Underfloor heating and linoleum search for the optimal design

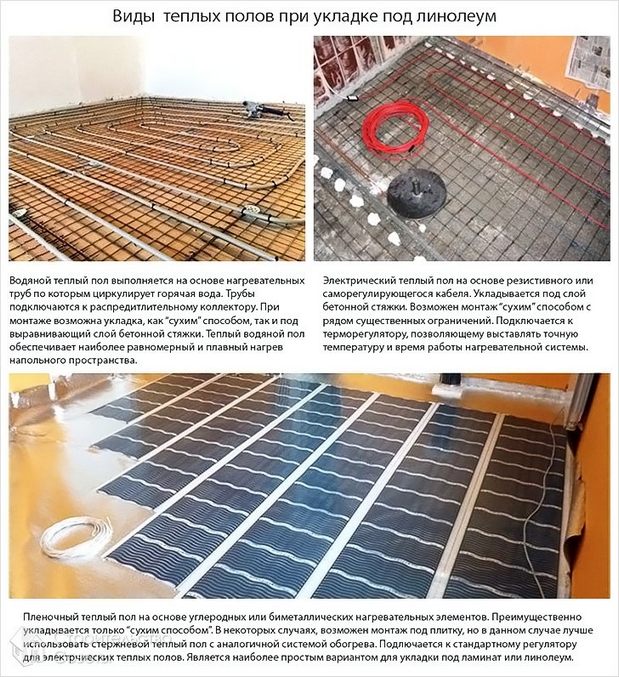

A typical underfloor heating draws energy either from the distribution of the main heating system or from the household electrical network. That is, in apartments or houses, you can equip only two options for underfloor heating: water or electric.

Linoleum on the floor

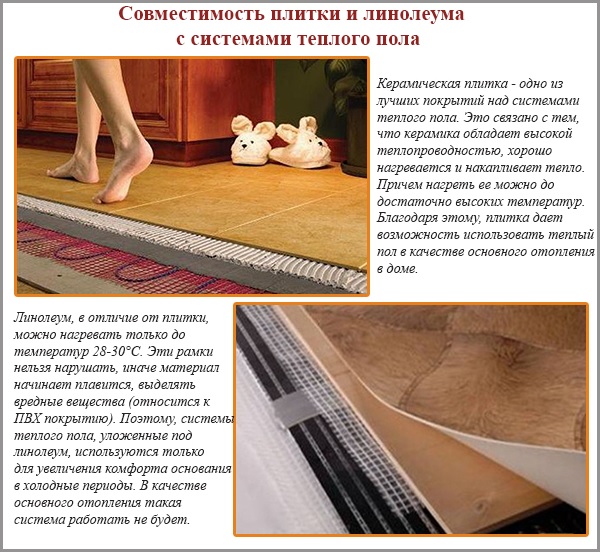

But the possible installation of a warm floor under the linoleum suggests that this giant "radiator" will only warm up to 27 degrees Celsius. Since it is at this border that the installation of the upper bar for the operating temperature of linoleum. And if the floor warms up above the indicated mark, then in addition to sensations that are controversial from the point of view of comfort, the user will also receive a dose of obviously harmful volatile components accumulated in this finishing material during the manufacturing process.

In addition, "overheated" linoleum will dry out very quickly and lose its elasticity and strength. As a result, a coating designed for years or even decades of operation will lose its “presentation” in a matter of months.

Therefore, the installation of a warm floor under linoleum has virtually no restrictions on the type of construction: after all, this type of coating is not afraid of either moisture or electricity (linoleum is a good dielectric with high hydrophobicity). However, both electric and water floors cannot be “warmed up” to 27 degrees Celsius. And the recommended upper temperature limit, in this case, is at around 24-26 ° C.

And if a water or electric heating system "warm floor" can fit into this range, then it can already be considered ideal. And further in the text, we will consider both options for the construction of "warm floors": both electric and water.

Important features of the thermal regime

In principle, in order to choose linoleum for underfloor heating, you do not need to have special knowledge and understand the properties of the material. The coating manufacturers themselves will indicate to you whether their products can be used for the underfloor heating system or not. How? Through marking.

The permissible heating temperature is also indicated next to the marking - it must be observed. For marmoleum, the limiting temperature is about 27°C; above this limit, its surface begins to soften, melt, and tear. Vinyl linoleum can be heated up to 29-30°C, after which it can swell, deform or lose color. Also, phenols and all sorts of unpleasant gases will almost certainly be asked to exit. To maintain the required temperature of the warm floor, you will definitely have to purchase a high-quality thermostat. which will automatically maintain the specified mode.

