Surface preparation

Before you start tinning, you must perform the following steps:

- degrease the surface with acetone, gasoline or any other solvent;

- remove the oxide film from the place where the soldering will be performed. For cleaning, sandpaper, an abrasive wheel or a brush with steel wire bristles are used. Alternatively, etching can be used, but this procedure is not so common due to its specificity.

It should be borne in mind that it will not be possible to completely remove the oxide film, since a new formation instantly appears in the cleaned place. Therefore, stripping is carried out not to completely remove the film, but to reduce its thickness in order to simplify the task of the flux.

Solder point heating

For soldering small parts, you can use a soldering iron with a power of at least 100W. Massive objects will require a more powerful heating tool.

The best option for heating is to use a gas burner or a blowtorch.

When using the burner as a heating tool, the following nuances should be taken into account:

- do not overheat the base metal, as it may melt. Therefore, the temperature must be regularly monitored during the process. This can be done by touching the heated element with solder. Melting the solder will let you know that the required temperature has been reached;

- oxygen should not be used to enrich the gas mixture, since it contributes to the strong oxidation of the metal surface.

Types and features of gas burners

A gas burner is rightfully considered the most convenient device for welding any copper products. The device has small weight and dimensions, it is convenient in work and economic. The ability to adjust the power of the flame allows you to set the parameters for specific types of work.

The standard design of a gas burner includes the following elements:

- Knot for fixing the tank with fuel.

- Instrument head.

- Nozzle.

- Reducer.

- Flame intensity regulator.

In addition, manufacturers include additional elements in the design: adapters, tips, flame deflector, etc.

Devices are classified according to several parameters. So, according to the technical capabilities of the device there are:

- Household. Inexpensive devices with a minimum set of functions. The temperature of the fire is regulated in the range of 1000-1500°C.

- Professional. More expensive burners designed for serious work. The flame has a temperature of 1500-2000°C.

Depending on the gas mixture used, burners are divided into several types:

- Propane. They are specialized or general. considered the most common. The gas produces an even, intense flame.

- On MARR gas. They are distinguished by a soft, but energetic flame, which is gentle on the pipe material, preventing its damage.

- Acetylene. Most often used when working on main objects. They are fed from disposable cylinders, or are stationary. The gas generates a high flame temperature, which has a positive effect on economy, but often leads to overheating of parts and increases the likelihood of damage.

Gas burners with disposable cylinders are easy to use, do not depend on electricity sources, are compact and safe. The only drawback is the need for frequent change of cylinders.

Stationary installations are distinguished by a powerful flame torch, which allows soldering quickly and efficiently. In everyday life are used extremely rarely.

How to use solder

In order for the seam after soldering to be strong and airtight, it is necessary:

- carefully prepare pipes before soldering.To do this, the ends of the pipes are cleaned of oxides and other types of contaminants with a metal brush, and the burrs formed after cutting the pipes are removed using a special device - a beveler;

Preparation of copper pipe for soldering

- expand the end of one pipe by a few millimeters so that the pipes easily fit together. If soldering is done using fittings (special elements designed to assemble a pipeline of various configurations), then the diameter of the fitting increases, and not the pipe;

Increasing the pipe diameter

- process the places of soldering pipes with flux;

Fluxing the pipe before soldering

Since the flux is a toxic compound, when working with it, safety rules must be strictly observed: work must be done with gloves and in a ventilated area.

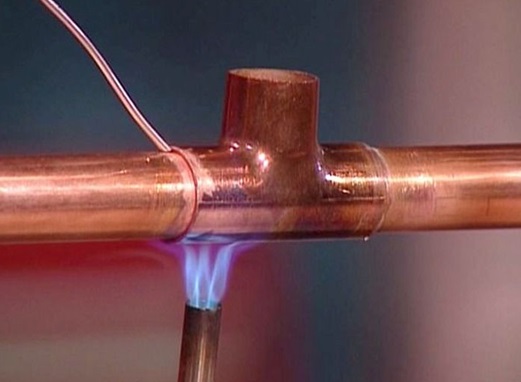

- prepare a gas burner (equipment designed for soldering pipes made of copper) and slightly heat the areas to be soldered;

- carefully apply solder around the entire perimeter of the pipe, which, during heating, will gradually change from a solid to a liquid state, thereby filling all the empty space;

Soldering with solder

- Allow the solder to cool completely while still. For complete cooling, depending on the type of solder, an average of 3-5 minutes is required.

