What to look for when choosing

The most important thing is to understand the simple truth that installing any kind of panels on a radiator leads to a decrease in heat transfer from it. At best, it will be 5%. But if you choose a grating that is blind with a minimum of holes, then the percentage of losses can increase significantly.

It seems like a little, but during the heating season, heat meters can wind up a serious surcharge. Therefore, the screen should have a maximum of slots for the unhindered movement of warm air.

To smooth this out and increase heat transfer, you need to hang a heat-reflecting screen made of foil material behind the battery on the wall. The heat will be reflected from it into the heated room, instead of pointlessly heating the wall.

Another way to reduce heat loss is to paint the inside surface of the decorative panel black. In this case, the screen will absorb more heat from the radiator and give it more to the room.

The design should be easily removable and disassembled. Radiators will need to be washed, and for the summer also drained. Permanent dismantling of the decor will only bring additional trouble and inconvenience. In addition, unhindered access must remain to the battery valves.

The easiest way is to make a screen for a heating battery with your own hands from MDF. To do this, you will have to knock down a rectangular box from the bars or chipboard to fit the size of the radiator and sheathe it with a decorative MDF board. On sale there are a lot of different hole shapes and colors. In addition, you can order cutting MDF boards on a programmable machine according to an individual sketch.

Do-it-yourself battery screen protection and comfort for the home

The interior of any room should have a finished uniform style.

A wide variety of decoration elements are used as finishing touches.

They complement or focus attention, hide flaws or increase the functionality of one or another component of the interior.

In this case, you can make a screen for the heating battery with your own hands.

But there are also decorative products that combine several functions at once. You can make a screen for a battery with your own hands or purchase it ready-made.

For example, such a decorative panel in the living room will cover the unpresentable appearance of the old radiator, serve as a shelf for flower pots and at the same time transform the entire decoration of the room with its appearance.

From a practical point of view, the main task of any screen covering the radiator is to protect anyone accidentally touched from a burn.

What is especially important when small children run around the house

Brutal mesh netting

The most common material that replaces the standard factory radiator grille is a fine-mesh chain-link grille. It can be products made of aluminum, plastic and even steel. You can find such a product in many places, and it will cost very modest money. Also, for the lattice transplant operation, the following inventory and tools will be required:

- hacksaw for metal;

- file;

- file;

- sandpaper;

- self-tapping screws or plastic clamps;

- cold welding.

Before you make a radiator grille in accordance with your own taste, you need to remove your own from regular places. Usually it is held with plastic grips, which you just need to squeeze out, after which everything can be easily removed. It is very undesirable to break the fasteners and the lattice frame, since the old structure will serve as a frame for new achievements. The same applies to the chrome lining, if any. After that, “under the root” all lattice lintels are cut off with a hacksaw or file - both vertical and horizontal.Do not be afraid if the part has noticeably lost in rigidity, because this is a natural side effect of such tuning.

How to install the product

Before proceeding with the installation of the grid, you will need to remove the grid. On some vehicles, this can only be done with a bumper. As a rule, for dismantling, you need to unscrew the retaining bolts that are hidden under the hood, and then bend the latches at the bottom of the grille. After that, it can be carefully removed from its place. In other models, the attachment is so simple that you don't even have to lift the hood cover: just pry the edges of the grille with a flat screwdriver and remove it from the grooves. More detailed instructions can be found in the vehicle's owner's manual.

Required Tools

To install the protection on the grate, prepare the following set of tools:

- finished safety net

- flat head screwdriver;

- a set of hex keys for grating dismantling;

You will need these tools regardless of your preferred mounting method. But besides them, you will need the fasteners themselves. Depending on how you connect the grid to the grid, you will need one of the following tools:

- regular holders

- cable ties approx. 18–20 cm long

- self-tapping screws and industrial hair dryer

- welding machine.

Mounting options

There are four different ways to anchor a grid:

- using regular holders;

- using cable ties;

- using self-tapping screws;

- fusing the stack into the grate.

Each of these methods has its pros and cons. For example, the best option is to install on regular clamps. Another option is to put the mesh on self-tapping screws. True, before that you will need to heat the screws and thereby prevent further cracking.

Rare motorists resort to the fusion method. First, you need to have special equipment. Secondly, if the grate is made of plastic, it can be easily melted. Well, in the end, you can’t remake a crookedly fused grating, and the whole part will go under replacement.

For these reasons, drivers who decide to independently upgrade the radiator grille most often use plastic construction clamps. They are inexpensive and available at any hardware store. To make the ties invisible, purchase them in the color of the future lattice and mesh.

Installation instructions

When the grid itself is ready, and the installation method is selected, you can begin the installation process.

- Carefully remove the grille. Be careful not to damage the cells.