Linoleum marking allowing the use of coating for underfloor heating systems

Underfloor heating tips

A few tips from experts will help extend the life of linoleum, laid on the floor with a heating system.

When choosing the type of underfloor heating, a financial issue can be a decisive factor. The water floor, although considered the most suitable for linoleum, requires serious installation costs and a high professional level of laying specialists. An electric floor is easier to install, but the power calculation confirms that it is quite energy-intensive to operate.

Infrared does not require a mandatory screed, but it may not withstand pressure from the outside due to its thin design. During its installation, it will be necessary to lay a solid layer between the coating and the heating films. For him, you will have to buy a more expensive commercial or semi-commercial version or marmoleum.

For all types of underfloor heating, the quality of the electric thermostat is relevant.Overheating the coating will cause blistering and cracking. Installation of a warm floor is a complicated procedure, if there is no experience in such work, it is better to contact specialists.

Related video: Installation of Caleo underfloor heating under laminate and linoleum

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Warm electric floor

Electric underfloor heating linoleum on wood the floor is considered the most optimal solution of all existing. In order to install a warm infrared floor, it is also necessary to manufacture the base, as described in detail above.

After preparing the base, it is necessary to prepare the tool and purchase the necessary consumables, namely:

- Knife and scissors;

- Utiki for crimping contacts;

- Screwdriver Set;

- Marker, ruler and multimert;

- Insulation with foil coating;

- Thermal insulation tape;

- Polyethylene film;

- Infrared film;

Initially, we make a choice of the place of installation of the temperature controller and thermostat.

Further, a separate supply line is laid to the selected installation sites.

The thermal sensor is mounted directly under the film at a distance of at least half a meter from the wall, and the regulator is installed on the wall in a place convenient for you.

Then the infrared film is laid and connected to the mains. Having completed the installation, it is necessary to check the resistance of the network using a multimeter. After measuring and making sure that the received system is in full working order, you can carry out a test run. After a successful launch and verification of the system's performance, it is permissible to start laying the finish coating.

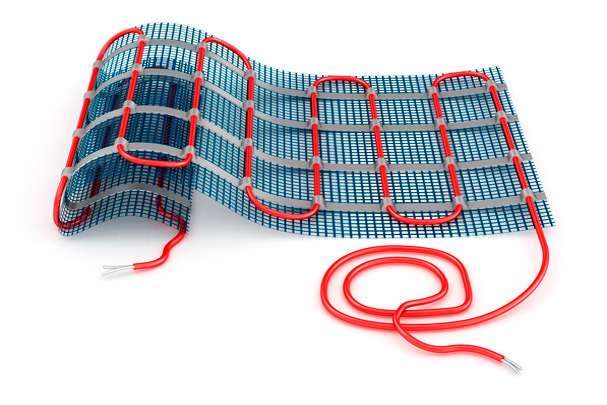

Electric heating film

Electric heating film

Is it possible to lay a film floor under linoleum

Laying an infrared film underfloor heating under linoleum is at least economically justified. Considering that the laying of mats can be done independently, and the cost of even a high-quality linoleum coating is lower than that of ceramic tiles, the savings when choosing this finishing material become obvious.

The only thing to consider if a decision is made to put an infrared warm floor under the linoleum is the safety of the coating itself. Therefore, when choosing a material for finishing, it is worth learning about its composition and safety class.

Usually, manufacturers themselves warn about the composition and the harmful substances included in it, making appropriate notes in the safety instructions. It is possible to lay an IR warm floor under linoleum, also for the reason that the heating system is intended, including for this type of coating, which is directly stated in the instruction manual.

Infrared floor under linoleum

This system is a flexible thin film that forms the basis of the heating system. This is a cutting-edge achievement in the field of electric heating systems. The work of the warm floor is based on the action of infrared rays.

Thermal film is characterized by a small thickness, but at the same time it provides good heating of the room. The infrared underfloor heating system is characterized by increased efficiency, as well as less energy consumptioncompared to traditional systems. The connection to the electrical network is carried out using a thermostat, which allows you to create maximum comfort for all family members.

Is it possible to lay linoleum on a warm floor a few simple tips for laying

From the Author: Hello, dear reader. Decided to insulate the floor? The right decision! The main heat loss occurs precisely on the floor surface, so if it is constantly cold, then the room will be cold all the time. But today we will not talk about the insulation of the floor itself, but about whether it is possible to lay linoleum on a warm floor. We know that linoleum is a versatile and practical floor covering, but we also know that under strong heating the material can soften, deform and become unusable ahead of time.

This can happen both with expensive coverage and with a more budget option. Now we will answer a common question, is it possible to make a warm floor under a coating such as linoleum.

