Boiler chemical cleaning

When using the chemical method, all water should be drained from the heating system, and then a booster should be connected to the boiler - a special flushing apparatus equipped with a pump. Pour the cleaning solution into it and run the product through the heat exchanger for several hours without stopping.

For chemical cleaning use:

Mixtures in powder form with sulfamic acid

These agents do not damage metal and sealing materials.

A solution of hydrochloric acid, but this should be done with great care: the product is very aggressive, and its waste is difficult to dispose of.

Citric acid - it acts quite effectively, but more carefully than hydrochloric acid .. After washing, you need to drive clean water several times

This method helps to clean hard-to-reach places of the device.

After washing, you need to drive clean water several times. This method helps to clean hard-to-reach places on the device.

If desired, you can clean the heat exchanger of a double-circuit boiler with your own hands, without resorting to the services of specialists. This procedure does not take much time, and besides, you do not need to spend extra money. The main thing is to follow some rules and know the principle of operation of a gas boiler. After spending only 2-3 hours of time, you can qualitatively clean the equipment from contamination.

A gas boiler heats water by burning gas in it. The heat exchanger of the building is a copper or steel curved pipe. When the gas is converted into energy, the heat exchanger also heats up, transferring heat to the heating system. Heating is carried out thanks to special plates, they also help to raise the temperature and direct it to one of the circuits of the two-circuit system.

The heat exchanger is made from the following materials:

- Copper;

- Stainless steel;

- copper alloys.

This is due to the fact that copper and its derivatives conduct heat well.

If the water is hard enough, you will have to clean the heat exchanger from scale once every 2 years. You can do it yourself by preparing the necessary tools in advance.

The procedure for cleaning the boiler from scale, soot and soot

If you decide to do the procedure for cleaning the structure with your own hands, before working at home, you need to turn off the electricity, turn off the gas, close all the valves of the heating system and boiler.

All actions should be carried out carefully, disassembly and assembly requires special care:

- The boiler cover is removed;

- Next, you should remove the gas burner, remove dirt in the form of soot from the electrodes, you can wash the surface with water and detergent, rinse;

- Clean the injector, nozzles with a brush with soft hair;

- Next, the fan is removed and its blades are cleaned;

- The wall of the AGV combustion chamber is removed;

- The heat exchanger should be cleaned of soot, rinsed with citric acid or a special compound;

- After dismantling the coil, it is necessary to clean the bottom of the boiler;

- Then the filter intended for cold water is cleaned, blown and washed with clean water;

- All parts are returned to their places;

- The tightness of the AOGV is checked.

After completing all the necessary procedures, you can open the gas valve and turn on the electricity.

When the boiler has been operating for a long enough time, pollution in the form of soot gradually forms on the burner. Accumulating in large quantities, it can cause equipment malfunctions. Therefore, it must be periodically removed.

For mechanical cleaning with small accumulations of dirt, you will need:

- Brush;

- Yorshik;

- Thin needle.

The gas duct is obligatory wiped. The surface of the nozzles is cleaned with brushes or a brush. A needle is used for holes.In no case should the hole be enlarged, as the combustion process may be disturbed.

If there is a lot of carbon deposits, acidic solvents can be used.

Why did the igniter go out

- The problem is caused by a power failure. For example, a voltage drop. To eliminate interruptions in the operation of volatile gas equipment, connect a stabilizer.

- The igniter often goes out when the nozzles and air filter are clogged. The solution is to clean the clogged elements.

- During long-term operation, the gap and wire contacts in the igniter may be violated. The situation calls for a specialist. You can clean the filter or check the current conductor yourself.

- If the flame goes out in isolation from the burner, and at the same time noise is heard from the nozzles, the thrust sensor has probably broken. If the cause is oxidation of the contacts, clean them.

- The wick goes out if the thermocouple fails - it can become dirty or burn out. Will have to replace.

- It is likely that the cause of the malfunction is the contacts of the automation unit, check them and, if necessary, clean them.

An extinguished burner is always a nuisance, but especially in severe frosts. At low temperatures there is a risk of pipes freezing. The extinction of the flame can be provoked by the wind penetrating through the chimney - reverse draft. As a result, protection is triggered - the device is completely turned off. Traction often causes failures - if it is insufficient, excessive, reverse.

Negative effects of deposits and frequency of cleaning

If you do not regularly carry out procedures for cleaning the boiler, then negative consequences cannot be avoided. First of all, heat transfer indicators decrease. The room will warm up slowly and heat will be distributed unevenly. The next disadvantage is that more fuel will need to be used, and costs will increase accordingly.

