The design of the gas-generating boiler Popov

The design of the device is presented in the form of two chambers: lower (pyrolysis), upper (afterburning chamber for pyrolysis

gases).

The afterburner consists of two sections separated by a horizontal partition. The boiler is equipped with three regulators:

- Small pipes of oxidizers, which are located under the door. They are responsible for adjusting the power of the unit. This process is carried out by changing the supply of oxygen to the pyrolysis chamber.

- Upper : it is located on the upper nozzle of the heat generator

. The main function of the gate is that by changing the rate of removal of flue gases, it regulates the operation of the boiler. - The damper, which is located in the middle from the front of the unit, does not allow smoke to enter the room.

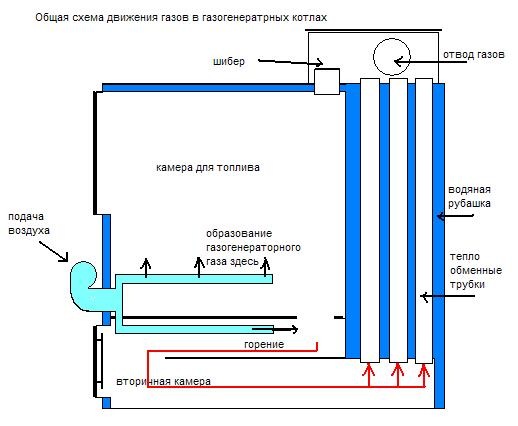

Above the combustion chamber there is a block into which secondary air enters, which is necessary for the afterburning of pyrolysis. The unit contains swirlers that evenly distribute warm air throughout the chamber.

The device of Popov's gas-generating boiler

When flue gases move towards the outlet, their heat exchange takes place.

with coolant

. Thanks to this process, the temperature of the combustion products is reduced to 140 °C.

In order to reduce the amount of heat loss, the design of the pyrolysis boiler has a water jacket

and external thermal insulation

layer.

As you know, for the operation of the boiler, the necessary draft is provided thanks to the chimney. Typically, the length of the pipe is from 7 m, while the length of the horizontal section should be no more than 1 m. The top should be 300 mm higher than the roof peak (or more). Thus, smoke will not enter the room. In order to have free access to the chimney for cleaning, a door is provided in the design.

If a water storage tank is connected to the system, then experts recommend installing.

Any type of solid fuel, including and, can be used as an energy carrier for a pyrolysis boiler. The main thing is that its humidity does not exceed 65%.

Popov's boiler is modern and productive equipment, on the basis of which you can build a complete air or water heating system. During the operation of the boiler, the loaded solid fuel undergoes a number of thermochemical processes, decomposing into solid and gaseous parts. Subsequently, the gases are also burned, which makes fuel consumption as efficient as possible.

Popov's boiler is perfect for heating rooms of various purposes and dimensions. Almost any solid fuel is suitable for the firebox. If necessary, such a boiler can even be used as a waste disposal unit. A lot of detailed diagrams and intelligible instructions are freely available, guided by which the heating unit in question can be assembled by hand.

The operation of the boiler in question is based on the principle of pyrolysis. In the furnace compartment of the unit, conditions for reduced air access are created. As a result, the fuel does not burn, but slowly smolders. In parallel with this, various gaseous combustible components with a very high calorific value are formed.

Loaded fuel decomposes at about 200-350 degrees. The resulting gases are directed to the afterburner compartment. There is already enough air in this chamber, which allows the gases to completely burn out and release a lot of heat. The resulting thermal energy is fed to the coolant.

The boiler room based on Popov's homemade boiler will not have to be equipped with smoke exhausters, because. The products of combustion will be sufficiently removed by means of a chimney.The equipment in question is equipped with a system of mechanical control of the coolant, which makes the unit independent of the power supply.

Popov's boiler is characterized by high accuracy - the temperature can be set with an accuracy of half a degree. It is enough to lay fuel 1-2 times a day. The specific frequency depends primarily on the size of the loading chamber.

