Causes of damage

There are not many reasons that cause problems with radiators. All of them can be divided into two types. These are mechanical causes and natural wear and tear, which contribute to various damages that violate the integrity and tightness of the device. Even a small stone that accidentally flew out from under the wheels can cause a breakdown and a radiator leak.

But sometimes auto mechanics are faced with a different factor - these are head-on collisions with other cars. Even a slight blow to the bumper is enough to cause a breakdown. In addition, mechanical reasons include various repairs that are done by novice motorists. This often leads to damage to important parts and components of the device.

Corrosion processes, as well as natural wear and tear, are the second group of reasons that cause a radiator to leak. It must be remembered that even minor scratches or chips can very quickly turn into a hotbed of active corrosion. If attention is not paid to this problem in time, then as a result of the destructive process, a hole will appear through which the coolant will flow out of the system. Minor cracks are quite difficult to detect. But if you seriously get down to business, then often all such damage can still be found.

These are two groups of typical causes that can cause depressurization and damage to the heat exchanger and subsequently coolant leakage. In addition, there are also some troubles during operation, which can cause improper circulation of antifreeze in the system.

How to seal the plastic parts of a car radiator

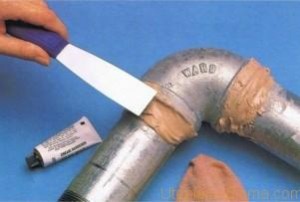

Let us consider in more detail the adhesive method of repairing a damaged radiator using the example of the use of Hosch two-component industrial adhesive.

To seal the radiator tank, you should prepare the following materials and tools:

- powder welding granulate and liquid component of glue-welding;

- sandpaper;

- acetone for degreasing surfaces;

- gloves;

- cotton swabs.

Stages of work:

- Training . Both surfaces to be bonded must be free of grease and other contaminants. If traces of other glue remain on the parts, they must be completely removed. In most cases, ordinary acetone is suitable for cleaning;

- Applying glue. The minimum amount of adhesive welding is applied directly to the crack. To fill the void or in the absence of body fragments, a powdered adhesive component is sprinkled onto the liquid base. If it is necessary to restore a large depression, gluing is recommended to be carried out in several stages (several layers are applied sequentially with an interval of 10 minutes). After the gap is filled with dry granulate, it must be evenly impregnated with the liquid component.

- Seam processing. After 10-15 minutes after completion of the work, you can start machining the seam with a grinder or fine-grained sandpaper to give the seam an aesthetic appearance.

VIDEO INSTRUCTION

Instructions - how to solder the plastic parts of a car cooling radiator

For soldering (welding) a plastic radiator, the following materials and tools should be prepared:

- Special building hair dryer for heating the place of soldering;

- Soldering iron with a sharp tip and precise temperature control;

- Solder for plastic - special welding rods. The marking on them must match the marking on the radiator housing. As a rule, it is "PA" - polyamide (nylon) or "PP" - polypropylene. Instead of purchased welding rods, you can use pre-prepared strips cut from a similar plastic tank;

- Acetone.

Work order:

- Degrease the repair site with acetone;

- While the soldering iron is heating up, we heat the junction with a building hair dryer;

- We connect the seam and gradually draw along it with a heated soldering iron, forming a groove equal in width to the thickness of the welding rod;

- We apply a welding rod and, heating it with a soldering iron, put it in the groove of the seam;

- We check the radiator for leaks, and then install it on the car.

The welding temperature (heating of the soldering iron) is selected in accordance with the brand of plastic. For PP, this is about 250 degrees.

Choice of repair and adhesive methods

There are several ways to restore the integrity and tightness of the cooling radiator:

- Soldering. Housing elements of modern automotive radiators made of heat-resistant plastic are perfectly soldered using a conventional soldering iron (we will consider this process in more detail below).

- Cold welding. This is the fastest way to join plastic parts without heating. A special plastic mass, which includes polymer resins, metal filler and chemical additives, connects the surfaces to be glued, forming a heat-resistant seam.

This process does not require special equipment, but such repairs cannot be called durable.

