Installation of the outer part of the pipe

The outer can be assembled from other materials. The transition of the "sandwich" of the pipe to the outer part is assembled taking into account the parts used. The main rule that must be observed is that each joint must be completely sealed. Smoke tends to seep into any gap, which is fraught with negative consequences.

If the combustion products are not completely removed outside the premises, this will negatively affect the health of all residents. Smoke will also negatively affect the condition of the house, exerting its destructive effect on all elements with which it will interact.

"Sandwich" on a brick pipe is one of the most common types of joints. This is not surprising, considering that such an external chimney has the best durability and is easy to design and build. The brick is well protected from destructive atmospheric action and is adapted to work with high temperatures. Now we are talking about heat-resistant brick, which is used in the construction of fireplaces, stoves and chimneys.

How to assemble a chimney

Search queries on how to assemble and how to install a "sandwich" pipe occupy a leading position on construction sites and forums. The people willingly join new technologies, and therefore seek to learn their essence. We live in an era where scientific discovery is made almost every day in almost every sector, in every industry, in every area of life. Therefore, people with conservative views are becoming less and less. The new generation is happy to master all the technologies being introduced, as they understand that they are designed to make a person's life even better.

Therefore, many professional builders maintain their own blogs, where they share their personal experiences. Often their words are supplied with visual photos and video tutorials that simplify the perception of information. So now any person with access to the Internet will be able to master almost all professions if they have the desire and free time. There is no need to overpay hired workers for installing a “sandwich” pipe if you can carry out this procedure yourself, without outside help.

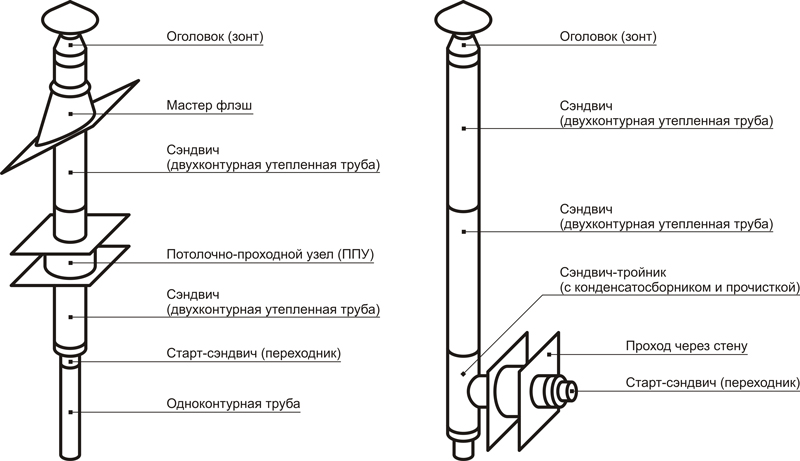

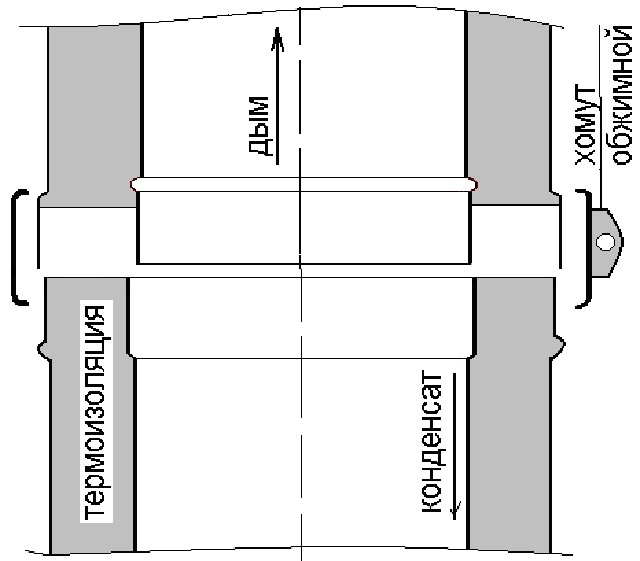

Fastening "sandwich" pipes is provided by their structure. Technologically, the parts are separate elements, each of which is inserted into the previous part to form a monolithic structure. All pipes are carefully matched to each other, so no additional materials are required for installation. The design turns out to be very durable and without external intervention, nothing threatens its integrity.