A solid fuel boiler that is not cleaned of ash, soot and tar in a timely manner will not last long, since its main elements responsible for high-quality heating will quickly fail.

By regular cleaning, you will ensure not only its efficient operation, but also increase its service life.

The frequency of cleaning procedures for a solid fuel boiler depends on the quality of the fuel used.

If you use high quality firewood, coal, etc., it will be enough to clean the unit once every 30-40 days. If you use low quality fuel with high humidity, then the boiler must be cleaned at least once every two weeks.

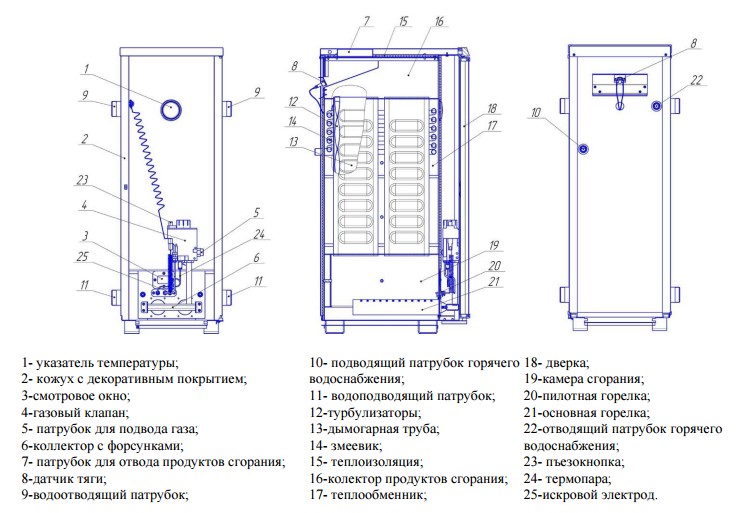

Boiler Aton Compact AOGVMND-7E technical specifications

| The country | Ukraine |

| Manufacturer | |

| Boiler type | |

| Working mode | |

| The combustion chamber | |

| Burner | |

| Max useful power, kW | |

| Max pressure will heat the circuit, Atm | |

| Expansion tank | |

| Circulation pump | |

| Max consumption of natural gas, m3/hour | |

| Nominal pressure of natural gas, mbar | |

| Connecting flue ø, mm | |

| Connecting ø gas pipeline, inch | |

| Connecting ø heating circuit, inch | |

| type of instalation | |

| Self-diagnosis | |

| Electronic control system | |

| pressure gauge | |

| Pump anti-blocking | |

| Functional LCD display | |

| Possibility of installation in a residential area | |

| Intuitive controls | |

| Dimensions (HxWxD), cm | |

| Weight, kg | |

| Guarantee |

Varieties

Parapet

A parapet or chimneyless boiler is structurally similar to condensing appliances. A distinctive feature is the closed type combustion chamber. Oxygen consumed during fuel combustion enters the furnace from the street. A horizontal coaxial smoke outlet is connected to the device. It is characterized by high efficiency and environmental friendliness. Economical use of energy resources. A number of parapet versions, in addition to a conventional radiator, have a built-in convection casing - for greater heating efficiency. The manufacturer offers parapet models:

Wall.Mostly volatile - they need electricity to function.

The floor version is non-volatile.

Mounted

Are intended for heating of the room and heating of water. Technical features of dual-circuit models:

Steel heat exchanger. Thickness 3 mm.

Profile smoke tubes are used - heat transfer increases by 15%.

Silent burner (made in England).

Automatic block - Italian and German.

Compact size and quiet operation means no need for additional sound insulation. The manufacturer includes in the basic package - an expansion tank, a circulation pump, an automatic unit and a security system.

floor standing

The stationary Aton unit is designed for heating large areas. It can have a capacity of up to 1 MW - this is exactly the capacity of one of the latest modifications of the Aton trademark. Floor versions for ease of choice can be divided into three groups:

2 contour. Connected to heating and hot water supply. Water is heated in a copper plate radiator.

Single-circuit. For heating only. They can be equipped with a built-in boiler or connected to a storage tank. They need electricity.

Non-volatile. These water heating stations are distinguished by their constructive simplicity. They don't need electricity. They are connected to heating, in which the coolant circulates without compulsion. Chimney floor version. There is an atmospheric burner - air circulating in the room is consumed for operation.

