Expert answers

Sklyar:

if the stove is brick, then it is better to re-shift it by installing the tank from above. at the same time, you will have to make a bypass chimney, but for that the water will warm up faster than the bath

Poli:

at my relatives I saw a healthy cauldron inside and it heats up from the firewood from below ... but in general they sell a lot of ready-made ones

Arseny Ievlev:

Yes, it will be good to warm up through the coil, only the water intake should be at the very bottom of the tank, and the return line is slightly higher. In your case, there will be no water circulation in the coil. The tank must be raised higher, the coil should be made almost horizontally. It must be taken into account that the water from the coil drains completely. If you drain the water from the tank in winter. I have the same system in my bathroom. I blow out the coil when I drain the water.

Vladimir Ivanov:

Do you use the bath once a week? Iron can't burn! Only oxidize under the action of moisture and temperature differences. On the issue. 1. Install the tank on the stove - hot air always tends to rise. It is possible to adapt the coil in this embodiment. 2. Why don't you make the tank the body of the oven? Apply stainless steel. Yes, it has a lower thermal conductivity than iron, but it is more durable. Place the firebox just below the bottom of the tank. I submitted an idea - go for it.

atman:

We usually make stoves: a tank with water above the firebox and heater and the pipe runs inside the tank

from n:

Look here, a lot is written there: svoyzagorodniydom /articles-2/articles-pechi-i-kaminy/banya-i-pech-dlya-nee

Andrey Volkov:

Recently I did a sauna - there was such a ready-made stove (installed). It works from firewood and from gas. But I didn’t look closely at the couple because of the simplicity of the design. In a week and a half - it will be necessary to make a house there - I’ll take a closer look and tell you. Instead of a door, a gas burner is stuck in - when there is no firewood

White Oleg:

Andrey, hello! At first I had it welded from a pipe of the 600th, now I adapted the old coal boiler - I cut windows in the shirt and covered the pebbles. The question is - will you heat the stones with gas enough for a steam room ???

silentcooler:

But maybe still think and buy a ready-made factory one? now they are not so expensive for themselves, they put rus12, an excellent stove, it seems to have cost 11.5 thousand

Roman Shved:

Somewhere on the net, a drawing of the Maximka stove-heater is running around. A friend of mine made one like this .... VESCH!!!!

Basic rules for installing stoves in the bath

Proper installation of the stove in the bath requires strict adherence to the basic installation rules. For the most part, they relate to operational safety.

There are several of them:

Strict implementation of fire safety rules. Everyone knows that stoves are the main cause of fire.

Particular attention should be paid to the joints of the pipe with the ceiling and roof of the building. If you plan to install an electric heater, you should also take care of electrical safety.

Wiring must withstand the maximum load for a long time and be laid in dry places.

Rules are not made to be broken

The general electrical wiring in the bath must withstand the total current consumption from all electrical appliances with a margin.

- Metal sauna stoves, from which there is a strong radiation of heat, should be lined with bricks.

- With a small area of the steam room, you should choose stoves with a screen or arrange a fence to avoid burns from touching the heated parts of the heater.

General cooking rules

So that the cooking process and its result do not disappoint, you need to follow simple rules:

- The oven must be properly preheated before cooking. Ideal condition - hot walls and burning coals.

- After heating, the hostess has no more than 4 hours to prepare dishes. If the stove has cooled down, then it is heated for 1-2 hours. If frying is supposed, then you need to have time to cook for this period.

- Food is taken out of the oven with a fork. If there is none, then an ordinary wooden shovel may come up. But it is better to practice these maneuvers in advance. As in any other unusual business, skill is needed here.

- The dishes are languishing in the oven at the same time. The exception is bread. It is always baked separately. Food that requires long languor is placed in the very depths.

Design features and types of furnaces

The classic Russian bath is close to many and is highly popular among owners of private houses and summer cottages. It is not only entertainment and relaxation, but also great health benefits. For this, so many people appreciate her, trying to provide themselves with such an attribute in their own home.

