Forms of mineral wool thermal insulation materials

Almost any type of mineral wool can be produced in various forms, which compensates for the initial shortcomings of the material and makes its use convenient for certain purposes. The list of the most common ones is as follows:

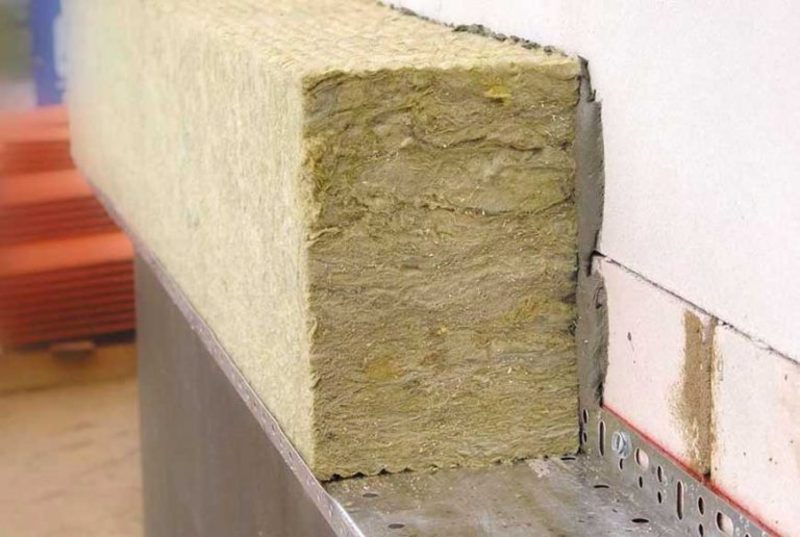

- Plates. Compressed mineral wool can be in the form of rigid plates, which are convenient to use as part of the currently popular sandwich insulation systems.

- Double layer boards. In this case, the first layer has a supporting function, giving additional rigidity to the material, while the second (inner) layer provides the main thermal insulation. Excellent for external insulation, especially in combination with decorative or heat-insulating plaster.

- Lamellar plates. A feature of this format is the perpendicular arrangement of the fibers relative to the surface plane. As a result, the heat-insulating properties are somewhat narrowed, but the material becomes more plastic, which allows it to be actively used for warming surfaces of complex shape.

- Laminated boards. On the one hand, such products are covered with a layer of polymer or fiberglass, which gives the material additional protection against destruction under the influence of air flows and condensate. Also often used in sandwich systems.

- Plates with a foil layer. A layer of foil, fixed with fiberglass mesh, acts as a vapor barrier, necessary for external insulation.

- Stitched mats. This flexible material is most often suitable for thermal insulation of attics and attics. Before use, rolls of tufted mats should be left flat for a while to return to their original shape.

- Mineral wool granules. Scraps formed during the production of one type of mineral wool can also serve as a good thermal insulation material. They find their application in specific blown insulation, which is implemented if it is not possible to dismantle the decorative wall decoration.

Additional modifications

When creating thermal insulation of inclined and vertical surfaces, a multilayer and rather complex system is performed, consisting of a windscreen, a moisture and vapor barrier.

Mineral wool with foil is great for preventing heat leakage as much as possible.

To facilitate the installation of this design will help special mats made of mineral fibers, which are equipped with additional layers, made according to the principle:

- laminating - fiberglass or polymer thin film prevents wind from blowing fibers out of the common layer;

- foiling - preventing moisture from entering the middle of the insulation, heat is retained in the room due to its reflection from the mirror surface;

- creating an external bituminous layer that acts as a waterproofing protection.

Mineral wool boards are versatile and multifunctional, thanks to which they have found a huge scope of use. Knowing the elementary features and technical parameters, you can independently choose a heat insulator for arranging a living space.

