Dimensions

Which pipe to choose for water supply - by this point the reader can already decide. Well, what about her size?

In order to determine the required pipe diameter, there are special hydrodynamic tables.

They start from the required water consumption in liters and take into account a number of factors:

- Pipe material and the associated roughness of the inner walls;

- The length of the water supply (the longer it is, the more resistance the water experiences when moving through the pipe;

- Number of pipe turns;

- Inevitable overgrowth of the steel pipe.

However, all these calculations are needed for the most part by engineers when developing a building design: there, simply reducing the diameter of the pipe to the minimum required will bring big savings.

Since the steel pipe for water supply is scorned by us, the problem of overgrowth can also be forgotten.

And if so, the rules are simple:

- To enter water into a private house, a galvanized pipe with a diameter of 3/4 inches, a polyethylene or polypropylene pipe with a diameter of 26 millimeters can be used. Polyethylene, as we remember, is used only for cold water;

- Wiring around the house or apartment is galvanized or copper with a diameter of 1/2 inch; metal-plastic with a diameter of 16 mm, polypropylene or polyethylene with an outer diameter of 20 mm.

These dimensions are sufficient for any reasonable number of plumbing fixtures in the home.

Preparatory work

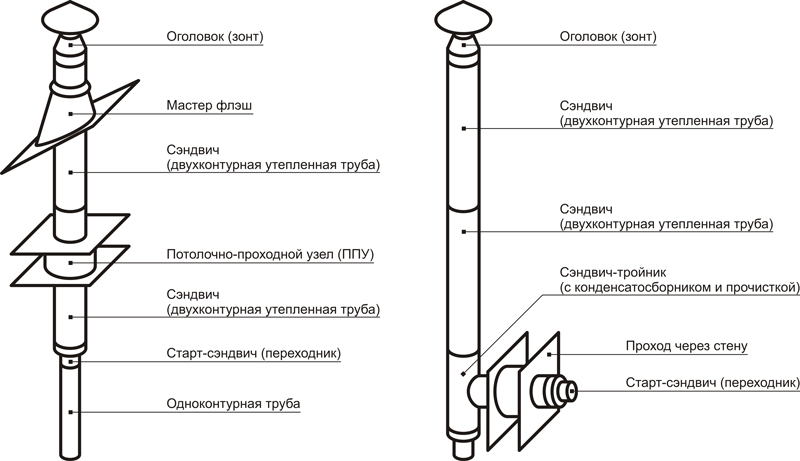

Scheme of the internal and external chimney from a steel pipe

Preparatory work before installing a chimney from a metal or sandwich pipe includes: drawing up a diagram of the outlet structure, calculating the number of elements to be connected, calculating connection nodes and mates with ceilings. After these conditions are met, you can proceed to the purchase of material and installation of the structure.

In the preparation process, the following conditions should be considered:

- The prefabricated chimney inside the room must run vertically upwards. An angle of no more than 45º is allowed. When branching horizontally, the maximum length of the pipe is not more than one meter.

- The length of the element coming from the outlet pipe of the furnace or boiler must be no more than one meter. For brick ovens, a single-walled metal pipe with a water tank is used as a connecting element.

- Docking of individual parts of the sandwich chimney is not allowed in the place of the interfloor and attic floors, as well as in the roof structure.

- The places where the pipe passes through the interfloor and attic floors are additionally protected by a metal box or a special sandwich ring. The distance from the outer surface of the pipe to the walls of the box is at least 15–17 cm. In the absence of cutting, the distance is increased to 50 cm.

- Cleaning and ventilation holes should be located in the lower part of the chimney (from the stove pipe to the ceiling of the steam room). When leaving the interfloor ceiling, the chimney is directed vertically upwards. It is allowed to install a branch when the pipe hits a load-bearing beam or other roof element.

- For roofing made of combustible materials (roofing material, isospan, glass isol), a deflector with a fine-mesh spark arrestor is installed at the end of the smoke channel.

For preventive purposes, the chimney should be inspected once every six months. With frequent use of heating equipment, the chimney is cleaned at least once a quarter.