Linoleum fits well only on a flat and rigid base. If the differences do not exceed 2 mm per 2 m², then you can safely start laying. If not, then the floor will have to be leveled. For more information on how to carry out repair work to eliminate floor defects, read the article " Do-it-yourself floor repair in an apartment".

There is an opinion that linoleum cannot be laid on a warm floor. But this statement applies only to material whose quality is below average. High-quality coating is quite suitable for underfloor heating. Now we will look at the types of linoleum and find out which linoleum is better to lay under a warm floor.

Types of linoleum for underfloor heating

There is an opinion among consumers that this coating is harmful, since it can release vinyl chloride, phenol and other hazardous substances when heated. However, this is only possible if the material is used incorrectly, or if the coating is chosen incorrectly. If you approach the choice of coverage wisely, you can find modern options that will be safe and last a long time.

What is linoleum and which is better to lay in the house?

Rubber (relin). Two-layer coating, which includes rubber, synthetic rubber, bitumen. Not suitable for residential use as it does not tolerate heat well.

Vinyl (PVC). The cheapest and therefore the most popular type of linoleum. PVC coating comes in several types. If you plan to lay linoleum on a warm floor, then it is better to use semi-commercial or commercial material, since they are more durable and easy to use than household ones. Professionals do not advise using a coating with a heat-insulating base, because it will become an obstacle to the passage of heat from the heating elements into the room. Accordingly, the efficiency of the "warm floor" system will be greatly reduced. It is better to opt for a cover that has a thin base of fabric or no fabric at all. Do not forget that the vinyl material is of synthetic origin, so when it is heated, an unpleasant odor may appear, but then it will disappear.

Colloxiline (nitrocellulose). Thin, single-layer coating, characterized by high moisture resistance. But at the same time it has a significant minus - it ignites easily. Rubber (relin) linoleum, PVC coatings and glyptal linoleum in the lower right corner

Rubber (relin) linoleum, PVC coatings and glyptal linoleum in the lower right corner

Glyphthalic (alkyd). Linoleum, which has a fabric base and has very good thermal insulation properties. But also, like relin, it does not tolerate heat and can lose its original shape over time.

Natural (marmoleum). The coating is completely safe and natural. It contains only natural ingredients: pine resin, lime powder, crushed cork, linseed oil, natural dyes. That is why when it is heated, unpleasant odors are not felt and harmful compounds are not released. Among its advantages are fire resistance, durability, antistatic, high resistance to deformation. In addition, it does not fade when exposed to ultraviolet rays and does not lose color over time. This material is more expensive than other types of linoleum.

As can be seen from the technical characteristics of the types of linoleum flooring, not everything can be laid over heated floors. It is best to use marmoleum or in a pinch the vinyl type. Experts do not recommend using glyphthalic, colloxylin or rubber material in tandem with underfloor heating.

Types of underfloor heating under linoleum

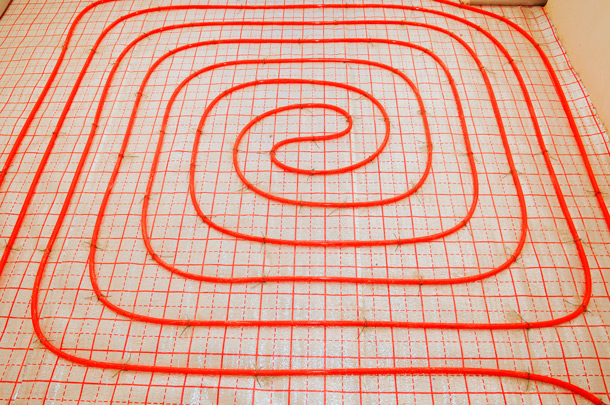

If you plan to lay linoleum, you need to responsibly think over the underfloor heating system. What kind of underfloor heating is better suited for linoleum finishing? In private homes, water floors are the most preferred option. Such a system has a high rate of inertia. The pipes heat up for a long time, but they also do not cool immediately. Since there are no sharp temperature drops, the material is not stressed. Therefore, the combination of water floors and linoleum coating can be called optimal.

The floor electrical system is essentially a large area electrical appliance that generates a magnetic field. How it affects the human body and animals, whether it is harmful, is still not known exactly. In addition, the magnetic field attracts all kinds of particles, as a result, dust will always collect on the floor covered with linoleum. In addition, electric floors quickly heat up and cool down, which can lead to deformation of the coating.

As for laying infrared floors under linoleum. then this is a good option. Graphite strips act as a heater here. When the system is connected to the mains, a gradual, uniform heating occurs, which prevents the deformation of the linoleum. For the proper operation of linoleum, a canvas with a power of 60-150 W / m2 will be enough.

