Rubric I know how ... how to properly heat a wood-fired heating boiler in a closed heating system.

read times: 6235

Greetings to you reading this article! From the first lines of the narrative, I want to make it clear that all the data in this article are real, obtained exclusively empirically for 2 years. Conditions for the use of a wood-fired boiler. The heating system is closed, with an electric heating boiler and a wood-burning boiler turned on. There are 2 pumps in the system (one in the boiler is working, the second in the system is a reserve. When the boiler is working, it is turned off. Everything can be seen in the photo).

The procedure for maintaining smoldering in a wood-burning boiler. 1. I kindle the boiler. The blower is open. The chimney is open. 2. When firewood flares up, I close the chimney (!) by 80% (with a damper. In the photo there is a red arrow). I don't touch the blower. 3. As soon as the temperature reaches the required parameters, I cover the blower. I leave 30% of what was open. 4. Smoldering. Free time from 1 to 2.5 hours. 5. The temperature went down. I open the chimney and put firewood on the coals. I don't touch the blower!!! When the firewood flares up, I close the damper of the pipe again.

What kind of wood do I use? Different. Dry - flare up faster and smolder faster. Not completely dry - they flare up longer, but also smolder better. I sawed firewood from a birch that had fallen this year. It seems that they are not dry, but they work with a bang. I can regulate the temperature of the boiler up to 60 degrees. (this is full Africa in the house. warm floors - it is not possible to walk))))

|

development and support of the IPV website 2011 – 2019 |

cotton wool

If you use ferrocerium flint for making fire, then this kindling will suit you just in time. Vata ignites from the slightest spark. With all this, cotton wool is also a multifunctional item that can be used not only as kindling, but also for its intended purpose (for medical purposes).

This kindling also has disadvantages:

- Cotton wool is a very hygroscopic material (it quickly absorbs liquid) and therefore it must be protected from water.

- And of course, this material cannot be found in nature in the form in which it is presented to the consumer (although cotton wool is made from cotton.

Although the issue of hygroscopicity of cotton wool can be solved by impregnating it with petroleum jelly (see below) or wax (paraffin).

Vaseline soaked cotton

Vaseline is an odorless and tasteless ointment liquid, consisting of a mixture of mineral oil and solid paraffins.

Vaseline is made from petroleum fractions and therefore burns very well.

To make a Vaseline-cotton ball you need:

- Squeeze petroleum jelly onto cotton wool (fluff the cotton first) and rinse well so that the petroleum jelly fills the pores (if I may say so) of cotton wool.

- Form balls of the diameter you need from the resulting mass

- Put in a bag or jar

Another indisputable advantage of this type of kindling fuel is that it burns for a considerable time. You can even boil a mug of water on a Vaseline ball.

plexiglass (plexiglass,polymethyl methacrylate)

Plexiglas is a thermoplastic plastic that burns very well. Aircraft glass is made from plexiglass. Due to the high boiling point (about 200 degrees), it is an excellent kindling. It is indispensable for winter ski trips, because it is able to inflame even damp firewood. Moisture is not afraid. It stinks when burned. There was a must-have (what you need to have with you) for all tourists from the times of the USSR. Plexiglas is very difficult to extinguish, so it is better to immediately cut the sheet into small parts for kindling

Cons: Do not kindle with a flint and flint.

Dry fuel (dry alcohol)

Dry alcohol (I wrote about dry alcohol in detail here). Not a bad kindling. Cons:

- Hygroscopic, damp and falling apart

- It is quite problematic to ignite it (it will not ignite for sure from a spark)

- It stinks of ammonia, it also stinks when burned

- Costs money

Pros: One tablet of dry fuel burns for about 5-7 minutes

Cotton wool or rag soaked in gasoline and other combustible substances

Kindling is good but there are also disadvantages:

- It must be stored in a tightly closed container (jar, etc.), because gasoline and kerosene can evaporate

- It stinks horribly. If a jar of kindling opens in your backpack, a persistent smell of gasoline or kerosene from all things throughout the trip is guaranteed.

- Pros. It ignites well and burns great

Lighting gel

Lighting gel is a good kindling option. Gels are sold in tubes and bottles up to 0.6 liters. A very controversial option for kindling, and it costs money. Burns out quickly (very quickly). A lot of gel is required to kindle damp firewood

Sawdust impregnated with paraffin

Sawdust impregnated with paraffin burns perfectly and for a long time. But the option is very labor intensive. Fractions of sawdust should be small so that the paraffin completely soaks them. Ready-made options with a sulfuric head are on sale

"Forest kindling"

This is a combined kindling, consisting of a piece of birch bark twisted into a tube, fixed with a thread and filled with pine resin, the holes in the tube are closed with birch bark on both sides. Because this kindling is done at home, you can immediately stick a couple of matches into it.