Nuances

Finally, a few general tips related to the selection and installation of pipes:

-

If you prefer metal-plastic pipes, opt for compression fittings

, without thread and union nut. They do not understand, but they flow much less often; -

Long sections of unreinforced polypropylene on hot water must include expansion joints

- U-shaped bends or loops; -

Only pipes with a low coefficient of thermal expansion are laid in the screed or plaster

- galvanized, copper, metal-plastic or reinforced polypropylene. Of course, we are still talking about hot water; - All connections, except for welded on polypropylene and soldered on copper, must be available after the repair is completed.

. First of all, this concerns metal-plastic; - The use of filters at the entrance to the apartment is mandatory. They will extend the life of both faucets and household appliances.

Installation of steel heating pipelines

The process of installing heating pipes from steel pipes can be carried out in two ways: threaded and welding. Both methods are quite reliable, but rather complicated from a technological point of view, and therefore, their implementation requires the involvement of professionals.

When connecting steel pipes by means of threaded twisting, first, threads must be cut on the ends of the joined products, after which they are interconnected by means of couplings, fittings, spurs and other intermediate products, the quality of which should be given special attention

Flax is not recommended as a winding for ordinary steel pipes, since constant moisture at the threaded joint can lead to corrosion.

The method of connection by welding is even more reliable, however, unlike a threaded joint, it is one-piece, that is, disassembling the connection, if necessary, becomes impossible.

The process of welding steel pipes can only be carried out by qualified specialists. This work requires the availability of special welding equipment, the work with which presents significant difficulties and is inaccessible to those who do not have professional skills.

In general, when carrying out welding work, it is necessary to adhere to the following important rules:

Installation of heating through steel pipes should begin with the installation of a riser; and then it is from the side of the riser that the pipeline should be laid. However, in most cases, work in residential facilities is not carried out from scratch, but comes down to replacing obsolete heating communications.

Therefore, depending on the situation, the welding process may have certain features. Galvanized steel pipes are welded using self-shielded wire with a diameter of about 1 millimeter. In some cases, it is possible to use electrodes with a diameter of up to 3 millimeters, having a rutile or calcium fluoride coating. The connection of non-galvanized steel pipes for heating, which at home usually have a diameter of no more than 25 millimeters, is most often overlapped. The assembly of such pipelines by the butt welding method is carried out only at enterprises. The weld seam when connecting steel pipes should be even with respect to the surface of the products being joined, and not have sags, cracks or other defects and flaws (read: “Options for welding galvanized pipes - advantages and disadvantages ways").

The main stages of installation

Installation of a heating system from steel pipes does not require special skills. Depending on the material from which the parts are made, you need to prepare a welding machine or a gas burner. The main stages of installing pipes of the heating system:

- Draw a drawing of the location of the heating system according to the building project. The figure shows the dimensions, key components, wiring, radiators, control panel, water drain valves.

- Clear the room of unnecessary items, pierce the walls, make holes for pipes.

- Assemble the system from individual parts, make exits to the radiators. The docking points are welded with an electric arc or gas from the nozzle of the apparatus. The seams are cleaned, treated with anti-corrosion compounds.

Before installing heating pipes, you need to think over the wiring nodes, the control system, and shutting off the pipeline.In addition to this, it is necessary to make a separate tap outside the house through which water can be poured from the system. The radiators must be equipped with temperature regulators, fluid supply. The first run should be a trial run to check the integrity of the overall design.

Installation of heating in a private house. Part 2. We work with metal pipes.

Watch this video on YouTube

Design and features

Elements of a modular chimney made of sandwich pipes

The steel chimney from a sandwich pipe is divided into two types according to the output method: external and internal. The external chimney is brought out through the load-bearing wall and fixed on the plane with the help of special brackets.

To assemble the chimney, the following elements are used:

- connector/adapter for branch pipe;

- sandwich pipe 50–100 cm long;

- pipe with inspection door;

- bend/elbow with 30–45º rotation angle;

- clamping / crimping collar;

- interfloor fastening;

- metal box for interfloor exit;

- metal plate for floor protection;

- apron and protective cone;

- conical end/deflector.