The latest models have design adjustments - they do not need a pilot burner for combustion. This solution allows to reduce the consumption of natural gas by 10-15%.

All modifications meet safety requirements. The maximum allowable water vapor pressure is 0.07 MPa. The maximum liquid temperature is 115 degrees.

Cleaning the boiler from soot

Along with cleaning the chimney, the channels of the gas boiler itself are also cleaned. If the chimney becomes dirty and there are problems with draft, the equipment is automatically switched off. With the accumulation of soot inside the boiler, the shutdown does not occur, and the residents of the house can be poisoned by combustion products. In addition, contaminated equipment does not function properly, so it is recommended to perform the cleaning procedure annually, especially for boilers operating year-round.

Disassembly and removal of soot

To remove the parts of the boiler and clean them, you will need a simple set of tools:

- screwdriver;

- brushes (soft and metal);

- brush;

- open-end wrenches (No. 8-17);

- rag.

By following the steps described in sequence, you can completely clean the internal parts of the geyser and prevent an accident or smoke in the room.

Any tools with which you can remove limescale from a metal surface will come in handy, as well as wrenches

So, the first thing to do is turn off the gas. Then we remove the boiler door and disconnect the wire leading to the piezoelectric element. Then, one by one, unscrew the thermocouple, the ignition electrode and the pilot burner tube. It is better to mark the position of the nozzle in the burner so as not to disturb the setting. The gasket under the pilot burner must be replaced with a new one. We carefully take out the nozzle, the copper tube, and after it the burner, unscrewing the set of clamps.

To unscrew the fixing nut of the copper tube, a key No. 17 is suitable, to remove the ignition electrode - No. 10, to unscrew the pilot burner fastening screws - a flat screwdriver

Having taken out the thermometer sleeve, remove the boiler cover together with the insulating sheet. Then we take out the flue, having previously disconnected the terminals from the traction sensor. The swirlers removed from the heat exchanger are cleaned with a brush. In a similar way, we clean the base and the outer part of the heat exchanger. We blow out the internal channels with a vacuum cleaner.

To clean the burner, we use brushes and a brush. The flue must be wiped from all sides. Cleaning the nozzle requires special attention: it is enough to clean the outer surface with a brush, and for the hole you need a thin needle, the diameter of which is smaller than the diameter of the hole. If you accidentally increase the width of the hole, the combustion mode will be disturbed.

All elements of the heat exchanger, internal and external, must be cleaned with a hard metal brush. Settled dust and lime residue can be easily removed with a vacuum cleaner and a damp cloth.

The brush is ideal for cleaning plaque from internal surfaces of any shape - heat exchanger elements, copper tubes. The longer the handle. the easier it is to reach hard-to-reach places

Assembly in reverse order

We return the main burner, copper tube and nozzle to their place. Then we install a pilot burner on a new gasket, having previously cleaned it with a metal brush. When connecting the ignition electrode, it is better not to use a key, but to act manually so as not to damage the ceramic base. The rest of the details are also fixed in place. As a control check, we use soaping of the joints. The tightness of fixation of copper pipes and burners can only be checked during switching on.

When assembling a pilot burner, one rule to remember: the tip of the thermocouple must be opposite the place where the flame appears

Preventive and cleaning work is best done on the eve of the heating season.

In any case, the parts will be covered with soot, which accumulates over time, so the procedure for cleaning the elements of a gas boiler is very important - both for the efficient functioning of the boiler itself and for the safety of the inhabitants of the house. And once again we remind you that it is better to entrust any work with gas equipment to specialists!

Every owner of a house or cottage who uses a solid fuel boiler to heat his home wants the unit to serve successfully for many years. However, many users forget that the key to stable and uninterrupted operation of the boiler is the regular cleaning of its components from soot, tar and other deposits formed during operation.

Cleaning a solid fuel boiler is the key to its efficient operation

Causes of combustion products

A solid fuel boiler can operate on various types of fuel:,.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery across all territory of the Russian Federation and the CIS countries.

After the fuel burns out, various deposits usually settle on the walls of the combustion chamber, such as: ash, ash, soot, tar, tar. All these residues adversely affect the operation of the boiler.

The formation of soot is due to a number of reasons:

- First of all, the fact that too little oxygen enters the system.

- Another reason is the insufficiently high temperature that accompanies the combustion process.

The following factors can serve as the reason for the appearance of deposits in the form of resin on the walls:

- crude fuel is used;

- solid fuel boiler operates at low temperature;

- too much fuel is loaded into one tab.