They came to the place, struck matches on Cherkash, kindling caught fire. This kindling lights up very well, burns brightly and for a long time. (This kind of kindling was seen on Helmut Weisswald's channel). Works great.

Conclusions:

What Kindling Do I Use?

I use several types of kindling, but of course this is birch bark (when it is possible to collect it), pine sticks (resin) and the last type of kindling “forest kindling.

Share the record, recommend it on social networks, it is very important for the development of the site. Protect the environment!

Protect the environment!

Kindling for a fire choose the best

Safety measures when kindling the boiler

The readings of the thermal expansion benchmarks are recorded in the operational log. Then they start filling the boiler with water, having previously opened the valves of the air outlet pipes on the drums to release air. Before kindling, the water level is raised to the lowest permissible level.

Before the start of kindling, the furnace and gas ducts are ventilated for 5-10 minutes, for which the smoke exhauster is turned on, and if the kindling is carried out on gas or fuel oil, then the fan is also turned on. Kindling is carried out at low heat. and little traction.Gas burners are ignited alternately with an igniter. First, an igniter is brought to the burner, and then gas is supplied. If the torch breaks or if the fuel (dust, gas) does not ignite, as well as in case of explosions and crackles in the furnace and gas ducts, immediately stop the supply of fuel and air to the furnace, and turn off the kindling device. Kindling is resumed only after thorough ventilation of the furnace and gas ducts. You can not light a torch from red-hot masonry and ignite fuel with open manholes and peepers. Inspection hatches for observing the torch must be covered with glass. During kindling, the water level in the drum and the pressure gauge readings on the water and steam lines are carefully monitored.

When the boiler is fired up, uneven heating of the drums, collectors and individual pipes is possible, which can lead to the formation of cracks and ruptures in them with the release of a large amount of hot water and steam into the room. The cause of damage can be pinching of screen pipes in the places of their passage through the lining of the furnace, the presence of foreign objects between the collectors and platforms that prevent their free movement. The causes of overvoltage in the metal of the boiler drums can be malfunctions and jamming in the movable supports of the drums. All these shortcomings are identified and eliminated before the boiler is kindled. Control over the movement of the benchmarks (see Fig. 6-1) during the kindling period allows you to timely identify areas of pinching or sluggish heating.

In order for the heating of all sections and elements of the boiler to be uniform, the core of the torch is supported in the center of the furnace and the lower points of the collectors are periodically blown through. If these measures fail to eliminate the uneven heating and thermal expansion, kindling is stopped until the causes are identified and eliminated.

The duration of the boiler kindling, the intensity of the rise in pressure in it, the size of the movement of its individual elements are regulated by the production instruction.

In those cases when the boiler is melted after repair work, in which its steam-water density was violated, the hatches and flange connections are tightened when a pressure of 0.3-0.5 MPa is reached. To avoid damage to the threads from excessive force when tightening them, it is forbidden to use wrenches with extended handles.

There may be cases when boilers that have passed a hydraulic test show leaks when checking for vapor density. Checking the steam density is carried out by inspecting all accessible elements and carefully listening to see if there is noise from the outflow of steam or water in the gas ducts and the furnace.

Work and duties of the boiler room operator

To become a good boiler house operator you need to be a responsible, diligent and stress-resistant person, because in the event of a boiler failure, it is the boiler house operator who will deal with hundreds of incoming phone calls from local residents who were left without heat.

Also, the employee must be attentive and be able to make decisions in a short time. Boiler operator responsibilities include:

- monitor the condition of the heating equipment in the boiler room;

- monitor the temperature that enters residential buildings and organizations;

- control heating devices;

- observe that the temperature regime does not go beyond the thermal limits;

- call an emergency team in case of danger in the boiler room;

- fill in the engineering book with daily indicators.

The main advantages of the work are that it does not require physical costs, and also with the well-established operation of the boiler, there is a certain amount of free time.

The disadvantages of the work are the noise in the boiler room, as well as an increased level of fire hazard.

Paper. Wax-impregnated toilet paper

Toilet paper impregnated with wax or paraffin, a fairly common kindling among the so-called. survivalists (bushcrafters). It is easy to make and lasts a long time.If the paper is well impregnated with wax, then it is not at all afraid of water.