The design of some modular sandwich chimneys includes a condensate collector, a silencer, various tees and plugs. Depending on the manufacturer and completeness, the names of the elements may vary.

The general principle of operation of a chimney with a cylindrical section of the smoke channel is the same. Due to the difference in air temperatures inside and outside the pipe, a ventilation effect is created, called draft. The density of hot air is several times less than that of cold air. This causes a pressure difference at the base of the pipe (nozzle) and outside the room. Due to this, the gas and combustion products quickly rise through the smoke channel, twisting in a spiral, and are ejected through the end of the pipe.

The draft effect directly depends on the cross section of the smoke channel, the number of its bends and height. To calculate these parameters, you should use a special table, which is based on the size of the furnace and the section of the pipe.

Installation work

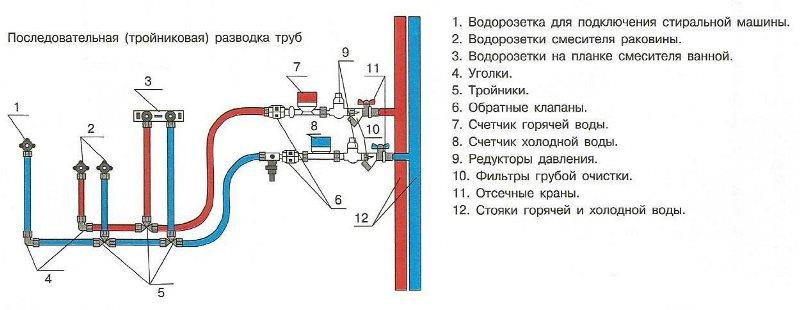

The principle of the tee wiring is as simple as possible and the installation of the system also does not cause problems, including for a novice plumber. The work is done in the following order:

- pipes and additional equipment are purchased according to a previously developed wiring diagram. The standard network includes devices such as water outlets, taps, coarse filters, meters, tees and elbows;

Standard tee wiring diagram

- the central riser is connected to the supply pipe. A tap is mounted at the junction, which allows shutting off the water supply of the system;

- pipes are gradually brought to all sources of consumption available in the apartment / country house;

Wiring for connecting a bathtub and a washbasin

- plumbing equipment is connected to the pipes.

In order to achieve an aesthetic appearance, the pipes can be closed with special boxes or "hidden" in the wall.

