Advantages and disadvantages

Advantages:

- Resistant to prolonged exposure to gas.

- The service life is about 100 years if the pipeline is not overloaded.

- High rate of flexibility. Thanks to this, it is possible to manufacture lines of complex configuration.

- Low weight of individual elements.

- On the smooth walls of the product does not accumulate sediment.

- The material is not susceptible to rust.

Flaws:

- Not resistant to high temperatures.

- It is impossible to install plastic pipelines on the street, since the material loses its technical characteristics in the cold.

- When heated, the material expands. Because of this, in order to increase the strength of the joints, individual sections of the pipeline need to install expansion joints.

- Low UV resistance.

If the pipeline is not overloaded, it will not break and will withstand decades of active operation.

Regulatory documents conditions and requirements for the pipeline

The norms determine the laying of any pipeline, regardless of what material it is made of. Many technical points are regulated in the so-called SNiPs.

Watch the video

They provide safety, allow you to carry out any work with high quality. Here are a number of requirements that must be met for laying in the ground.

- Accounting is required for the point at which the soil freezes through. Its level is often equal to 1.4 meters. In winter, the water inside the plumbing will simply freeze if it is lower. The operation of the water supply will become impossible.

- Laying and its method will vary depending on what structures and structures are already present on the territory. And from the presence of highways, communication networks, routes. It is better to contact specialized firms if you are not completely sure about where to carry out the installation.

- Features of the soil and relief are important for those who lay the water supply underground.

Do-it-yourself rules for laying in the ground

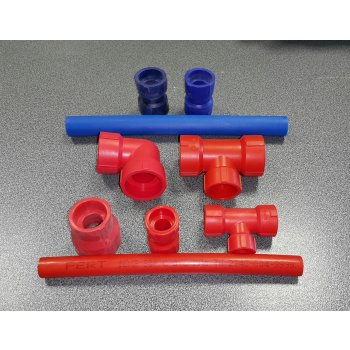

GOST says that for laying in the ground, pipes must have a diameter of at least 32 millimeters. For convenient and quick installation, a set of fittings is purchased.

Watch the video

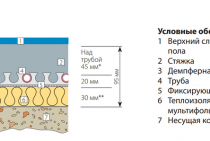

- First, a trench is dug in the ground. The regulations indicate that the depth of the trenches should exceed the level of soil freezing. It is better to use special tables to determine the level of freezing specifically for your region. 0.5 meters - the optimal width for the seam.

- We seal the trench - the bottom and also the walls.

- Create a pillow that gives cushioning. For it, it is enough to pour a layer, for example, sand gravel or sand, from about 10 - 15 cm.

- It is obligatory to wind the water pipe with a heat-insulating layer. Then the products are laid in a ditch, and connected using fittings.

- The pipeline is filled with sand. The main thing is that the highest point is 5 centimeters higher than the pipeline itself.

- We cover the place where the water supply is located with tiles. In the same case, broken bricks with tiles will become indispensable helpers.

- We fill the trench with earth. It is easy to understand that installing polypropylene pipes into the ground is not such a difficult process.

Advantages of using polypropylene pipes

Polypropylene pipes are optimal when laying sewer systems for summer cottages, supplying water for domestic needs, watering a garden, and greenhouses.

The use of polypropylene pipes today is justified in many areas, from plumbing to sewage. Among the advantages of using such pipes are:

- resistance to corrosion, various mechanical influences;

- ease of installation (by trench method), which does not take much time;

- the possibility of using polypropylene pipes for supplying drinking water;

- reliability and durability.

Such pipes are optimal for laying sewer systems for summer cottages, supplying water for domestic needs, watering a garden, and greenhouses. In this case, all work is carried out quickly, the pipes themselves do not need complex and expensive maintenance.

Specifications

The technical characteristics of the material determine the scope of its application. In the manufacture of a gas pipeline, you can use different types of plastic pipes. Each of them has its own technical characteristics.