Between the pipes there is a layer of thermal insulation, which will minimize the exchange of the working part with the environment. Therefore, the design itself was called the American sandwich. Insulation allows you to easily carry out communications in wooden rooms, without fear that the walls will catch fire from high temperatures. The main element in the production of pipes is alloy steel or copper alloys. These parts are used in the internal chimney.

Do-it-yourself step-by-step connection technique

When the question is decided how to install a metal pipe with insulation with your own hands, the condition of the existing brick structure is assessed. If signs of destruction are visible, it is recommended to dismantle it. When it is planned to install a metal product according to the fitting method, it is necessary not only to disassemble the collapsing section of the chimney, but also to build a new structure after that.

Necessary tools and materials

For work you will need:

- perforator;

- chisel;

- sledgehammer;

- Circular Saw;

- refractory mixture;

- sealant;

- screwdriver;

- self-tapping screws;

- Master OK.

The installation rules are followed, and the components are selected taking into account the chosen mounting method.

Work progress

After the dismantling of the obsolete structure, a new brick superstructure is erected on the roof. To fix the steel product in the ceiling, a through-type pipe is used. The transition of a brick pipe into a sandwich is made using a sealing material. In this case, a reinforcing platform is used, it is fixed with self-tapping screws. To connect sections of a metal pipeline, special clamps are used.

Mounting Features

When it is planned to disassemble the chimney near the stove, in order to avoid overheating, a thick-walled stainless steel pipe should be used as the first link in the transitional structure. There should be no insulation inside. Installing a sandwich pipe can lead to through-burning of the metal.

To properly assemble the chimney, it is necessary to sequentially perform installation. In the process of completing the work, a cap is installed on top of the metal pipe. However, the deflector causes a lot of controversy regarding the installation of this element on top of the sandwich pipe. This measure enhances traction. However, an earlier version of the regulatory documentation mentions the prohibition of the use of such products when installed on chimneys. This is due to a decrease in the lumen of the pipe, the accelerated formation of a layer of soot on the structural elements.

How to install a sandwich pipe on a brick oven

To ensure a safe and high-quality transition, special adapters can be used. When choosing which, it is necessary to maintain the correspondence of their diameter (usually from 10 to 50 cm) with the cross section of the chimney, which is most often 13-26 cm.

Today the range of such solutions is presented:

- Single line adapters. Used to switch to a structure consisting of two circuits.

- Square transitions, which are installed on a brick pipe, and on the other side, with the help of a branch pipe, are attached to a sandwich pipe. A flange is put on the end of the square.

The advantages of this mounting method include:

- Improving traction;

- Tightness of the transition;

- Mobility;

- Overheat resistance.

If it is not possible to buy ready-made devices, you can make a quality transition from a brick chimney to a sandwich with your own hands, although this will require more effort and time.

Trading house "Elits" offers to mount the system according to the following instructions:

At the base of the oven, cut a round hole, half a brick deep.

Its diameter should be slightly larger than the inside of the sandwich pipe.

Iron pipes are placed in the sawn hole, gaps are filled with a special sealant on a brick oven.

The place of support of the outer part also needs to be treated with a special oven mixture.

Next, the components of the pipe must be fixed to each other and inserted into each other with a gap.

At the point where the pipe passes through the roofing materials, the system is fastened with stainless steel self-tapping screws.

It is important to ensure only plumb complete fixation. Regardless of which method of installing a sandwich pipe on a brick pipe you have chosen, our specialists will help you choose and purchase only high-quality and certified materials for the efficient operation of the system

Regardless of which method of installing a sandwich pipe on a brick pipe you have chosen, our specialists will help you choose and purchase only high-quality and certified materials for the efficient operation of the system.

Basic rules for installing chimneys

Before installing the chimney, it is recommended that you familiarize yourself with the following rules:

- the total height of the chimney from its junction with the heating equipment to the final element of the system, which is the head, must be more than 5 m. Otherwise, the chimney will not have enough natural draft to remove harmful substances formed as a result of combustion;

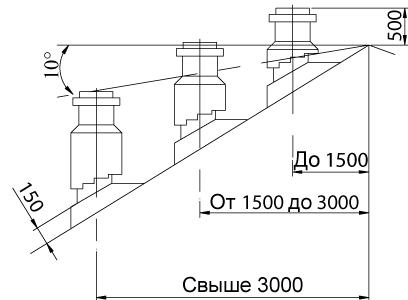

- the height of the chimney on the flat roof of the building must be at least 0.5 m.For other roofs and ways of placing a chimney on it, there is a specific diagram shown in the figure;