Typically, this design has a weight of about 800 kg. This makes it necessary to prepare for its installation. The foundation must be at least half a meter deep and 5 cm larger than the dimensions of the stove on each side. If the iron stove for a bath is a simplified version and not so heavy, then a foundation is usually not needed. It can be installed on a concrete floor.

If you have a wood burning stove, you will need a grate. You can make it yourself or order a ready-made version in the store. The grate is set in height as the level of the firebox door itself. From the side of the fuel compartment, 30 cm from the door.

The outer wall is half a brick in thickness. Inside the fuel chamber, such a trick is often used: they make bevels for the coal that has burned out so that it ends up on the grate.

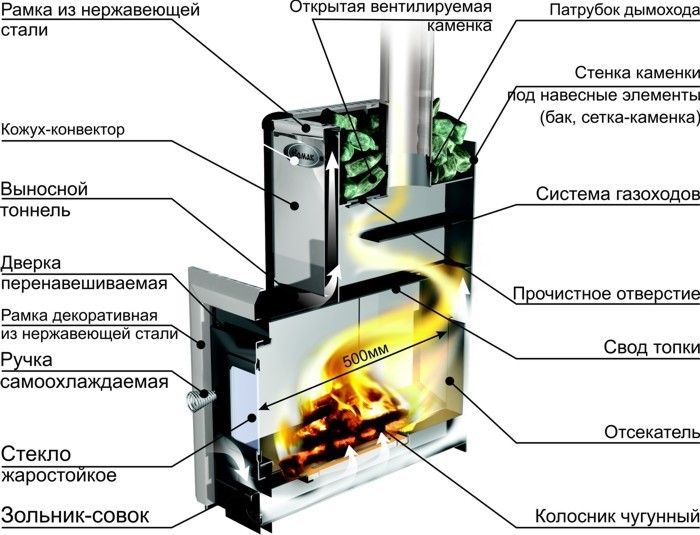

Any oven will still consist of the following main parts:

- Ash pan. This is the space under the firebox for collecting ash, which will need to be periodically cleaned from there.

- This door needs air flow to the structure so that the fuel flares up better.

- Chimney damper. It is necessary to ensure the necessary traction in the stove. When it is fully open, the fuel burns more strongly, and burns out, respectively, faster. When the firewood burns out and coals remain, the valve is closed. which helps keep you warm. But this should be done after they cool down, when they stop burning. Otherwise, in order to avoid harm to health, a gap of about two cm is left for air to pass through.

- Boiler (coil). Here the water is heated, due to the steam of which the bath “works”.

Each oven has its own characteristics. Types of ovens:

Wood-fired sauna stove. This is the most popular oven option. It consists of a furnace, a chimney, an ash pan and grates. Such furnaces are made of metal or stone. They are so often the choice among bath fans because they have advantages: even small dimensions of the device can provide enough heat to warm up a large room. Such furnaces are used even when there is no gas supply at the facility. This type of oven is the easiest to perform. It also has a calming effect - the sound of crackling firewood.

Cast iron oven. They, in turn, are divided into temporary and permanent combustion furnaces. In the first case, firewood is used for the firebox. You can use the sauna when all the firewood is burned. For a continuous combustion furnace, liquid fuel or gas is used as fuel. In the second option, the steam room is suitable for use even when the stove is only heated. This type of stove will heat the rooms faster and distribute the steam more evenly over the entire area of the room.

Electric oven.It comes in different sizes, has different characteristics in terms of efficiency and power. Like the previous one, it heats up quickly and lasts a long time. The advantage is that an electric oven does not need a chimney. They are also not costly.

Furnace for the Finnish sauna. They give dry steam combined with high temperature. Such stoves are both in the electric version, and using firewood as fuel. You can make such an oven with your own hands. Only special drawings and instructions are required.