Mineral wool board is a heat-insulating material that is made from mineral wool and a synthetic binder. Minplate is resistant to high temperatures, and if it was made from natural rocks, they will begin to melt only after two hours of exposure to a temperature of a thousand degrees. In addition, the mineral wool board is resistant to most chemical aggressive substances: alkalis, oils, solvents. Slabs made of mineral wool (mineral wool) have different hardness and density.Another advantage is the high vapor permeability coefficient, which makes it possible for water vapor to freely penetrate. This helps to keep the material from forming moisture, which can lead to the spread of mold and various pests.

The advantages of a mineral wool board include the following: - Low moisture absorption - no more than 1.5%. - Complete incombustibility. — Ease and convenience of operation. The material does not need special fasteners, it is easy to cut and lay. - The fibrous structure provides elasticity and high strength to the material. - No deformation even under heavy loads. - Due to the fibrous structure, such a plate is a good sound insulator. This quality is very useful in industrial construction, as the soundproofing properties help to reduce the thickness of the installed insulation. — Durability. The material performs its functions up to 25 years. — Environmental friendliness. - High thermal insulation properties.

The use of mineral wool boards

Mineral wool boards differ in the degree of rigidity. So allocate soft, semi-rigid and rigid plates. In construction, semi-rigid and rigid are more often used: the former for thermal insulation of wall partitions, roofs and in multilayer systems, and the latter for thermal insulation of roofs, facades, floors. Soft plates are mainly used for thermal insulation of communications.

- Residential construction. Minplita is the most common insulation for the house, it is used to insulate all parts of the building, including the floor and basement. - Insulation of floors. - Insulation of interrafter spaces. - Thermal insulation of the facade. - Insulation of the roof and attic. - Insulation of water supply and heating equipment, as well as plumbing equipment and pipelines. - Industrial engineering.

This material can be used both on newly built houses and on those already in operation. Today, mineral wool boards are the safest, most environmentally friendly and effective heat and sound insulator.

Introduction to thermal conductivity

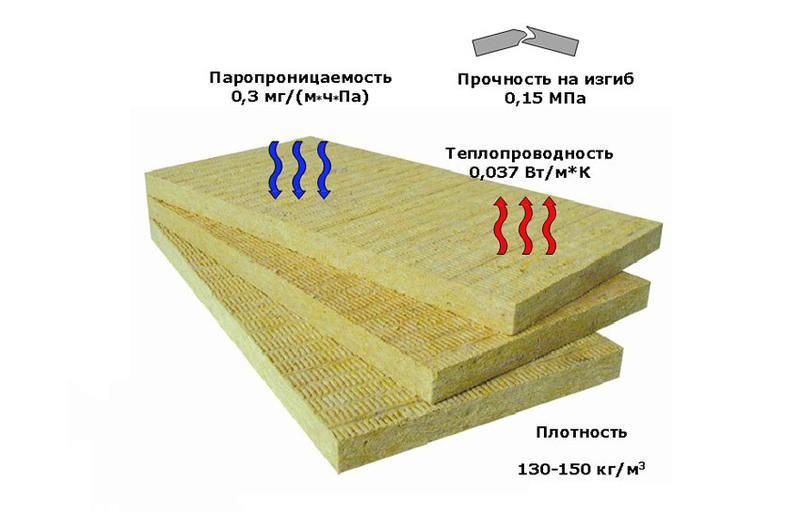

Sufficient insulation of slab mineral wool products, preventing heat leakage, is provided by a special fibrous structure. If we consider its specific indicators, then they depend on the purpose and type of material and vary from 0.036 to 0.042 W / (m * K). In this case, the temperature regime is represented by 10-25 ° C.

The value of fire resistance

One of the rare hallmarks of mineral wool is its resistance to fire. Used as an insulating layer for a living space, it will not ignite from an accidental spark or electrical wire short circuit. In the event of a fire, it prevents the spread of fire.

Due to its properties, mineral wool is used to insulate rooms where various flammable substances are stored.

