Common Causes of Radiator Failures

Wrong model selection. The choice of battery type depends on the diameter of the pipes, pressure and temperature of the coolant.

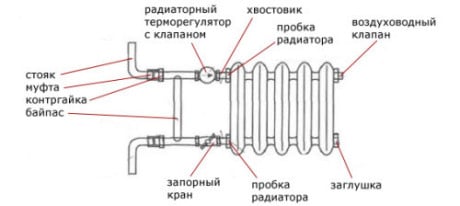

Repair of heating radiators can be the result of incorrect connection to the pipes.

If there is a large amount of chemical impurities in the coolant or pressure drops occur too often, the battery metal will corrode.

Low-quality water contributes to the formation of plaque at the joints of radiator sections, and also clogs pipes, which entails the need for cleaning.

Repair of heating radiators is often necessary due to the destruction of threaded nipples

To prevent a leak from taking you by surprise, it is important to systematically change the gaskets.

Battery noise - if you hear clicks, this does not always indicate a malfunction. However, it is better to call a team of plumbers who will carry out soundproofing.

Air locks are formed due to low pressure or due to leaking pipes.

Due to scale in the boiler and leaks at the junction of pipes, pressure drops.

Preparation for disassembly

At this stage, you need to prepare all the necessary tools and dismantle the battery from the attachment point. For work, depending on the type and condition of the radiator, you may need the following tools:

- radiator (nipple) key;

- adjustable wrench or a set of wrenches with different head sizes;

- autogen or grinder;

- building hair dryer;

- hammer, sledgehammer;

- chisel.

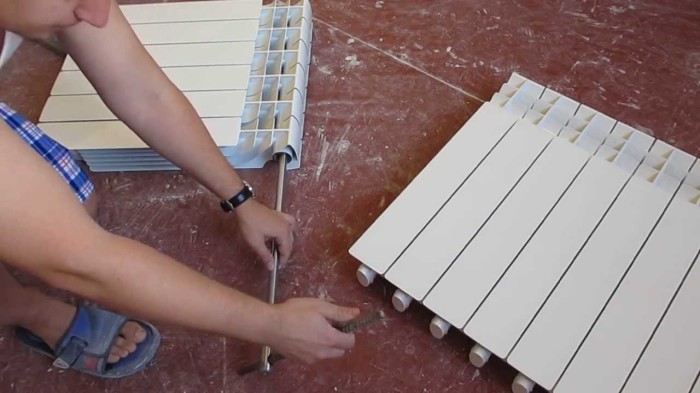

Tools for disassembling radiators

A nipple wrench is an iron rod with a spade-shaped head at one end and a hole or bent "ear" at the other. The tool purchased in the store has serifs, the distance between which is equal to the width of the sections of the heating radiator. They will help you find the location of the desired nipple nut.

After preparing the tools, it is necessary to equip a place for disassembling the radiator. A floor or a sturdy table will do. It must be taken into account that dirty water will flow from the battery, and do not forget to lay a waterproof cloth under it.

Wake up sleeping Li-ion battery

Lithium-ion batteries contain a protective circuit that protects the battery from accidents when over-discharged. The transition to sleep mode can occur when the lithium-ion package is stored in a discharged state for any period of time, when self-discharge gradually depletes the remaining charge. Depending on the manufacturer, the Li-ion protection circuit is cut off between 2.2 and 2.9 V, and you need to know how to repair the laptop battery in this case.

Some chargers have a wake-up or "boost" feature to turn on again and recharge batteries that have "slumbered". Without this provision, the charger renders them unusable.

Boost applies a small charging current to activate the protection circuit. If the correct cell voltage can be reached, the charger starts normal charging. If the storage of lithium-ion batteries presents a clear uncertainty, then manufacturers recommend keeping them at a state of charge of 40-50%. But at the same time, they warn about the possible loss of the device due to excessive discharge. There is a wide range of action between these criteria, and if the user is in doubt, it is better to store the battery with a higher charge and in a cool place.

DIY Hp laptop battery repair

Laptop batteries are made up of lithium cells called 18650 cells. They don't last forever and have a lifespan of about 2 years. If the laptop is fully charged, but charging does not last even half an hour, this means that the cells inside the battery are dead.

With an old laptop battery in stock, some wires, and tools like a wire cutter and electrical tape, you can start repairing your laptop battery yourself:

- Open the old battery and take out 6 cells that are in a 2 x 2 parallel connection.

