Design and types of fan heaters

- Protective case made of plastic or metal.

- Electric motor.

- Impeller with blades.

- A heating element.

- Protective grid.

- Elements of regulation and control.

Depending on the chosen design and purpose of the device, additional components are selected. It is possible to manufacture almost all types of electric heaters with your own hands. For domestic needs, a do-it-yourself mini heat gun is made to warm up and dry the room, a do-it-yourself electric fireplace will allow you to realize your own design ideas and give the room an atmosphere of comfort, and a duct air heater is built into the supply ventilation or air conditioning system.

Assembly features of some types of fan heaters

There are several types of fan heaters, each of them, quite naturally, has its own characteristic pros and cons. Before you start assembling the fan with your own hands, you should familiarize yourself with some of the features of the device.

fan heater

Assembling the simplest heat fan with your own hands is not difficult for a home craftsman. Some of the necessary parts can be found in stocks of old equipment stored in a pantry or garage. Do-it-yourself heater can be assembled on the basis of an old computer system unit. For this you will need:

- A sheet of textolite measuring 20 × 30 cm.

- A couple of meters of nichrome wire with a diameter of 0.2-0.3 mm.

- System unit (details, except for the cooler, are removed from the unit).

- Power supply 12V.

- Thermal fuse for the heater, designed to switch off at temperatures above 70°C.

- Cable, regulators, switches, fasteners, electrical tape or heat shrink tubing.

The design of the heater is very simple and it will not be difficult to assemble it yourself

- Parts are cut out of fiberglass to make a frame with slots for installing a tena (nichrome spiral).

- The nichrome thread is twisted into a spiral (for this purpose, a drill or a screwdriver operating at slow speeds is used, with a fixed rod with a diameter of 2-3 mm).

- The spiral is installed in the frame and fixed, power is connected at the points of fastening of the ends of the spiral, a thermal fuse is mounted in the gap of the power wire.

- A frame with a spiral is installed in the system unit.

- The 12V power supply is connected to the cooler.

- The body is closed, placed on a stand made of dielectric material, and the operation of the heater is checked.

An economical option is a water heater. In this case, a heat exchanger independently made of a copper pipe or a used car radiator acts as a heating element. The coolant for the heat exchanger comes from central heating pipes or individual heating, and electricity is consumed only to ensure the operation of the fan. It is recommended to install such a fan heater in the heating system on the return pipe. When installed at the supply, a running fan cools the pipe strongly and the coolant enters the heating radiators below the required temperature.

heat gun

Making a heat gun with your own hands is quite simple. This type of heater is used for quick heating and drying of walls, floors, damp cellars and during certain types of construction work. To make a mini gun, you can use some parts of unusable household appliances, and buy the missing ones.

You will need the following list of materials:

- Motor and impeller (suitable from a failed vacuum cleaner or kitchen hood).

- As a heating element, a spiral from an unnecessary electric stove is used.

- A pipe with a diameter of 150 mm or more with a wall thickness of 3-5 mm can be made independently from sheet metal.

- Thermal relay that opens the circuit when overheating, switch,

- Asbestos sheet.

- Metal lattice.

- Cable and fixing materials (rivets or bolts with nuts).

Assembly is carried out in several stages:

- The electric motor and fan are attached at the end of the pipe.

- Strips are cut out of asbestos and a grid is assembled on which a heating coil is attached (ceramic insulators can be used for this purpose).

- The resulting heating element is mounted on the opposite end of the pipe from the fan.

- The motor and spiral are connected to the switch. The scheme provides a separate connection.

- Metal protective gratings are installed at both ends of the pipe.

- A mobile or stationary stand is made from improvised materials that are resistant to temperature effects.

WATCH VIDEO

Optionally, a layer of thermal insulation is attached to the pipe. On the one hand, this increases the level of safety during work, on the other hand, it reduces the heat transfer of the device.

Electric fireplace

A homemade fan heater is used as a heat source for an electric fireplace. A do-it-yourself portal for a fireplace is easy to make from drywall. To do this, a frame is mounted from a metal profile of the required configuration and sheathed with sheets of drywall, after which the outer surface is decorated with facing materials. Inside the portal, a structure is installed that simulates the burning of firewood or coal (finished products are equipped with lighting)

It is important to foresee a hole in the structure for laying the cable

Power calculation and installation requirements

Before you select the necessary materials and proceed with the assembly, determine the required power of the device based on the tasks that it performs. A low-power portable heater is suitable for heating a working space or a sleeping place with a directed air flow without taking into account the total area of \u200b\u200bthe room. If the task is to raise the temperature in the entire room to a comfortable level (18-21 ° C), then the calculation is made based on the ratio of 40 W of heater power per 1 m³ of room volume.