Choose only high-quality fuel for a solid fuel boiler. Otherwise, your unit will often break down and its service life will be significantly reduced.

Tar occurs as a result of the following shortcomings:

- little air enters the combustion chamber;

- the design of the heater is incorrect;

- too low chimney height.

Cleaning methods

There are three ways to clean a solid fuel boiler from soot, tar and tar: mechanical, steam and chemical.

Each of the methods has its own distinctive features. Let's consider each of them.

Mechanical

The process of mechanical cleaning of the boiler is based on the removal of combustion products from the walls of the unit with special tools. For this, the following are used: a poker, scrapers of different sizes, shovels, metal brushes, ruffs.

Do not forget that it is necessary to start the process of cleaning the boiler from soot only after the device has completely cooled down.

It is important that in the process of cleaning the boiler from soot, the damper is not closed. Removal of resin and tar from the walls of the unit is carried out as follows:

Removal of resin and tar from the walls of the unit is carried out as follows:

- Initially, the heater must be warmed up. Resin and tar are quite hard, and when the boilers are heated, they soften and it becomes easier to get rid of them.

- Further, using shovels and scrapers, you need to get rid of these deposits.

- After the cleaning process is completed, it is necessary to increase the temperature regime of the boiler. This is done so that the remnants of tar and tar burn out.

Chemical

This method of cleaning a solid fuel boiler is very popular. It is based on the use of different chemical compositions.

To clean the unit with a chemical agent, you need to heat the reagent and use a special pump to fill the boiler system with it.

The most commonly used acids are: sulfamic, adipic, helium.

Adipic acid is diluted with water and carefully poured into the boiler with a pump. Once in the device, the mixture reacts with deposits, is converted into acidic salts and dissolves. The next step is to release the pressure and wait until the salts precipitate, and then wash them off with water.

Sulfamic acid is also diluted with water, only in a separate container. Then it must be pumped into a cooled boiler under pressure. Next, you need to wait a while for the acid to react with plaque and rinse the unit.

In order to clean the chimney from soot, rock salt is most often used. It is added to the furnace at the moment when the fuel burns. However, this method is used only for preventive purposes. It will not work to completely get rid of soot with its help.

More effective in the fight against soot are peeling potatoes. The method is as follows: while the fuel is burning, they must be poured into the combustion chamber. Along with the steam, starch will begin to stand out. It is due to him that soot will soften and will be removed from the chimney. After completing this procedure, the boiler must be thoroughly cleaned.

When cleaning a solid fuel boiler with chemicals, strictly observe safety measures.

Steam

This method involves processing the walls of a solid fuel boiler by means of a steam generator. So you will not only get rid of pollution, but also from fungus and mold in your heater.

Thus, it is possible to clean the boiler from tar, soot and tar using any of the proposed methods. Some will take longer and require a lot of effort from you. Others will allow you to quickly get rid of deposits, but will be more expensive. In any case, the choice of method is yours. The main thing is not to forget to regularly clean the solid fuel boiler, because the efficiency of its work will depend on this.

Cleaning the igniter, burners with nozzles

If the igniter

functions well and without failure, its flame resembles a cone with a blue tint. In the case when it is yellow, this indicates only one thing - the contamination of the burner.

In order to clean the igniter, you need to perform a series of sequential steps:

- it is necessary to shut off the gas supply to the boiler;

- unscrew the igniter;

- using a metal brush, you need to clean the device well;

- then you need to blow out the igniter and return it to its place.

Such a detail as a burner is a very important element of wall-mounted and floor-mounted gas boilers.

Set of brushes for cleaning the boiler

To clean the burner:

- close the valve

supply gas and remove the device; - Next, you need to carefully unscrew the nozzle

; - nozzle cleaning process

carried out with the help of a brush; - to clean the burner itself directly, you must use a brush, and its hole must be blown with a hand pump;

- then put the nozzle and burner back in place.

How to prevent wind blowing

When designing the location of the device, it is necessary to take into account such nuances as wind blowing - whether it happens from the side of the house of interest, and if so, how strong. The chimney diagram must be correct, if it does not correspond to the project, it is necessary to make changes to the device. The pipe that discharges gases should be insulated. It should rise half a meter above the roof ridge. The diameter is selected according to the power of the equipment. To avoid blowing, you need a lot of traction, for this:

- Clean the chimney from soot and soot.

- Increase the air flow to the maximum. The opening through which air enters should be located near the floor and as close as possible to the device.