And, of course, when choosing underfloor heating, you should not forget about the financial side of the issue. Installation of water floors will require significant costs, but operation is very economical. Installing electric floors will cost less, but energy bills can go up. Leave your comments on the article in the form below!

Related Materials:

What are the sizes of linoleum and how to choose the right width

It needs to be known

There are several useful things to consider before choosing linoleum for a room with underfloor heating:

- one type of linoleum is called marmoleum. It is a natural material that does not contain toxic and synthetic impurities. If it has a base, then it is also a natural material, such as jute fabric. It consists mainly of wood flour, resin, linseed oil and limestone. Even the dyes for it are made from natural materials. It is not only ideal for use due to its naturalness, but also prevents the spread of fire (if one occurs) and is easy to clean in any convenient way, even without the use of detergents.

- do not forget about elementary safety rules when starting laying a warm floor and checking it in action. First of all, before installing it and connecting it to the network, be sure to turn off the power in the house! Even if you are a professional electrician, this will not save you from accidental electric shock if the rules are not followed, especially since you have to work with non-insulated material. Never turn on the underfloor heating system without carefully checking its insulation. Do not try to turn on the thermostat at a temperature exceeding 30 degrees - this is fraught not only with system failure, but also with a fire in your house. In no case do not lay the thermal film in more than one layer, even if you think that in this way you will achieve a greater effect and heating - in fact, a short circuit will simply happen in the network.

- if you have the opportunity or you are not confident in your abilities, use the services of an experienced electrician to install the system. You will not spend so much money, but you will be sure of the quality of the heating, the reliability of the insulation installation and the safety of use.

What types of linoleum can be used

We used to think that linoleum is a thin vinyl coating, which is dominated by chemical components. But it is not so. There are 5 groups of this material on the modern market:

natural (marmoleum) - a completely safe, natural material that is durable, fireproof, antistatic;

PVC (vinyl) linoleum - the most popular and inexpensive, when heated, it can exude an unpleasant odor;

alkyd (glyphthalic) - produced on a fabric basis, has high thermal insulation properties. Over time (especially when heated), it can noticeably deform;

nitrocellulose (colloxylin) - a thin single-layer material with good moisture resistance, but a significant drawback - rapid flammability;

rubber (relin) - two-layer linoleum, which contains rubber particles, bitumen, synthetic rubber. It does not tolerate heat well and is rarely used in residential areas.

Judging by these characteristics, not all types of linoleums are suitable for laying on a warm base. The most optimal choice is natural linoleum, slightly worse - PVC linoleum. Alkyd, nitrocellulose and rubber coatings on heated substrates are rarely used.

Option # 1 - natural "marmoleum"

If your budget allows, give preference to natural linoleum. It is made from natural ingredients: linseed oil, pine resin, crushed cork, lime powder, natural dyes. Accordingly, when heated, this type of linoleum is not able to release harmful substances into the air. And this is the most important argument in favor of marmoleum as a coating for underfloor heating. In addition to absolute safety, natural linoleum completely retains its dimensions when heated and does not deform. It is fire resistant and does not contribute to the spread of fire in the event of a fire. Marmoleum does not change its color over time and does not fade in the sun.

Marmoleum begins to soften already at 27°C, so the power of the warm floor under it should not exceed 60W/m2

Option #2 - Vinyl Linoleum (PVC)

Marmoleum, although good, is not yet very common on our shelves. Therefore, if you could not find it, you can get by with “little blood” - purchase PVC linoleum for a warm floor. It is best to use for these purposes not household, but commercial or semi-commercial types, which are distinguished by higher strength and better performance properties. Immediately discard the material on a heat-insulating basis. It will prevent the passage of heat from the heating elements into the room, which will significantly reduce the efficiency of the underfloor heating system. Choose linoleum on a thin fabric basis or without it at all. When using vinyl linoleum, remember its synthetic origin. At first, when heated, even high-quality vinyl emits an unpleasant odor, which disappears after a few weeks.

Between thin vinyl linoleum and infrared heating mats, plywood or fiberboard is usually laid - to level the surface and prevent deformation of the coating

Installation of underfloor heating under linoleum

First of all, it is necessary to eliminate all slopes and irregularities, after which a leveling screed is made. Next, a hard coating is placed on the floor - plywood, chipboard, GVL, etc.

Heat-reflecting material should be laid over the entire floor area - surface down. Then it is carefully fastened with masking tape.Do not forget that the material must lie flat on the floor, and for this it can be fastened with anchors or self-tapping screws.

Video editing

Warm floors in your house will definitely give you a feeling of comfort at any time of the year. Of course, the use of this heating technology for linoleum will require certain knowledge, skills, financial costs and time from you, but the result, believe me, will definitely please you!