Due to the low adhesion of plastic, cold welding is very weak. This method allows you to only temporarily solve the problem (for example, to get to the nearest car service).

Application of glue. If the damage is small, special glue will help restore the tightness of the case.

Such compositions have proven themselves well, such as:

3M DP8005 Two-Part Adhesive is a specialized acrylic-based compound designed for bonding difficult-to-bond plastics, polyethylene, and polypropylene.

Great for repairing a cracked radiator. The adhesive seam formed by DP8005 adhesive from the 3M trademark is resistant to aggressive solutions and high temperatures.

The only drawback of this glue is the high price (1300-1500 rubles per pack of 38 grams).

Adhesive welding for Hosch plastics. This two-component industrial adhesive effectively repairs cracks and other damage in all plastic products.

The adhesive seam is able to withstand exposure to high and low temperatures, as well as pressure up to 12 atmospheres, so they can easily glue a plastic radiator with it.

Often the junction is stronger than the plastic being glued. The average cost of a set of two complementary components is 1500-1700 rubles.

How to fix a leak in a radiator with sealant

Sealant is a special composition for sealing cracks and holes in the cooling system and especially in the radiator.

There are several types of sealants:

- Powder. We fall asleep in the radiator when a coolant leak occurs. The simplest and most popular option for domestic car owners is mustard. Some motorists even use tobacco and other equally exotic substances for these purposes.

- Advantages. The advantages of dry products include low cost and the ability to eliminate defects of small sizes (up to 1 mm).

- Flaws. There is also a significant drawback, which lies in the fact that not only the leaks are clogged, but also the radiator channels in the cooling and heating system.

- liquid preparations. Preparations of this type are based on polymers with the addition of small particles of metals. As a rule, such products are used to eliminate leaks in the engine block, but also partially in radiators. The principle of operation is as follows: polymers cling to small roughness and sharp edges and envelop them.

- Advantages. The advantages of this option include the fact that the sealant is constantly in the coolant and when it is replaced, it is removed from the cooling system.

- Flaw.Only small holes (no more than 1 mm) can be sealed with a polymer preparation;

- Modern means of polymer type. Means of this type in their composition have special fibers. A striking example of such a substance is LAVR STOP LEAK radiator sealant. Thanks to the fibers, the adhesion of the particles of the agent between themselves and the edges of the cracks improves.

- Advantages. The main advantage of this option is that in a few minutes you can close up a hole up to 2 mm.

- Flaws. High price.

Sealant for car radiator - application

The main mistake of most motorists is that they do not know the main function of the gremetic. And it is simple - eliminating the leakage of coolant during its temporary use. Therefore, it is recommended to use a gremetic only in cases where it is not possible to eliminate the leak in stationary conditions or in the garage.

If a sealant was nevertheless used to eliminate the cause of the leak, then, if possible, drain the coolant, flush the system and make a complete repair of the radiator.

Driver actions when using sealants:

- A temperature sensor may indicate a leak from the radiator while driving. If the car is parked, then a puddle of coolant can tell us that it is necessary to check its level.

- In cases where such a problem nevertheless arose, then turn off the engine, wait until the coolant cools down and proceed to inspect the damage. If the liquid still continues to flow, we install a container under this place to collect it.

- Remember! Do not open the radiator cap of a car while the engine is running or hot, as this can cause serious burns.

- If you have a powder or liquid product on hand, then place it in the radiator in accordance with the instructions.

Then we start the engine for a few minutes, turn it off and after a while we check again for leaks on the running unit.

If the leak is small and the sealant has been used in accordance with its instructions, then the coolant should no longer leak.

In cases where the defect still could not be eliminated, then this may tell us that the hole is large. In this case, soldering is no longer enough.

How to choose the right sealant?