If we consider special basalt-containing products, then they withstand the action of open fire (up to +1000 ° C) for several hours, but on condition that fillers based on synthetic combustible components were not used in the process of creating plates.

Density indicators

Rigidity is an important indicator of mineral wool boards, which, along with resistance to deformation changes against the background of external loads, depends on the density of the material. It is by density that it is customary to classify the described thermal insulation:

- solid slabs are represented by the brands PT-250, PT-220, PT-300, characterized by a value of 220-300 kg / m³;

- products with increased rigidity - grades PPZH-200, PPZH-180, PPZH-160, the strength index reaches 160-210 kg / m³;

- soft plates are presented with a density of 40-55 kg / m³, the most popular markings are PM-50, PM-40;

- rigid type plates - 100-150 kg / m³, the category includes the PZh-120, PZh-100, PZh-140 brands;

- semi-rigid devices for insulation - 60-90 kg / m³, marked PP-80, PP-70, PP-60.

Moisture and vapor permeability

Mineral wool is able to absorb excess moisture, as a result of which its properties regarding strength and durability deteriorate. But the replacement of liquid with air masses leads to a strong increase in thermal conductivity, so the operational properties of the plates deteriorate.

The best option is the use of special fillers at the production stage, which hydrophobize the final product. The current GOST indicates that the level of moisture resistance of mineral wool boards should vary within 4-7 pH.

As for vapor permeability, mineral wool has the highest indicator in comparison with other heaters - 480 × 10 −6 g / (m × hour × Pa). Insulating structures that do not have a vapor barrier (material for finishing external walls for plastering) or are equipped with a gas-permeable layer, optimally maintain normal gas exchange. As a result, a favorable microclimate is created inside the room.

Technical parameters and types

Mats made of mineral fibers differ in technical characteristics, which depend on the density of the product, the location of the fiber raw material and the quality of the raw material involved.

When choosing a heater, experts advise taking into account the specifics of the scope of application, comparing it with the properties of the required product.

As for the variety of mineral plates for the floor, ceiling and walls, it is represented by slag, glass wool and stone wool. It is worth dwelling on each option in more detail:

- Glass wool is the most affordable insulation in this series. The raw material is limestone, dolomite, soda, sand, borax. From all this, a fiber of 5-15 microns is produced, reaching a thickness of 15-50 mm. The permissible temperature range at which the material is allowed to be used varies from -60 to +450°C. Over time, glass wool can caking, which leads to a decrease in its heat-shielding function. In the process, this fragile material breaks, so it is imperative to use protective equipment. Preventing the entry of glass dust into the room is ensured by a special vapor barrier.

- Slag wool is distinguished by a low indicator of environmental safety, since it is produced from blast-furnace slag. Because of this feature, the insulation is not recommended for installation inside residential premises. The thickness of the fiber reaches 4-12 microns, its length is 16 mm.

- The basalt version of mineral wool as a heat insulator is considered the safest and most effective. The material does not crumble, does not penetrate into the indoor air, has high wear rates, is durable and fire resistant. If phenol-formaldehyde resins are not involved in the production process, basalt slabs can be called completely environmentally friendly. Their major drawback is their high price.

If we consider the structural feature of minplates, then they are distinguished by a chaotic or lamellar arrangement of fibers.

Building insulation IZOMIN

On the basis of basalt fiber obtained by melting rocks, a wide range of heat and sound insulating products is produced for use in various structural elements (roofs, partitions, walls, ceilings, etc.) of buildings and structures for various purposes. The quality of products fully complies with international standards. All ISOMIN products belong to the group of non-combustible materials and contain water-repellent additives. Products are packed in polyethylene film.

