned to each Object. The performance of works is carried out by multi-stage control at all stages.

The established direct contacts with manufacturers of equipment and materials allow us to complete the Objects quickly and at attractive prices.

Are you looking for a reliable Contractor for heating industrial premises and workshops?

We guarantee that our cooperation will be pleasant, devoid of "headache", and mutually beneficial!

Types of heating devices

Today's realities show that the infrared type of heating is in sufficient demand, so equipment manufacturers are trying to approach the issue of manufacturing carefully. Depending on the purpose of the measures, the types of heating devices operating from infrared radiation can be divided into the following types:

- heaters. Almost everyone is familiar with a device with a lamp, often equipped with an additional support. Such devices are good during gatherings on the terrace or in the gazebo. You can also use them for heating private buildings and even greenhouses;

- lamp devices. Lamps with IR radiation are not much different from heaters, except for the method of installation. They are attached to the ceiling at a certain slope. Thus, large industrial premises and workshops are heated;

- panels. Infrared panel equipment is probably the smartest solution for home heating. A beautiful smooth surface, sometimes with the chosen design, fits perfectly into the overall interior and does not create any special problems for residents;

- film. There is also a film type of devices. This is an indispensable basis for obtaining heat in the house based on the "warm floor" technology. But when installing equipment, it is quite possible to place it on the walls of the room.

In general, infrared heating has a number of advantages.It works silently, does not give dust and carbon deposits on surfaces, does not take up storage space.

Infrared heater

Advantages and disadvantages

The air heating method has undeniable advantages:

- The efficiency reaches 93%. When organizing heating, the installation of intermediate heating devices is not required.

- Heating systems of this type can be fully integrated with ventilation systems. This allows you to constantly maintain an optimal microclimate inside the production complexes.

- Very low level of inertia. Immediately after the activation of the equipment in the room, the air temperature begins to rise.

- High efficiency has a positive effect on the economic performance of production and lower production costs.

Along with this, air heating has obvious disadvantages:

- Constant technical maintenance of the active elements of the system is required. It is quite difficult to modernize existing installations.

- In order to avoid interruptions in heat supply, a backup power supply is needed.

Choosing a system for heating industrial premises

Heating of industrial premises is carried out using different types of systems, each of which requires detailed consideration. The most popular are centralized liquid or air systems, but you can often find local heaters.

The following parameters influence the choice of the type of heating system:

- dimensions of the heated room;

- the amount of thermal energy required to comply with the temperature regime;

- ease of maintenance and availability of repair.

Each system has its pros and cons, and the choice will primarily depend on the compliance of the functionality of the selected system with the requirements that apply to it. When choosing the type of system, it is necessary to calculate the heating system of an industrial building in order to have a clear understanding of how much heat the building needs.

conclusions

In practice, the air heating system using stationary gas air heaters (GVO) is the most efficient. The air duct system allows for the highest quality air mixing in order to reduce the temperature gradient. For example, at facilities where local air heating is used (heating and ventilation units (AVO, Volcanoes, etc.) or smooth-tube registers), taking into account the height of the ceilings up to 15 m, the temperature difference in the working area at a height of 2 m and under the ceiling can be 10–13 °C.

Measurement results at warehouse facilities using the hot water system in the winter of 2018 (Tbunk = –15 °С) showed that the temperature at the lower and upper points of the premises was from +20–22 °С to +20–25 °С. At the same time, high-quality air mixing is achieved provided that the calculated air exchange rate k = 0.7–1 is observed.

In order to save energy resources on ventilation machines, additional recirculation with mixing (75% fresh air and 25% recirculation) and heat recovery can be used. Those. 75% fresh air (Tbunk = -24 °C) is first mixed with the exhaust air (mixture point temperature -2.6 °C), heated by the heat of the exhaust air to +10 °C in the heat exchanger and then heated to +26 °C in the indirect gas heater. The required power to compensate for heat loss through the building envelope is supplied in the calculated volume of air with ΔТ = 10 °С (26–16 °С). To ensure the estimated volume (31,000 m3/h 2 pcs.), two air handling units with electric motor power (18.5 2) 2 = 74 kW are required.

Today, building codes (SNiP and SP current) for warehouses clearly recommend only two types of heating systems as a priority - air or radiant (infrared). Convective heating (radiators, "warm floor") for such objects is already an anachronism.Although it happens that they are still used.

Infrared ceiling water panels are a fairly effective (with their own characteristics) solution, not yet so common in the Russian Federation, but no longer a novelty in the professional environment.

The GVO system is the right and economical option for the customer of warehouse and shopping complexes under construction. Implementation practice has convincingly proved their cost-effectiveness and ease of use.

In Europe, for air heating of high/volumetric (warehouse) premises, as a rule, two options for constructing an air distribution system are used, placing ceiling fans (destratifiers) inside the warehouse and using textile air ducts with special openings that create air jets with an induction effect.

Undoubtedly, we should look up to the European experience, since the supply of our energy carriers is not infinite. And, as practice shows, a properly selected and built heating system can not only save the customer's money, but is also the key to long-term operation of the building as a whole.