How to make kindling toilet paper soaked in wax

- STEP 1. We take an unnecessary container in which you can melt the paraffin (the best solution is to use a can of canned food)

- STEP 2. Melt paraffin or wax and immerse toilet paper there (you can directly in a roll (not a full roll))

- STEP 3. Dry. Kindling is ready

Cons of this kindling: You have to carry it with you. You can’t find it in the forest. It literally melts in summer))). Sticks together

Professional training

In order to start a career as a boiler operator, you need to get a higher education, preferably technical in the direction of engineering. It is the knowledge of the specifics of an engineer that will allow the fastest way to master all the intricacies of this profession, as well as special technical equipment.

During the training, such disciplines as the structure and types of gas boilers, safety regulations when working in a boiler room, boiler failures and methods for their elimination, and various types of GOSTs in organizing work will be studied.

In practical classes, the process of mastering the profession will be much more productive, because almost from the first days of practice, the beginner will be assigned a mentor, with whom he must spend all the time. The mentor should guide his trainee, introduce him to the boiler management course, and also pass on his own experience. It is the mentor who will have the final say in passing the qualifying exam, and decide whether or not to allow the newcomer to work.

What a Boiler Operator Should Know

The boiler operator must know:

arrangement and operation of boilers and all auxiliary equipment that it serves;

schemes of gas pipelines (fuel oil pipelines);

designs of gas burners (fuel oil injectors) and the limits of their regulation;

rules for the safe operation of gas (liquid) fuel boilers and auxiliary equipment of the boiler room;

instructions:

a) production for the operation of equipment;

b) fire fighting;

c) for the prevention and elimination of accidents.

In addition, the operator must know to whom he is subordinate, whose orders he is obliged to carry out, whom to notify about accidents and malfunctions, about fire and accidents.

From ETKS:

Must know: arrangement of serviced boilers; device and principle of operation of centrifugal and piston pumps, electric motors and steam engines; schemes of heat, steam and water pipelines of the boiler plant and external heating networks; the procedure for accounting for the results of equipment operation and heat supplied to consumers; the device of simple and average complexity of control and measuring devices.

4. Classification of accidents and accidents in the boiler room.

Damage and accidents in boiler rooms can be divided into two groups for the reasons that cause them:

1.

improper combustion of gas or improper maintenance of burners and gas equipment, which leads to an explosion of the gas-air mixture;

2. non-compliance with operating modes and operating rules for boilers and their individual elements.

Accidents and damage to boiler rooms cause:

— long-term downtime of equipment;

— a break in the supply of heat to the consumer;

— equipment failure for a long time;

— destruction of boiler houses;

- Injury to service personnel.

The most common causes of the formation of an explosive gas-air mixture are:

- improper purging of gas pipelines;

- gas supply to the burner before the introduction or formation of an incendiary torch;

- incorrect placement or separation of the flame of a portable igniter in the furnace when igniting the burners;

- premature opening of valves (gate valves) in front of the burners and improper manipulation of them (open - close the valve);

- an attempt to ignite a neighboring burner from a working one without using an ignition torch;

- insufficient ventilation of the furnace and gas ducts during the primary or repeated, after the failure of the torch, the inclusion of burners.

Causes of gas pollution and explosions when igniting burners, there may also be:

- incorrect installation or malfunction of the ignition device;

- leakage of locking devices and personnel errors in fixing their position;

- malfunction of measuring instruments or incorrect assessment of their readings;

- turning on the burners with a faulty or disabled automatic flame control;

- detachment, breakthrough of the flame.

The reasons for the extinction of the torch may be:

- short-term interruption of gas supply;

- separation of the flame with a sharp increase in rarefaction in the furnace;

- a change in gas concentration below the lower or more upper ignition limits (contamination of the burner gas openings, malfunction of the gas pressure regulator, stop of the blower fan or smoke exhauster);

- incorrect action of the operating personnel when regulating the thermal power of the burners.

Damage to boilers that lead to an explosion can occur in the following cases:

- exceeding the operating pressure in the boiler;

- water leakage from the boiler;

- overfeeding the boiler with water and foaming it, which leads to hydraulic shocks and damage to the main steam collector and fittings;

- excessive overheating of certain places of the heating surfaces in the furnace with a large flame length.

The causes of accidents and malfunctions of boilers can be:

- factory defect in the boiler, not detected during internal inspection and hydraulic testing;

- unsatisfactory condition of the equipment due to poor-quality installation or repair, as well as due to wear or poor quality of the material from which individual components are made;

— scale deposits, intergranular and chemical corrosion;

- technical malfunction of water-indicating devices, purge and supply fittings, supply and signaling devices;

- Violation of the burner operation - vibration of the fittings, headset and pipe system of the boiler.

