Is it profitable to use penoplex 45

Affordable price and thermal insulation characteristics provided foam 45 with a wide area of operation and stable demand in the market.

Penoplex was used in the insulation of foundations, basements, basement floors of residential and public buildings, inverted roofs, floors in production shops and workshops.

It is used in the reconstruction of city streets and as a “substrate” for ice arenas, sports grounds, car parks, and pedestrian zones.

Additional thermal insulation of transport highways eliminates the risk of freezing and frost heaving of the soil, which means it prevents the appearance of potholes, cracks and dents on the road surfaces.

The economic feasibility of using insulation is aimed at saving energy resources and is due to a reduction in the cost of heating buildings, restoration of structures, and road maintenance.

Applications

"Penoplex 45" has a fairly affordable price, which, together with good technical data, allowed him to receive increased demand in the construction market. The cost of the material is just over 3200 rubles.

Blocks have a fairly wide scope.

Plates can be used for insulation of basements, house foundations, basement, floors and walls in various premises (residential or public).

Products insulate streets, sports grounds, parking lots for cars, as well as pedestrian areas.

Highways and runways at airports also need thermal insulation, so Penoplex 45 is also used in these cases, since the increased strength and wear resistance of the material guarantee a long service life. In addition to strength, foam blocks give roads and protection against cracking after severe frosts. If the tracks are built from a special type of soil that does not have moisture resistance, they can swell after rain, snowfall or hail. Insulation will help prevent such a case and prevent roads from freezing.

In addition to insulation, Penoplex 45 also performs stabilization, vibration damping with frequent dynamic surface loading. Their strength allows them to withstand about fifty tons of weight per 1 m2 and uniformly distribute gravity over the entire base.

The presence of such material is very important for better road safety and security.

"Penoplex 45" in some cases becomes an auxiliary element of load-bearing walls. In this case, it not only insulates, but also strengthens the structure, giving it additional reliability.

Standard sizes penoplex 45

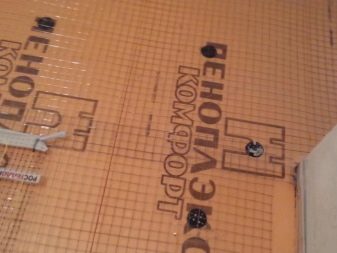

Penoplex 45 plate dimensions: standard length - 2400 mm, width - 600 mm, thickness varies between 40-100 mm. Products of a different format with individual dimensions and thickness are made to order.

If necessary, during the installation process, the Penoplex panels are cut into separate segments, adjusting to the desired dimensions.

After laying, to maintain the integrity of the outer surface, the insulation is covered with finishing materials, a reinforcing mesh. And during storage, in order to protect the penoplex from exposure to ultraviolet radiation, they control the safety of the factory packaging. Penoplex insulation is a convenient and reliable thermal insulation that will last a long time if you follow the technology of storing and laying the material.

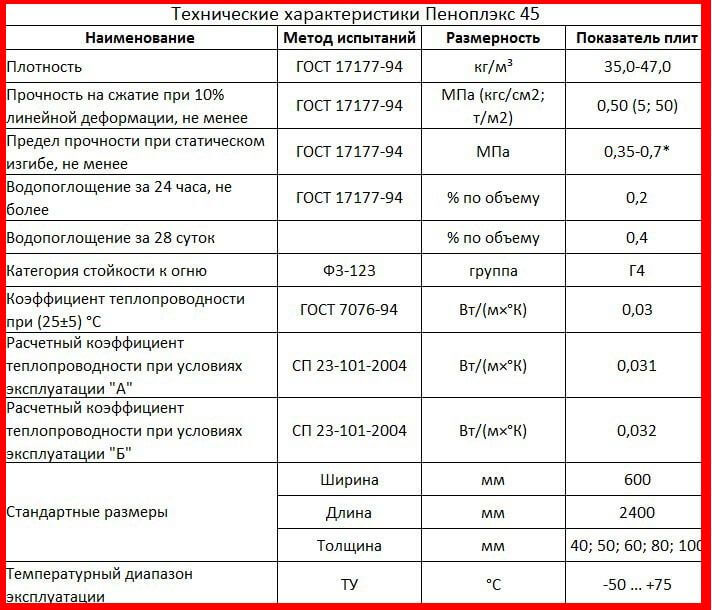

Characteristics Penoplex 45

Thermal insulation "Penoplex 45" - the Russian name for extruded polystyrene foam, which is a modified foam.