The layout of the chimney pipe on the roof of the building

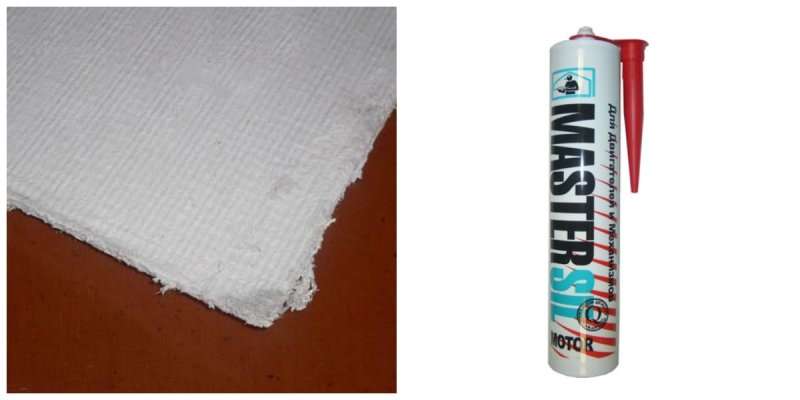

- when arranging the transitions of chimney pipes through the walls and roof of the building, all joints with the house must be insulated. For this, non-combustible materials are used that can withstand high temperatures. For example, asbestos sheets;

- before installing the chimney, you should determine the diameter of the pipe, the required length and shape. The diameter of the chimney depends on the power of the heater and is calculated based on the requirements of GOST. For 1 kW of power, it is recommended to use a pipe with a diameter of 8 cm²;

- correct installation of chimneys requires absolute tightness of all existing joints. Additional insulation at the joints can be given with a heat-resistant sealant.

High temperature protection materials: asbestos sheet and heat resistant sealant

All basic rules for installing a chimney must be observed. Otherwise, the system will not work properly, which may cause a fire.

When is a brick chimney needed?

If the stove in the bathhouse or house is built of brick, it would be logical to make the chimney well with brickwork. For large stoves in a house with a constant heat load, a brick chimney will be the simplest and most durable system for venting gas. Brick walls accumulate and retain heat well, which allows you to light the stove every 10-12 hours without any problems.

For gas-fired brick ovens, sauna stoves, and hobs, the brick chimney option is not mandatory.

For a sauna stove, it is important to ensure rapid heating with the possibility of slow afterburning of a wood-burning bookmark within 5-6 hours. A brick chimney is perfect for these purposes, but due to the heavy weight, a solid foundation will be required to a depth of at least 70-80 cm. Important! .In this case, the stability of heavy and high brickwork can be ensured if the upper part of the brick pipe is tied with stretch marks to the walls, the ceiling and the core on the roof. In some cases, the use of a brick pipe does not make sense at all

For example, for a small bathhouse made of wooden beams with a strip foundation for a stove and a brick chimney, most of the floor will need to be poured under the foundation, with a volume of at least two cubes of concrete with rubble filling. The walls of the house and the frame on the roof will simply not be able to hold the high and heavy structure of the chimney, without a meter foundation. For the brewing scheme, high temperature and smooth draft adjustment are more important.

Advantages and disadvantages of a sandwich pipe for a chimney

Private developers highlight the following advantages of stainless sandwich pipes for the removal of combustion products:

- the ability to easily and quickly install a chimney, without the involvement of stove specialists;

- small size;

- versatility of use (the product can be displayed through the roof or walls);

- the presence of several layers, which prevents the formation of condensate and the growth of soot;

- resistance to aggressive environments and extreme conditions (chemical components, high temperatures, etc.);

- resistance to possible fires;

- the possibility of installation, despite the truss system.

It was possible to achieve a wide list of advantages thanks to the special design of the pipe. It consists of:

- internal raincoat made of stainless steel with resistance to corrosive processes;

- outer casing;

- basalt thermal insulation pad.

The disadvantages are insignificant, such that are inherent in all diversion systems:

- high cost of construction;

- service life up to 15 years (but it should be borne in mind that the thicker the stainless steel layer, the longer the product will last);

- the risk of reducing the tightness of the system.

Sandwich pipes can be used in houses made of any building material, but most often it becomes necessary to equip the transition between a masonry pipe and a sandwich.

How to make a transition with a special adapter?

There are at least two ways to make the transition from a brick pipe to a sandwich. The first of them is associated with the presence of special adapters. Their main purpose is to provide the chimney with tightness at the junction.