In order to use the oven to the maximum, it is desirable to know some features. For example, a wood-burning sauna stove can also be fired with other solid fuels. Coal and briquettes are allowed. If you correctly approach the task of how to make a stove for a bath, then it will serve for a long time and please with reliable operation.

Cast iron furnaces are connected to the central gas supply for operation. The use of gas cylinders for these purposes is not recommended, due to the increased explosion hazard.

Furnaces that use liquid for combustion emit a specific odor.

When choosing an electric furnace, it is better to check the wiring beforehand. Such stoves are not very economical for large rooms, which is also worth considering.

The cost of assembling the furnace itself will depend on many parameters, primarily on its size.

Preparation for work

Before you decide to weld the oven, you will need to buy or find a suitable workpiece. The best option is a 200 liter barrel. It is best to give your choice in favor of a product made of fairly thick metal. You can also weld a furnace from a metal pipe. For this task, a pipe with a diameter of 500-800 mm and a length of up to 1 m is suitable. These are the optimal dimensions of the workpiece. Such a stove will be enough to heat a bath room with an area of up to 12-14 m².

Scheme of the movement of fuel gases.

In view of this, to heat the bath room to the required temperature, it will be necessary to spend a much larger amount of fuel, which will significantly increase operating costs.

The bottom of a homemade stove is made of iron. Use a round blank up to 5 cm thick to create the bottom. Supports are easily made from pieces of reinforcement. Prepare reinforcing bars with a diameter of 14 mm and a length of about 30 mm. In addition, you should make a blank suitable for making a grate. To do this, take a circle of metal with a thickness of 50 mm. In this workpiece, longitudinal slots should be created. It is through these slots that air will be supplied to the loaded fuel. You will also need to find, buy or make another round iron blank, which will serve as a cover for the bath boiler and, at the same time, support for the stacked stones. The thickness of this workpiece should be no more than 1 cm.

In order to weld the oven, you will need to prepare the following tools and materials:

- metal sheet for the manufacture of boxes and internal partitions;

- a container (tank) of a suitable volume for water, made of stainless steel or galvanized steel;

- oven doors;

- grinder with circles of 18 cm;

- welding machine;

- piece of pipe for the chimney device.

Before starting work, familiarize yourself with the boiler diagram shown in the image.

Practical advice and real photos of finished stoves

Master or beginner - everyone can turn on their imagination and come up with their own way to improve a do-it-yourself sauna stove. Such a correction may affect the dimensions of the furnace or completely revise the design features of the heating device.

We will provide some useful tips so that you can determine the best option for yourself and make a suitable wood-burning sauna stove.

The legs of the product are best done as a longitudinal slide.This technique will help to avoid excessive pressure on the flooring, due to the even distribution of the weight of the stove on several floorboards. This makes sense, because in addition to the weight of the stove itself, the weight of the stones and water in the tank also presses on the floor. The legs can be made from any metal that comes to hand with the desired dimensions. And the sleds themselves are made of square. It is best not to make the sled too large, as it will protrude beyond the surface of the stove and you may trip and injure yourself.

The bottom and sides of the furnace are laid out with refractory bricks, so the metal walls heat up less and the heat in the furnace will linger longer. Bricks for such purposes are different: heavy (which conduct heat) and light (they isolate heat). Insulating ones are used mainly for melting type furnaces so that the high temperature inside the structure does not pass to the surface (they can be completely cold at the same time). We indicate this separately so that you do not make a mistake when choosing a material. Lightweight insulating bricks are not suitable for sauna stoves. If you plan to increase the thermal conductivity of the structure in this way, do not forget to take into account the place in the furnace for them.