|

Product name |

Recommended area of application |

Density (kg/m3) |

Overall dimensions, mm) |

Thermal conductivity at 250C (W/m•K), no more |

Compressive strength at 10% linear deformation (kPa), not less than |

Water absorption at full immersion by volume (%), no more |

Content of organic substances by mass, (%), no more |

Humidity by weight (%), no more |

Peel-off strength of layers (kPa), not less than |

Vapor permeability (mg/m•h•Pa) |

Flammability class according to GOST 30244 |

|

Izomin Light |

As an unloaded heat and sound insulation of horizontal, vertical and inclined building enclosing structures of all types of buildings, including low-rise and cottage types of individual buildings. |

35 50 |

1000x500x50-200 1000x500x50-200 |

0.037 0.036 |

— — |

2,0 2,0 |

2,5 2,5 |

1,0 1,0 |

— — |

0,38 0,38 |

NG NG |

|

Izomin Caviti |

As an unloaded heat and sound insulation of horizontal, vertical and inclined building enclosing structures of all types of buildings, including for the installation of floors, ceilings, internal partitions. As a heater in lightweight frame-type enclosing structures. As an average heat-insulating layer in three-layer lightweight walls of low-rise buildings made of brick, expanded clay concrete, aerated concrete and other blocks. |

60 70 |

1000x500x50-200 1000x500x50-200 |

0,036 0,036 |

3,0 3,5 |

2,0 2,0 |

3,0 3,0 |

1,0 1,0 |

— — |

0,38 0,38 |

NG NG |

|

Izomin Venti |

On the outside of all types of buildings as a heat and sound insulating layer when installing facade structures with a ventilated gap. |

80 90 100 |

1000x500x50-200 1000x500x50-200 1000x500x50-200 |

0,035 0,035 0,035 |

6,0 17,5 20,0 |

1,5 1,5 1,5 |

3,5 3,5 3,5 |

1,0 1,0 1,0 |

2,5 5,0 5,5 |

0,37 0,37 0,37 |

NG NG NG |

|

Izomin Facade |

On the outside of all types of buildings as a heat and sound insulating layer, followed by plastering or applying a protective cover layer. |

150 160 175 |

1000x500x20-100 1000x500x20-100 1000x500x20-100 |

0,037 0,037 0,038 |

40,0 50,0 60,0 |

1,5 1,5 1,5 |

4,5 4,5 4,5 |

1,0 1,0 1,0 |

10,0 11,0 12,0 |

0,37 0,37 0,37 |

NG NG NG |

|

Izomin Ruf-N |

As a lower heat and sound insulating layer in multilayer coatings of flat roofs, including when laying on the surface without a cement screed. Izomin RUF-N boards are recommended to be used in combination with Izomin RUF-V boards. |

110 120 130 |

1000x500x40-150 1000x500x40-150 1000x500x40-150 |

0,035 0,035 0,036 |

24,0 28,0 33,0 |

1,5 1,5 1,5 |

3,5 4,0 4,0 |

1,0 1,0 1,0 |

5,5 6,0 6,5 |

0,37 0,37 0,37 |

NG NG NG |

|

Izomin Ruf |

As a heat and sound insulating layer in flat roof coverings, including when laying on the surface without a cement screed. |

140 150 160 |

1000x500x40-120 1000x500x40-120 1000x500x40-120 |

0,037 0,037 0,037 |

35,0 40,0 50,0 |

1,5 1,5 1,5 |

4,5 4,5 4,5 |

1,0 1,0 1,0 |

7,5 8,0 9,0 |

0,37 0,37 0,37 |

NG NG NG |

|

Izomin Ruf-V |

As an upper heat and sound insulating layer in multilayer coatings of flat roofs, including when laying on the surface without a cement screed. Izomin RUF-V boards are recommended to be used in combination with Izomin RUF-N boards. |

180 190 200 |

1000x500x30-60 1000x500x30-60 1000x500x30-60 |

0,038 0,038 0,038 |

62,0 65,0 70,0 |

1,5 1,5 1,5 |

4,5 4,5 4,5 |

1,0 1,0 1,0 |

10,0 11,0 12,0 |

0,37 0,37 0,37 |

NG NG NG |

By agreement with the customer, it is possible to manufacture products of non-standard sizes, in the range of length up to 2000mm and width up to 1000mm.