The exhaust flue gases are free of tar and carbon, which makes it possible to assemble the chimney from pipes with smooth inner walls. Soot on them still will not accumulate. Design features allow you to clean the unit without any difficulty. If necessary, the chimney is disconnected from the main part of the system and all units are cleaned in a convenient way.

Popov's boiler can be cleaned of ash without even stopping its operation. At the same time, it is not necessary to remove all the ash. A layer of ash should remain near large pipes, having a thickness of the order of 1-5 cm. It will act as a catalyst for the thermochemical processes occurring in the boiler.

Boiler design features

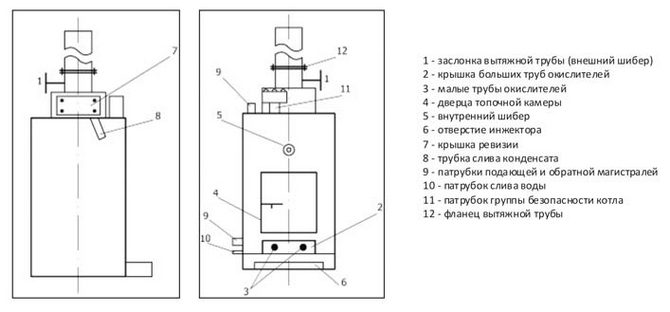

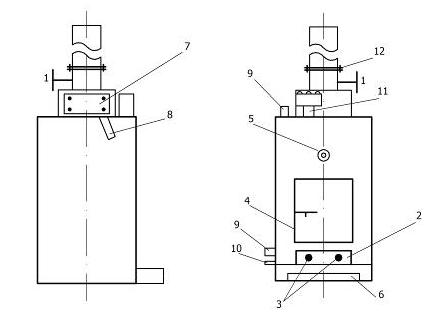

1 - exhaust pipe damper (external gate) 2 - cover of large oxidizer pipes 3 - small oxidizer pipes 4 - combustion chamber door 5 - internal gate 6 - injector hole 7 - revision cover 8 - condensate drain pipe 9 - supply and return pipes 10 - water drain pipe 11 - safety group pipe boiler12 - exhaust pipe flange

The unit itself is assembled from 2 main chambers. The pyrolysis process takes place in the lower chamber, and the resulting pyrolysis gases are burned in the compartment installed at the top. The upper section is additionally divided into 2 sections using a horizontal partition.

The boiler is equipped with regulators in the amount of three pieces, namely:

- small pipes. These elements are installed below the boiler door. These oxidizer pipes are needed to change the power of the heating unit by changing the volume of air supplied;

- top slider. This element is placed on the upper heat generating branch pipe. Allows you to adjust the main characteristics of the boiler by changing the speed of smoke removal;

- central slider. Mounted on the front of the unit. Thanks to this device, smoke will be prevented in the boiler room.

A block is installed above the fuel combustion compartment, through which secondary air enters the chamber, which is necessary for the afterburning of pyrolysis gases. The design of this unit includes swirlers, thanks to which the most uniform distribution of heated air throughout the chamber space is ensured.

The flue gases move towards the exit from the chamber. At this stage, there is a very intensive transfer of their heat in favor of the coolant used. As a result, the combustion products cool down to about 140 degrees.

Popov's boiler

The recommended length of the flue pipe of the Popov boiler is 700 cm. When using a shorter pipe, a deterioration in draft will be noted. Try to keep the length of the horizontal section of the chimney no more than 100 cm. The "street" part of the pipe must be insulated. At the bottom of the chimney, make a hole with a door. Through it, you can conveniently clean the structure as it becomes clogged.

If desired, a storage tank for water can be connected to the boiler. In this case, it is recommended to install a three-way valve. Thanks to him, the coolant will be able to pass in a smaller circle through the tank, due to which the water temperature at the return inlet to the unit will increase. This will help increase the life of the Popov boiler.

Modifications of boilers equipped with gas burners are available for sale, through which you can set up the operation of the unit using liquefied or main gas. However, it is better to refuse self-assembly of the gas modification of the boiler, because.This is a very responsible job that requires high qualifications. The slightest mistake can lead to life-threatening situations.

