Is it possible to lay laminate in an unheated room

The idea to beautifully decorate balconies, loggias, summer cottages, summer gardens is not new. Only one question arises: is it possible to lay a laminate in an unheated room? Many residents of country houses are trying to answer this question. They give not only practical advice, but also share their experience and observations, who has passed such a number, and who has filled bumps from a stupid idea. So who do you still believe and what to do so as not to make mistakes and not redo it for the next season.

To begin with, let's figure out in what conditions for living we settle our laminate. An unheated room is a loggia, balcony, cottage, where you want to create comfortable conditions for relaxation. Laminate, of course, is a way out in this situation, but how not to make a mistake and make the right choice.

First of all, what is a laminate? This is a board, the basis of which is HDF board, the functionality of the laminate depends on its composition and quality. An important role is played by the method of manufacturing the plate itself. Some manufacturers use pulverized wood for the production of lamellas and glue it, then subject it to strong pressure. Other manufacturers independently grind wood fibers into a larger fraction for their production, and then glue and also squeeze. It should be noted that the second method gives the plate more resistant to temperature fluctuations and changes in humidity.

Some consumers turn to the Internet as a source of information and read reviews about a particular brand, how it behaves in different conditions, and then draw conclusions for themselves and make a decision.

Types of materials used

Distinguish between vinyl and fabric. It is these materials that manufacturers of stretch ceilings offer today and the differences between them are very significant.

vinyl sheet

- this is a thin PVC film with a thickness of 0.15-0.37 mm, produced in rolls with a width of 1.3 to 5 meters. The main qualities of vinyl ceilings:

- harmlessness to humans and the environment;

- fire safety - PVC film does not support combustion, the material melts, but does not ignite;

- biological stability - mold does not form on the surface of the canvas;

- elasticity - when heated, vinyl can stretch up to 220%;

- strength - withstands loads up to 17 MPa;

- water resistance - does not allow moisture to pass through.

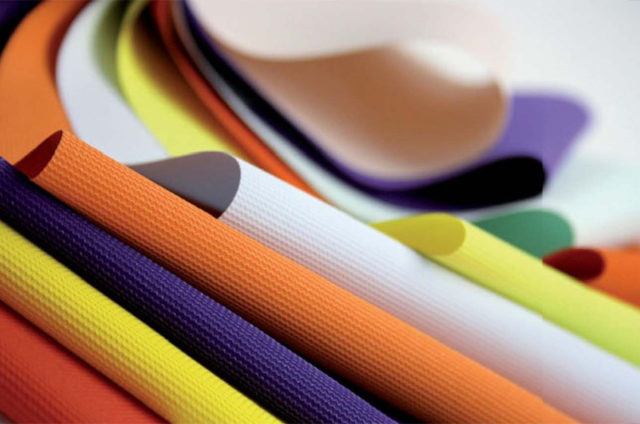

Manufacturers offer glossy, matte and satin canvases with a huge number of shades. Vinyl film is distinguished by its bright colors, allows you to combine materials and apply photo printing, which provides endless possibilities for use in different interior styles.

Due to its strength and water resistance, the PVC ceiling is able to hold up to 100 liters of liquid for a long time in case of flooding or roof leakage. In the future, the water is easily drained and the canvas is re-stretched. For rooms with high humidity, PVC is the most suitable option.

Among the shortcomings, it is worth noting the airtightness. In a room with insufficient ventilation, the “greenhouse effect” manifests itself - humidity increases and it becomes stuffy. Also, the stretched canvas is easy to damage with a sharp object. Even a “shot” with a champagne cork can lead to sad consequences. Therefore, the film requires special care.

fabric ceiling

- is a synthetic polyester fabric impregnated with polyurethane, 0.12 mm thick, sold in rolls from 3.1 to 5.1 m wide. Main material properties:

environmental friendliness - does not contain and does not emit harmful chemical compounds, thanks to special perforation, the polyester ceiling is able to "breathe", which is important for creating a comfortable microclimate in the room;

thermal resistance - the material withstands a wide temperature range (from -40 ° C to +80 ° C) without losing its properties;

relative elasticity - it can stretch up to 120%, but when heated, unlike vinyl, it shrinks;

fire safety - thanks to special impregnations, the textile fabric does not ignite and does not support combustion;

high strength - accidental damage to polyester is unlikely;

quick installation - no heat gun required;

easy care - the antiseptic coating of the canvas prevents the accumulation of dust on the surface;

water permeability - polyester is "not friendly" with water and is not suitable for wet rooms;

the possibility of repeated dyeing - textiles can be dyed with acrylic paints, but not more than 5 times to avoid sagging.

