Replacing antifreeze with a Gazelle

Not many motorists managed to deal with the issue of replacing the coolant on a Gazelle car. Therefore, this article will try to solve the problem by picking up the most practical tips in this direction.

Where to approach the problem

You should start by setting the deadlines for replacing the coolant, they are usually set by the car manufacturer. In this case, it is recommended to replace the antifreeze (antifreeze) after 60 thousand km, or after 2 years of operation. An additional reason that serves as a signal to replace the fluid is a change in its factory color to reddish. Such changes indicate the production of inhibitory additives, which is fraught with the cooling system.

Note. It is advisable to follow the manufacturer's recommendations when choosing a coolant. Replacement of antifreeze (antifreeze) should be carried out exclusively on a cooled motor. During the work on replacing antifreeze (antifreeze), you must be extremely careful.

We release the Gazelle cooling system

Motorists who want to replace the coolant on their own need to have a box wrench, tray, antifreeze (antifreeze) on hand. The procedure for draining the liquid is as follows:

- The car is installed on a flat surface;

- The cover of the expansion tank is removed;

- The heater tap opens by turning it all the way to the right;

- A hose of the appropriate diameter is put on the radiator drain pipe;

- A tray is installed for draining the waste liquid;

- The drain hose is lowered into the tray and the radiator valve is opened;

- The waste liquid is drained.

After draining the spent fluid from the radiator, according to the same scheme, the drain hose is thrown to the tap, which is located on the left side of the engine, and the remaining antifreeze (antifreeze) is drained from the channels of the cylinder block. After that, both drain valves are closed.

Filling the system with antifreeze

To begin with, it is advisable to flush the cooling system from the remnants of the old fluid. To do this, the required amount of tap water is poured through the expansion tank. After that, the car engine starts for 5 minutes and then turns off. The water is drained in the same way as the liquid was drained before, after which the system is ready to be filled with fresh antifreeze (antifreeze).

Since the coolant is toxic to the environment, in order not to spill it on the ground, it is better to use a watering can (funnel) with a wide mouth. So, by inserting a funnel into the neck of the expansion tank, you can slowly pour antifreeze (antifreeze) into it. In case the liquid being poured slowly passes through the system, you need to push the radiator hose by hand. After filling the system to the desired level, it is necessary to start the engine again and warm it up to operating temperature.

Note. If the fan does not turn on when the engine is running, and cold air is supplied from the heater, then an air lock has formed. In this case, you need to turn off the engine and let it cool, then open the expansion tank cap and start the engine again for 5 minutes. Then screw the tank cap on tightly.

Advice. If the car is equipped with an additional heater, the electric pump must be turned on. After that, liquid is added and the reservoir cap is closed. Then you should let the motor cool down to check the fluid level again.

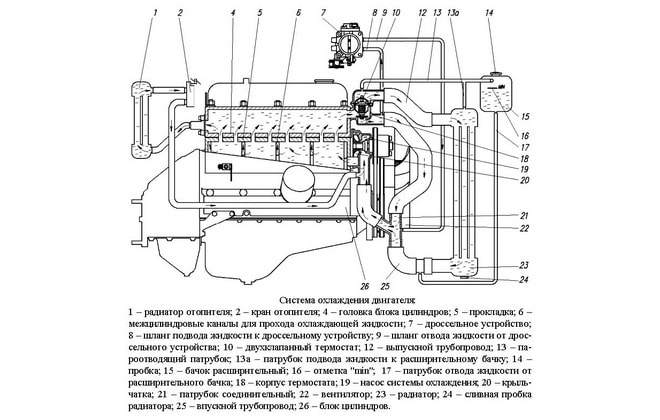

The composition of the Gazelle cooling system

Any engine cooling system consists of certain components, each of which performs its function. So, in order to understand what the whole structure of the system consists of and the purpose of the nodes, it is not enough to look at the diagram. Consider all the details, as well as their characteristics.

Radiator

The radiator is one of the essential parts of the cooling system. It is in this element that the coolant that circulates through the system is cooled. A radiator of aluminum construction is often installed on the Gazelle, in which tubes run in three rows.

It has an inlet and an outlet, where a hot “cooler” enters the first, and the cooled liquid exits the second. Cooling occurs due to the oncoming wind flow that passes through the part.

electric fan

To help the radiator, if it can not cope, comes the cooling fan, which works automatically when the temperature of the liquid in the system reaches 105 degrees. At the same time, the fan quickly and effectively cools the radiator cells, and when the temperature drops, it turns off.