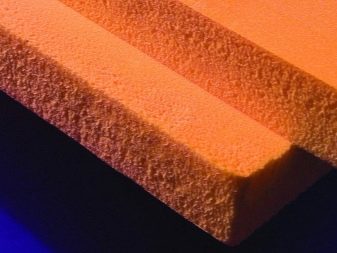

The product is produced in the form of orange rectangular slabs with a homogeneous cellular-porous structure. In addition to polystyrene, foaming agents, flame retardants, plasticizers and dyes are included in the foam insulation.

The density of foam with marking 45 is 35.0-47.0 kg / m³.The product is able to withstand heavy loads without surface deformation and damage to the original quality criteria.

Technical characteristics of penoplex 45:

- operating temperature range -50…+75°С;

- water absorption - no more than 0.2% by volume in 24 hours;

- vapor permeability coefficient - 0.05 mg / (m * h * Pa);

- combustibility group (resistance to fire) - G4;

- thermal conductivity - 0.03 W * m * 0K;

- modulus of elasticity - 15 MPa;

- service life - 50-60 years.

The environmental safety of the insulation is achieved through the introduction of freon-free technologies into the production cycle and the use of non-toxic components.

Penoplex products are resistant to negative environmental influences and most chemicals: organic and inorganic acids, alcohols, alkalis, bleach, ammonia, etc.

PENOPLEX Facade

PENOPLEKSFacade thermal insulation boards are produced according to TU 5767-006-54349294-2014

Description

Insulation of external walls is one of the main tasks for thermal insulation of a house. It is through poorly insulated walls, depending on the design, that the house loses up to 45% of heat. That is why it is necessary to choose a high-quality insulation: resistant to deformation, environmentally friendly, moisture resistant with maximum thermal protection. The use of PENOPLEX Facade thermal insulation (corresponds to the old type of PENOPLEX 31 with fire retardants) is the most effective way to save heat and save on electricity or other fuels.

PENOPLEX Fasad is focused primarily on the use of external and internal enclosing structures (walls, partitions, facade systems) for insulation. The plates have a milled surface, which improves the adhesion of plasters and adhesives to the surface of the material and reduces the time for plastering.

Areas of use

Insulation for the house PENOPLEX Facade is optimal for use in the insulation of external and internal enclosing structures, such as plinths, walls, partitions, facade systems.

Thermal insulation PENOPLEX Facade is actively used in the construction of walls according to the "well masonry" system. This wall erection system will make it possible to reduce their thickness by several times compared to the construction of walls built exclusively of bricks and to obtain reliable and energy-efficient enclosing structures, the thickness of which does not exceed 0.44-0.64 m. The most effective way to protect buildings from cold bridges is This is the insulation of the outer surface of the walls with heat-insulating material. The surface of PENOPLEX Facade thermal insulation gives an optimal effect of adhesion to finishing materials. Deformation-resistant and moisture-resistant heat-insulating boards can be successfully used as insulation for both facade panels and decorative lining.

Another popular wall construction technology using PENOPLEX Facade thermal insulation is a plaster system. This system will allow you to implement the most daring design solutions for the facade of your house, thanks to a large selection of textures and colors of decorative plaster, presented on the modern construction market.

Thermal insulation of the walls from the inside is recommended in cases where a quick renovation of the room is required, as well as when thermal insulation from the outside is not possible, for example, in basements. Insulation for walls PENOPLEX Facade is widely used for these purposes, because. combines excellent durable thermal insulation properties with ease of processing and installation.

Pipe insulation

Thermal insulation of pipes. An actively developing area is the use of PENOPLEX material as thermal insulation for gas and oil pipelines in the conditions of the Far North.

The use of pipe insulation makes it possible to replace the above-ground and semi-buried pipeline laying with a buried (trench) one, which minimizes the thermal impact of the pipeline on permafrost soils in the conditions of the Far North.This prevents soil thawing and possible deformation of the pipeline. It should be noted that at the same time, the volume of earthworks for the creation of sand bedding is halved, the construction period of the gas pipeline is reduced and its working life is increased.

Thermal insulation of oil pipelines significantly reduces the cost of their operation, because. minimizes the possibility of a temporary failure of the oil pipeline due to the effect of low temperatures on the oil (especially in cases of high waxing).

Reliable thermal insulation of water pipes, water intake facilities, sewerage systems and heating mains. Due to the high mechanical strength, the material does not require additional external protection (casings).