How to clean the boiler with a chemical method

These methods are rarely combined. For the cleaning process to be successful, you will need:

- scrapers;

- brushes;

- scrapers

- screwdriver;

- fabric gloves;

- appropriate electrical appliances (swing-out and non-swing heads).

Before any kind of cleaning, the boiler must be turned off and the power supply must be disconnected. After that, you need to close the gas valve and heating shut-off valves, then wait for the boiler to cool completely

When choosing a tool, pay attention to the absence of sharp edges and ends that can damage the internal parts of the unit and subsequently provoke corrosion.

Chemical cleaning of boilers is very common precisely because of the ease of the process. To do this, the reagent is heated to the required temperature, then, using a special pump, it enters the boiler system and enters into a chemical reaction with deposits and scale.

Cleaning acids:

- adipic;

- sulfamic;

- gel.

Adipic acid is diluted with water and, using a pump, is very carefully poured into the cooled boiler. Carbon dioxide affects carbonates, which are converted to acid salts and subsequently dissolved.

After that, it is necessary to release the pressure and wait until the acid salts precipitate, which is easily washed off with ordinary water. Sulfamic acid must be diluted with water in a separate vessel, and then pumped under pressure into a cooled gas boiler. After some time, the boiler is washed with a large pressure of water and dried. The gel does not belong to acids, but it is able to dissolve any petroleum derivatives, as well as effectively separate scale from metal parts. The gel allows you to clean the gas boiler gently and carefully, without damaging its walls.

The disadvantage of chemical cleaning of the boiler can be considered the fact that the acid cannot be controlled. In the process of exposure, along with scale, acid reacts not only with deposits, but also with metal parts of the boiler that are not covered with dirt. This impact can be reduced by adding inhibitors to the cleaning composition.

Cleaning the gas boiler allows you to use it as efficiently as possible throughout the entire period of operation. The article describes step by step the cleaning process before the start of the heating season using the example of the Zhytomyr-3 floor-standing chimney boiler with Eurosit-630 automation.

Cleaning the domestic gas boiler before the start of the heating season must be carried out without fail. For boilers operating year-round, this procedure is carried out at least once a year. Gas combustion in equipment with partially clogged flue ducts occurs in the wrong mode, which only aggravates the situation, further clogging the boiler with soot. The result is carbon monoxide poisoning.By the way, automatic traction is able to work out only in case of clogging of the chimney, but not in case of clogging of the channels of the boiler itself. Therefore, you should not rely solely on automation and neglect cleaning.

It is important to know that gas hazardous work should be carried out exclusively by representatives of specialized organizations that have the appropriate permits. This work is provided for informational purposes only, however, it will allow the owner of the gas boiler to control the quality of the work performed by the gas service

What are the benefits

Advantages of Ukrainian ATON gas equipment:

- Only components of European manufacturers.

- Affordable price 8 000-25 0000 rubles. Even products from the low price segment meet European standards, are durable and reliable.

- High quality knots. Automation allows you to set the temperature of the coolant with high accuracy, adjust the flow of fuel. The heat exchanger is made of steel sheets - cut with a punching press, and then welded. Even at maximum heat, welds retain their integrity.

- Wide performance range - from 8 kW to 1 MW. You can choose an option for a room of any size.

- Simple operation. Most of the minor work the consumer can do on their own. The principle of operation and design are simple, so it is enough to check the operation of the equipment every six months - the fuel supply setting, etc.

- Safe. Thanks to the draft sensor, it is possible to prevent dangerous situations in which the exhausted gases are blown back into the furnace by the wind. When the pressure in the gas pipes drops, the system turns off automatically - there will be no gas leakage.

- Elegant design.

- Protective powder coating.

How to clean a gas boiler

In order to avoid overheating of equipment parts, breakdown and increase in fuel costs, periodic flushing and cleaning of the heat exchanger and other elements is required.

The heat exchanger can be cleaned in several ways:

- Manual cleaning, involving the removal of the coil, it can be carried out mechanically or you will have to flush the pipe with a special composition that dissolves salt;

- Cleaning with an acidic liquid using a booster;

- A variant of hydrodynamic flushing with the use of increased pressure is possible.

Manual cleaning is done with a stiff brush and a vacuum cleaner. For a double-circuit boiler, you should use an anti-salt liquid from limescale. First, the coil is removed, and after the procedure it returns to its place

Particular attention must be paid to checking the tightness

The hydrodynamic method allows you to effectively destroy plaque and deposits by increasing pressure and using abrasive substances pumped into the coil.