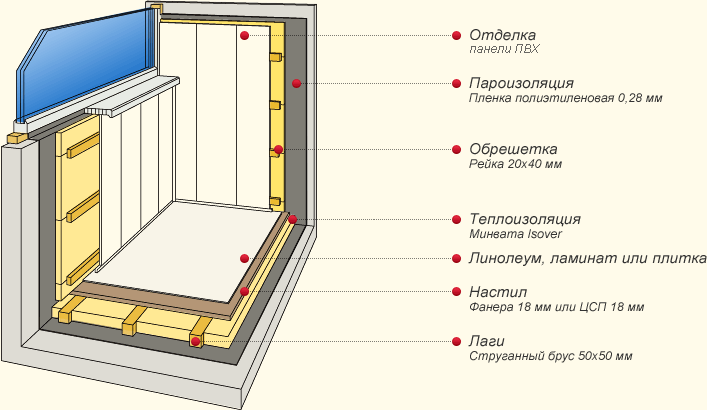

Preparatory stage

preliminary calculations

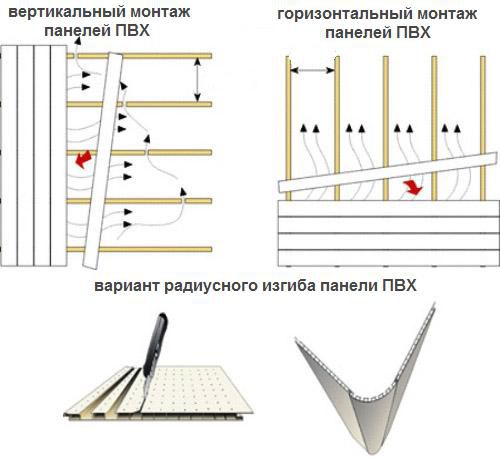

You need to start by calculating the amount of finishing material so that you do not have to overpay or go to the store for an additional batch. Panels can be mounted both vertically and horizontally, depending on the desire of the owners of the apartment. With vertical fastening, the number of panels is calculated as follows: measure the length of the perimeter of the room, subtract the width of the openings and divide by the width of one panel. 2-3 lamellas are added to the resulting number in reserve.

For horizontal installation, the area of the room is measured minus the door and window openings and divided by the area of \u200b\u200bone panel. Here, the margin should be at least 10%, since the consumption of material for trimming increases. Additionally, you need to calculate the number of rails for the crate and fasteners. First, the height of the walls is divided by the step of the crate, which is usually 0.5 m, and multiplied by the perimeter of the room. The resulting number indicates the length of the rails in linear meters. By measuring the height of the corners and multiplying it by their number, we get the total footage of the corner profiles; to this number you need to add the perimeter of window and door openings.

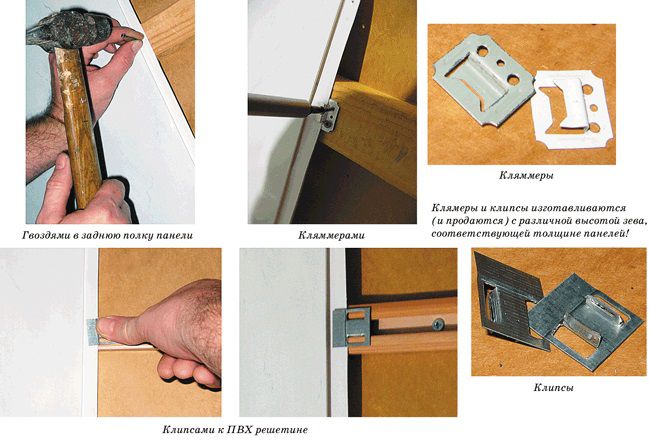

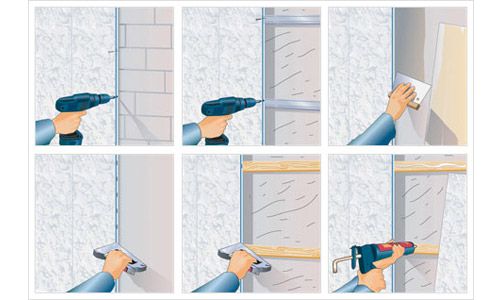

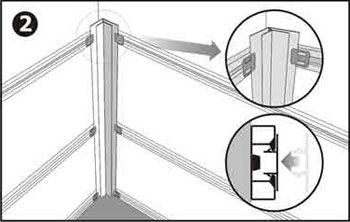

Methods for attaching lamellas

There are three ways to fix the panels on the wall - with glue, self-tapping screws and clamps. The first method is suitable for very even and smooth walls; glue is used special for PVC, universal "Moment-mounting" or "liquid nails".