Popov oven principle of operation and clear advantages

An alternative to similar devices is Popov's solid fuel boiler, based on the use of the pyrolysis effect. What does this mean? The design of the combustion chamber of this device is made practically sealed, i.e., the access of oxygen to it is strictly limited. It is no secret to anyone that oxygen is necessary for a full-fledged combustion process, otherwise it simply will not occur.

Based on this factor, the minimum air intake into the combustion chamber is still provided. However, its amount is so negligible that full-fledged combustion does not occur. Instead, there is a procedure of slow smoldering of solid fuel. Heat transfer in this case has significantly lower rates than with full-fledged combustion of materials. But due to its design, this difference is almost imperceptible.

Popov's stove contains one secret embedded in its design. It consists in the re-combustion of exhaust gases. What does this mean? During the slow decay of wood, which is the main fuel element used in this stove, a significant amount of smoke is released, which contains some unused fuel. It is he who is redirected to the next compartment, where he is reused.

As a result of this process, it is partially burned and the heat transfer of the entire device is increased. Remains of double-processed fuel are discharged outside through the chimney. Ultimately, the Popov furnace gives excellent performance with a relatively small consumption of solid fuel. All these factors make it possible to single out and structure the advantages of this device over other similar devices. They look like this and in the best way characterize the qualities of this furnace:

The above qualities made the Popov furnace one of the most functional solid fuel devices that exist today. Its heat transfer characteristics and relatively low wood consumption allow us to speak about the optimal qualities of this device.

Service

Maintenance of the Popov boiler is not a complicated process. When it works on solid fuel material, a smoke exhauster and other devices are not required. The main thing is to build the right chimney.

The equipment does not need electrical power. The temperature is controlled mechanically, with great precision.

Fuel is added 1-2 times per 24 hours. Each subsequent filling of fuel maintains the set temperature stably. This is convenient for a large enterprise, where the stoker does not need to add raw materials every hour to maintain a stable temperature. There is no need to clean the ash every few days, the pipe does not clog and is not susceptible to thermal damage. To stop the operation of the boiler, sand in the box is not needed, sophisticated methods, but only a system for adjusting the device.

Heating with the Popov boiler is continuous, regardless of the size of the installation. And the use of pyrolysis heating units is close to comfortable central heating.

Humidity of solid material for heating should be no higher than 65%. This applies to any type: both coal fuel and peat. There are also devices with gas burners that operate on gas lines or on reduced gas (methane, propane). Heating is possible in rooms of 200-2000 cubic meters. m. The test was also carried out by units with a power of 500 kW. Their use, in the future, is also possible in an apartment building where there is no gas.

This type of heating is very economical, convenient and safe. There is no need for frequent maintenance of the device, cleaning, buying expensive raw materials in large quantities.You can heat a room not only with wood and coal, but also with paper, sticks, grassy waste, the main thing is fantasy. With a small family budget that a diesel appliance cannot afford, a gas, solid fuel pyrolysis boiler will perform all its intended functions no worse than its counterparts.

What could be better than what is made with your own hands? Any owner of a personal plot dreams of a multifunctional stove, but often the options on store shelves do not fit in terms of functionality or price category, so the only way out is to make a stove with your own hands. Popov's boiler is a modern heating unit, on the basis of which it is possible to make heating, conduct hot water, and dispose of waste. The principle of operation of the unit is quite simple, so it is easy to do it yourself.

The principle of operation, the nuances of setting

Unlike standard solid fuel models, you need to know how to heat Popov's boiler correctly. It is recommended to use bulk fuel - sawdust, wood shavings. Their mass creates the required pressure on the pyrolysis zone, the density does not allow the gas to rise up.

- Loading fuel, checking the tightness of the top cover.

- Ignition of logs, the lower damper is maximally open.

- After the flame is formed, air access to the fuel chamber is limited.

- During the combustion of pyrolysis gases, the temperature of the water in the heat exchanger is controlled.

At the first stage, it is important to ensure good traction. The top gate must be fully open.

After 20-30 minutes of operation, it can be partially closed. If combustion products enter the boiler room, the gate is opened again.