- Check the voltage with a multimeter of your own battery. As a rule, a voltage of less than 3.6 volts for batteries indicates that they need to be replaced urgently.

- Using one wire, connect all cells in series. The circuit should provide about 12 volts.

- Open the original block, remove the faulty cells and, keeping the scheme, replace them with working cells.

- Assemble the circuit on the native battery. The battery pack will also have 4 wires - 1 negative and 3 positive (one attached to the end and two between the battery pack).

- Check the circuit with a multimeter before closing the unit.

- Close the battery case, insert into PC and start charging.

Safe extraction

Before disassembling, make sure that the laptop battery is completely discharged. Once the charge is completely depleted, you need to double check the laptop before removing the battery

It is important!

Do-it-yourself Asus laptop battery repair procedure:

Open battery case

To do this, carefully unpack it using a flathead screwdriver and a utility knife. Once the battery case has been opened, the type of batteries needed can be analyzed and the wiring diagram for installing them can be analyzed.

Before disassembly, it is better to take a picture or draw a connection diagram of the elements so as not to forget before restoring

It is also important to take all measures when opening to prevent deformation or breakage of the plastic case of the battery. Cell replacement

Use a voltmeter to make sure old cells are fully discharged before removing them. This will prevent possible electric shock. Use the model number on the battery to find suitable replacement cells. Solder the new cells to the wires, making sure they connect to the correct wires. Protective goggles are used when replacing lithium-ion cells. They are handled with care as they are capable of exploding. Once the battery case is closed and placed back into the laptop, it must be fully charged.

Dismantling a cast iron battery

Disassembling a cast-iron battery with your own hands at first glance is quite simple, but it is not. So, first you need to heat the plugs on the battery, for this I use a blowtorch. After the plugs have warmed up, they can be unscrewed much easier than without heating. (See also: Cast iron radiators)

With the help of a grinder, the battery is cut very carefully between sections. After cutting, the radiator sections are disconnected

Cast iron batteries have a nipple that must be carefully knocked out of the battery using a chisel. This is required if you decide to clean the radiator or replace a separate section

With a complete replacement of the radiator, it is naturally not necessary to clean anything. It is enough to cut it with a grinder and take it out.

The nipple must be removed so that the thread is not damaged. It is subsequently thoroughly cleaned of rust. Next, perform grouping and collection of individual sections. In order for the battery to have good tightness between the sections, you need to install gaskets and coat all joints with silicone. A little later, when everything is dry, the battery can be gently rinsed using a hose.

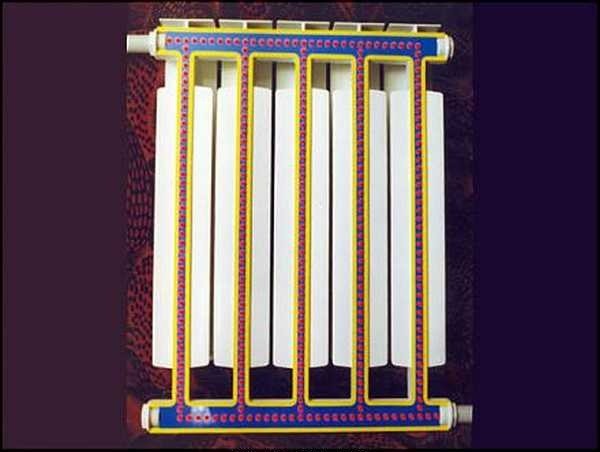

The design and principle of operation of cast iron radiators

Radiators have a sectional design. In appearance, the sections resemble metal columns, inside of which channels for the coolant are provided. These elements are interconnected using a nipple system. The joints are sealed with paronite or rubber gaskets.The height of the devices is 350-1500 mm, the depth reaches 65-500 mm. The power of radiators depends on the number of sections and the heat transfer area. In the premises, cast iron batteries are placed under the window sills. Usually wall mounts are brackets, but there are floor models with legs.

Depending on the model, cast iron radiators have a power of 100-300 watts. Approximately 25-35% of heat is transferred by radiation (radiation), part - by convection. Thanks to radiation, heating is better: the radiator heats objects, not just air. Warm layers of air rise up, and radiation provides heating of the lower part of the room. This creates the most comfortable temperature conditions.

Joint repair

To carry out the repair you will need:

- special radiator key;

- gas key No. 2 or No. 3.

We will assume that the radiator is removed. It must be placed on a flat surface. After that, the plugs and fittings (plugs with holes for pipes) are removed using a gas wrench.