- Wash the parts and clean from debris accumulated during operation.

- Attach the mesh to the outside or inside of the radiator depending on the final location.

- If you are installing the mesh on the outside, fold in the allowances at the edges.

- Fix the mesh on the grate with clamps. It is best to use a symmetrical scheme. The staggered ties look beautiful and hold tightly.

- Cut off the long tails of the cable ties. Make sure that the fastening is not broken, and the clamp does not fly off.

- Install the grille back into the car.

Why do you need a protective mesh on the grille

First, let's figure out what functions the radiator itself performs. The radiator is one of the main elements of the car's cooling system, which is located in the bow near the bumper.

During operation, a spark is generated inside the internal combustion engine, which ignites the fuel. It, in turn, releases thermal energy, which is subsequently converted and becomes the driving force for the car. It's no surprise that the engine gets hot all the time. However, overheating of this part can cause partial or complete damage to the car. Therefore, cooling is a necessary process for the correct operation of the car.

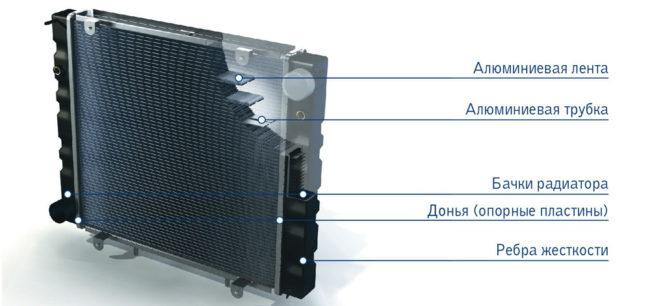

It is for this that the automakers invented the radiator. It is a system of metal plates and tubes through which coolant circulates. A grille is installed on the outside, which closes the technological openings for oncoming air.

Unfortunately, the radiator grille has rather large cells, so it often gets dirty due to particles of dust, sand, gravel and even insects flying into it. Not all motorists pay enough attention to cleaning this element of the car. The same sin and professional car washes. A large amount of debris prevents the cooling system from functioning properly, which can lead to overheating and engine failure.

A protective mesh, which is installed on the inside or outside of the grill, will help to avoid this. Its small cells do not let even the smallest insects into the radiator. In addition, it is quite easy to remove and clean. At the same time, it does not adversely affect the oncoming air flow and does not interfere with the operation of the system.

Mesh on the outside of the grate

Most often, the mesh is installed on the outside of the radiator grille. This method has many advantages:

- you do not have to dismantle the bumper and grill to install the grid;

- such a grid is easier to remove and clean;

- the grate itself will also remain clean;

- you can change the look of your car.

However, not everyone likes such changes in the appearance of the vehicle. If for this and any other reasons you do not want to mount the mesh from the outside, there is another method for you.

From the inside

In cars of a high price category, even the radiator grille is a design element. Just remember the cars of the BMW brand: you can’t confuse their grilles with any others, they fit so seamlessly into the overall image. Not surprisingly, many motorists do not want to hide them. In this case, the method of installing the grid from the inside comes to the rescue.

The mesh hidden under the grille will not be conspicuous. At the same time, it will be no less effective in protecting against all contaminants. True, there are disadvantages in installing an internal grid. For example, the need to dismantle the grate itself. And some cars have a design in which the grille can only be removed together with the bumper. This will take you extra time and effort, but the overall design of the car will remain more harmonious.

In any case, the choice between the appearance and the efforts made is up to you, because the functionality of the part will not decrease from this.

Coloring

The grid can be left in its original form, or it can be painted. So you give it an original look.Moreover, you can paint not only the grid itself, but also the grid along with it. As you might guess, the mesh is colored before connecting to the grate, unless you want to make them the same color.

To do this, carefully degrease the surface of the mesh. For better adhesion of paint and surface, apply a layer of primer. Choose a primer depending on the type of material: different compositions are used for metal and plastic.

After that, you can safely proceed to coloring. In order not to wash paint stains from the garage floor, lay out unnecessary newspapers or an old rag. The easiest way to paint is using an aerosol can. Hold it at a distance of 40-45 cm from the surface. Apply 2 thin coats. Give each of them about an hour to dry. Make sure there are no bulges. If desired, you can cover the mesh with a grate with an additional layer of varnish.

As you can see, there is nothing complicated in the independent production of a protective mesh for the radiator grille, as well as subsequent installation. All the necessary materials and tools can be purchased at no extra cost at any building supermarket or auto parts store. Speaking of costs: making a grid with your own hands is several times cheaper than buying a ready-made one. You only need a little time and effort to give it the desired shape and install it in its place.