Parameters of metal-plastic:

- High chemical resistance.

- The material is not subject to oxidation.

- The maximum coolant temperature is up to 95 degrees.

- The maximum allowable pressure is up to 25 bar. If the temperature is high, the allowable pressure is reduced to 10 bar.

- The thickness of the metal layer, between the plastic - up to 0.3 mm.

Polyethylene characteristics:

- the outer diameter of the tubes is 10–110 mm;

- maximum coolant temperature - up to 95 degrees;

- at high temperatures, the maximum pressure is up to 10 bar.

Polypropylene parameters:

- maximum coolant temperature - 90 degrees;

- allowable pressure at maximum temperature - up to 10 bar.

Polypropylene pipes can withstand short-term overheating up to 110 degrees.

Diameter of plastic pipes

Independent search for pipes underground

Of great importance is the material from which the desired elements are made. Not only how to find water pipes in the ground depends on this, but also what to look for, and what to do.

Technologies vary, and a modern method of independently searching for underground utilities can be aimed at determining the location:

- Metal plumbing for hot and cold water.

- Steel heating "T" in the collectors.

- Power cables and wires of communication systems.

- Cast iron sewer lines.

- Plastic, polyethylene, polypropylene pipelines;

- Metal-plastic and ceramic technical means of provision and removal.

To fully probe an unfamiliar area for the presence of underground routes, all methods are used. In this case, the choice of technique depends on the depth of laying, and on the actual working pressure of the liquid inside the pipeline.

Metal detector application

If the pipe was laid at a depth of up to one and a half meters, it can be detected using metal detectors (professional, semi-professional or amateur). At the same time, the presence of insulation and waterproofing on the “T” does not interfere with the procedure.

The price of equipment can reach up to 130 thousand rubles. This means that for a one-time use, its purchase is impractical. Cheap models cost up to 6 thousand, but they are less effective.

Is it possible to use polypropylene pipes for gas

In Western countries, metal pipes are used only for the assembly of industrial pipelines. In the manufacture of water and gas supply systems, plastic elements are used. This is due to the performance characteristics of the material. Gas passes through the plastic pipe without any difficulty. Before the gas pipeline is put into operation, it is necessary to check the tightness of the connections of individual elements in order to prevent violation of the integrity of the system.

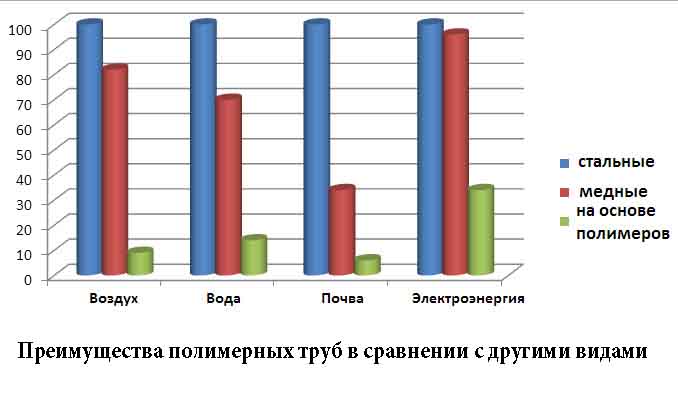

To figure out which is better - a pipeline made of metal or plastic, you can compare these two materials. Differences:

- Weight - plastic pipes weigh less than metal parts. Due to this, they are easier to mount, they do not require additional fastenings on vertical surfaces.

- Versatility - there are more factors to consider when choosing metal pipes than when using plastic parts.

- Price - tubes made of polymers are cheaper than metal ones.

Metal tubes outperform plastic tubes in terms of strength, durability, resistance to mechanical stress.