The process of soldering copper pipes with solder is shown in the video.

When choosing solder and flux, it is necessary to take into account all the main characteristics of the substances, that is, if high-temperature solder is used for soldering, then the flux should also be designed for high-temperature soldering. Properly selected and matched materials contribute to obtaining not only a sealed seam, but also the most durable connection.

The most popular models and manufacturers

The construction market today presents a large number of devices from various manufacturers. Gas burners of domestic production are popular: Profi-Tools; Allgas; Donmet. Foreign manufacturers also enjoy a good reputation: Rothenberger; Kemper; Virax; Rems; Uniweld.

Most companies offer burners of different classes - from hand-held mobile devices to professional powerful devices. A semi-professional propane burner costs from 1.5 to 10 thousand rubles. Professional units will cost more - the minimum cost is from 20 thousand rubles.

What you need for soldering

For capillary connection copper pipes will require the following tools and materials:

- tools for pre-treatment of connected elements;

- flux and solder;

- special fum tape;

- threading tool and ferrules;

Types of solders

Solders are of two types - hard and soft. Soft solder is a wire made of metals and alloys with a low melting point (tin, lead, silver, etc.). The diameter of such solder is not more than 3 mm.

Hard solders are made from refractory metals and have a larger diameter.

Flux and solder paste

Flux or paste is used to secure the connection. This substance prevents foreign elements from entering the junction, the seam is reliable without pores. The flux is based on boric or hydrochloric acid, zinc chloride. In order to create a protective film at the junction, resins, rosin, and wax are used.

Soldering fluxes are divided into liquid, solid and special pastes. The finished mixture is more expensive than other materials, but it is much more convenient to work with it.

Fitting

Fittings are called special parts that are mounted at the junction of blanks of different diameters, connecting several pipes at one point or when switching to another pipeline material.

If it is necessary to use fittings from a different material, it is important that the coefficient of thermal expansion and other technical parameters of the material of pipes and fittings match

Flux

When choosing a flux, it must be taken into account that not all of them can be active towards aluminum. We can recommend using for such purposes the products of a domestic manufacturer - F-59A, F-61A, F-64, they consist of ammonium fluoroborates with the addition of triethanolamine. As a rule, there is a mark on the vial - “for aluminum” or “for soldering aluminum”.

For high-temperature soldering, you should purchase flux, manufactured under the brand name 34A. It consists of potassium chloride (50%), lithium chloride (32%), sodium fluoride (10%) and zinc chloride (8%). Such a composition is most optimal if high-temperature soldering is performed.

Flux

For most types of solders, pre-treatment of pipes with a special composition, which is called a flux, is necessary.

Flux is produced:

in liquid form;

Soldering compounds in liquid form

in the form of a paste.

Soldering compound in the form of a paste

It is more preferable and more convenient to use a flux made in the form of a paste, since a more solid composition contributes to uniform application and does not spread over the surface of the pipe.

Flux allows:

- perform additional cleaning of pipes from oxides;

- more evenly distribute the solder during the soldering process;

- protect the joint from corrosion and oxide formation.

Equipment and materials needed for soldering

Like any technological process, soldering requires the use of special devices and tools. First of all, the following tools are needed for soldering copper pipes.

Burner. It can be of various designs. When choosing, it is worth considering what kind of solder you are going to work with, because each of them needs a certain temperature.

Torch for soldering copper pipes

Structurally, burners can work:

- from disposable cartridges with combustible gas (more compact version),

- from standard refillable cylinders.

Pipe cutter for copper pipes

For cutting blanks, it is best to use special pipe cutters. In principle, you can get by with a simple hacksaw, but it is very problematic to cut with it in some hard-to-reach places, and the cleanliness of the cut will be low. The cost of the tool directly depends on the diameter of the pipes that they can cut.

The connection of copper pipes without expensive fittings, by the method of telescopic docking (one tube enters another, which has a slightly larger diameter), followed by capillary brazing, can be completely carried out for domestic plumbing and heating networks, the water temperature in which does not exceed 110 degrees. This requires a special pipe expander.