There are two main types of adapters:

- square nozzles. They are superimposed on a brick pipe on one side, and on the other hand, they are connected through a special pipe;

- single-circuit adapter, which serves to ensure the transition to a double-circuit design. Its wide platform is attached to a brick opening, and the single-circuit element goes down.

This installation may create gaps. They must be closed so that the chimney is airtight. For this, compositions on a non-combustible basis are used.

Adapters mounted on the chimney are used to connect elements of different sizes and structures.

They are characterized by the following indicators:

- do not create obstacles to the removal of combustion products, this contributes to good chimney draft;

- have an optimal geometry to ensure a tight transition from brickwork to a sandwich pipe;

- some models can scroll 45˚;

- able to withstand short-term overheating without compromising the integrity of the structure.

The diameter of the adapters varies from 100 to 500 mm. When choosing an adapter between a brick and a sandwich pipe, it is necessary to focus on their cross section. For example, a chimney has a standard section of 130x260 mm.

How to choose and calculate a brick chimney

Before making a chimney, you will have to rack your brains and calculate the dimensions of the future channel, look at literature and projects, maybe look at neighbors or acquaintances - see their version of the chimney for the house and for the stove in the bath. No matter how smart advice or calculations are, there is nothing to replace practical experience.

The operation of the chimney of a stove for a bathhouse and a residential building are similar, but have specific differences. For a bath, a stove is built with the fastest possible acceleration of heat and warming up of the room; for a house, the economy of the stove and the ability to flare up in any weather are important. Before laying the chimney for the stove in the bath, you will need to carefully consider a few basic questions: Calculate the power of the furnace and determine the maximum and minimum height pipes, masonry exit from the brick on the roof; Determine the location of the chimney in the design of the bath room, prepare a place for the foundation and the node for passing the pipe through the ceiling and roof; Choose a chimney design with minimal resistance to the movement of hot gases

This option will allow you to quickly “disperse” even slightly damp firewood into the flame. Important! In addition, the chimney should be easy to maintain and clean the channel from soot

Therefore, it will be necessary to provide for an inspection entrance in the design, not less than the size of the chimney section. Most often it is installed at a level of 40-50 cm above the bundle - the junction of the furnace furnace with a free-standing chimney column. Such an entrance should be blocked by a special block - a brick plug, and hermetically closed with a metal hatch on screw fasteners. Properly made revision entrance has practically no effect on the level of traction, but makes it possible to clean the channel without much effort. At the same time, under the size of the revision, you can make a ruff for cleaning chimneys with your own hands.

How to make a transition using a steel platform with a spigot

This method combines the advantages of the two previous methods, as it allows you to equip a chimney without a special adapter, and get rid of the laborious filling of a brick opening.

Place of transition to a sandwich pipe

Installation includes the following steps:

- Cut out a platform from a metal plate so that its size matches the size of the brick part. It is better that the plate does not go beyond its edges. Mark the places where the platform will be attached to the brick opening. It is necessary to ensure that the fasteners are not located at the seams or at the edges of the brick. In the intended places of the sheet, you need to make holes for the screws, and in the brickwork - holes for the dowels. Insert the dowels into the holes made. a metal pad on a layer of sealant. Pull it evenly with the surface of the brick using self-tapping screws. After the sealant has dried, proceed with the installation of the air vent system from the sandwich pipe.

After installing a home-made adapter with a pipe, the installation of the system is carried out quickly, since the pipes fit well together through holes with a narrowed and expanded end.

Making the transition of a brick into a sandwich pipe

There are several ways to combine a rectangular brick chimney and a round sandwich pipe.

With a special adapter

Such parts are produced by some manufacturers. They are designed in such a way as to completely eliminate the leakage of smoke in the docking area. Adapters can have one of the following versions:

- Square nozzle with a round nozzle: the lower part of such an adapter must be installed on the end of the brick pipe, and the sandwich pipe must be attached to its nozzle on the other side.

- Square Flange Tube Insert: This adapter consists of two tubes welded to a square flange on both sides. One pipe has a rectangular cross section, the other is round. The rectangular part of the adapter is inserted into a brick pipe, so that the flange rests on its end. Now you need to screw it with dowels and install a sandwich chimney on the second part of the adapter (round).

Smoke can seep into the gap between the rectangular insert of the adapter and the brick walls of the chimney, so care must be taken to seal the pipe with asbestos cord or heat-resistant sealant.