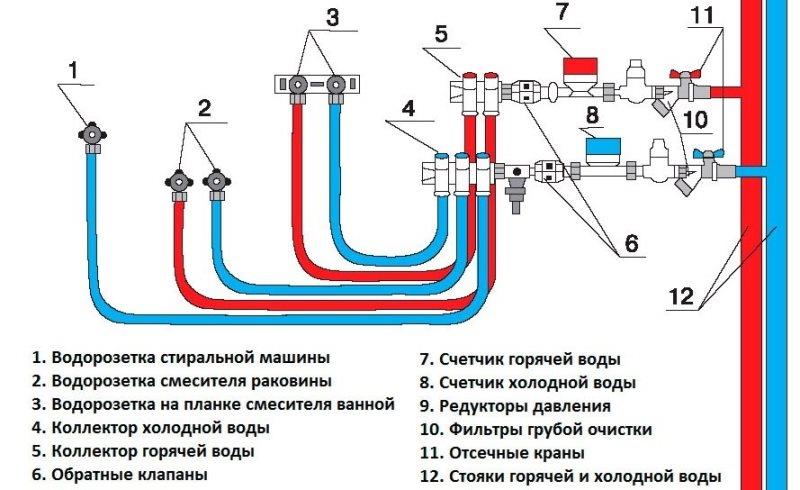

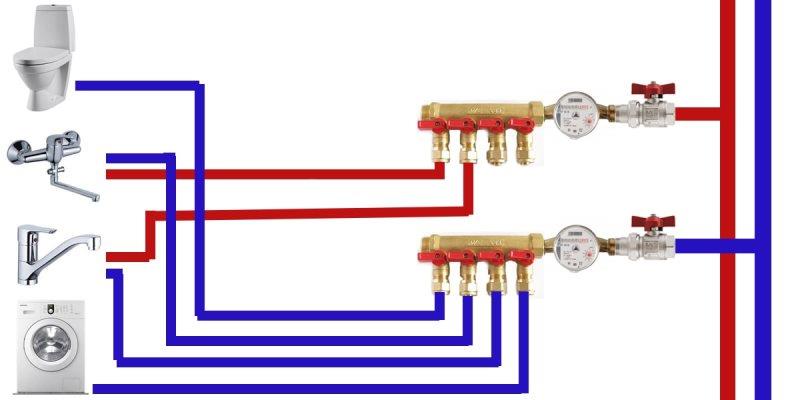

Installation of collector wiring is carried out according to the following scheme:

- a wiring diagram is being developed, the necessary materials are being purchased;

Collector Wiring Diagram

- collectors are connected to the central drain. Before each device, it is recommended to additionally install a tap to completely shut off the system, a coarse filter, a water meter and a check valve, which will extend the life of the system and its individual elements;

Sequence of arrangement of equipment before mounting the collector

- connection and piping to each plumbing fixture.

An overview of the collector wiring and the sequence of equipment installation are presented in the video.

All joints of pipes, fittings and equipment connections must be sealed. Before putting the system into operation, it is recommended to check the tightness and strength of the connections by applying the maximum pressure.

Connection methods

- Application of an oxy-fuel welding method connecting pipes with smooth ends.

- The use of connecting screwing, sealed with a special gasket, which ensures the tightness of the connection.

- Flange fasteners, in which the connection is bolted to the ends of the pipe.

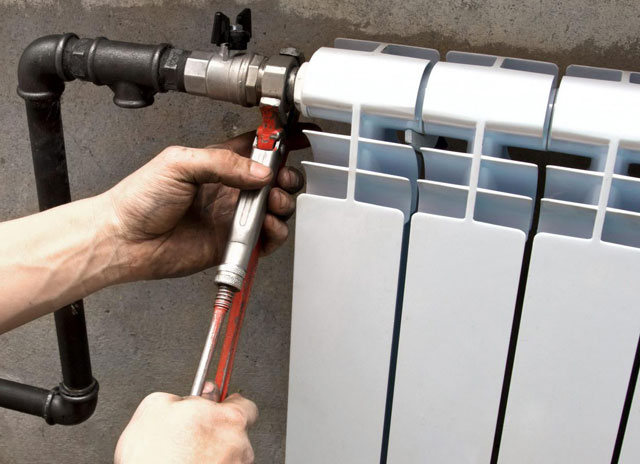

It is recommended to use a gas generator to connect pipes to radiators. Preference should be given to seamless pipes, high-quality spurs and radiators. The connection scheme consists of the following steps:

- Cutting old pipes, knocking them out of ceiling joints, followed by drawing new steel pipes for heating;

- Warming up the pipe, bending it and welding-free connection to the radiator;

- Installation of a drive with a suitable thread, followed by screwing the radiator;

- Application of silicone sealant or linen fibers to the threads to prevent water leakage.

Before installation, it is necessary to check the integrity of all elements, because correct and high-quality installation is the key to the long-term functioning of the heating system.

How and what to insulate

Non-combustible heat-insulating material in cylinders for chimney insulation

Chimney insulation is carried out both at the stage of its installation, if a single-walled steel pipe was chosen as the material, and after the construction of the structure. For insulation of steel chimneys, non-combustible types of insulation are used: expanded clay, mineral and basalt wool.

The thickness of the insulation depends on the air temperature in winter and is selected individually for a specific type of chimney. For example, a heat-insulating cylinder from Rockwool with a thickness of 300 mm and a cross section of 133 mm will cost 275 rubles per linear meter.

An alternative to cylinders are stitched mats - this is a heater of the same composition in a roll, which during installation will have to be adjusted to the outer diameter of the chimney. Mats vary in size depending on the manufacturer. For example, a stitching mat from TechnoNIKOL with dimensions of 2400x1200x40 will cost 970–1000 rubles per pack.