The use of this method facilitates and reduces the cost of the installation process, since there is no need to fix the crate. Disadvantages: it is impossible to replace a damaged panel, it is difficult to remove the coating from the wall during subsequent repairs.

Self-tapping screws are a reliable and convenient option that does not require a perfectly flat surface. To screw in the screws, you definitely need a screwdriver, otherwise the installation process will be delayed for a long time. Disadvantages of the method: a wooden frame is better suited for self-tapping screws, therefore, additional time is spent on sawing the timber and processing it

The third option is the most optimal. Kleimers are conveniently and quickly attached to the crate and securely fix the panels on the wall. The crate is mounted from a metal profile, the assembly of the coating is effortless. A damaged lamella is easy to replace with a new one, and the dismantling of the finish also does not take much time.

Tools and necessary materials

In the process of work, everything should be at hand, so materials and tools for installation are prepared in advance. You will need:

- fine-toothed hacksaw;

- pencil and tape measure;

- level;

- square;

- plastic panels;

- rails or plastic profile;

- dowel-nails, self-tapping screws or kleimers;

- screwdriver;

- perforator;

- antiseptic composition;

- sealant;

- ceiling plinth.

Wall preparation

Before paneling, the walls must be cleaned of the old coating, repaired to one crack, noticeable defects and treated with an antifungal agent.Due to this, dust will not accumulate under the plastic and mold will not develop, which negatively affects the microclimate in the room. If the installation will be carried out on the frame, it is not necessary to additionally level the surface.

Features of PVC boats to consider

The popularity of PVC boats is due to their availability and the widest range. Everyone will be able to choose a product depending on the purpose of use and at the best price. So, to just ride with the family on the calm water surface near the beach, an inexpensive light boat made of a single-layer material is quite enough. For fishermen, higher strength and the ability to install a motor are needed. And for lovers of extreme rafting on stormy rivers, a swimming facility made of durable, multi-layer, reinforced PVC is necessary.

In the summer, storing these products does not cause much trouble. They tolerate high humidity and high temperatures well. But keeping them in the sun all the same is not desirable.

This material does not deteriorate from low temperatures, but if the thermometer needle drops below minus 10 ° C, it becomes very brittle and can burst at the folds even from a slight impact, for example, when shifting from place to place. PVC products, according to unknown reasons, mice and rats are very fond of. Therefore, they need to be stored in places that are inaccessible to these rodents.

Thus, in winter, the boat can be stored in any dry, closed room, such as a garage. A barn, a pantry, an insulated balcony or a summer kitchen are quite suitable for these purposes. It is optimal that the temperature in the storage be in the range from minus 10 to plus 45°C.

It is not advisable to lay such products under beds, in drawers of sofas and other places in the living room, since substances harmful to the human body are released from PVC.

It is not necessary to sprinkle this material with talc, or wipe with any lubricants before long-term storage (as is done with rubber boats).

In no case should PVC products be allowed to come into contact with aggressive materials - solvents, gasoline, oils, silicone, as well as their vapors.

Material selection

The main factor that you should pay attention to when choosing a material for finishing a summer house is the lack of heating - in summer the atmosphere inside the room will be warm, and in winter it will drop below zero. Accordingly, the first and most important parameter is the frost-resistant structure of the material, which will not deform under the influence of frost.

The second negative factor is the increased humidity, which falls on the walls in the form of condensate. If you visit the cottage in the winter and periodically turn on the heating, then this phenomenon is inevitable, since the air warms up much faster than the walls, which in turn causes condensation to form. Finishing is impregnated with dampness and after drying begins to deform.

The best solution to this problem would be to choose a moisture-resistant material or maintain a stable temperature regime, which is possible only if you do not visit the cottage in the winter.

There are several materials that are most optimal for this purpose, through which the interior decoration of the cottage is carried out, among which the following should be noted.

Plaster

Plaster is the most traditional, which is successfully used to this day. Despite its relatively rough texture, it looks good in combination with light topcoats. The main components for plaster are cement and sand, which are mixed in various proportions, depending on the composition of the polymer additives.