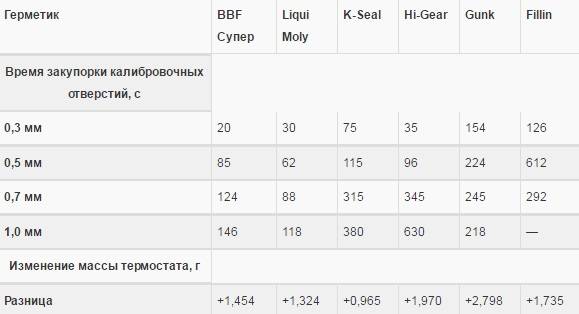

A summary table with two characteristics will help to facilitate the choice: the clogging time of holes of different diameters and the level of deposits. To evaluate the latter parameter, we used the mass of the thermostat before and after the application of the additive. Such a test of sealants was carried out at the Department of Internal Combustion Engines of the St. Petersburg Polytechnic University.

table

The table shows that sealants cope with microcracks successfully, even large holes overlap within 2-10 minutes.

Types of leaks and how to fix them

There are several main types of leaks:

- crack in the case of a sectional, tubular or panel radiator;

- violation of the tightness of the seam connecting the sections of the battery;

- leakage at the place where the radiator is connected by a pipeline;

- pipe leaks.

Leak in radiator piping

Using clamp and rubber gasket

Before sealing a leak in a heating battery. formed at the place of connection of the supply or return of the coolant, it is necessary to prepare some tools, these are:

- aluminum clamp;

- rubber gasket;

- wire;

- pliers.

Fixing leaks with FUM tape

According to OKPD, the repair of the heating system on an individual basis can be carried out using a special FUM tape.

Violation of the tightness of a sectional, panel or tubular radiator

In most cases, a damaged radiator will need to be replaced.

Application of cold welding

Removal of cracks in the cylinder block and cylinder head

Blocks and heads of engine blocks consist of various metal alloys. Technologies that exist today often make it possible to restore damaged elements. Next, we will consider ways to fix the breakdown and answer the question of how to remove cracks in the cylinder block and repair cracks in the cylinder head. In some cases, crack repair can be done by hand.

One of the most widely used ways to eliminate cracks in the cylinder block and cylinder head is to repair defects in silumin and cast iron blocks by welding.

Welding can be either electric or "cold". Cold welding should be understood as the sealing of cracks with various polymer-based materials. Almost all cracks can be welded by the first or second method, except for cracks in the valve seat area, cylinder walls, as well as those surfaces where the BC and cylinder head fit.

What is the danger of a constant leak of coolant

If the cooling radiator has leaked, you need to know what to do or which specialists to contact to fix such a problem. Constant leakage can lead to negative and even dangerous situations:

- overheating of the engine and its further failure;

- changing the configuration of the cooling system and violating the integrity of the material used as a gasket;

- engine jamming, which will entail costly and lengthy repairs;

- thermal burns that can occur when a crack bursts on a radiator and hot liquid flows out in the form of a fountain.

What a radiator is for and why its leaks are dangerous, we figured it out, it's time to move on to the main question - considering ways to eliminate leaks and return the cooling system to tightness.

This is interesting: Description, properties and application of adhesives brand BF (video)

Estimating the extent of damage to the radiator

The radiator itself is usually installed in the engine compartment, or rather in its front part. This is how it is possible to create the effect of blowing with an oncoming air flow while the vehicle is moving. The disadvantage of a car heat exchanger is fragility. Often this device is called the most vulnerable part of any car.

Even if the smallest impact occurs, the probability of mechanical damage to the part in question is quite high. Especially often heat exchangers break down, the water tanks of which are made of plastic. Therefore, when deciding how to repair a radiator, you need to focus primarily on your capabilities. Carefully study all the methods presented above and try to figure out which method will be the most convenient and simple from a practical point of view.

It is also important to preliminarily assess the extent of damage. If it is strong enough, it is recommended to focus on a direct soldering

So you can deal with really large cracks that cannot be repaired with ordinary glue. If the crack is not the largest, cold welding putty is quite suitable. Glue will be the best solution for repairing small cracks.

If you are not sure that you know how to seal the car cooling system, it is better to focus on repairing the system in a car service. In addition, the mechanic does not have to spend too much money on restoration work, because the process itself is not considered difficult.