Radiator sections are interconnected by nipples. This is a short pipe made of cast iron with an external pipe thread (half right, half left) and an internal hole in which there are two protrusions.

It is these protrusions that are the place where the edges of the radiator key will rest. In fact, these are stops.

At this stage, you will need an assistant who will fix the heating device in a fixed position. The key is inserted into the hole in the section so that the edges of the tool rest against the protrusions of the nipple. Now you need to forcefully turn the key at least a quarter of a turn.

The thing is that the long-term operation of cast-iron batteries, where a high-temperature coolant is used, creates conditions under which the nipple and the device section are soldered together. The result is a monolith.

Therefore, great efforts will have to be made to break these ties. As soon as the nipple moves off the dead center a little, go to the second parallel element. It is impossible to unwind the sections only on one side, a distortion will occur, which will complicate subsequent operations.

Thus, all sections are parsed. Now you need to clean the joint surfaces with an iron brush and sandpaper. Just need to remove the rust.

Be sure to inspect the nipples, if their condition is in doubt, it is better to replace them with new ones.

Focus on carving

At this stage, it is best to flush the battery sections. A hose jet and a pin (wooden or metal) will do the job perfectly.

After that, you can proceed to the assembly, having previously prepared the gaskets. They can be made independently from heat-resistant paranite or rubber 1 mm thick. Currently, craftsmen suggest using a silicone sealant that can withstand high temperatures.

The battery is assembled in the reverse order. Be careful when screwing the nipples

Here it is important not to twist, so as not to squeeze the gasket to a critical rate. She just might break

As with disassembly, the two nipples must be screwed in alternately.

Often there are situations when the stops inside the nipple become rusty under the influence of long contact with the coolant. And with pressure from the side of the radiator key, these stops are cut off. What to do in this case, because the sections simply cannot be promoted. Option one is to break the section on which the fistula appeared.

This can be done in two ways:

- Just smash the battery section with a sledgehammer. Do this carefully so as not to break good elements.

- Can be cut with a grinder. But the junction will still have to be broken with a hammer.

How to assemble an aluminum radiator

Assemble in reverse order. We place the sections on a flat surface (a table of suitable size or simply put it on the floor). If the radiator is not new, unscrew the end cap and Mayevsky's tap.

Before installation, the threads and grooves should be well examined, they must be of high quality, without chips and drops. On the mounted section for the sample, we “drive” the thread by screwing in and out of the nipple

Here you need to pay attention to the fact that before the carving, under a layer of factory paint, there may be a gasket. Rub the end lightly with fine sandpaper, if it is found there, then it must be carefully cut with a knife with a sharp blade

So the aluminum radiator looks in section

Before adding sections of the heating radiator, be sure to clean the ends to a smooth surface. We even remove factory paint. At the ends of the radiators, it is not needed, but will only contribute to the early manifestation of leaks. Sooner or later, coolant will begin to seep under the paint. In the case of antifreeze liquids, this will happen very soon, if water is used in the system, then not very much, but it will definitely happen. And then the coolant will begin to leak between the sections, although the gaskets are still in perfect condition. And the thing is that the paint on the ends exfoliated or corroded it, microcracks appeared. So be sure to clean the ends to bare metal, but use fine sandpaper so that the metal surface is smooth and without scratches. This guarantees the operation of the system without leakage in the radiators.

For better tightness, the ends then need to be degreased (you can use gasoline). Gaskets are also degreased, but they must be washed with ordinary soapy water. For a system that will be filled with water, degreasing is an optional procedure, but for systems that will operate on antifreeze, it must be carried out. Antifreezes have a high fluidity and seep into the smallest pores. After everything is dry, we begin to assemble aluminum radiators.

Then we bait both nipple nuts half a turn. Heat-resistant paronite (silicone) gaskets are put on top of the nipple to seal the joints. Now we take the section that needs to be screwed on and attach it tightly to the nuts, checking the tightness of their fit. Next, insert the key into the upper hole and twist 1-2 turns. In this case, we do not use the lever yet. We turn our hands. Then we do the same operation in the lower hole. Repeat several times, alternately tightening both nuts a few turns.

We unscrew the sections gradually, one or two turns of the nut, then from below, then from above

We twist as much as we can. Only after manual tightening can the lever be used. This must be done in two steps on each nipple. It is better not to apply excessive force during the final tightening of the nipples, since you can easily strip the thread: aluminum is a soft metal, do not forget.