1 Types of radiator grilles for modern cars

Before starting tuning work, it is necessary to determine the material from which your grille is made. The choice of tools and the order of the work themselves will depend on this. To date, in the manufacture of radiator grilles, several popular materials are used, such as:

- aluminum (the most expensive type);

- fiberglass or ABS plastic (budget option for domestic cars);

- stainless steel (universal option);

- carbon fiber (expensive, but effective option).

In the photo - the radiator grill of a modern car

As a rule, aluminum radiator grilles can be found on more expensive car models, SUVs or business class cars. Aluminum is a great option for making a grille, but the manufacturing process is quite expensive, so stainless steel, high-quality plastic or carbon options are more suitable for DIY tuning. Which type to choose is up to the car owner to decide, while the choice of a new grille or tuning it depends on the specific car model and performance.

>

Manufacturing and installation

Now, you need to take a fine mesh and fold it in half, so that the rib under the rib lies and it folds more tightly. The edges of the galvanized mesh are incredibly sharp and tenacious, so protect your hands with gloves. After the mesh is folded as tightly as possible, we temporarily fix it with ties in the four corners. Next, we impose the same layout on this grid and cut out the future grid. It is most convenient to cut such a grid with scissors for metal.

The second step is to fit the mesh onto the frame. For use as a base, a grid with larger cells will serve. According to the layout, the desired contour should be cut out of it. Then we apply a workpiece from a mesh with a small cell on top of it, and align the edges so that they match perfectly. If you use the layout when cutting out the details, be attentive and careful, then all three parts will be the same size and, when superimposed on each other, will give an even, perfect, three-layer edge. If everything is correct, we fix our parts in this position, tightly pulling them together with ties

It is important to arrange the ties in compliance with a certain pattern - either in a checkerboard pattern, or every even row, with distances through three cells.The accuracy of geometric shapes always fascinates, and after the final decoration, the view will change even more.

Our do-it-yourself mesh for the radiator grill turned out to be much stronger than the factory one and much denser, however, it is perfectly ventilated and does not create any obstacles to the air flow. Now you need to process the edges of the finished lattice. To do this, we take a car door seal, and carefully, slowly - so as not to accidentally tear it by hooking on the sharp edge of the mesh, “put it on”. Starting from the lower right corner, millimeter by millimeter, it isolates the sharp cuts of the edge of the grille, plunging them into the depth of the seal. Having completed the full circle, we will return to the starting point, now we can cut off the excess.

In fact, the grille is already ready for use, but it would be nice to give it a more presentable look. Tuning the radiator grille with your own hands, too, is a completely feasible task, and it takes very little. First of all, you should cut off all the hanging "tails" of the screeds - do not remove them completely, but cut off the excess, hanging part. Now lay the grid on a clean sheet of paper face up. Shake the can of paint well and start painting.

First, standing to the right, then, after waiting a little (an hour or an hour and a half), standing to the left of the grate. Such a “crossing” coloring in the directions of the jet will more thoroughly cover the entire surface of the craft

If you approach the question of how to make a radiator grille with your own hands, you can get a high-quality and reliable grille in just a few hours.

2 We create an original lattice with our own hands

The most affordable and now common way to do tuning the radiator grille with your own hands is to install a special mesh that is attached to the frame using a certain set of tools. To create a "grid" you will need the following tools and materials:

- hacksaw for metal;

- welding machine;

- a set of fasteners (self-tapping screws, plastic clamps, etc.);

- file, 120 grit sandpaper and a few screwdrivers.

The first step is to dismantle the regular grille. Removing it with your own hands is simple, for this you need to disconnect the plastic clips, unfasten the latches, release all hoses and wires and remove the part.

Photo of dismantling the grille

After dismantling, it is necessary to cut off all unnecessary inside with a hacksaw. All existing holes can be sealed with fiberglass or putty. Next, the process of grouting the resulting irregularities occurs, for which sandpaper is used. In the future, the radiator grille will need to be painted, so eliminating irregularities is an important and most time-consuming process when tuning.

In the photo - making a radiator grill with your own hands

If you do not want to paint the grille, you can use vinyl film and wrap the resulting frame with it. To do this, you need to purchase a film and a building hair dryer. Place the frame on the wire rack and gently smooth the edges by heating the film with a hair dryer. However, at this stage, you should be careful with the temperature so that the film does not start to melt. On the sides, the film is fixed with construction tape or homemade clips that can be cut out of unnecessary plastic material.

Next, you need to cut the grid, this is done according to the same principle as the film sticker. The frame is placed on a grid, which is cut along the contour. Further, the grid can be fixed on plastic clamps from five sides, but over time they collapse under the influence of weather conditions (rain, temperature changes, etc.). Therefore, for greater reliability, it is better to fix the grid with self-tapping screws. After that, the tuning grille is installed back on the standard mounts.