Design features, characteristics

The essence of pyrolysis is the decomposition of organic substances during smoldering, with minimal access to oxygen. As a result, volatile combustible gases with a high calorific value are formed - hydrogen, carbon monoxide, ethylene, methanol. They are also the main source of heat.

The basic design of the Popov boiler includes the following elements:

- Fuel chamber located at the front. Loading is carried out through the top hatch, ignition - through a small side door. It is possible to increase the volume of fuel by installing an additional unit.

- Burning chamber. It has an L-shape, the entrance to it is located under the fuel compartment, behind the grate. The main combustion area is at the rear of the structure.

- A damper that regulates the volume of air inflow. It is connected to a mechanical thermostat.

- Heat exchanger. It has a spiral shape, located at the back.

- Pipe for connecting the chimney.

Popov's boiler in the context is not difficult. Its design is similar to traditional "mine" models. Innovative solutions - the possibility of increasing the fuel chamber, a spiral heat exchanger. In some models, an indirect heating tank can be connected.

To control the combustion process, the following components are provided in the design:

- Pipes of oxidizers. Required to control the flow of air into the afterburner. Adjustment occurs by changing the position of the lower flap.

- Upper gate. Limits the removal of carbon monoxide gases through the chimney.

- Silencers. Designed for maintenance of equipment, prevent the ingress of combustion products into the room.

These are the main features that Popov's solid fuel boiler has. Additional information - the gas combustion zone is made of heat-resistant steel 10 mm thick. This affects the cost upwards, but significantly increases the energy resource of the equipment.

Do-it-yourself Popov boiler assembly manual

Pressed sawdust

Do-it-yourself boiler assembly is carried out in a few simple steps. However, first you need to thoroughly understand the operation of the equipment, then it will be much easier to assemble it.

Raw materials are put into the furnace in several layers, each of which is carefully compacted.The denser you compact the raw materials, the higher the efficiency of the unit will be. Even an ordinary stove will heat much more efficiently if it is loaded with carefully dried firewood, to say nothing of Popov's pyrolysis boiler.

The simplest version of such a boiler is in many ways similar to an ordinary potbelly stove. However, the home-made unit in question, unlike a potbelly stove, can work on one load of fuel for half a day, or even a whole day! The duration of operation depends on the volume of the loading chamber and the characteristics of the fuel used. If desired, such a boiler can be used not only for heating the house, but also for smoking various meat products.

Popov boiler assembly kit

- Fuel tank.

- Steel sheets. You will need sheets with a thickness of 2-3 mm and 4-5 mm.

- Apparatus for welding.

- Bulgarian.

- Rectangular pipes 6x4 cm.

- Round pipes with a diameter of 4 and 5 cm.

- cement mortar.

- Bricks.

First stage

Make 2 cylinders from sheet steel. One cylinder should have a slightly larger diameter than the other. You insert the smaller cylinder into the larger one, and attach the lid on top. It can also be made independently from sheet steel. Weld the bottom underneath. The lid and bottom should be twice as thick as the tank walls. Cylinders are welded from steel 2-3 mm thick, and for the manufacture of the cover and bottom, use 4-5 mm steel.

Second phase

Prepare pipes. Products should be of such a size that they can be normally inserted into each other - this will make it easier for you to assemble Popov's boiler. Rectangular pipes are installed vertically, round pipes are welded to the boiler horizontally.

In total, two pipes will be connected to the boiler. Through one, heated water will be discharged, through the second, cold liquid will be supplied. To install pipes, first prepare holes with a diameter of 0.5 cm in the walls of the boiler.

Fourth stage

Check the boiler body for leaks

It is important that the installation does not let smoke and water through. The check is extremely simple - just pour water into the pipes and monitor the state of the system

If leaks are found, seal the holes by welding.

Fifth stage

Install the assembled structure in the frame. The frame is laid out of brick. For masonry, use cement mortar. If possible, this frame is recommended to be done in advance, but this is not critical.

Loading fuel into the Popov boiler

Thus, there is nothing complicated in self-assembly of Popov's boiler. Perform the tasks described in sequence, and you will have at your disposal an efficient, productive, reliable and cost-effective heating unit that is in no way inferior to expensive factory-made analogues.

Successful work!