Dimensions of sauna stoves

In order for the bath to be well heated, it is necessary to correctly calculate the dimensions of the furnace for it.

Before doing this, you need to pay attention to what material the firebox will be made of. This factor directly affects the method for determining the dimensions of the furnace.

metal

Various metal swords are currently available on the market. Most often they are made of steel or cast iron. They can be designed for fuels such as wood, gas or electricity.

At the moment, there are steel and cast iron stoves for steam rooms, differing in the following dimensions (in mm):

- "Anapa" from "EasySteam": 420x730x800.

- "Angara 2012" from "Termofor": 415x595x800.

- "Vesuvius Russian Steam" from "Vesuvius": 660x860x1120.

- "Hephaestus ZK" from "Hephaestus": 500x855x700.

- Zhikhorka from Zhar-Gorynych: 450x450x1300.

- "Emelyanych" from "Teplostal": 500x600x950.

- "Kalita Russian Steam" from "Magnum": 650x800x1100.

- "Classic Steam" from "Feringer": 480x810x800.

- "Kuban" from "Teplodar": 500x700x865.

- "Kutkin 1.0" from "Kutkin": 460x450x900.

- "Slavyanka Russian Steam" from "Svarozhich": 480x570x900.

- "Khangar" from "Teklar": 440x670x800.

In addition to the above popular models of stoves, there are others. This also applies to electric heaters. Depending on the manufacturer, the latter can have completely different sizes. That is why the buyer can easily choose for his steam room exactly the device that best suits him.

from brick

In order to determine the dimensions of brick ovens for a bath, it is necessary first of all to pay attention to the dimensions of the brick itself, such as:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

It is from bricks of standard sizes that stoves for baths are most often made. In this case, the inner core of the heating structure is protected by the so-called fireclay layer.

Having information about the dimensions of the material from which the furnace is created, you can easily find out the width and length of the structure, if there is an order

First of all, you should pay attention to the first row of bricks, which will clearly show the number of units of structural elements on each side. In order to calculate the future height of the furnace, it is enough just to multiply the number of rows by the height of the brick and take into account 0.5 cm of each seam

Thus, the calculation of the dimensions of a brick furnace takes no more than a few minutes of free time.

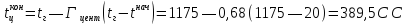

Metal heating time

Temperature

flue gases leaving the furnace

equal

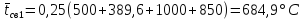

;

temperature

kilns in the holding zone at 50℃

above the heating temperature of the metal, i.e.

1300°WITH.

Temperature distribution along the length of the furnace

shown in Fig.62.

Insofar as

the main purpose of the methodological

zone is slow heating

metal to a state of plasticity,

then the temperature at the center of the metal at

transition from methodical to welding

zone should be of the order of 400-500 °C.

Difference

temperatures between the surface and the middle

blanks for the methodical zone of furnaces

rolling production can be accepted

equal to (700-800) S,

where

S

- heated (calculated) thickness. V

in this case bilateral

heating

m

and hence

,

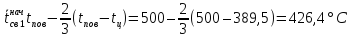

i.e. you should take the temperature

slab surface at the end of the methodical

zone equal to 500 °C.

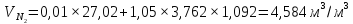

Let's define

approximate dimensions of the furnace. At

single-row arrangement of blanks

oven width will be

Here

—

gaps between slabs and furnace walls.

V

recommended height

furnaces are taken equal: in the languid

zone 1.65 m, in the welding zone 2.8 m, in

methodical zone 1.6 m.

We find

masonry development degree (per 1 m of length

ovens) for:

methodical

zones

;

welding

zones

;

lingering

zones

.

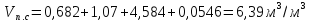

Let's define

effective beam length, m:

methodical

zone

welding

zone

lingering

zone

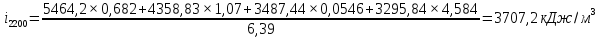

Definition

heating time of the metal in the methodical

zone

We find

flue gas emissivity

at medium temperature

partial

pressure

equals:

By

nomograms in Fig. 13-15 we find

;

;

.