If the section is fully assembled, we screw a plug onto the unused holes on one side, and on the other, a Mayevsky tap (to bleed air from the system). Now you know how to assemble sections of a heating radiator and, if necessary, you can grow several sections.

Repair step by step

It is worth saying again that repairing a radiator on your own is not difficult at all. In this case, the most important thing is the availability of the necessary tools. The main tool for repairing a radiator is a special radiator key.

The most common malfunction is a leaking heating battery, the cause of which may be a torn gasket. This defect is corrected by replacing the damaged structural element. It happens that a leak occurs as a result of the formation of a small hole in the battery. This hole can be welded with cold welding.

Location of cast iron battery leak

If any of the above happened, then do-it-yourself radiator repair begins by draining the water. It is most convenient to carry out repair work not during the heating season, when the battery is cold, but you don’t have to choose.Sometimes, after draining, a certain amount of liquid remains inside the radiator so that it does not get on the floor, you just need to substitute a basin and the leak will not spoil the floor covering.

Tap for draining water from the heating system

Very often, repair work is hampered by the fact that plugs and fittings are not unscrewed. This situation arises as a result of "gluing" these parts. In this case, it would be advisable to call a wizard who will solve this problem with the help of an autogen. This, of course, costs money, but you can’t do without the described actions.

Sometimes the repair of cast-iron radiators is, rather, their restoration, since the defect is damage to the appearance. You can fix this inconvenience with your own hands using paint, so the cost of repairing radiators of this type, in this case, directly depends on what kind of paint you are going to use.

Removing old paint from a battery

Batteries are painted only if the surface of the heater is cold. Before applying a new layer of paint, it is necessary to remove the old one, then thoroughly wash the battery and degrease its surface.

It happens that the only way to fix a defective radiator is to replace it. Dismantling the battery must be carried out when the heating is turned off so that the product is cold. The radiator is separated from the system using special tools. Such work is urgent, especially in cold weather, otherwise you can be left without heating at all.

Changing the radiator is easier, but expensive

As for other types of batteries (aluminum, bimetallic, steel), their repair is not much different. If the damage is not complicated, you can fix it yourself. A small leak can be sealed with cold welding. Such structures are dismantled quite simply, although two people are needed to complete this task, no less.

Repair of oil radiators can also be done by hand, but here it must be borne in mind that the breakdown may concern an electric heater.

https://youtube.com/watch?v=3BaaUUG4JZE

Repair and manufacture of radiators is now carried out by many companies. Their pricing policy is different, as is the quality of products and services. Therefore, you need to choose very carefully, analyzing and calculating all the options. However, if we are talking about a minor malfunction, it is better to do all the repair work yourself, enjoying the process and saving money.

Repairing radiators with your own hands is a responsible matter (especially given the high pressure under which the coolant is supplied), but quite feasible. If your experience is not enough for this, use our advice or consult with a qualified specialist.

Disassembly of old batteries

The key is required to assemble and disassemble the cast iron battery.

To disassemble old cast-iron batteries, since the threads in them stick, they must be heated at the location of the nipple with an autogenous or blowtorch. Warming up is done in a circular motion at the location of the nipple, sequentially heating the parallel joints of the battery.

After heating the joints while they are hot, a radiator key is inserted inside and about half a turn is made, then the key is quickly moved to another nipple.

In the same way, stuck plugs and futors are turned out of cast-iron batteries.

Sometimes it is impossible to unscrew the nipple, due to the fact that corrosion completely ate its turnkey protrusions. In this case, the sections at the joints are cut with a hacksaw or grinder. Then, cut nipples are turned out of the sections by heating. After that, the thread is cleaned with a brush for metal.

If the old heating radiator cannot be untwisted by the above methods, then one thing remains - using a sledgehammer to break some of the sections.To do this, the battery is placed horizontally on the floor, and the middle part of the sections is hit with a sledgehammer until a through piece of the section breaks off. Then the battery is turned over to the other side and the other half of the section is broken.

After that, the cast-iron radiator is set in a vertical position and strikes the remaining pieces of the sections, then they are untwisted. However, when performing this operation, the heating radiator loses its tightness at other joints. And you can lose half the battery.

Dismantling and disassembling cast iron radiators is not an easy process, but sometimes it is necessary, so it is very useful to know how this operation is performed correctly.