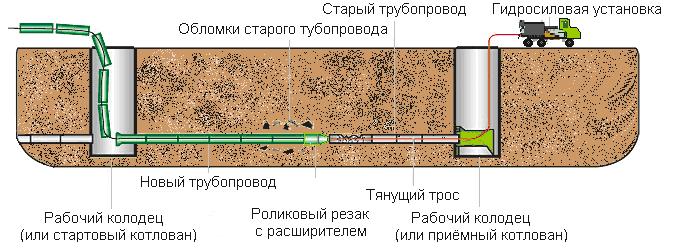

Trenchless laying methods

One of the promising methods for laying polypropylene pipes is trenchless installation, which has the following advantages:

- reduction of time and financial costs;

- minimizing harm to the environment;

- there is no need to dig trenches during laying, destroy green spaces, destroy the asphalt pavement.

Today, the following methods are used:

Renovation is a technology in which the old pipe is destroyed simultaneously with the laying of a new one. It is used only when the bandwidth is no longer enough.

- Sanitation, that is, the replacement of old pipes with new ones. There are two ways to do the job:

- relining, which involves pulling a new polypropylene pipe into the old ones, but here a preliminary inspection of the condition of the already standing pipe is required. It is necessary to make sure that there are no foreign objects, debris in it, the diameter of the old pipeline must be sufficient for laying a new one;

- renovation is a technology in which the old pipe is destroyed simultaneously with the laying of a new one. It is used only when the bandwidth is no longer enough.

- Piercing is used when laying polypropylene pipes with a diameter of up to 150 mm. This work is carried out in several stages:

- first, two pits are dug along both parts of the route;

- then a hydraulic jack is placed in one of them, pushing a small steel pipe with a steel tip;

- when pushing, the pipe grows, a polypropylene pipe is inserted into its cavity;

- after the puncture, the pipeline is connected to the necessary systems.

Using this method, it is possible to lay polypropylene pipes only for small sections, the method works great if it is necessary to lay under a house, highway, garden, etc.

Polypropylene pipes for the installation of pipelines are used in many areas, ranging from simple communications for summer cottages and ending with a sewer or water supply network. Today, two methods of laying pipelines are used, but underground is considered the most optimal, which allows you not to touch above-ground structures, not to spoil the landscape.

Laying in the ground has many advantages, despite the need for digging a pit. This allows you to keep them intact, out of the reach of ultraviolet rays, mechanical damage is also minimized.

Because You are not logged in. To come in.

Because The topic is archived.

How to deal with insulation

For this, for example, special cases are used. The existing water supply is laid inside another pipe, with a small diameter. This contributes to the formation of an air cushion between the walls of different products. This keeps the heat in the water.

Or the pipeline is simply poured using polystyrene concrete or foam concrete. This is a monolithic layer, with a base in the form of concrete with a low weight and a porous structure.

Plumbing is sometimes wrapped with insulation. Or heating cable. The latter is laid both inside and outside the structure. Laying is recommended in two available ways:

- Two lines parallel to each other.

- Spiral around the plumbing.

Not every system is designed in such a way that it builds pressure without problems. But this method of protection is able to boast of efficiency.

When high pressure is maintained inside, the liquid does not freeze. Even if there is no physical thermal insulation.

When installing external non-pressure types of sewage, the so-called socket connection is used. The main thing is the absence of pollution on the plastic, then the connections will acquire high tightness.Silicone or liquid soap lubricates parts that require connection.

Sealant treatment will provide additional protection during work such as laying water pipes from polypropylene pipes in the ground.

Only compliance with all requirements and technologies will allow you to get a water supply system that will function for a long time. And it will help reduce operating costs.

Installing filters

If there is no scale or sand in the water, then elements such as fittings on toilet bowls, automatic washing machines, and ceramic faucets live much longer.

Do not give preference to filters that are disassembled manually. Inside such structures are rubber seals, whose durability leaves much to be desired.

The preparation process depends on which type of pipes you have chosen. If it is galvanized, then we use a grinder to cut the blanks of the sizes we need with our own hands. You can also do this with a hacksaw.

It is more convenient to cut metal-plastic or polypropylene products immediately in place. Even small misses in size will not be terrible.