Sand-cement plaster is not afraid of frost and temperature changes, which makes it indispensable in unheated rooms.Whatever climatic conditions develop in your absence, the coating will retain its original appearance. Also, the reliability of the plaster coating is explained by its structure - concrete is one of the most durable building materials today.

The instructions for installing the panels are not difficult, but the standard recommendations often do not take into account the specifics of the room.

Mandatory conditions for the installation of PVC lining in an unheated room are:

- When sheathing an unheated cottage, metal or plastic profiles should be used for the frame - a wooden beam can swell and deform under the influence of moisture. After warming, the entire structure can be damaged, since the panels lie directly on the supporting frame;

- Since temperature fluctuations will be permanent, there must be expansion joints between the sheathed plane and the wall / inner corner / floor / ceiling. If the panels are large enough, then an expansion gap must also be provided between them;

Expert answers

Besprozvanova:

Depends on the quality of the film (and the stretch ceiling is a synthetic film). That is, from the country of origin. Real French is not afraid of frost (up to -15) or heat (up to +32). Chinese - and there are most of them in Russia, when it's -5-7 it already cracks, when it's +25 it sags terribly. There are also fabric ceilings - they have much better lower and upper temperature limits. Remember, also, that almost all of these films contain harmful volatile impurities - formaldehyde, for example. This can then cause allergies, headaches, decreased potency, etc. It also depends on whether you will simply stretch this ceiling in a cold room (for example, stretch the ceiling and change windows in winter :-)) or are going to use it in winter. For example, in cold warehouses. Good luck with the repair! Interior designer — Marina Abramova

madam:

where are you going to put them on?

Chairman:

Of course: it's PLASTIC!

Lavrenty Pavlovich:

Do you live in a hut?

Marina Savinova:

Quality should not be afraid of anything

Julia L.:

I don't think there will be anything in the apartment...

Artem Sobko:

The thickness is not large, but still thermoplastic. I think that minus 30 can not be transferred. but in the company that will install, ask about the guarantee and temperature conditions for each manufacturer, they have their own. if the modes suit you and the warranty covers it, put it as a last resort will change)

and you are going to pull it on the street

Hooligan:

if you pulled them somewhere on the street, then maybe ... What are they afraid of in the room? ? We don't seem to be afraid of anything...

Vladimir Yakovlev:

no, they’re not afraid, I pulled myself in the street toilet for 2 years already and they don’t care

Ginger:

no, it's been two years now

flea bear:

Nothing terrible will happen, moreover, I will say and give an example. At the entrance to the office building of the headquarters, one of the inventors of stretch ceilings, the BARRISOL company in France, has broken figures of animals covered with PVC film all year round. It is not frost or heat that is terrible, it is the mechanical impact that is terrible, especially if the areas are large. Say, in a strong wind at 20 degrees below zero, the canvas can definitely burst, since the plasticizer dubs, but if the ceiling in the house is in an unheated dacha, then with a high-quality installation (the baguette does not have sharp edges, usually at room temperature, the edges of the baguette are unprocessed in most cases by installers, film forgives everything), PVC film will withstand minus forty, although manufacturers do not guarantee operation at such low temperatures. But such temperatures in apartments, as you understand, do not happen, and airing even in the most severe frost will not cool to ultra-low temperatures.

f:

They did stretch ceilings in a country house. So there infrared heaters remained behind the ceiling! I mean those that go in thin sheets somewhere around 1.5m by 0.5m.We just tightened them up. In my opinion, it was warm, but not enough. Now, if they were placed from below, I think it would be just right. The use of infrared heaters is entirely possible. Place it anywhere =) At least from all sides. Any power. The stretch ceiling is afraid of high temperatures (incandescent lamps, open flames, and perhaps very, very hot battery risers) since the principle of heat generation for an infrared heater is different, so everything will be fine with you and with the ceilings =) You can see a lot of interesting things

sln:

I don’t understand, are you going to sculpt it on the ceiling, is this heater? Or live in an unheated room for the sake of the ceiling? Look here, for example: radugapotolkov /articles/pamyatka_klienta/sovety_po_ekspluatacii/

Viktor Tyulenev:

I am very interested in whether it is possible to make an infrared ceiling behind a stretch one. What are the features? Norms? Isn't it dangerous?

Natalya Kruglik:

Is it possible to make a PLEN behind a stretch ceiling

Pros and cons of stretch ceilings in a cold room

From the foregoing, the conclusion suggests itself that at sub-zero temperatures it is better to use synthetic fabric. But not everything is so clear.