Turning this unit on and off is carried out using a coolant temperature sensor and an electronic engine control unit that regulates all engine operation processes.

Thermostat

The thermostat is one of the elements that is familiar to almost all motorists. The element helps to warm up the engine, as well as cool it. As you know, car engines have two cooling circles, each of which performs its own function. So, if the thermostat is closed, then the liquid circulates in a small circle without the participation of the radiator.

Usually, this system is necessary for fast and efficient heating of the power unit. When the thermostat opens (at 65-70 degrees), the coolant begins to circulate through the radiator, which allows it not to overheat.

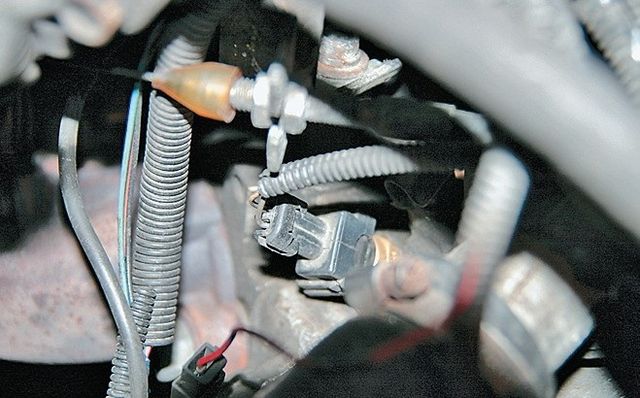

temperature sensor

The temperature sensor is the only electrical part of the engine cooling system that reads system temperature data and sends it to the engine control unit. Subsequently, based on the data received, the "brains" decide whether to turn on the cooling fan or not.

It is worth noting that a malfunction of this sensor usually brings a lot of problems to the owners of the power unit, since, based on the temperature data, not only the inclusion of the electric fan is regulated, but also the fuel consumption, as well as the operation of auxiliary systems.

Expansion tank

The expansion tank is a plastic container that is located above the rest of the cooling system and shows the level of “coolant” in the engine. In addition, an excess amount of fluid from the system is squeezed into it.

Expansion tank plug

A very important element of cooling is the plug of the expansion tank, since it is through it that hot or boiling coolant will be squeezed out in case of overheating of the power unit. It also serves as a valve that indicates the presence of problems in the cooling system.

Water pump

One of the most important elements of the motor is a water pump or just a pump. This unit circulates the coolant throughout the system. The faster the pump runs, the faster the cooling of the engine.

The pump is driven by an alternator belt, which is driven by a crankshaft pulley. On Gazelle 405 engines, a modern water pump is installed, not collapsible, therefore, in the event of failure, the element changes as an assembly.

Branch pipes

On 405 motors, nozzles are installed that connect the nodes of the system to each other and provide fluid circulation. Native pipes are rubber and often diverge when exposed to temperature differences, so many motorists try to replace them with silicone ones, which are not cheap.

stove radiator

The use of a stove radiator is a seasonal phenomenon. Of course, when viewed from the cooling side of the engine, the heater absorbs a sufficient amount of generated heat. But, this node is used only in the winter. In the event of a breakdown of the thermostat and electric fan, the stove is used as an additional cooling unit, but in the summer this creates significant discomfort.

Device and technical data

The device of this motor includes the following elements:

- A block of cylindrical parts made of aluminum.

- Cylinder heads, which are mounted on the axial rocker mechanism.

- Crankshaft equipped with main and connecting rod journals, which improved engine performance.

- Single-mass flywheel equipped with a toothed rim.

- The piston part of the motor. Each piston has 2 compression rings and one oil scraper ring.

Parameters and technical characteristics of UMZ-4216:

| Engine displacement | 2.89 l |

| piston stroke | 100 mm |

| Compression ratio | 9,2 |

| Diameter of cylindrical parts | 92 mm |

| Power unit power | 107 horsepower |

| Full mass | 177 kg |

Cooling system

The 4216 engine cooling system includes:

- radiator;

- thermostat valve;

- fan;

- stove tap;

- expansion tank for working fluid;

- small and large cooling circuit.