Branded adapters have a number of advantages:

- They are made of high-quality acid and heat-resistant stainless steel, as a result of which they are very durable and can withstand severe overheating (short-term) without damage.

- They provide a smooth transition from a brick pipe to a sandwich, excluding resistance to flue gases and the appearance of turbulence in their flow.

- They have a design that allows you to easily and reliably seal the joint.

- They have an attractive appearance.

- They may have various useful options. So, for example, in some models, the nozzle can be rotated by 45 °.

The standard size range of sandwich adapters starts with a diameter of 100 mm and ends with a diameter of 500 mm, which is more than enough for domestic needs.

Fitting a brick pipe

It is possible to achieve a smooth transition of a brick into a round pipe without an adapter. Many users turn to this particular method, since finding a proprietary adapter turned out to be not easy. The essence of the technology is as follows:

- Having dismantled the pipe that has served its purpose, a short superstructure with a gradual narrowing is erected on its remains with refractory bricks. This add-on is an adapter, only the user makes it himself using a brick.It is necessary to narrow the pipe so that a special element of a sandwich chimney can be installed on it - the so-called mono-thermo transition or a lower nozzle, which is a base on which a barrel is assembled from individual sections of the pipe. To achieve a reduction in the external size of the brick pipe, the brick is installed on a spoon (long end), laying broken tiles if necessary.

- From the inside, the superstructure must be plastered - if there is a smooth surface, the resistance to the flow of gases will be minimal.

- A mono-thermo transition is installed on top of the brick superstructure, which, for stability and tightness, should be filled with a mixture of cement mortar and stones. To prevent loosening of the base, it must be additionally fixed with a clamp made of steel strip or rods.

For internal brick chimneys, it is often necessary to dismantle only the outer part, since the rest of the masonry located inside the house is in a satisfactory condition. In this case, the sandwich, due to its short length and low weight, can be installed without a mono-thermo transition.

//www.youtube.com/watch?v=ZUFeXlfm5cw

A part of the casing with thermal insulation is cut off from the sandwich, after which the inner pipe is simply inserted into the adapter superstructure on the brick chimney. In this case, the trimmed casing will rest on the brickwork. It remains to fill all the cracks with oven mortar or sealant.

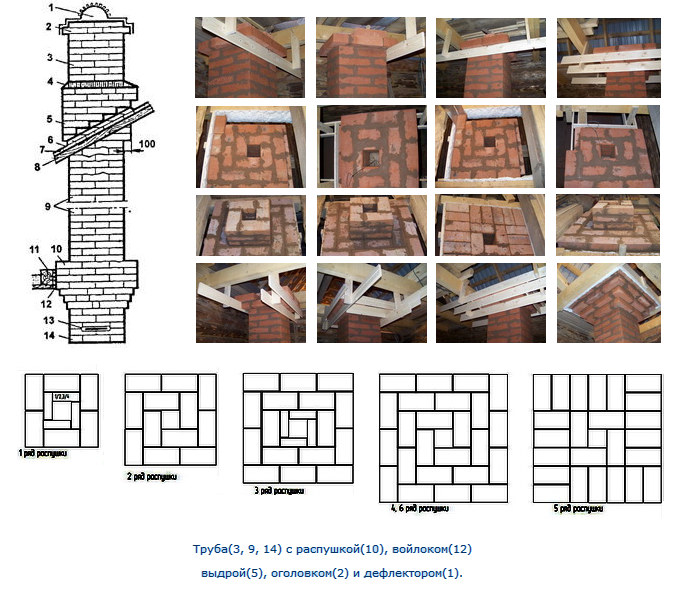

Features of a brick chimney

A properly installed brick chimney always has excellent draft. If the structure is erected in accordance with the rules, it serves for many years. Destroyed brickwork can block the path of escaping combustion products. To mount a new top, you need to purchase a sandwich pipe with a base of the same diameter as the metal pipe, a deflector and a roofing element to go with the roof.

But first, you should disassemble the old pipe (its upper part). Dismantling of chimney brick pipes is carried out taking into account the dimensions of the structure and its location. Professional repairers use circular saws, hammer drills, sledgehammers or hydraulic tools when disassembling the barrel. If a pipe is planned to fall, the angle of its inclination and the place of the fall should be calculated.

The main components of the chimney design are: foundation, trunk (part of the pipe to the roof), cap, tin collar (allows the gas exhaust channel to fit snugly against the roof), otter (part of the pipe extended by 10 cm), neck of the pipe (has the same size as chimney riser), head (a deflector is installed on it, protecting the structure from snow or rain).