Then

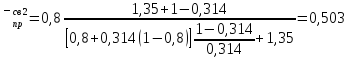

Reduced

emissivity of the system under consideration

is equal to

degree

the blackness of the metal is taken equal to

.

Average

along the length of the methodical zone coefficient

heat transfer by radiation is determined by

formula (67, b)

We define

temperature criterion Ɵ and criterion

Bi:

For

carbon steel with medium weight

metal temperature

on

Appendix IX we find

and

By

found values of Ɵ and Bi

on

nomograms in Fig. 22 for surface

plates, we find the Fourier criterion

.

Then

heating time of the metal in the methodical

furnace zone is equal to

We find

slab center temperature at the end

methodical zone. According to the nomogram

in fig. 24 for insert center at

and temperature

criterion.

Now it's easy to find the temperature of the center

slab

Definition

metal heating time in I welding

zone

Let's find

flue gas emissivity at:

By

nomograms in Fig. 13-15 we find

;

;

Then

.

We take the surface temperature

metal at the end of I welding zone 1000°C.

Reduced

degree of emissivity I of the welding zone is equal to

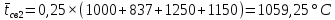

We find

cross-sectional average temperature of the metal

at the beginning of I welding (at the end of methodical)

zones

We find

temperature criterion for the surface

slabs

So

as at the average temperature of the metal

annex IX thermal conductivity

carbon steel is

,

and the coefficient of thermal diffusivity, then

At

determination of the average temperature of the metal

in welding zone I, it was assumed that

temperature at the center of the slab at the end

zone is 850 °C. Now according to the nomogram

in fig. 22 find the Fourier criterion

.

Time

heating in I welding zone

We define

temperature in the center of the slab at the end I

welding zone. According to the nomogram in Fig.

24

at values

and

find

meaning

,

with which we determine

Definition

heating time

metal in

II

welding zone

We find

degree of emissivity of flue gases at.

By

nomograms in Fig. 13-15 we find

;

and

Now

Reduced

degree of emissivity II of the welding zone is equal to

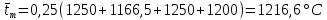

Medium

metal temperature at the beginning of II welding

zones

is equal to

Temperature

criterion for the surface of the slabs at the end

II welding zone is equal to

At

average metal temperature in the zone

(Appendix

IX).

Then

Now

according to the nomogram in Fig. 22 find FO

= l,l.

Time

metal heating in welding zone II

equals

Temperature

slab center at the end of welding zone II

determined by the nomogram in Fig. 24 at

values

ai

.

Then

Definition

metal languishing time

drop

temperatures across the thickness of the metal at the beginning

lingering zone is

.

Permissible temperature difference in

end of heating is

Degree

temperature equalization is

At

coefficient of asymmetry of heating,

equal to

criterion

for

lingering zone according to the nomogram

in fig. 19 (curve 3) is

.

At

the average temperature of the metal in the holding room

zone

and

(annex IX).

Time

longing

Complete

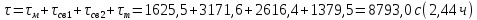

the residence time of the metal in the furnace is

Expert answers

Peacemaker With Bazooka:

The power of the furnace is selected depending on the volume of the steam room. With good insulation, 1 m3 of sauna requires an electric heater with a power of 1 kW. 1 m2 of uninsulated stone, glass or similar surface requires a 20% increase in heater power. vds-sm /elctroharvia My opinion is fiction. Enough and 4 kilowatts for your bath. Here's more The power of the electric heater depends on the volume of the steam room, the quality of the thermal insulation of its walls and the temperature of the atmosphere. Roughly, it can be assumed that for 1 m3 of steam room volume, the power consumption is 0.7 kW. This means that with a ceiling height of 2–2.2 m for heating 1 sq. m.the area of the steam room requires 1.4–1.6 kW of energy. .zavodprom /stati_o_stroit/mosh_eletrokam/index I can definitely say that you have beautiful walls with excellent thermal insulation. If you have made a vapor barrier inside. .aquastyle /electrokamenki/

Ilya Vaslievich:

***Convection ovens - principle of operation***

Convection ovens can operate on almost any fuel. It can be firewood, coal, fuel oil, agricultural waste, pellets, briquettes, and so on.