- Firstly, there is an alternative in the form of expensive special films that feel great in houses without heating. They do not deteriorate from frost and temperature changes, retaining their properties for many years. True, not everyone can afford such pleasure. In addition, the choice of colors and textures is much more modest compared to conventional film, and the maximum width of such material does not yet exceed 3 m.

- Secondly, with all the advantages, fabric ceilings are prone to the formation of fungus. And if the roof leaks, they will not save you from flooding. Another drawback: with high dampness in a cold room, synthetic fabrics are saturated with moisture. All this leads to irreparable damage to the material, which will have to be replaced. In addition, if necessary, dismantle the ceiling, for example, to gain access to communications, it is very problematic to install the canvas back. The fact is that after stretching, the excess fabric is cut off and there will be practically nothing to grab onto when re-installing. Although there are exceptions.

- Thirdly, some unheated rooms do not cool down to sub-zero temperatures even in unusually harsh winters. Balconies and loggias soundly insulated from the outside can be passively heated by adjacent warm rooms. Therefore, PVC film is often used as a ceiling covering.

We make the right choice and features of installation

You need to buy finishing material for walls all at once and from one batch so that they do not differ in shade. When buying, you need to check the quality of the surface: it should not have chips, cracks, dents and other defects. The seams must be of high quality, in order to check them, it is necessary to connect the strips, while they must be even and inconspicuous.

If the material is of high quality, then with a slight pressure on it there will be no cracks.

When calculating the required amount of material, it must be taken into account that the material is sold in strips, sheets or squares, therefore, their quantity must be counted, and not proceed from the square of the room.

To avoid unnecessary expenses, you should find out the exact dimensions of the sheathed premises before buying. In order to perform high-quality installation, the panels must be kept in the room where they will be mounted before installation.

This will make it possible to avoid gaps during installation. Polyvinyl chloride materials increase in size with increasing temperature, for example, a three-meter panel increases by 1 cm if the temperature increases from -10 to 40 degrees. This also applies to width.

As the temperature rises, the gaps disappear. To achieve a monolithic surface, installation is best done at a temperature slightly lower than that which is usually maintained in this room.

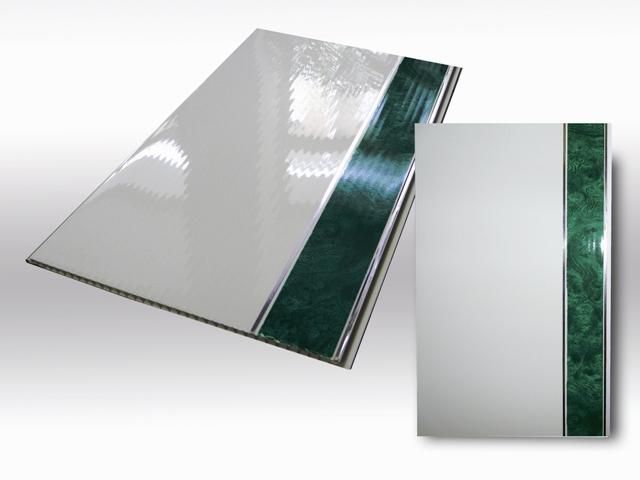

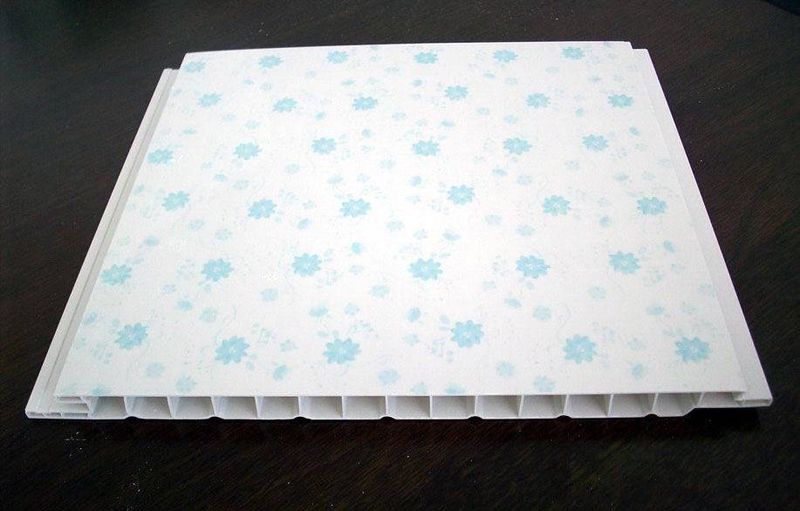

PVC panels are a practical and durable material, and therefore are widely used in. They are suitable for any room, and a variety of textures, shapes and colors allows you to make the interior not only cozy, but also very stylish. The mounting technology is quite simple, so decorating the walls with plastic panels is a great option for a novice master.