Protection of pipelines from mechanical damage

The high strength characteristics of PENOPLEX provide reliable protection of pipelines from mechanical damage, including sharp rocks. An example is the construction of the Blue Stream gas pipeline, where extruded polystyrene foam segments are used to protect the gas pipeline in areas of active tectonic faults. This protection keeps the waterproofing of the pipeline and minimizes ground impact in the event of an earthquake.

Insulation PENOPLEX has all the necessary certificates and is recommended for use by Gosgortekhnadzor of Russia, Gosstroy of Russia RU.SL42.N00024. JSC VNIIST and OOO VNIIGAZ developed and JSC GAZPROM approved the Specifications TU 5767-001-01297858-02 for thermal insulation for pipelines with a diameter of 57 mm to 1420 mm. By agreement with the customer, our company can produce thermal insulation for pipelines of any diameter and size.

An example of symbols for PENOPLEX insulation elements: The unit of measurement is running meters.

PENOPLEX 45 PC-1250.80.30 - TU 5767-001-01297858-02, where:

45 – brand (average material density) of the semi-cylinder ПЦ – product name – semi-cylinder1250 – product length, mm80 – internal diameter of the semi-cylinder, mm30 – thickness of the semi-cylinder, mm

PENOPLEX45 S-2500.730.80 - TU 5767-001-01297858-02, where:

45 – segment brand С – product name – segment2500 – product length, mm730 – segment inner diameter, mm80 – segment thickness, mm

Application advice for extruded polystyrene foam (XPS)

Extruded polystyrene foam PENOPLEX PENOPLEX 45

Low prices at the official dealer "Maxmir"

from 6680 rub./cu.m.

Find out the wholesale price by phone: +7(495)755-77-70

Expanded polystyrene 45 is an extruded foam insulation, which is obtained by molding the original polymer (forcing a viscous mass through special holes). It is available in slab form. Working with it is possible under completely different weather conditions (humidity, severe frost, wind, etc.). This thermal insulation material is easy and simple to work with due to its low weight. The main feature of this brand is increased compressive strength, so it is ideal for use under serious stress.

| Length, mm | Width, mm | Thickness, mm |

| 2400 | 600 | 40; 50; 60; 80; 100; 120; 150 |

This type of thermal insulation is chosen for the arrangement of loaded and inverted roofs with green areas, parking lots and pedestrian areas. It is also used in the construction of airport runways, highways and railways, especially in the northern regions, which are characterized by low temperatures and even permafrost. In this case, the frozen soil is protected from thawing and the absence of subsidence of the roadway is guaranteed.

The material prevents such a common phenomenon as frost heaving. Its essence is that many types of soils actively absorb moisture in spring and summer, and in winter the water freezes and expands, thereby lifting the cover up. As a result, serious cracks and dents are formed. Insulation also allows you to eliminate or reduce the freezing of the soil.If you decide to buy PENOPLEX 45 extruded material, you will receive thermal insulation with unique qualities. It is characterized by high density and strength, which persist throughout the entire operation (that is, more than 50-60 years).

| No. p / p | Name of indicator | Control methods | Units | PENOPLEX 45 |

| 1. | Plate thickness | GOST 15588-2014 | mm | 40-100 |

| 2. | Average density | GOST 15588-2014 | kg/m3 | from 38.0 to 47.0 |

| 3. | Achieving full strength | GOST EN 826-2011 | days | 180 |

| 4. | Full compressive strength at 10% linear deformation, not less than | GOST EN 826-2011 | MPa | 0,62 |

| 5. | Water absorption in 24 hours, no more | GOST 15588-2014 | % by volume | 0,20 |

| 6. | Thermal conductivity, λ25 | GOST 7076-99 | W/(m K) | 0,030 |

| 7. | Flammability group | F3 No. 123-FZ | group | G4 (highly flammable) |

| 8. | Standard sizes | width | mm | 600* |

| length | mm | 2400* | ||

| 9. | Operating temperature range | THAT | °С | -70 . +75 |

| 10. | Durability | NIISF Protocol | years | more than 50 |

* - without taking into account the edge of 15 mm.

When using extruded polystyrene foam 45 in road construction, the technological process includes:

- soil planning and compaction in accordance with current regulations;

- dumping and compaction of the leveling sand layer;

- laying thermal insulation manually according to the installation diagrams;

- fixing the extreme rows with metal pins 40 cm long and 0.6-0.8 cm in diameter;

- backfilling of the first sandy layer over the insulation using the “push” method;

- sand spreading by grader/bulldozer;

- compaction with special vibration means.