Considering that a home-made cannon heats up the room unevenly, it is recommended to install an additional heater (or several) at different ends of the room. In this case, the calculated power is divided by the number of heaters.

You also need to take into account the permissible load on the electrical network. An electric heater with a power of not more than 6 kW can be connected to a household network with a voltage of 220V. If you need more power, you will need a 380V network or a heater that works on a different principle (homemade gas gun or another).

How can you repair a fan heater with your own hands

A fan heater is an electric heating device in which a heating element is combined with a built-in fan. This is an excellent option for auxiliary heating of residential buildings and apartments, or independent heating of office and industrial premises. Thanks to the fan heater, the air heats up quickly, and it does not consume a lot of electricity. In addition, the electrical device has a fairly simple device. The fan heater circuit can be understood by anyone, even those who have at least the slightest knowledge and skills in electrics. And in this regard, in case of malfunctions, it will not be difficult to fix the breakdown of the fan heater on your own.

About the device and the scheme of the fan heater

In the device of any heater, the most important thing is its heating unit. And the heater is no exception.The role of its heating element, as a rule, is a spiral made of a special alloy of metals, which has a high electrical resistance or a closed ceramic heating element. In fact, this is a load that will be connected to the mains through a specially designed thermal fuse. This device has a bimetallic thermostat, which guarantees protection against overheating and other protective elements, the presence of which already depends on the specific model of the fan heater.

The fan heater circuit also includes a screw with an electric motor, which rotates quickly and distributes air heated by a spiral or heating element. It should be noted that a ceramic fan heater is a more reliable unit than its spiral counterpart. The fact is that its heating element is protected from external influences and, as a rule, problems and breakdowns of the fan heater can be due to the troubles of the thermostat or are associated with a power outage. As a rule, the electrical diagram of the fan heater can be found on the packaging, in the instructions for the device, or directly on its case.

About malfunctions of the fan heater and how to eliminate them

During the operation of the fan heater, malfunctions may occur, which may be associated with both a factory defect and non-compliance with the rules for using the device. The most common fan heater malfunctions are as follows:

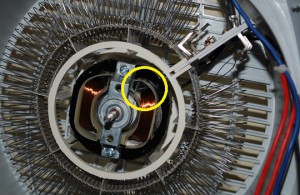

First, the device is working, but the fan is not spinning. This malfunction of the fan heater may be due to the fact that the electric motor burned out and it is necessary to replace it. In addition, dirt and dust could wrap around the fan pulley, and it is necessary to clean it.

Secondly, although the motor turns the fan, the air does not heat up. Here, the most likely cause of this kind of malfunction of the fan heater may be that the heating unit has burned out. And if in a device with a spiral this is simply visible, then in ceramic fan heaters a special tester will be required to determine the breakdown.

Thirdly, the fan heater, after being plugged into the outlet, simply does not work. This indicates a probable problem that has arisen in the control unit and fuses, which is included in the fan heater circuit. With such a malfunction of the fan heater, obviously, it should be given to a specialist for repair.

Wiring diagram for Volcano VR fan heaters

ATTENTION! Before starting the connection of fan heaters, it is necessary to turn off the power supply! The wiring connections must be carried out by qualified personnel in accordance with the instructions. Due to the fact that VTS Euroheat has updated its line of VOLCANO VR water fan heaters, and now they all have a three-speed electric motor, in our opinion it is advisable to use the 3 most popular methods of electrical connection of VOLCANO VR fan heaters

The nominal cross section of the connected wire is 1.5mm2, for example, PVA 3x1.5.

Method No. 1 Direct connection of VOLCANO VR fan heaters to the network

The diagram clearly shows how to connect the VOLCANO VR fan heater directly to the network. Where:

"L" - PHASE;

"N" - ZERO;

"PE" - EARTH.

Let's analyze in detail:

At number 1, we have a 1-phase power supply network 220V-50Hz, VOLCANO VR fan heaters are powered by a conventional 220V household network, which expands the scope of their application.

Number 2 is the main switch, fuses. Recommended protection: against overvoltage (VOLCANO VR fan heater - 4 A), as well as differential protection.

Depending on where to connect the power wire of the phase, the choice of the speed of rotation of the electric motor and its performance in m3 / h (air consumption) will depend:

- Maximum power, phase is connected to connector No. 8;

- Average power, phase is connected to connector No. 7;

- Minimum power, phase is connected to connector No. 6.