It does not matter how to heat such an oven. It is important that during the furnace, thanks to its device, it starts to warm up the room very quickly.

A conventional convection oven has holes in a special air jacket that surrounds the firebox, or has ribbed surfaces that quickly and strongly heat the air next to them. Hot air from the jacket or heat exchanger rises. It is immediately replaced by cold air, which is sucked into the shirts from below.

The more powerful the stove, the more it affects the rate of mixing of air masses inside the room. This means that a 20 kW convection oven heats the room faster than the same one, but by 10-15 kW.

And even if you need a 10 kW oven to heat your room, a powerful convection oven will heat this room much faster.

*** Convection ovens for the home - pros and cons ***

The main advantages that are inherent in convection ovens are as follows:

Quick heating of the room, due to the ability to actively mix warm and cold air masses in the room. Possibility to choose a model with a long burning mode. Compactness and undemanding installation. ).Convection ovens for wood and coal 3

There are, however, disadvantages of this class of heating devices:

The presence of hot surfaces that can burn you. Short heat transfer time after heating. High requirements for the installation of a chimney to maintain draft and lack of condensate. such - where they are unprofitable.

Best of all, such heat generators can be used for heating small rooms or private houses, especially country houses. In a situation where the fastest heating of a cold room is required, in which, for example, people come only for the weekend.

It is completely unprofitable to use convection ovens where heating of several separate rooms is required, especially those located on different levels / floors. In this case, it seems much more appropriate to use a heating boiler with a radiator system, or to use gas or electric convectors.

Eliminates the problem of RAPID COOLING of convection ovens - CAST IRON SAUNA FURNACE. Good, reliable cast-iron bath stoves are Svarozhich and Hephaestus, most of which use the convection principle. Cast iron does not burn out, they serve at least 30 years with a 5-year manufacturer's warranty.

You can view and order in Russia here: Svarozhich: kamin-komfort /?Page=items&ParentID=2191

Thermofor: kamin-comfort /?Page=items&ParentID=553

Tatyana Mesyatseva:

But you can also try stoves from other manufacturers, look at the tylo sauna stove website .saunapechi /pechi1.php?&second=1&about=1&model_ind=1650010089&index=89&count_prod=3&index_cat=9&table_main=price is also very good.

den olko:

Do you need a sauna stove, or a regular one? For a bath, you do not need to heat the air, but heat the stones, which will evaporate the steam and heat the steam room. To do this, you need a sauna stove svarojich /catalog/pechi_dlya_bani

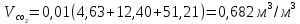

Calculation of fuel combustion

Payment

combustion of fuel (a mixture of natural and

blast-furnace gases) is produced similarly

calculation of a mixture of coke and blast-furnace

gases discussed in example 34.

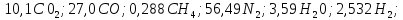

Compound

source gases, %:

domain

gas -

natural

gas -

Taking

moisture content in gases equal to

and

recalculating according to the formula (91, a),

we get the following composition of wet

gases, %:

domain

gas -

natural

gas -

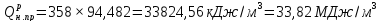

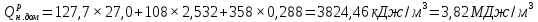

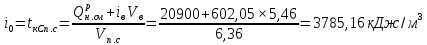

Heat

gas combustion

By

formula (92) we find the composition of the mixed

gas, %:

Consumption

oxygen for mixed gas combustion

of the considered composition at

equals

Consumption

air at

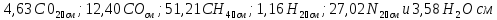

Compound

combustion products are found by the formulas

(96)

Total

the volume of combustion products is

Percentage

composition of combustion products

;

;

;

.