This is interesting: Unusual use of a glue gun - what can be done from hot glue

How to seal a car radiator

Now let's talk about how to glue the radiator and what glue is best for this. So, one of the best options is the 3M DP 8805 two-component adhesive. The basis of its composition is acrylic, which makes it possible to use the composition to work with difficult-to-bond materials:

- the main advantages of such an adhesive is the ability to create a sufficiently strong and reliable seam that will not lose its original shape when exposed to high temperatures;

- The disadvantage is the rather high cost.

Also a good option would be special adhesive welding. They are designed for quick, and most importantly - effective elimination of defects on plastic surfaces. Glue seams after such compositions perfectly tolerate not only high, but also low temperatures. In addition, they are not afraid of high atmospheric pressure.

In order not to make a mistake in the choice, we recommend that you buy the required adhesive from a certified automotive store.

Ways to repair radiators

-

You can also use a gas burner for soldering.

To quickly eliminate leaks from broken radiator tubes. You can silence them. To do this, bend both torn edges of each tube and clamp with pliers. This method is suitable if no more than 5 tubes are punched. Such a repair is justified if the radiator is aluminum and you cannot solder it.

- When the radiator is aluminum and it has a broken plastic tank. If the length of the hole is not too different from its width, a rubber plug will help close the hole. You need to do it like this: A cork is cut out of rubber with a thickness of at least 1 cm in the shape of a hole. A hole with a diameter of about 5 mm is made in the center in it. An M6 screw is inserted into the hole, onto which the corresponding nut is screwed. The cork is inserted into the hole. The screw is tightened until the plug compressed by it and the nut, expanding, does not lose mobility. After that, the cork will reliably clog the hole. You can add antifreeze. If the screw head or nut will fall into the hole, and the plug will not expand enough, place a washer under them. After filling with antifreeze, an air lock usually forms in the system. It is removed by undocking the top point of the car's cooling system.

-

If the pipe of the copper radiator has a crack near the tank.

Remember that by buying such compounds, you risk even more damage to the engine cooling system.

Strip it, degrease it and solder it well by pouring a thick layer of solder on it. Such a repair is quite acceptable.

- When the plastic pipe has a crack near the tank. Order the turner to make a tube with an outer diameter equal to the inner diameter of the pipe 3-4 cm long. Remove a piece of pipe from the tank, clean it, degrease it and dry it from the inside. Glue a tube made by a turner into it onto liquid glass so that half of its length remains outside. Dry the structure and glue it into the radiator tank. You need to do this with the same glue. From above, it is better to strengthen the joint with a textile bandage on liquid glass.

An oil cooler must be made taking into account what it is made of. Its repair begins with the fact that oil is drained from it. Cork is also made. You just need to make it from oil-resistant rubber, since other oil will quickly become unusable. Before soldering, the oil cooler should be thoroughly washed inside and oil removed from the outside. And it is better not to repair the oil cooler, but to buy a new one.

How to find a crack

The following methods are used to detect cracks:

- ultrasonic detection method;

- use of magnetically sensitive equipment;

- pneumatic crimping method;

- search for cracks by means of hydrocontrol;

In practice, crack detection in many car services is carried out by pumping air or water into a faulty engine element.In the case of air, the part is additionally immersed in a bath and defects are found by bubbles. If water is pumped into the element, then the need for immersion is eliminated, since cracks are diagnosed by fluid seepage.

To determine the exact boundaries of the crack, a pair of magnets are attached to both sides of the split, the space between the magnets is filled with special conductive sawdust. The presence of a crack will cause the magnetic field lines to break, the sawdust to be partially grouped on the split surface. This method allows you to clearly identify a crack in the cylinder block or cylinder head.