During the installation of roofs, the products are laid tightly to each other on top of the waterproofing layer. Then geotextiles are overlapped, and gravel is poured. Roofs accessible to pedestrians and vehicles also have a load-bearing layer of paving slabs laid on sand, cement or a mixture of these two components. When creating roofs with landscaping, the top layer is the soil substrate with plants.

Expanded polystyrene 45 extruded is offered by us at an affordable price, since we have been the official distributor of Penoplex since 2001. Delivery of the order is carried out to any specified place within 24 hours. All related products (fasteners, mortars, etc.) can also be purchased from us.

Pro Tips

When laying Penoplex 45 segments and semi-cylinders, a special adhesive composition is used. First you need to thoroughly clean the surface of dust and dirt, prime cracks and eliminate irregularities. Then glue is applied to the plate, and it is tightly pressed against the wall. In some cases, the insulation is additionally fixed with metal or plastic dowels. The first option is used during work with the external walls of the building, the second - when the insulation takes place inside.

Dowels allow you to achieve a greater density of installation, but they violate the tightness of the sheets. Another reliable fastener that improves the quality of laying the penoplex is self-tapping screws, which also negatively affect the tightness of products.

When choosing an adhesive composition, one should proceed from the type of finishing work and the type of room. For example, when laying in a room with a high level of humidity, it is recommended to buy polyurethane adhesive. You should also focus on the material of the treated surface. Before buying, be sure to read the instructions and technical characteristics of the mixture and correlate them with the properties of the penoplex, if they are compatible, you can safely take the mixture.

In any hardware store, you can contact a consultant who will give professional advice and help you make the right choice.

Features and Benefits

The first extrusion apparatus appeared in the USA in the middle of the last century. During the production of the material, high pressure and temperature act on the polystyrene half-cylinders. The process is accelerated by a special foaming agent, consisting of carbon dioxide and light freon.The final mixture is more like whipped cream, it is she who passes through the extrusion apparatus, as a result of which the resulting mass becomes finely porous.

Each ball measuring 0.1-0.2 mm is isolated from the rest. Their uniform arrangement provides an increased density of the final block, which has a large number of advantages.

- One of the main advantages is the almost complete moisture resistance of the product. Like all new products, Penoplex 45 was tested before being put into operation. The creators conducted the following experiment: the blocks were completely immersed in water for a month. Only very little water was absorbed, and then only for the first nine days, the subsequent period of the plate no longer absorbed moisture. At the end of the experiment, it turned out that water could only penetrate the outer walls of the material, while the inner ones remained intact.

- The next advantage of the product is the low level of thermal conductivity, especially in comparison with other heat insulators. Its value is 0.03 W/mK. Thanks to the previous point, foam blocks can also be installed in places with high humidity, while the level of its thermal conductivity remains almost the same, it can vary between 0.01-0.03 W / mK. That is why the materials are recommended for insulating roofs, attics and even foundations without installing an additional protective layer.

- The reduced vapor permeability of the foam is another plus of the material, which, along with others, ensures its long service life. The extrusion-type expanded polystyrene was repeatedly frozen and then allowed to thaw, while each time its characteristics were measured, which remained unchanged. Thus, the researchers concluded that the foam blocks will last more than fifty years, taking into account all atmospheric changes.

- Uniform arrangement of balls inside the plates and structural uniformity provide increased strength of the material, so the foam plastic is not deformed even under heavy load. Due to its low weight, Penoplex 45 is easy to install, it can be quickly laid along the walls, and even beginners in the repair business can do such work. Blocks are easy to cut with an ordinary knife, they do not need a certain level of humidity or temperature, they are mounted even in bad weather. The foam blocks are completely environmentally friendly, their production does not harm the environment, and the freons included in the composition are not subject to fire, do not have a toxic smell and do not destroy the ozone layer.

- Among the advantages of the material, biostability is also indicated, due to which the appearance of mold or fungus is prevented. It is also inedible to rodents and insects. Foam blocks are not exposed to any chemicals used in repair or construction work.

However, there are still some types of materials that can adversely affect the foam, deform it, or even dissolve. These include the following: formalin, acetone, gasoline or kerosene, any ether mixtures and polyesters, as well as coal tar and oil paints.

The only disadvantage of expanded polystyrene is its rapid flammability, which at a certain temperature can harm the plates. Therefore, it is recommended to lay them, focusing on the temperature indicated in the insulation passport.