See the user manual for a complete diagram. The type of cooling system is liquid. With the help of a centrifugal pumping mechanism, the forced circulation of the coolant in the system begins. Passing through the heater device, it is brought to the desired temperature, and in the radiator part, the process of cooling begins. The liquid itself passes through two circles of circulation: small and large. The small circle does not include the passage through the radiator.

Clutch

The design of the coupling mechanism includes the following elements:

- crankshaft;

- flywheel;

- slave type disk;

- pressure disc;

- protective cover;

- springs;

- push handle;

- bearing;

- pipeline;

- gears;

- gearbox housing;

- master cylinder.

When the driver presses the pedal, the force is transmitted through the rod and the piston part, after which the pressure passes from the pistons to the working cylinder. Then the rod begins to move the clutch release fork and the pressure bearing, from which the force is transmitted to the gears. When the driver releases the pedal, the spring parts begin to act, and all parts return to their original position.

Clutch replacement occurs only with the engine turned off.

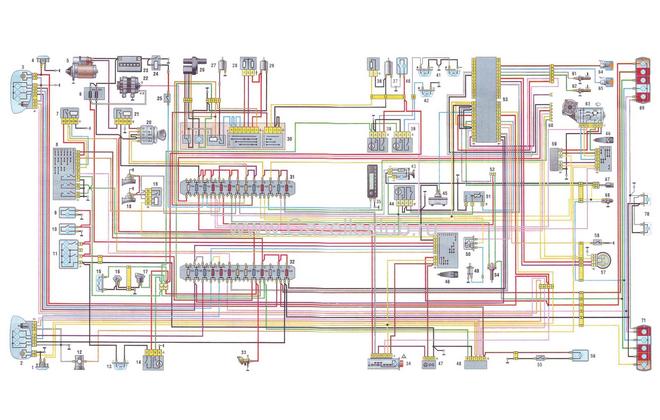

wiring diagram

The electrical equipment connection diagram consists of such elements as:

- rechargeable batteries;

- electric starter;

- ammeter;

- ignition coil;

- control relay;

- generator set;

- spark plug.

Before starting work, it is always recommended to conduct an external inspection of the wiring for damage, breaks and defects. The rated voltage in the electrical equipment connection system is 12 V.

During the operation of the motor with a small number of revolutions, the consumers are powered by batteries, because. the generator set does not develop the necessary electromotive force. All consumers are connected in parallel.

Fuel consumption

This model of the power unit is produced by the Ulyanovsk Motor Plant. The average gasoline consumption of the engine power system in summer is 18 liters per 100 km. The fuel consumption of the GAZelle UMZ-4216 in winter is 26 liters per 100 km.

The main breakdowns of the UMZ 4216 engine

A more common failure is a rupture of the intake manifold. According to the manufacturer, on the UMP engine 4216 an intake manifold made of insufficiently strong steel was installed. In 2010, this problem was successfully corrected. UMP engines with a collector made of solid steel began to be installed on the Gazelle car.

How to drain antifreeze from the umz 4216 block.

The next most popular malfunction is in the cooling system of the UMZ motor 4216. At medium speeds at speeds above 60 km / h, the engine temperature is normal. One has only to slow down the speed, the temperature rises evenly and the antifreeze does not boil for long. If the Gazelle got stuck in a traffic jam, then overheating of the motor is inevitable.

for gazelle and other cars.

On the UMZ 4216 engines, an electric clutch is installed, using which} {the radiator fan is engaged.This clutch starts to work incorrectly, the fan does not turn on. Naturally - overheating of the motor. Methods to get rid of overheating:

- Install copper heatsink. Copper conducts heat better, cools the liquid more efficiently.

- Instead of antifreeze, fill in high-quality antifreeze.

- Fool the fan drive - make manual activation from the cab. As a better option, get rid of the electric clutch in the UMP cooling system 4216 and install an electric fan with the largest number of blades and a thermal switch.

HBO on the UMP engine 4216

In order to save on Gazelle cars create an installation of gas-balloon equipment. UMP engines 4216 even from the factory they come with installed gas equipment. For installation at an outside HBO office, the manufacturer does not refuse to provide a guarantee.

What are the advantages of installing HBO:

- The absence of deposits such as soot in the combustion chamber of the motor.

- Reduction in exhaust gases of harmful substances.

- Increasing the resource of the motor.

- Fuel economy. Gas is half the price of gasoline. HBO pays off in about 30 thousand kilometers.