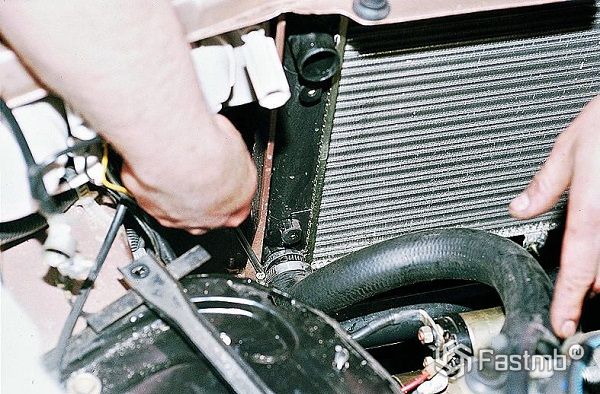

How to pinpoint the exact location of a radiator leak

Before you start repairing the radiator, you need to determine the nature and location of the malfunction itself. Almost all external malfunctions of the radiator (except for ordinary pollution) consist in a violation of its tightness, which means that there must be a coolant leak.

The intensity of fluid leakage from the radiator can be different, and at the initial stage it is visually imperceptible, but a rapid decrease in the fluid level in the tank is noticed almost immediately. After all, a decrease in the level of antifreeze or antifreeze leads to overheating of the engine, which will be immediately signaled by a special temperature sensor on the driver's instrument panel.

To accurately determine the location of a fluid leak, two methods can be used. In this case, it will be necessary to completely drain the coolant from the radiator, and disconnect the radiator itself, pull it out of the car and rinse thoroughly.

Also removed, empty and clean radiator, but with all inlets plugged, completely immerse in a suitable container with water. Air bubbles will come out of the holes in the damaged areas. If air does not come out, pressurize the radiator with a pump or compressor.

Soldering aluminum radiators

Do not rush to take on a soldering iron - it will always be in time. First you need to study the scale of the tragedy and choose the most appropriate repair option.

- in a place with a small defect, you can simply pour solder;

- a breakdown with impressive dimensions will have to be closed with a patch and soldered along the entire contour.

Next will be described in detail how to solder the radiator. If you follow this instruction, even a person without relevant experience will definitely succeed.

We dismantle the device, drain the liquid from it, disconnect the pipes, bolts and remove the assembly.

At the site of the leak, we remove contaminants, clean off dust and dry.

We apply rosin on a dry and clean surface, but it is better to use soldering acid.

For an aluminum heatsink, it is important to use an active aluminum flux or solder. This is due to the oxide film, which is formed instantly

It can disrupt the entire repair process.

A leak can form on the tube - this situation is not uncommon. In this case, you will need to warm up the place of soldering and remove the tube. Then soldering is carried out or the tube is changed to a new one if the damage is large.

It is not always possible to get to the tube so easily with a soldering iron. In this case, it will be necessary to insert a heated rod into the damaged tube. The temperature will make the solder soft, which will allow you to remove the tube without problems.

Since we are talking about soldering radiators, it is worth giving advice on similar repair of copper and brass structures. To repair such parts, you need to use a special soldering iron that is designed to work with such materials. The power of such a soldering iron must necessarily exceed 250 watts. The work is carried out according to the following scheme:

- the surface is also cleaned and dried;

- the material is warmed up;

- rosin is applied as evenly as possible;

- solder is also applied in an even layer.

How to fix a leak in a heating pipe, radiator, between sections

The method of eliminating leaks in the heating system largely depends on the place where the leak appeared. The leak may be:

- on a solid pipe;

- at the junction of pipes and radiators, pipes and fittings (adapters, tees, etc.);

- between battery sections;

- right on the radiator.

Depending on the scale of the disaster (how else to call it?), the actions differ. If these are only the first bells - a few drops per hour or a very thin trickle - you can try to eliminate it yourself, using improvised or purchased means.

You can fix a leak in the radiator and pipe with your own hands. The main thing is that it does not flow too much

If it flows strongly, for residents of high-rise buildings, the first thing to do is to call an emergency team. The next step is common to all: shut off the coolant supply. There are several options here:

- The radiator is leaking. At the same time, there are shut-off valves at its inlet and outlet. Then just close the faucets. For owners of individual heating, everything is simple, but for subscribers of centralized heating, there are several situations.

- The radiator is installed with a bypass, then when the device is turned off in your apartment, nothing happens to the common riser, the heating continues to work. No problem, easy repair.

- There is no bypass. Then you need to either inform the neighbors and (or) the DEZ, ZhEK, etc. and then fix the problem.