To eliminate burrs and burrs on the edge of the workpiece, a chamfering device is required, they are also available in various modifications.

For soldering pipelines for various purposes, and even more so for elements that will work in especially critical conditions, special solders are needed.

- Standard. It is used most often, but is not recommended for use in drinking water systems.

- Soft solder. The consumable used for soldering fittings and red bronze products is widely used for connecting copper pipe with brass fittings.

- Hard solders. The most popular solders when connecting copper pipes. Its use in capillary soldering of almost any communications, even gas lines, provides a reliable connection. These solders, which are in the category of copper-phosphorus silver-containing soldering consumables, do not require additional flux. However, it is not recommended when joining products made of aluminum bronze and alloys containing more than 10% nickel, this is due to some brittleness of the solder.

- Silver solders are the most expensive, but they can be used to join a variety of colored materials.

To prevent the formation of oxides at the place of soldering, when using standard and soft solders, flux treatment is mandatory.

soldering process

Before proceeding directly to the connection of the cut blanks, they must be pre-processed. First, the joint is cleaned, minor defects and burrs are eliminated. After that, the surfaces of the pipes to be joined are treated with brushes and brushes from the outside and from the inside. Do not use abrasive tools, otherwise scratches will occur.

If required, one tube expands. The diameter of the copper pipes must be such that one workpiece freely enters the other. Before that, it must be heated, otherwise mechanical damage will appear, which will further affect the tightness of the connection.

To protect against air ingress into the seam and for better adhesion, a flux or paste is applied to the surface.

Only after completing the preparatory work, you should start heating the solder and pipes with a burner. Heating must be carried out evenly to prevent overheating.

After the pipes have warmed up, solder wire is introduced into the gap between them. It melts and fills the gap at the pipe joint, forming a seam. After cooling, the flux is removed.

Safety

In order to avoid injuries and other unpleasant consequences, it is important to comply with safety requirements: install and repair pipelines only with protective gloves and goggles, in work overalls, prevent the burner flame and hot metal from touching unprotected skin, do not work with open fire near flammable materials

Basic Mistakes

The process of soldering copper pipes is not particularly complicated, however, beginners often make mistakes that subsequently affect the quality of the connection. Common mistakes beginners make:

- insufficient pre-treatment of the place of soldering;

- pressing - non-observance of a sufficient gap between the pipes, as a result of which the seam is uneven;

- using the wrong solder;

- overheating of pipes, which leads to a deterioration in performance;

- insufficiently thorough cleaning of the flux after soldering, which causes corrosion.

In addition, it is required to follow a pre-prepared design scheme.

Process video

For a better understanding of the installation process, watch the video here:

Subscribe to new articles - there is a lot of interesting things ahead!

Varieties of burners

The equipment presented on the construction market is divided into several types.

Burners with fixed and disposable cylinders

Such devices are equipped with disposable gas cylinders with propane, acetylene, etc. The advantages of using this type of equipment include mobility, ease of operation, and safety.

You can use such a tool both for the installation of plumbing and heating systems.

Hand burners

The advantages of such equipment include, first of all, compactness. Using a hand soldering iron, it is convenient to assemble a pipeline in a small room, solder pipes in the most inaccessible places.

The hand burner runs on a disposable combustible gas cylinder. The tool is equipped with a flame length regulator, the kit usually includes nozzles of different diameters. The tool does not require an electrical connection. If you follow all the rules of work, the connection is reliable and durable. A hand tool will easily cope with the installation of air conditioning systems and other household communications.

Professional burners

Equipment belonging to the professional category is capable of working with especially refractory solder. It is used in the installation of structures at industrial facilities where the pipeline is subjected to significant loads.

Large weight and dimensions will not allow you to work in a cramped apartment. For domestic and personal use, it is not advisable to purchase such devices - household communications do not require such a connection quality, and the cost of the device is higher than that of other types.

Homemade burners

Sometimes masters use devices assembled by their own hands. They differ in their characteristics and belong to both manual and stationary types. Homemade burners consist of the same basic elements as purchased ones. However, it is not recommended to use such devices, as there is no guarantee of safe operation. And in terms of performance, they are usually inferior to factory equipment.