Doors can be made from parts of metal left over from cutting holes. To get pieces of metal suitable for further use, when cutting, try to cut evenly, and to reduce the width of the cut, use thin discs. Such disks add labor intensity to the process, but it “pays off” due to the time saved for making the door later. Metal consumption is correspondingly less. The doors themselves will be slightly smaller than the holes for them, even with the minimum thickness of the cutting disc. To prevent them from falling inward when closing, we make stops. Small metal strips are suitable, which are welded on the back of the slot. In order to increase the tightness of the door with this technique, weld the stops not individually, but along the perimeter of the hole for the door.

The water tank is best made of stainless steel. To weld such a metal, appropriate electrodes will be required. Welding stainless steel requires experience, as the process is more complicated than conventional welding. The current must be adjusted specifically for stainless steel.

To protect yourself and children from accidentally touching a hot oven, install a protective fence around the structure of the oven. It can be attached to the device itself or be portable. The main thing is that the fence creates a safe environment for using the bath.

Is your oven not producing as much heat as you would like? Everything can be fixed. To increase the amount of heat supplied by the furnace, you need to add the area of \u200b\u200bthe structure itself. It is possible to weld metal plates to the sides of the structure. They will be a kind of radiators, complementing the amount of heat coming from the stove.

Another way to add heat: we take two curved pipes with a large diameter (about 50 cm) and weld them on both sides of the stove so that one end looks down (and is below the stove), and the other is up (above the structure). Due to this technique, due to the difference in temperatures inside the pipes, the air from below (cold) will be drawn in, and hot will come out from above.

It is better to supplement the firebox door with a device for adjusting the air flow. The easiest way is to make it from a piece of pipe. To do this, take a small metal pipe (up to 10 cm) and a piece of sheet metal. We make a hole in the door according to the diameter of the pipe and cut out a round part from a sheet of metal, which will be slightly smaller than the diameter. We drill two holes in the pipe at the same level along the axis of the pipe. The distance between them must be equal to more than half of the diameter itself, otherwise the air flows will pass worse. A piece of wire rod of a suitable size is threaded into the holes. The top edge folds up like a handle.The circle that we previously cut out of the steel sheet is welded to the edge of the wire rod.

This is only part of the techniques that are used when making homemade sauna stoves. Imagine, implement and share new methods of improvement from your practice.

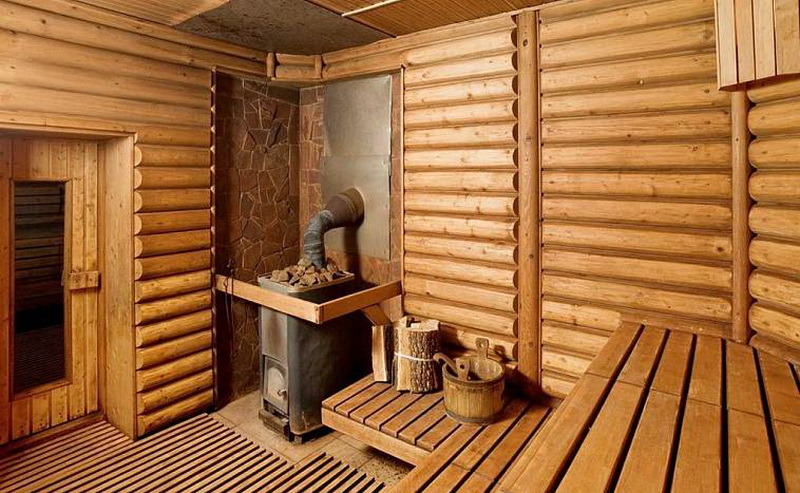

Iron stove installation

Before installing the heater, regardless of whether you bought it in a store or welded it yourself, you should decide on the installation location. In addition, you must familiarize yourself with the basic rules and regulations.

Choose a place and install the unit

The rules for the installation of an iron structure in a bath are regulated by SNiP 2.04.05-91.