- There are no taps blocking the supply, or they do not save the situation - they are in the wrong places. Owners of private houses need to stop heating, residents of high-rise buildings need to block the riser. If the DEZ did not report by closing the valve yourself, hang a sign explaining the reason so that people do not turn on and spoil the process of fixing the leak.

We really don’t like to call “emergency gangs” and often try to fix everything ourselves. There is a chance to eliminate the leak with your own hands if it does not flow “within the radius”. Then let's try to localize the problem.

The difference between new and used pipe is obvious

How to fix a strong leak in the battery

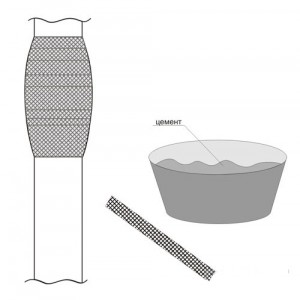

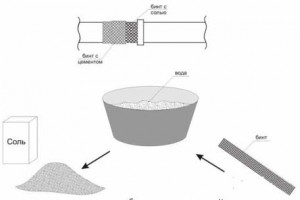

If the radiator flows strongly enough due to frost (the battery could simply break), then in this case, you need to do the following.

Cut pieces of rubber about 3-4 cm thick and about 20-30 cm long (depending on the thickness of your battery). An old bike tube would be a great solution.

Tightly wrap the problem area with rubber strips. Secure the ends of the rubber with homemade metal wire clamps. Radiator leak should decrease slightly and stop. Next, you need to do the previously described operation with alabaster, bandage and cement. Wrap this cocoon on top of the rubber.

If your radiator is leaking, after the end of the heating season, it is advisable to drain the water from the system and replace the problem area.

What to do if a cast-iron radiator is leaking?

Sometimes it happens that even recognized centenarians, cast-iron radiators, begin to leak. The reasons for this are cracks, holes and fistulas. And this happens even despite the fact that the walls of such batteries are quite thick. As a rule, the radiator flows between the sections and at the junction of the battery with the pipe, or a fistula appears on the radiator itself, then it becomes necessary to restore the cast-iron battery.

First of all, you need to diagnose a leak. Of course, it's hard not to notice that the cast-iron radiator is leaking, because. the humidity level increases significantly in the room and traces of water appear. However, these signs are clearly visible only during the heating season. Therefore, you need to know how to determine the place where the cast-iron radiator leaks when the heating is turned off.

At home, it is quite difficult to carry out such a diagnosis. Cast iron batteries are very heavy on their own, and to test them, you need to fill the structure with water and see where it comes from. Another method is to submerge the battery in a bath of water and see where the bubbles come from.

The third method is almost impossible to implement at home, because. you need to blow the radiator with high-pressure air, after covering it with soapy foam. This will show you where the air is coming from. In addition, there will be a hiss in this area and the jet can be felt with your hand.

Cast iron radiators: repair features

The features of its repair depend on where exactly the cast-iron battery flows. If a small break has appeared at the junction of the radiator sections, then this can be fixed with a conventional clamp, which is sold at any hardware store or market. Clamps come in a wide variety of sizes, so choosing the right one for your battery is no problem.

Another way with which you can repair cast-iron radiators at the junction of sections in the absence of a clamp at hand is to use ordinary rubber. Repairing a cast-iron radiator using this method does not differ from repairing other types of batteries, the principle of which was described earlier.

A cast iron radiator can also be repaired with cold welding. Another available material for repairing section joints is epoxy. For such a repair, you need to wrap the problem area with a bandage pre-impregnated with epoxy glue. After the glue has set, the leakage should stop.

In addition to all of the above, you can buy a powder or polymer sealant that can temporarily eliminate the leak. The principle of operation of this kind of composition is polymerization at the moment of contact with air. Such a sealant is able to withstand elevated temperatures, it does not evaporate and perfectly resists leakage.

Restoration of radiators by the methods described above is short-term, soon you will still have to call a professional team to repair or replace the battery, because in some cases it is impossible to do without welding or replacing the entire battery with a new one.