The overhead part is laid out in a special way, installed directly on the furnace and contains a valve. It ends 5-6 rows before the overlap between floors. In the fluff zone, the trunk expands by 25-40 cm, however, the cross-sectional area should remain unchanged along the entire length of the structure.

The continuation of the main pipe is made of refractory bricks, and at the very top the chimney should narrow to the size of the base of the sandwich pipe.

The order of work is the following.

- A solution is applied to the surface of the bricks, masonry is performed. Then the horizontal and vertical planes are checked by level and suspension. Rectangular masonry is the simplest, the evenness of the masonry can be checked with a metal rectangle.

- The inner surface of the chimney is overwritten so that the joints are airtight.

- Refractory fireclay bricks are ideal for a chimney, they withstand high temperatures and are frost resistant. You can also replace it with a double silicate brick M 150.

- The plug is installed in the first rows of the chimney, the ventilation window is necessary for draft control.

- Closer to the roof, a window is made to clean the pipe from soot.

- A non-combustible material, such as mineral wool, is laid between the roof and the chimney.

Transition from a brick chimney to a metal one

In order to switch from a rectangular brick chimney to a round metal chimney, you will need a flat steel platform with a branch pipe, the diameter of which corresponds to the diameter of the steel pipe.

The external dimensions (perimeter) of a brick chimney are 500 x 370 mm.

I purchased a stainless steel platform measuring 500 x 500 mm., In the center of which there is a branch pipe with a diameter of 200 mm. (that is, with a cross section equal to that of a stainless steel pipe).

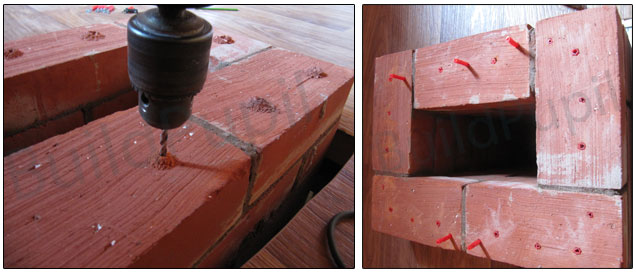

Now the platform with the pipe needs to be fixed somehow.

We will fix the site with dowels and screws.

|

The transition from a brick chimney to a metal one must be not only reliable, but also airtight, that is, there should be no gaps and cracks between the bricks and the stainless steel platform. To achieve the necessary tightness, we use a special sealant for fireplaces. I used TYTAN fire retardant silicate sealant for stoves and fireplaces. It is intended for long-term repairs, filling joints, cracks, gaps in fireplaces, stoves, furnaces, chimneys and is distinguished by: - good adhesion (adhesion of surfaces of dissimilar solid and / or liquid bodies) to many building materials: to metal, brick, concrete; – high temperature resistance – up to +1250°C and - does not crumble and does not crack after hardening, does not contain asbestos. In general, TYTAN fire-resistant silicate sealant is what we need in our case. |

Installation of a steel platform with a branch pipe |

|

Now let's take a look at the installation of a steel chimney in order ... What we have to do in order to move from a brick chimney to a metal one: We cut out the platform in such a way that it would correspond to the dimensions of the brick chimney: 500 x 370 mm. (or not exceed them). We estimate the places of attachment of the platform to the brick chimney. Be careful: the attachment points should not coincide with the masonry seam or fall into the edge of the brick. Now is the time to remind you that in order to strengthen and give strength to the masonry, I laid out the last two rows of a brick chimney on a complex one. After the attachment points of the steel platform with the pipe are determined, we drill holes in it for self-tapping screws, and in bricks we drill holes for dowels. We insert the dowels into the prepared holes. We install a metal platform on a brick base, on which we first apply a fire-resistant sealant. We evenly attract the platform with self-tapping screws around its entire perimeter. Although the site is well drawn with self-tapping screws (I used a lot of them), I decided to wait until the sealant dries. And only after that you can proceed directly to the installation of a chimney made of stainless steel pipes. |

Brief conclusion

The furnace in the house performs a number of important functions. The heating system must be cleaned of combustion products in time. A wide range of alternative elements of chimney systems is presented on the modern building materials market. Often the usual masonry is combined with lighter sandwich pipes.

In this case, it is important to connect the two elements hermetically using one of the transition methods, observing building codes and regulations. Do not forget about safety

Smoke streams must be freely removed from the system.