Connection of metal heating pipes without welding

The fastest way to connect without the use of welding is a compression fitting. Nevertheless, we will consider other methods: threaded connection and installation of a repair and installation clip. The latter is used both for docking and for eliminating leaks resulting from metal cracking.

Thread

It will be possible to create a threaded connection only if there is free access to the pipe, i.e. at the initial installation stage. In other cases, threading will be quite problematic or impossible. The procedure itself is carried out according to the following scheme:

Criterias of choice

Before you make a heating system from metal pipes, you need to buy consumables

When choosing, you need to pay attention to such factors:

- gravity or forced system;

- the material from which the parts are made;

- shape, dimensions;

- installation methods;

- the maximum load that the parts, connections can withstand;

- admissible indicators of pressure, temperature.

Heating installations made of different materials have certain characteristics that affect the performance of the pipeline.

The choice of pipes for heating

Prices

The price of parts for creating a heating system is affected by the diameter, the material used, the manufacturer. If we talk about products made of non-ferrous metals, the price for them is set depending on the footage. For example, 1 meter of copper pipe costs about 250 rubles. For ferrous metals, the price is set depending on the mass. One ton of cast iron products costs from 5 thousand rubles.

Pros and cons

Before buying parts, you need to know their strengths and weaknesses. Advantages:

- high thermal conductivity;

- maximum level of tightness;

- strength, wear resistance, durability;

- low price.

Disadvantages of metal pipes for heating:

- The metal is prone to rust. Requires protective coating.

- It has a large mass, which complicates installation.

- Increased hardness does not allow bending parts.

- For installation, you need to prepare a welding machine or a gas burner.

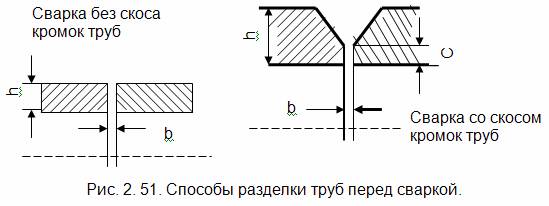

Weld quality according to GOST

When connecting pipes by welding of any type, it is worth monitoring the quality of the seam

When connecting pipes by welding of any type, it is worth monitoring the quality of the seam. This process allows timely detection of defects in welded joints and prevention of pipeline depressurization. Control, according to GOST, is carried out in several ways:

- Visual inspection of the weld at all stages of its formation. So, during a visual inspection, the presence of fistulas, cracks and burns in the metal should be detected. If such defects are found, the pipeline is re-digested, after cutting off the substandard section.

Mechanical tests of pipe welding over the formed seam and pipe joint.

In this case, the weld is checked for tension, bending, impact strength or tension, depending on the purpose of the line. In order to carry out mechanical tests of the obtained seam, the operator must simultaneously perform welding of test joints during welding. They then serve as samples for mechanical control.

A physical method for controlling pipe welding, which involves the use of x-rays, gamma rays, ultrasonic waves, etc. Such test methods are also performed only on special-purpose pipelines. In this case, the resulting seams are subjected to X-ray transillumination in order to identify internal cracks, pores, and slag.

At the same time, you should know that there are not only industrial X-ray installations, but also mobile ones, for performing physical control in installation conditions. Gamma rays are used in a similar way and for the same purposes. When penetrating through the weld, the beam leaves its imprint on the film from the inside of the joint.

And if flaws and defects are found in the welded joint, then the film in these places will be darker. Physical verification is carried out in accordance with GOST 7512-55. In this case, sections of the pipeline with such defects in the connection are subject to rejection:

- Cracks of any shape and size; The presence of slag in the weld and pores, the number of which exceeds 10% of the pipe wall thickness; The presence of lack of fusion in the joint, if its volume is 15% or more of the metal wall thickness.

- Pneumatic and hydraulic tests.

https://youtube.com/watch?v=zpU_14iZYc8rel%3D0%26controls%3D0%26showinfo%3D0

- 101santenik.ru

- experttrub.ru

- tubespec.com

- vodakanazer.ru

Varieties of metal pipes

It is not easy to choose pipes for heating, they are bred around the entire perimeter of the house, and therefore must be resistant to corrosion, strong, reliable and last a long time.