Comparative technical characteristics of the mineral plate

Today, a large number of reliable heat-shielding materials are produced. The table shows the specifications of three common new generation insulators:

- synthetic polymer foam boards;

- expanded polystyrene;

- mineral slabs for wall (facade) insulation "Izover".

| Indicators and Materials | Polyfoam PSB-S 15 | Expanded polystyrene boards Technoplex | Minplate facade Isover |

| Density, kg/m3 | 8-10 | 28-35 | 34-165 |

| Compressive strength, kPa | 500 | 250 | 45 |

| Bending strength, MPa | 0,07 | 0,3-0,7 | — |

| Tensile strength, kPa | — | — | 4-15 |

| Thermal conductivity, W / m * K | 0,037 | 0,029 | 0,037-0,053 |

| Water absorption for 24 hours, kg/m2 | 0,01 | 0,2 | 1 |

| combustibility | G3 | G4 | incombustible |

| Additionally:average price per m2 | 34-84 | 198 | 140 |

A comparative analysis shows that, with similar performance, mineral insulation is fire resistant, differs in variability in density, has a better ability to compress, which is useful in packaging and transportation. The price of a mini-plate (50 mm) Izover is preferable to the cost of an innovative polystyrene foam Technoplex. The disadvantages include relatively high water absorption and a large mass.

Which manufacturer to choose?

Izover trademark heaters are distinguished by innovative technologies for the manufacture of harmless, dust-free cotton wool, combining softness, elasticity and strength. The company is the world leader in terms of output and the only manufacturer of mineral wool boards represented in the Russian Federation.

Minplates "Ursa" (a brand of the Spanish concern Uralita, which has 3 production sites in Russia) - this is the versatility of use and the best performance: external and internal insulation of them is easy to install / dismantle; safety and durability. The structure of staple (cut) fiber conglomerates gives heat-insulating layers of Ursa mineral wool special chemical and physical properties:

- low specific gravity;

- stability of strength indicators;

- surface plasticity.

The Danish company "Rockwool" (literally, stone wool) is the oldest manufacturer of basalt wool (since 1937). Today, these are more than 20 high-tech enterprises in 15 countries that produce mineral plates for any structures erected in residential and industrial construction.

Unlike fiberglass materials, Rockwool mineral basalt slab is a three-dimensional canvas formed from randomly entangled fibers with numerous thread crossing points. This structure gives the material strength and stability with considerable flexibility.

Price

The average prices of the above brands are presented in the table:

| Name | Application | Dimensions, mm | Price per m2, rubles | ||

| Length | Width | Thickness | |||

| Izover (stone fiber) | |||||

| Isover Optimal | Unloaded surfaces | 1000 | 500 | 100 | 199,58 |

| Izover Venti | Hinged facades | 1200 | 600 | 100 | 398,36 |

| Izover Facade | Facades for plaster | 1200 | 600 | 100 | 654,05 |

| Izover Ruf N Optimal | 1200 | 600 | 100 | 420,53 | |

| Ursa Geo (fiberglass) | |||||

| Ursa Geo Frame | Frame structures | 1000 | 600 | 50 | 152,00 |

| Ursa Geo P-15 | Floors, partitions | 1250 | 600 | 50 | 70,00 |

| Ursa Geo (universal) | Walls, for private housing construction | 1000 | 600 | 50 | 66,50 |

| Rockwool Mineral Slab | |||||

| Facade Butts | External walls, under plaster | 1000 | 600 | 50 | 343,75 |

| Light Butts Scandic | Universal thermal insulation | 1200 | 600 | 100 | 161,81 |

| Acoustic Butts | Soundproofing internal | 1000 | 600 | 50 | 111,50 |

The capabilities of the leading factories allow us to produce a wide range of standard sizes in a compact package that is convenient for transportation.