On the Gazelle cars with the UMZ 4216 engine, gas-cylinder equipment of the 4th generation is installed. The engine ECU is structurally assembled in one housing with the HBO control unit. What do 4th generation slots have? And most importantly - all the work of gas equipment excludes human intervention. The choice of the type of fuel is made by the control unit of the machine.

A temperature sensor is installed on the evaporator reducer. When setting the operating modes of the engine and HBO, the temperature of operation of the solenoid valve for switching the type of fuel is indicated. When the threshold temperature is reached, the supply of gasoline stops, the gas supply is turned on. Based on the "gasoline" map of the operation of the UMZ 4216 engine, calibration takes place block HBO management. Due to the difference in the octane numbers of gasoline and gas, the opening time of gas injectors will be somewhat different than just the opening time of gasoline ones.

10 Electrical equipment of the engine 4216

The composition of the electrical equipment of the engine, except for

electrical appliances of the power supply and ignition system also include: starter, generator,

oil pressure and coolant temperature sensors.

Starter.

Three types of starters are used on the engine: 4216.3708000-01, 422.3708000,

5732.3708000, which are completely interchangeable.

The starter is an electric motor

direct current series excitation with a drive consisting of

drive gear and freewheel roller clutch.

Rules for using the starter:

1. Prohibited

move the car using the starter. This could cause the starter to come out.

out of service.

2. In

winter time, it is impossible to start a cold engine that has not been prepared

preheating, by scrolling it for a long time with a starter. Similar

attempting to do so could damage the starter and battery.

Generator.

The engine is equipped with an alternator with a built-in

rectifier and integrated voltage regulator.

The maximum output current of the generator is 64 A.

Two types of generators are used: 9402.3701-17

or 33.37.71.010, which are completely interchangeable.

In operation, it is necessary to check the work

generator according to the voltage indicator installed in the instrument cluster

car.

Basic rules for operating the generator:

1. Prohibited

even a short-term connection of the outputs of the regulator or generator to each other and

on the body, because this will damage the voltage regulator.

2. Prohibited

running the engine with the battery disconnected.

3. Prohibited

starting the engine with the positive wire of the generator disconnected, because it leads to

the occurrence on the rectifier of the generator of increased voltage, dangerous for

rectifier diodes.

4.Forbidden

checking the malfunction of the generator and regulator circuit by dialing

megaohmmeter, or by means of a lamp powered by a mains voltage of more than 36 V.

Checking the insulation of wires with a megohmmeter or a lamp powered by mains voltage

more than 36 V, allowed only when switching off semiconductor devices

generator and regulator.

5. When

When washing the engine, do not allow a direct hit of a jet of water on the generator.

6. When

maintenance of the brush assembly of the generator is necessary:

- brush holder

and wipe the brushes with a clean cloth soaked in gasoline;

- check

the integrity of the brushes, whether they stick in the brush holders, and the reliability

their contact with contact rings;

- brushes

worn to 8

mm to be replaced.

Emergency oil pressure sensor.

Emergency oil pressure sensor 30.3829

contact type, installed in the engine oil line (Fig. 4, item 12),

works in the signal lamp circuit. Contact closure occurs at pressure

0.4–0.8 kgf/cm2 (0.04–0.08 MPa)..

..

1

2

3

4

5

6

7 ..

Engine maintenance

The entire range of maintenance that needs to be carried out so that the 4216 engine continues to work perfectly can be divided into 3 parts: checking the condition, monitoring and diagnostic aspect and routine maintenance.

Checking the status consists of the following actions:

- Checking the oil level;

- Checking the liquid level;

- Checking the tightness of power, cooling and lubrication systems.

The number of KDRs (control and diagnostic work) that the UMZ 4216 engine must undergo during maintenance:

- Checking the thermostat, coolant sensors, oil temperature and pressure;

- Tightness of crankcase ventilation systems, power supply, lubrication, cooling systems;

- Condition of contacts in electrical equipment;

- Diagnostics of KMPSUD and elimination of detected problems;

- Check for extraneous sounds during operation;

- Check the condition of the alternator and fan belts;

- Compression check in cylinders;

- Checking the operation of the generator.

And the last list - routine maintenance:

- Tighten fasteners;

- Adjustment of valves UMP 4216 (the procedure for adjusting valves depends on personal desire);

- Adjust gaps;

- Clean from soot and dirt;

- Flush the cooling system, then replace the liquid;

- Flush the crankcase ventilation system;

- Change the oil filter;

- Change oil.