Investigation of accidents and accidents in this case is carried out in the manner prescribed by the inspection of Kotlonadzor.

The administration of the boiler house notifies the inspector of the local Kotlonadzor about each case of accidents and damages and, upon his arrival, ensures the safety of the entire situation, if this does not threaten people's lives and does not cause further development of the accident.

2015-2018 poisk-ru.ru All rights belong to their authors.

What foods will help make a fire

In addition to the listed canned food with sprats and sunflower oil, which by themselves are not capable of burning, other food products can be used as kindling.

So, nut kernels burn on their own due to their high fat content. Also, their shells can be used as kindling, which, however, ignites worse and does not burn so confidently. For example, I had a chance to experiment with a walnut that grows in our region - its core flares up from the first match, burns with a long quiet flame.

Another good option that came to my mind a few years ago and was successfully tried is lard. This is a high-calorie food that is often taken with you on hikes, especially in winter, when it is recommended to consume more fat.

Pig fat can be set on fire by itself: it will burn when it is slightly charred. That is why I would recommend setting fire not to a thick piece, but to cut off a strip with a pointed end from it.

But it is better to stick a match into a piece of fat as a wick, which then set fire to. Also for these purposes, you can wrap the bacon in toilet paper, as was the case with a candle, and so that the paper does not unfold, pierce it with lard through sharp wood chips.

Lard burns without additional tricks, it can be cut into pieces of the desired size, and fat dripping into the fire contributes to a faster flare-up. In addition, pork fat is not afraid of moisture.

It is also often suggested to use chips as kindling, but this option is not suitable for a hike, since usually no one takes chips with them, and they are afraid of moisture.

Kindling from food is usually always with you, except for emergencies, and this is its big plus

In addition, neither nuts, nor lard, nor butter, nor canned fish and stews are not afraid of moisture, which is also important for wild conditions, where you often have to get caught in the rain, go through fogs, and sometimes cross water obstacles. Such kindling usually burns for a long time, but is not always easily ignited.

Resinous branches.

Resin is resinous firewood, chips, branches.

Resin can be found by cutting off a dry pine branch near the base. As a rule, the most resinous branches are found where there was a fire and the trees were slightly burned, then the resin concentration is very high.

Resin burns very well, even after rain, if you cut off such a resinous branch, it will easily catch fire. Resin fills all the pores of the tree. For better ignition, it is recommended to plan as finely as possible, then the resin can be ignited even with the help of a steel.

If possible, I always take a small piece of tar with me, it is very easy to inflame.

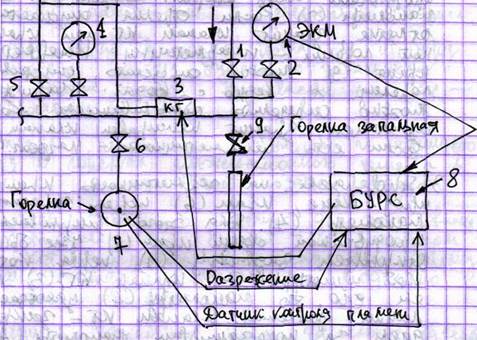

Boiler ignition.

The work on ignition of the boiler is gas hazardous, it is carried out without a work permit, but with a record of the performance of this work in a special journal. It belongs to the second group of gas-hazardous work. It is carried out by order of the head or foreman of the boiler room.

Before lighting up the boiler, make sure that it is filled with water, make sure that the network pumps are working (according to the readings of the pressure gauges installed on the boiler for water), i.e. that they are turned on and water circulates through the boiler and heating system.

We check the tightness of the gas equipment in front of the boiler:

1. Check the tightness of the valve (1). We make sure that the KG valve is closed. The pointer on the pressure gauge (2) is at zero. We observe the readings of the pressure gauge (2), if the pressure rises, then the valve (1) is leaking. The boiler must not be fired. You need to call a locksmith for repairs.

2. We check the tightness of the valve KG (3) and the valve (9) of the ignition burner, for this we briefly open the valve (1), build up pressure, make sure of this by the pressure gauge (2). The cock (5) of the purge plug is open. We follow the readings of the manometer (2). If the pointer drops to zero, then the valve KG or the valve (9) of the pilot burner are leaky. The leakage of the tap (9 can) be determined by lowering the ignition burner into a bucket of water. External leaks can be determined by washing. If the tap (9) is tight, then the KG valve (3) is faulty. If there are leaks, it is impossible to ignite.