Right

we check the calculation by compiling

material balance.

Received

kg:

Combustion products received, kg:

Gas:

For

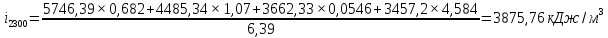

determination of calorimetric temperature

combustion, you need to find the enthalpy

combustion products

Here

—

enthalpy of air at (Appendix II).

At

temperature

enthalpy

combustion products is

At

By

formula (98) we find

Having accepted

pyrometric coefficient equal to

,

find the actual temperature

burning fuel

Selection of stoves for heated rooms.

The second factor thermal power stove heating at home is an selection of stoves for heated rooms.

Choosing an oven:

- between nursery and living room - in terms of 1.66 x 0.64 = 1.06 m2, i.e. The selected oven is a large oven - from 0.7 to 1.0 m2;

- between bedroom and kitchen - in terms of 1.15 x 0.64 = 0.74 m2, i.e. The selected oven also applies to large size ovens − from 0.7 to 1.0 m2;

These calculations will be useful to us below.

Table 2: Calculation of the heat output of heating and cooking stoves.

| p.p. | Name and types of heating | Types of premises | Stove size | Area of the heat transfer surface of the furnace walls, F=(perimeter x height) m2 | Amount of heat from 1 m2 of furnace (W) | The amount of heat from the total area of the furnace (W) | ||||

| width | length | height | with 1 firebox per day | with 2 furnaces per day | with 1 firebox per day | with 2 furnaces per day | ||||

| A | B | V | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Heating furnace - Total: | X | 0,64 | 1,66 | 2,4 | 9,50 | 290-360 medium 325 | 590-600 medium 595 | 3089 | 5655 | |

| 1 | including: | children's | 1,66 | X | 2,4 | 3,98 | 1295 | 2370 | ||

| 2 | living room | 0,64 | 1,66 | 2,4 | 5,52 | 1794 | 3284 | |||

| X | a) kitchen oven-sidewall | X | 0,79 | 1,15 | 0,77 | 1,49 | X | X | ||

| X | b) kitchen oven (stove) | X | 0,64 | 1,15 | X | 0,74 | X | X | ||

| X | c) protruding part above the stove (rough) | X | 0,15 | 1,15 | 2,4 | 3,12 | X | X | ||

| X | d) protruding part into the adjacent room (rough) | X | 1,15 | X | 2,4 | 2,76 | X | X | ||

| Kitchen oven - Total: | X | X | X | X | 8,11 | 2636 | 4825 | |||

| 3 | including: | kitchen | 0,79 | 1,15 | 0,77 | 1,49 | X | X | ||

| 0,64 | 1,15 | X | 0,74 | X | X | |||||

| 0,15 | 1,15 | 2,4 | 3,12 | X | X | |||||

| X | kitchen room - Total: | X | X | X | 5,35 | 1739 | 3183 | |||

| 4 | bedroom | 1,15 | X | 2,4 | 2,76 | 897 | 1642 | |||

| Total: | X | X | X | X | 17,61 | X | X | 6178 | 11310 |

For removal of combustion products it is advisable to lay out one root (on its own foundation) chimneylocated near the front walls of the furnaces.

ATTENTION! A cut should be provided at the point where the combustion products enter the chimney so that the combustion products do not penetrate into the adjacent furnace during combustion. The height of the stove (2.4 m) provides for an air cushion between the stove and the ceiling (with a ceiling height of 2.6 m), to increase fire safety

The location of heat-releasing surfaces is taken in such a way as to ensure the replenishment of heat losses in the premises. Bedroom, nursery, living room and kitchen are heated by two stoves

Furnace height (2.4 m) provides an air cushion between the stove and the ceiling (with a ceiling height of 2.6 m), to improve fire safety. Location heat-releasing surfaces taken in such a way as to ensure the replenishment of heat losses in the premises. Bedroom, nursery, living room and kitchen heated by two stoves.