The cost of materials exceeds all other costs in the amount of financial costs for insulation. However, the dependence of the total cost on the type of installation work should be taken into account. Spraying liquid foam per unit area, for example, costs 1200 rubles. Convenience and relative cheapness of installation of minplates - from 80 rubles / m2 (floor soundproofing) to 300 rubles / m2 (roof protection) - makes their use the most effective.

Basic properties

When choosing an insulating material for wall, floor, ceiling and roof surfaces, its thermal insulation performance should be taken into account.

Equally important is the class of fire resistance, vapor permeability, resistance to moisture. In all these respects, mineral wool is superior to many competing materials, and it also belongs to the budget category.

In all these respects, mineral wool is superior to many competing materials, and it also belongs to the budget category.

When choosing a heater from mineral wool boards, it is necessary to understand the main criteria by which its suitability for use in certain conditions is assessed. The fibers of the material have a number of advantages:

high strength, the indicator of which is affected by the density of the plate;

insignificant mass, which is very important in order to avoid overloading the created structure;

prevention of decay processes and the formation of fungi;

repelling small pests;

resistance to ignition;

service life up to 50 years.

The correct meaning of the markings

Current standards and regulations require the separation of mineral wool boards. Their subspecies are marked with the corresponding marks:

- Insulation P-150 is applicable as sound and heat insulation of the roof, has a high rate of fire resistance. The compression ratio parameter is 2%, strength - 0.01 MPa or more, density - 150 kg / m³.

- The value of PP-125 marks plates of a semi-rigid type. Their main purpose is to isolate attic structures and pitched roofs. The material has a density of 125 kg / m³ and a compression of 12%, while the thermal conductivity is 0.049 W / mK.

- Rigid heat insulator plates are represented by the PZh-200, PZh-175 brands. The maximum allowable load reaches 175 and 200 kg / m³, making the material suitable for arranging flat roofs, which are subjected to strong deformation loads.

When purchasing mineral wool, pay attention to its marking - the thickness, density of the material depends on it

Do-it-yourself house facade decor ideas

Making the facade of the house is an individual task for each owner. Someone will stop at traditional plaster or frame framing. The more progressive part will use design solutions for decorating with stucco. Currently, facades of houses with a bay window are in demand.

A bay window is a part of the facade that protrudes beyond the plane of the wall, fully or partially glazed. To decorate such a part of the building, stucco molding is used, which frames the entire perimeter of the glazing. Under the bay window, you can install two decorative consoles, it will turn out like a box in a theater.

Everyone can find a way to decorate the facade of the house with their own hands. To do this, you can use catalogs in magazines or specialized sites on the Internet.

Benefits of slab insulation

The characteristics of rigid mineral wool boards indicate their excellent operating properties. Due to the separate structure, the shape is well maintained, and the product itself, if necessary, is easily processed (cutting, drilling).

If we talk about the external arrangement of the roof, then mineral wool heat-insulating rigid slabs on a synthetic binder are mounted on a pre-prepared plane using special fasteners or fixing glue. Mineral wool is fastened on street walls under plaster with special devices equipped with umbrella hats. An indisputable plus of the described non-combustible heat insulator lies in its affordable cost.

Areas of use

During the production of mineral wool, blast-furnace slags, glass, rocks of volcanic origin are used. From the prepared melt, processed in special centrifuges, fibers are made, which are then mixed with synthetic-based binders. The mass obtained in this way is formed into plates that are convenient for use, differing in such parameters as rigidity, density, and overall dimensions.

The resulting material based on mineral fibers is suitable for providing reliable sound and heat insulation:

- panels of three-layer type, roof structures;

- floors;

- ceilings;

- pitched or flat roofs;

- floor coverings;

- partitions;

- load-bearing solid walls;

- three-layer special walls built from blocks, inside of which mineral wool is placed.