The range of plastic panels is so large that it is very difficult for an inexperienced buyer to figure it out. To avoid mistakes, you should familiarize yourself with the characteristics of this material and its varieties in advance. It is worth considering only certified material, because low-quality panels do not have the required strength and quickly burn out.

The main advantages of plastic panels:

minus

This material has a low impact resistance, so the panels should be handled with care during transportation and installation. Depending on the coating, the panels are divided into matte and glossy, and according to the drawing technology, they are divided into film and printed.

Standard sizes:

- width from 200 to 350 mm;

- length from 2700 to 3000 mm;

- thickness from 8 to 10 mm.

The strength of the material depends not only on the wall thickness, but also on the number of stiffeners located inside the panel. To check how durable the material is, you need to press your finger on the surface - if the plastic is bent, the panel will not last long.

In addition, you should not buy panels if:

Comparative table of characteristics of PVC panels

| Indicator / Panel | PVC panel ТМ Decomax | Average Chinese panel | Average European panel |

|---|---|---|---|

| Front surface thickness, mm | 2,5 | 1,5 | 2,0 |

| Number of stiffeners, pcs | 29 | 20 | 29 |

| State of the stiffeners | smooth, without deformation | smooth, there are minor deformations | smooth, without deformation |

| PVC panel weight, kg/sq.m | 2,2 | 1,7 | 2,0 |

| Appearance | The coating is even, but with pronounced gaps in the stiffening ribs, there are slight deformations | The coating is smooth, without manifestations of stiffening ribs | |

| Raw material | after a slight pressure, the panel is deformed, which proves the high content of chalk | after a slight pressing, the panel returns to its original form, which indicates a low content of chalk |

Is it worth it to make a stretch ceiling in the country

Vinyl film is not intended for use in freezing rooms. If you periodically heat the cottage in winter, it may be possible to avoid critical hypothermia. But at the same time, the unstable temperature in the room will affect the state of the stretch ceiling. From strong cooling, the PVC film will narrow, and when the cottage is heated, on the contrary, it will stretch. As a result, the canvas, even if it does not tear, will sag after 2-3 seasons, partially losing its elasticity.

But that's not the biggest problem. In winter, when the ground freezes and the area is covered with snow, field mice find shelter in the country house. These seasonal "owners" in the cold gnaw on everything that comes across. And if at least one of them crawls from the attic into the inter-ceiling space, then without hesitation, it will turn the PVC sheet into a sieve. Hoping for poison with an irregular visit to the dacha is not worth it. One day, some circumstances will prevent you from getting there on time, and hungry mice will have time to deal with the ceiling in 1-2 days.

It is possible that a frost-resistant fabric cloth solves the temperature problem, but in a cold house in winter it will quickly become damp and almost inevitably covered with mold, which is then almost impossible to wash off. So stretch ceilings in the country, which will not be heated in winter, are not a mandatory thing at all, if not useless. Most owners will be quite satisfied with a more modest finish. Consider the existing options:

-

Plastic lining or panels

. For summer cottages, this is the cheapest and most convenient way to finish.The panels can be washed, they are too tough for mice, they are not afraid of frost at all, and colors - as much as you like. Installation is so simple that any home master can easily cope with it. -

Wooden lining

. In terms of costs, this option is not cheaper than tension structures, and installation will take a little more time. But if you do it yourself, the savings will be significant. Such a ceiling can be varnished, preserving the natural look of wood, or painted in your favorite color. Clapboard is a very clean, practical and representative way of finishing. -

Plywood

. Inexpensive and original option, especially in the presence of wooden furniture. At the same time, the external similarity of the surface texture with wood will create a single interior of the room. Various front finishes allow you to choose the right color. If necessary, you can paint the surface or process the stain of the desired shade. The material is easy to process and mount even without an assistant. -

foam tiles

. Also an inexpensive and quick way to finish the country ceiling. The choice of such tiles - both in size and in pattern is very wide. And if there is no suitable shade on sale, the foam is easily painted in the desired color. Ceiling tiles are glued without any preliminary preparation. It is better if the foam is laminated. Dirt on such a surface does not hold, and it is very easy to clean. Mice will not eat it, since with such a finish there is no inter-ceiling space, the tile is glued directly to the ceiling. -

Plain whitewash

. Perhaps the easiest way to put the ceilings in order. Even a person who does not have the skills of a painter can cope with the work. The bactericidal properties of lime protect the ceiling from mold, however, the whitewashing process cannot be called clean - splashes of the solution inevitably fall on walls, furniture and floors and are not easy to remove later. Therefore, all surfaces before the procedure are carefully covered with a film. The disadvantages of this method of finishing include the need to periodically re-whitewash the ceiling, since over time cracks appear on the surface and in some areas the lime begins to fall off.