Are common heat loss rooms are (according to Table 1) 11414 W. The lack of heat will be:

11310 W - 11414 W = - 104 W

Or 0,9 % - such a lack of heat is permissible (within 3% room heat loss). Those. selected oven sizes (with two fireboxes per day) allowable for this house heat living quarters at design (winter) outdoor air temperature T = -35°C.

Calculation of heating elements

Initial data:

- rated power of the furnace;

- supply voltage.

Characteristics of the heater made of X20H80 alloy:

- the maximum allowable temperature of the heater;

— resistivity at a temperature of 700ºС;

is the density of the heater.

Connection type of heaters - zig-zag. The connection scheme is a triangle.

is the temperature of the metal in the furnace.

is the oven chamber temperature.

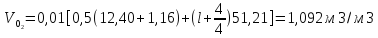

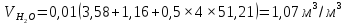

Dome surface area:

. (2.145)

The length of the arc of the arch of the vault:

. (2.146)

For a given furnace temperature, according to the schedule, appendix 24, I determine the allowable specific surface power for an ideal heater when aluminum is heated (Fig. 2.5).

For a tape zigzag heater, when aluminum is heated ( is the radiation coefficient), I will determine the recommended ratio by . From here I will find the surface power for a real heater

Single phase power: . (2.147)

Rice. 2.5 Graph of permissible specific surface powers for an ideal heater when heating aluminum

Taking the ratio, I determine, according to the calculations, the approximate thickness of the tape (a).

. (2.148)

Following from the calculation, I accept the standard section of the tape 3 x 30 mm.

I calculate the resistance of the phase heating element:

. (2.149)

Tape section:

. (2.150)

Hence the phase length:

. (2.151)

The actual specific surface power will be equal to:

, (2.152)

where is the total surface of the phase heater,

is the perimeter of the heater.

Single phase heater weight:

, (2.153)

given a margin of 10% - ;

I place the heater in the grooves of the refractory roof, ten spirals per phase. Mass of one spiral: . I accept the height of the zigzag 140 (mm) (with the expectation of a possible location in the grooves and their easy replacement), the length of each wave (coil) 280 (mm), the number of waves (coils) per phase: 87700/280 = 313, the number of waves (coils ) per helix: \u003d 313 / 10 \u003d 31.3? 31.5. The length of one spiral: uncompressed - = 8770 (mm), compressed - = 1328 (mm), hence the step:

. (2.154)

I check the temperature of the heater in operation:

Heater surface:

, (2.155)

where is the thickness of the tape,

- belt width

is the distance between adjacent heater zigzags.

Separate zigzags of tape heaters affect each other, since a certain number of rays emanating from one zigzag falls on another. The effect of such mutual shielding on heat transfer can be taken into account by the coefficient of mutual exposure:

.(2.156)

Thus, taking into account mutual shielding, the mutual irradiation surface is equal to:

, (2.157)

where is a coefficient that takes into account the shielding effect of the groove walls (I do not take it into account in the calculation).

I define the heat-receiving surface:

. (2.158)

Mutual surface, depending on the change in the ratio of the distance between the heaters and the charge to the width of the furnace chamber:

. (2.159)

Determination of the active surface of the heater, taking the calculated heat loss coefficient , I will make according to the formula (Table 6-2,):

. (2.160)

Product surface:

. (2.161)

The heat transfer equation of the heater-product system has the form:

(2.162)

Thus, the expression for the maximum temperature of the heater has the form:

. (2.163)

The temperature value obtained as a result of calculations is below the maximum (,), which satisfies the conditions for the normal operation of heaters, based on this I conclude that the selected heating elements (X20H80, ZIG-ZAG type, tape, S = 3 x 30, 10 spirals per phase, 1.328 (m) long) must ensure sufficient service life of the spirals and the allocation of sufficient power to them.