Designs of heating radiators

If a heating element breaks down, especially during the cold season, it must be repaired or replaced immediately. Whether the radiator can be dismantled depends on the type of its design. Quite often, non-separable types of radiators are installed in apartments, which cannot be restored. In this case, it is better to immediately purchase a new battery. But there are also collapsible models that can be dismantled to replace a damaged element and installed back.

Products are divided into two main types:

- Sectional batteries assembled from several identical sections, securely interconnected. Each of them has a channel through which water circulates, and fins that radiate heat heat the room. Sectional batteries are the most popular because the cost of such radiators is lower. In the event of a breakdown, it is enough to replace only the damaged section, and if necessary, you can always add or remove ribs.

Sectional heating batteries

- Monolithic products are one solid structure that does not have separate sections. By external signs, these radiators may resemble sectional counterparts, but the differences between them are obvious. In monolithic devices, there are no connecting joints, due to which they are able to withstand more pressure. From this, the uptime of these structures is almost twice as long as that of sectional ones. But in the event of a leak, the monolithic device will have to be completely changed. In sectional products, it will be enough to replace the damaged element.

Bimetallic monolithic radiator

Do-it-yourself cast-iron radiator repair

Usually the place of leakage is determined without difficulty. If there are difficulties with the diagnosis, the radiator is removed, immersed in a bath of water and monitored for the appearance of air bubbles. The place from which they rise is not airtight. When the leaking area is determined, materials and tools should be prepared:

- thin metal cable;

- putty;

- a piece of cloth;

- a metal clamp or something that can replace it: electrical tape, wire, etc.

Work order

- Cover the floor with oilcloth, put a rag on top to absorb excess moisture.

- With a thin cable, clean the leaking section of the radiator to the metal, degrease with any solvent or gasoline.

- Seal up the leak. Apply the putty to a strip of fabric and wrap it tightly over the damaged area in several layers. If metal powder or epoxy resin is used as putty, then it is enough to make 2-3 layers. If zinc white - 4-5. Cold welding is also used as putty. It doesn't need fabric.

- Put a metal clamp on the putty, tighten with bolts and nuts. Make sure the connection is on the opposite side of the leak. If electrical tape is used instead of a clamp, wind it in several layers and secure with wire.

Repairing cast iron batteries is not difficult, does not require special knowledge and skills, but if there is doubt in your abilities or the leakage is really serious, it is better to contact specialists.It makes sense to replace old radiators that have leaked more than once, otherwise their repair will become a permanent occupation during each heating season.

Dismantling of bimetallic and aluminum sectional products

To disconnect the radiator from the system and remove it from its mounting location, you must do the following:

- Stop water circulation and relieve pressure.

- If the heating battery is hot, you need to wait until it cools down, and then disconnect it from the system. To do this, unscrew the couplings at the inlet and outlet.

- Move the coupling away from the radiator along the pipe and remove the device from the brackets.

- Drain the remaining water and place the product face up in the disassembly area.

- Pull out and rinse the filter immediately so that the dirt on it does not dry out.

Dismantling of bimetallic and aluminum sectional products

At the next stage, the radiator is disassembled into separate sections. To avoid damage during operation, you need to figure out which way to turn the nipple nut. This element is an annular nut with external threads and grooves inside on both sides. At the same time, one nut has right and left thread. If you unscrew it, then the adjacent sections of the battery will be evenly moved apart, and when twisted, they will be pulled together.

Usually, manufacturers make marks on the front of the plugs and futors, which indicate the direction of the thread. The "D" mark indicates a right-hand thread, "S" - a left-hand thread. To accurately determine the direction of movement, it is recommended to take a free nipple nut and try to screw it onto the threads in the radiator. Having decided in which direction it twists, it will become clear where to turn the key to separate the sections.

Important! If you turn the nipple-nut in the wrong direction, you can easily break the threads on it and on the radiator

Having decided on the direction of the thread, insert the nipple wrench into the radiator and advance to the desired nut. Notches on the tool will help to do this. When it is in the grooves, insert the lever into the hole on the other side of it. It will take some force to move the nut out of place. Call an assistant to fix the radiator in one place.

Repair of bimetallic radiators

When the nut has advanced half a turn, go to the other side to unscrew the second one and do the same. After making sure that both nuts rotate without applying great physical force, gradually unscrew one side or the other, moving 5-7 mm.

Gasket between radiator sections

After separation, take away the metal spacers that were between the sections. If they are in good condition, then they can be installed back during assembly, if in poor condition, then use them as a reference for buying new ones. Silicone gaskets need to be replaced.