There are certain types of pipes, consider some of them, their advantages and disadvantages:

Stainless steel pipes

Metal pipes for heating from stainless steel.

They can be called an ideal option for a number of reasons:

- very long service life (100 years);

- high resistance to corrosion;

- high strength properties;

- great look.

Unfortunately, with all these high-class properties, there is a significant drawback - the high price of not only pipes, but also their installation will also cost you dearly. Very often this is what becomes the reason in favor of other types of pipes.

Steel pipes

Made of high quality steel, which has high strength, excellent weldability and a relatively long service life. Steel pipes have a high thermal conductivity, but this advantage applies only to the heating system.

The main disadvantage is that steel pipes are not coated with anything and, in contact with water, this leads to metal corrosion.Corrosion is the cause of rusty water, the inner diameter of the pipe slowly overgrows, and this entails a decrease in water flow.

That is why steel pipes have a low price, but still need to be replaced relatively often.

Galvanized steel pipes

To avoid corrosion of steel pipes, a layer of zinc coating is applied to them, but this does not completely protect, but only slows down the corrosion process.

Copper pipes

The advantages of these pipes are similar to the advantages of copper itself:

- has bactericidal properties;

- has high plasticity;

- almost does not corrode;

- long service life;

- withstand sudden changes in temperature;

- when water freezes in them, they do not crack, so you do not have to think about.

Metal pipes are manufactured using various technologies, for example, they can be seamless (seamless) or welded.

Seamless metal heating pipes are perhaps the most reliable and high-quality material among all existing ones. They are a single product (why they are called seamless) and are not assembled from component parts.

This is what makes them durable. They can be coated with zinc, which protects the pipes, and there will be no need to take measures against the formation of rust.

Such pipes do not require painting or priming, only at the joints (they have threads, and with such manipulation, the galvanization is damaged). Seamless pipes, as well as welded ones (galvanized or not galvanized), are interconnected by special devices - couplings, and they are also called fittings.

Welded pipes are widely used in many industries. New and improved welding techniques guarantee high strength of the seam, which will not be lower than the strength of the pipe itself. All these technologies make it possible to use welded pipes in industries where only seamless pipes could be used.

A metal pipe for heating, welded compared to a seamless one, is produced with smaller deviations in thickness and with a thinner wall. This technological feature is an advantage.

According to their thickness, pipes are of the following types:

- reinforced thickness;

- ordinary;

- lungs.

A large thickness of the metal has both a plus (high anti-corrosion performance) and a minus - they are very difficult to bend during installation and repair work.

Mounting pipes for heating is a rather difficult and painstaking task when building or repairing a house. Very minor errors can lead to a short service life or disable the entire system.

Kinds

Sandwich pipe with basalt insulation

The chimney, assembled on the basis of steel pipes, has a design of three types:

- Single-walled - a chimney made of metal up to 2 mm thick. It is installed in an existing chimney system in order to eliminate any shortcomings. For example, to repair damage in brick or ceramic chimneys.

- Sandwich chimney - is a double-walled structure made of pipes of various diameters. Between the pipes there is a fire-resistant heat-insulating material with a low coefficient of thermal conductivity.

- Coaxial - a double-walled chimney with the possibility of air intake from outside the room. It is similar in design to a sandwich pipe, with the only difference being that gases go outside through the central pipe, and cold air is drawn through the outer one.

All presented types of steel chimneys can be made independently. A coaxial chimney, compared to a single-wall or sandwich chimney, has a more complex device, but if you have a properly drawn up scheme, it will not be a problem to build it.

For DIY, it is better to use a chimney based on sandwich pipes. This design provides a constant level of thrust, is safe, easy to repair, does not require constant cleaning of the internal channel.

Types of wiring. Their advantages and disadvantages

For water supply and heating systems in a residential area, the following schemes can be used:

- tee;

- collector.