3. We check for tightness the valve valve (5) on the purge candle, the valve (6) in front of the burner and the pressure gauge (4). To do this, close the valve (5) of the purge plug, the valve (6) has already been closed. Open the valve (1) in front of the boiler. Using a screwdriver, slightly open the KG valve (3) and close it. On the pressure gauge (4) we make sure that there is pressure. KG valve is closed. We observe the readings of the manometer (4). If the pointer of the pressure gauge drops to the zero mark of the scale, then the valves (5) and (6) are leaky. External leaks are determined by washing all welded, threaded and flanged joints. If the equipment is leaking, it is impossible to kindle the boiler. Let's assume that all the equipment in front of the boiler is hermetically sealed. The result of the leak test is recorded in a replaceable journal.

4. We ventilate the boiler furnace. To do this, open the primary air regulators, secondary, if any, open the gate behind the boiler. We ventilate the furnace for 15 minutes.

5. After ventilation, we determine the gas contamination of the furnace space of the boiler. The sample is taken from the top of the furnace with a gas analyzer. The gas content in the furnace space should not exceed 1%. The result of the analysis of the air environment of the furnace is recorded in a removable journal.

6. Check the draft in the boiler furnace using the instrument or bring a piece of paper to the ignition hole. If the paper breaks out of your hands, the traction is sufficient.

7. We close the primary and secondary air regulators in injection type burners and in burners with forced air supply.

8. We ignite the pilot burner, for this we first set fire to a sheet of paper on the concrete floor of the boiler room, bring the pilot burner into the flame of burning paper and slowly open the tap (9).

9. We bring a lit igniter through the pilot hole into the furnace to the mouth of the burner, look through the peephole so that the torch of the pilot burner does not go out.

10. The second operator turns on the “NETWORK” button on the BURS unit, applies voltage to the KG valve, the valve opens, pressure will appear on the pressure gauge (4).

11. The first operator slowly opens the valve (6) in front of the burner, makes sure that the main burner has ignited, a torch has appeared. Tap (6) is not yet fully open.

12. Take out the pilot burner, close the edge (9). The ignition burner is hung in place. The operator supplies some primary air by opening the damper and gradually brings the burner to normal combustion. It is necessary to increase the load of the burner by supplying gas first. and then air. Reduce the performance of the burner on the contrary - first reduce the air, and then the gas (because without air there is no combustion and no explosion).

13. On the BURS block, we move the toggle switch to the “NORMAL OPERATION” position, while all sensors for controlling the operation of the boiler will be activated:

· gas pressure in front of the burner;

· vacuum in the boiler furnace;

· the presence of a torch in the furnace;

· air pressure in forced air burners;

· water pressure at the outlet of the boiler and at the inlet to the boiler;

· boiler water temperature.

Those. the boiler will be protected by safety automatics.

14. If, during the ignition process, the flame breaks off from the burner or slips into the burner, it is necessary to immediately close the valve (6) in front of the burner, identify the cause, write it down in a replaceable log and repeat the ignition from the beginning, according to the instructions.

Replacing branded lighting fluids in tourism

In tourism, it is better to use alcohol from a first-aid kit or gasoline from a car tank as such liquids. In addition, gasoline is sometimes carried in a backpack for burners, which are used when no other fuel is available, for example, in the mountains.

You can simply pour alcohol or gasoline into a fire made of firewood, and then throw a match there.

But this option is good for dry firewood. In order to save these substances and kindle a fire in wet weather, a little sand is poured into a tin can, poured over with a combustible liquid and set on fire. In this case, the fire will not be as bright, but its burning time will be much longer, which will allow you to dry the raw firewood and light it.

This method has disadvantages compared to the previous one. In the case of alcohol, this is its price (branded lighter fluids are much cheaper), and gasoline is bad for its smell and ability to seep through any leaky dishes and spill into a backpack

In addition, both of these substances are flammable and, if handled carelessly, can lead to a fire and even an explosion.

Sunflower oil can be considered a good alternative to lighting fluids in tourism. Many take it with them on camping trips for cooking on a fire. In addition, oil is usually found in various types of canned fish.

Sunflower oil does not burn on its own, but allows the fuel to burn longer and brighter.

The fact that oil does not burn on its own makes it a safe fire starter. In addition, it is cheap and completely safe when it comes into contact with the body, which cannot be said about branded lighter fluids.

Contrary to popular belief, it is impossible to smear burns with oil and other fats (for example, whale oil or kefir after the same sunburns). It will harm the victim.