So, we tried to briefly describe the main options for finishing ceilings in a country house or in the country, the advantages and disadvantages of each method, but the choice, as always, is up to the owner.

Installation of plastic panels

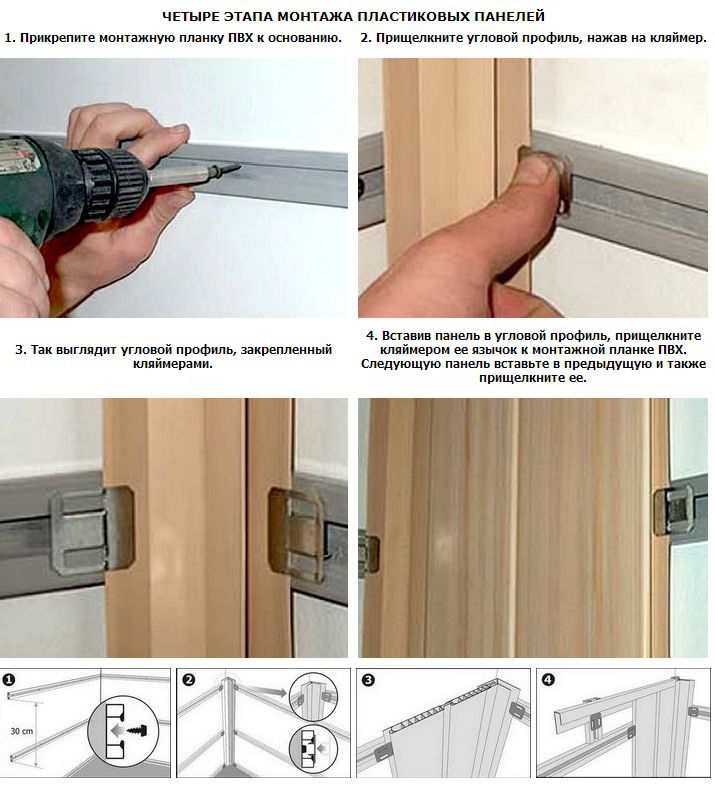

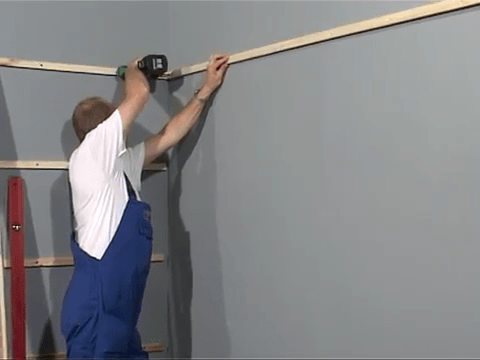

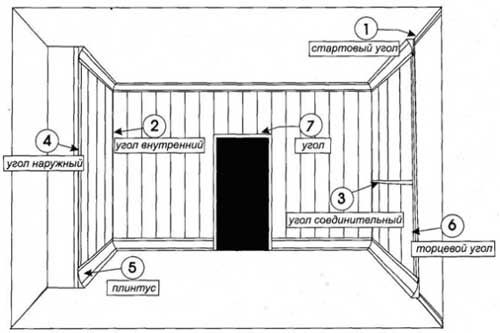

Step 1. Marking the walls

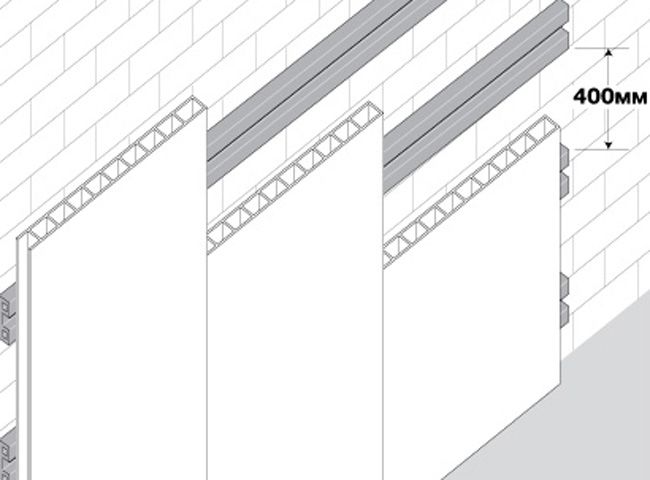

The crate should be fixed strictly according to the level, this will help to avoid distortions. In order not to measure each rail, you should make markings on the walls. The bottom row of the crate should be located 1-2 cm above the floor, so a point is marked on the wall with a pencil at this height, and then a horizontal line is drawn along the entire perimeter using a level. Exactly the same line is drawn under the ceiling or along the edge of the finish, if the walls are not sheathed to the full height. Further, 40-50 cm are measured upwards from the bottom line, a beacon is placed, and so on to the very top. Strictly parallel lines are drawn through the beacons along the perimeter of the walls. The markup is ready.

The panels must be attached to the crate perpendicularly, so the horizontal frame is sheathed vertically, and vice versa. To make a markup for a vertical crate, the first line is drawn in the corner from the ceiling to the floor using a plumb line. Next, mark the second corner, and then draw the rest of the lines in increments of 50 cm.

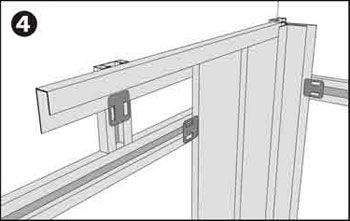

Step 2. Mounting the crate

If a tree is used for the crate, all slats must be primed with an antiseptic in advance. Holes for dowels are drilled along the marking lines with a puncher at a distance of 50 cm, then slats are applied, leveled horizontally and fixed on the wall. Where the walls have irregularities, wooden wedges are laid under the crate. If there is wiring along the wall, it must be hidden under the trim. To do this, make measurements, drill holes in the wall and fix the wires with clamps so that they do not protrude beyond the plane of the crate.