Here are some excerpts from it:

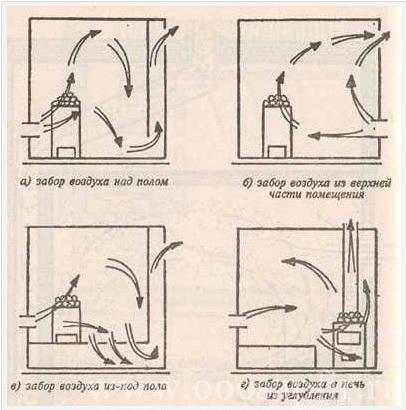

- Before installation, it is required to carry out supply and exhaust ventilation;

- For air inflow, it is necessary to install a channel located below ground level;

- If the body of the unit has legs that lift it off the floor, it is possible to place ventilation holes under its bottom;

- The cross section of the ventilation duct must be at least 100 cm2.

- The ventilation duct must be closed with a grate at the entrance to the steam room.

The principle of the ventilation device

In addition to the requirements of SNiP, the correct installation of a sauna stove implies the following rules:

- The unit must be mounted on a solid base, which is constructed using non-combustible materials. If the furnace is not lined with bricks, then the foundation is not required;

- Thermal insulation should be laid in front of the firebox and covered with sheet metal;

- The distance from the heater to the walls must be at least 1m;

- Combustible wall surfaces must be protected with metal screens;

- It is advisable to place the heating boiler in a separate room.

Installation scheme

After the oven is installed on the base and securely fixed, you can proceed to the next step.

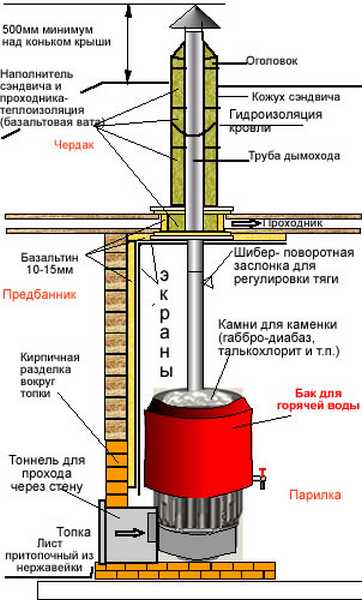

Chimney installation

The ideal option, of course, would be to buy a finished pipe in a specialized store. These pipes are made using a special technology that prevents the formation of carbon deposits, which means they are safer and will last longer.

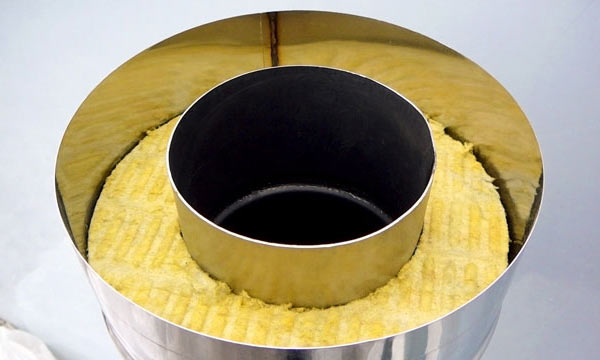

You can make chimney pipes with your own hands. To do this, pipes of different diameters are taken and inserted one into the other. The space between the pipes is densely filled with mineral wool.

Chimney sandwich pipe

Regardless of how the chimney will be removed, through the wall or through the ceiling, it must pass through a special adapter device. Such devices should be installed on all ceilings or walls through which the pipe passes.

In the photo - the wrong installation of the chimney

Bunkers of transition devices are filled with non-combustible material. It can be mineral wool, basalt fiber or just expanded clay. The main condition is that the material must be a non-combustible heat insulator and prevent ignition even in the case of intense heating.

Subject to all the rules, the correct installation of the sauna stove is not a particularly difficult matter, if the safety requirements are carefully followed. When using an iron heater, it should also be borne in mind that it gives a hard heat, and the room in which it is installed requires periodic ventilation.

The video in this article will help you understand the intricacies of installing a sauna stove.