Advantage:

- Convenient switching between the speeds (air flow) of the fan heater, in its structure, it simply switches the voltage supply through the phase, between;

- Room temperature control, when the set temperature is reached on the speed and temperature controller WING/VR (TR110C-B), it turns off the power to the fans;

- Possibility to switch the fan heaters on and off via the switch on the TR110C-B panel.

Maximum one such speed and temperature controller TR110C-B can be connected to:

It is recommended to use a 5x1mm2 cable.

The maximum cable length from VOLCANO to TR110C-B must not exceed 100m.

For our speed and temperature controllers that we brought especially for ourselves, a slightly different connection scheme.

The numbering of fans connection to the speed and temperature controller has been slightly changed. This regulator is PROMOTIONAL, it costs much less than the VTS regulator, we can give it to good customers.

Method #3 Connection of VOLCANO VR fan heaters via speed and temperature controller WING/VR (TR110C-B) + two-way valve with servomotor

We carry out repairs

First of all, you need to disassemble the body of the device. It usually consists of two parts, which are interconnected by small screws. They need to be unscrewed using a screwdriver.

Now that the case has been disassembled, it is necessary to inspect the inside of the device for burnt wires or disconnected parts or assemblies. If this is found, then it is better to replace the burnt wires with new ones, it is good to attach the detached parts using standard methods.

Quality is important here and guarantees that this will not happen again.

If in this case the fan heater did not work, then it is necessary to look for a more complex cause of its breakdown.

- If during the process of connecting the plug to the outlet the fan did not even move, did not make a single sound, then first of all check the connecting wire. Suddenly there was a gap. To do this, insert the plug into the socket and move the cord, usually the place of the break begins to contact and the fan may suddenly start working. Often a spark and a clearly audible crack of electric current appear at the place of the gap. Therefore, advice - either replace the cord with a new one, or make a cut at the break point and connect the wires well with subsequent insulation.

- Often two fuses can burn out: one thermal, the second from overheating. They are usually located next to each other. Each of them must be called by a tester. If the control device shows that an electric current passes through them, then the cause of the breakdown must be sought elsewhere. If the tester shows that the current does not pass, then it is impossible to repair two fuses. They must be changed. By the way, if only the thermal fuse is out of order, then it can be replaced with a copper wire jumper. It is not recommended to do this with the second fuse. There is a high chance of fan fire. So don't even think about it. Both devices cost a penny, and you can replace them in a couple of minutes using a regular soldering iron.

- Often the fan itself works, the air is expelled from the heater, and the spirals do not heat up. That is, the unit works like a conventional fan. In this case, you just need to inspect the spirals for a break. If one is found, then it can be repaired by correctly connecting the two ends of the wire. To do this, you need a copper tube, where the ends of the wire are inserted from both sides. They must first be straightened. Insert until it stops until both ends collide with each other. After that, crimp the tube so that its walls clamp the wire. This connection is the most reliable. If you simply twist both ends together, then after a couple of hours of work, a break will occur again in the same place.

- There are models of fan heaters in which there is no spiral part, but a special heating element is installed. If it is out of order, then you should not think about whether to make repairs or not. It just needs to be replaced.

- The group of inclusion and switching of modes does not work. One of the most common types of breakdowns. This block is most often a Chinese-made product, and therefore quickly fails. If the tips are burned out, they can still be repaired. But if the switch or thermostat itself burned out, then only replacing them with new ones will save the situation.

Complicated breakdown

And another very complex breakdown, which will be very difficult to repair with your own hands. Therefore, I would like to consider it separately. Usually it is characterized by a ten-second operation of the device, after which it suddenly turns off. There are two reasons here:

- The first is a blown fuse, which is located on the primary winding of the electric motor. Getting to him will not be easy. To do this, you will have to disassemble the engine and pull the rotor out of it. Check the fuse for continuity. If everything is fine, then the second reason worked here. If the device is burned out, then it must be replaced or a jumper installed.

- The second reason is the most unpleasant - the electric motor burned out. We will not go into details of how to repair it. It will be difficult and expensive, so it makes sense to throw the fan in the trash and buy a new unit.

These are the reasons that usually occur when your fan heater stops working. As you can see, it will not be difficult to deal with such breakdowns. The electrical circuit of a heating household appliance is simple, it is found in all household appliances, so if you have coped with the repair of the fan, then master other units.