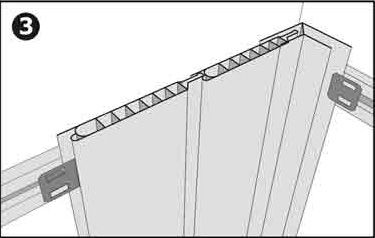

Step 3. Fixing the slats

The first lamella is installed in the far corner from the entrance, which is considered the most noticeable.

Make measurements, if necessary, cut the panel along the length with a hacksaw. With one edge, the panel is inserted into the side molding, applied to the corner and fastened to the crate from the back side.

The second lamella is inserted into the mounting groove of the first, the joints are pressed tightly and fixed to the frame rails.

To achieve maximum sealing of the joints, the side edges are lightly smeared with silicone before insertion. All subsequent elements are mounted in the same way.

Holes are cut out under the switches and sockets in the panels with a sharp knife, and after installation, these areas are covered with plastic boxes. The last lamella most often requires trimming in width, so first they try it on the wall, mark the cut line with a pencil and cut off the excess with a hacksaw.

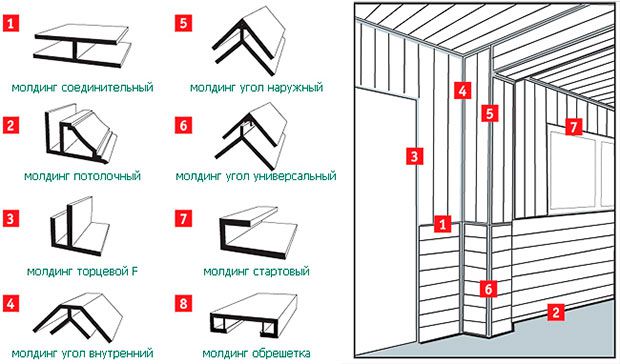

Step 4. Installing moldings

After installing all the elements, the surface should look monolithic and even, without gaps at the seams and around the perimeter. To do this, all corners, joints and joints are closed with special plastic moldings. Their design allows you to carefully insert the edges of the panels on both sides, making the corners look much more attractive.

Finally, a decorative molding is installed around the perimeter of the ceiling, and a plastic molding is attached around the perimeter of the floor. On this wall decoration with PVC panels is considered complete. With careful operation, the panels do not lose their attractiveness for a long time and do not require repair.