When connecting, preference is given to two methods. For example, through a collector, which plays the role of wiring for individual devices, when each of them has its own fittings. Or through a simple tee.

We work with steel products

With the appropriate tools at hand, such as welding, for example, it is used to connect a metal structure.

It is easy to use for welding threads. Or bends that were bent on a special machine, the so-called pipe bender.

You can use dies or holders and do the work manually. Threaded connections are made in the same way as in the case of valves.

About metal-plastic pipes

In this case, the connection is made using fittings, which are supplied with union nuts. After cutting off the pipe section, proceed to chamfering from the inside, using a knife. The union nut is put on the pipe together with the split ring.

Watch the video

We place the fitting from the fitting inside the pipe

The main thing is to proceed carefully, otherwise the rings with sealing characteristics will shift. The nut is tightened just as carefully, without sudden movements.

Products with a polypropylene base

To do the job, it will be enough to purchase an inexpensive soldering iron. Heat is applied to the inner fitting surface by selecting the desired nozzle.

We do the same with the end where the polypropylene pipe is located. We insert one part into another, wait until everything cools down.

Conditions for conducting according to regulatory documents

The laying of any pipeline, whether it be polypropylene or steel, is determined by the standards. It is SNiP that regulate many technical issues that allow you to perform all work efficiently, ensuring safety. For laying polypropylene pipes, the following requirements must be met:

Scheme of the advantages of polypropylene pipes over other materials

- Be sure to take into account the freezing point of the soil. Usually it is at a level of 1.4 meters, so if the pipeline is at a lower level, then in winter the water in it will simply freeze, and it will not be possible to use the pipe. Therefore, during installation, it is necessary to accurately calculate such moments, in the future it will only benefit.

- The laying of pipes largely depends on what buildings are located on the site, whether there are roads and highways nearby, laid communication and other engineering networks. If you are not sure where exactly you can lay the pipeline, it is better to contact specialized construction companies.

- When laying underground, we also take into account the features of the relief, soil, in some cases it is necessary to protect the pipe with the help of special casings.

A polypropylene pipeline is laid subject to the following steps:

- To begin with, you will have to prepare a trench for laying, which should be larger than the diameter of the pipe. So, for 110 mm pipes, you will need a trench with a width of 600 mm. The minimum distance between the pipe wall and the trench should be 20 cm. The depth should be 50 cm more.

- The bottom is sprinkled with sand with a cushion thickness of approximately 50-100 mm, after which the sand is compacted.

- The laying starts from the building; when installing sewer pipes, the socket should look at the end of the pipe that goes out;

- To connect the individual elements, a special lubricant is used.

- When laying sewers, it must be remembered that a slope of 2 cm must be observed for each m of the route.

- After laying the pipeline is covered with sand, it is compacted only from the sides. If necessary, before this, the pipe is wrapped with a heat-insulating layer;

- At the very end, polypropylene pipes are connected to a common highway, a treatment plant, and so on. This should be done using polypropylene solder.

What problems can arise during installation?

When laying polypropylene pipes underground, some problems may arise:

- the structure of the soil does not allow digging at the required depth;

- in winter, the soil freezes heavily, which can cause damage to pipes;

- There is a building on the site that cannot be bypassed.

In this case, there are several ways to solve these problems:

- If the soil is too loose or hard, it is recommended to make a puncture, in which a steel pipe is first laid, and a polypropylene pipeline is already inserted into its cavity.

- When the soil freezes, it is recommended to lay a heating cable throughout the entire route. This requires significant costs, the costs during the winter period may be higher than planned, but in any case, this option is cheaper than the constant repair of burst pipes.

- When there is a building or object on the route that cannot be damaged, it is recommended to perform trenchless laying methods, that is, a puncture. In this case, it is possible not only to lay the pipeline, but also to protect it with a steel casing. When laying such networks, it is necessary to carefully look at the layout of communications on the site so as not to damage the existing ones.