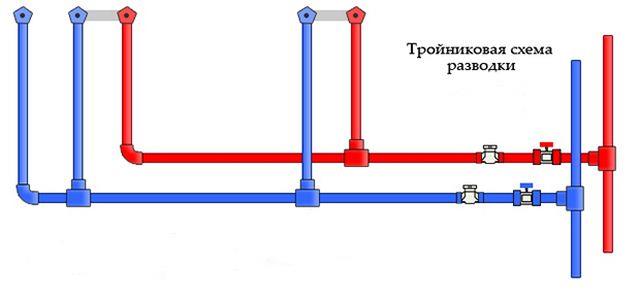

Tee wiring

A tee wiring diagram is a series connection of pipes and their supply to water intake points (sink, shower, toilet, and so on).

Serial connection of water intake points

The advantages of such a system for connecting water pipes are:

- low cost, since when using a serial connection, a minimum number of pipes and connecting fittings is required;

- ease of installation of the system;

- compactness - pipes occupy a minimum amount of living space.

Among the disadvantages are:

- lack of pressure with the simultaneous inclusion of several taps included in the water supply or heating system;

- difficulty in finding a leak in the event of a strong pressure drop in the fluid in the system;

- the need to completely turn off the water supply of the system to perform repair and / or maintenance work.

Tee wiring is mainly used in the arrangement of communications in small apartments or country houses with a small number of water intake points.

Collector wiring

Collector wiring is a parallel connection of pipes of the water supply / heating system to the central riser using a specialized device - a collector, which is installed at the system inlet to the building.

Parallel connection of water intake points

This plumbing connection system also has its advantages and disadvantages. The positives include:

- stability of the water supply pressure to all connected devices, regardless of the use of other plumbing devices;

- the ability to quickly detect malfunctions in the operation of one or another equipment, as well as places of leakage;

- the possibility of performing repair work without the need to disconnect other points of consumption from the water supply;

- temperature uniformity of the supplied liquid.

The negative aspects include the installation time, since each plumbing fixture requires a separate pipe, and an increase in the cost of materials (pipes, tees, fittings, holders, and so on).

Collector wiring, in contrast to the tee, allows you to optimize the operation of each plumbing equipment individually. For example, for a washing machine, you can install an additional filter, which will significantly extend its life.

Features of pipe welding in hard-to-reach places

The greatest difficulty is the welding of heating pipes located close to the walls of the room. Typically, pipes operating under increased pressure are placed in this way.

Working with such pipes is as follows:

- The welding process starts from the central lower part of the pipe. The placement of the electrode must be perpendicular to the welding point. However, to weld vertically located seams, the position of the electrode is changed, directing it at an angle upwards, or they resort to the spot welding method. Welding horizontal sections is not particularly difficult, however, the welds must be made carefully and accurately. Upon completion of work with the central lower part of the pipeline, weld the seam is cleaned of slags, after which it is possible to proceed to work from the opposite side of the pipe, starting again from the bottom. it should be borne in mind that the combustion and evaporation of zinc occurs at a temperature of 900 ° C, and the welding temperature is much higher than these figures. Therefore, the process of welding galvanized pipes is accompanied by the complete disappearance of the zinc coating at the joints, and the welded sections may subsequently be subject to corrosion.

Taking into account the presence of certain shortcomings in steel pipes compared to modern polymer products, when choosing them for a heating system, you should try as much as possible to perform all the work efficiently and reliably. This is possible only if any manipulations with pipes are carried out only by qualified specialists. Professionalism in the installation of steel pipes will make the heating system work properly and efficiently, while achieving a significant extension of the service life and preventing any problems and malfunctions. Installation of highways for any purpose from pipe rolling is carried out most often with the help of welding

Moreover, pipe welding at home can be done in two ways: In this case, both types of welding can be divided into categories: Plastic (pressure welding); Electrode and solder metal fusion welding. Each of the metal joining methods has certain requirements that should be followed to obtain a high the quality of the weld. Important: welding is carried out mainly with an industrial seam, which corresponds to SNiP III-G.9-62. Compliance with the rules and regulations allows you to learn a high quality seam

When performing work, they mainly use automatic or semi-automatic equipment.