Valve classification

This fitting contains in its composition a whole set of fasteners, assemblies, fixtures, parts that are used to regulate various flows. Among them are the following elements:

- valves; gate valves; taps; gates; valves.

They are installed on various pipelines, in tanks and on units.

These elements are activated using a special electrical device or manually. There are several types of equipment such as shut-off valves for water supply. Types of elements are safety and mixing.

The requirements for this type of equipment must comply with the following standards:

- The material of manufacture is brass, steel, bronze, plastics, cast iron. Each element meets special operating conditions. The throughput is quite high. Shut-off valves for water supply are designed for a certain pressure and temperature. A mandatory requirement is an anti-corrosion coating that prevents rust.

Distribution and mixing fittings

Distribution and mixing fittings serve to distribute liquids (hot and cold water, heat carriers) in certain directions or to mix flows. This device is made in the form of multi-way taps and valves.

You can consider this plumbing fixture using the example of a low-temperature underfloor heating system. The essence of this solution lies in the maximum increase in the dissipating power of thermal devices and the supply of an optimal temperature to the heating circuits of the coolant, sufficient to compensate for heat losses in the premises. To implement these principles of operation, three-way distribution valves are being installed.

The device of three-way valves is based on the principle of controlling the flow of liquids. Therefore, any product of this type, as a rule, has three inlets: one of them is common, the other two are switchable. The fluid flow is switched using a rotary (or rod) damper having two extreme positions. In the extreme position, the flow of liquid occurs only through one of the switchable holes. At any intermediate position of the damper, the fluid flows are mixed in a certain proportion.

Do-it-yourself fitting installation

Any type of shut-off valves for water supply can be installed in three ways:

- welding method;

- on flanges;

- using carving.

Installation of fittings by welding

Welded fittings in private plumbing systems are currently used extremely rarely, since the installation of such a device requires a welding machine and skills to work with it.

Device installed with a welding machine

However, the welding method is still used in the installation of industrial pipelines. How to install fittings by welding:

- a section of pipes is cut out at the installation site of a crane, valve or valve;

- the edges are cleaned and polished;

- reinforcement is installed on the prepared area and fixed with a welding machine;

- welding seams are protected and covered with a layer of paint or primer.

Reinforcement fixed with a welding machine

The welding seam cannot be separated to repair the reinforcement, that is, in the event of a breakdown, the device installed earlier will have to be cut out. However, the welding seam is the most durable and sealed.

Mounting with threaded connection

The threaded connection is detachable, that is, if the fitting breaks down, it can be replaced as soon as possible without any problems.

To arrange a threaded connection, you will need:

- grinder for cutting pipes;

- threading tools;

- wrench.

Threaded shut-off valves of the water supply system are installed according to the following scheme:

- section of pipeline is cut. The ends of pipes are processed;

- thread is cut;

Thread cutting for installation of valves

- the thread on the reinforcement is sealed with any material, for example, FUM tape or linen thread;

Sealing the threads on fittings to increase the tightness of the connection

- the device is fixed;

- the tightness of the obtained connections is checked.

How to properly cut the thread and install the valves can be viewed on the video.

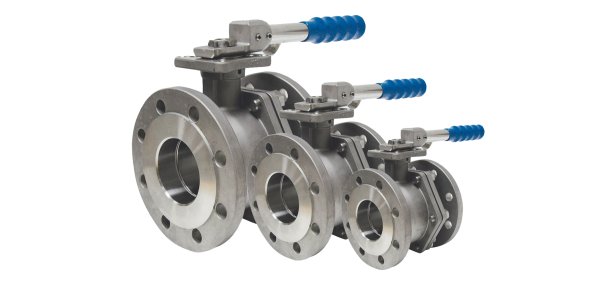

Installation of fittings on flanges

The flange connection is also detachable, but is mainly used in industrial plumbing systems.

It is rather difficult to equip a flange connection on a domestic water supply system, since it is necessary to initially weld special rings on which the fittings will be fixed. If such rings were installed earlier, then flange fittings can be installed according to the following scheme:

- between the ring on the pipe and the flange located on the installed device there is a sealing gasket that increases the level of tightness of the connection;

- the device is fixed using the fixing bolts that are attached to the fittings upon purchase.

Mounting fittings with flange connection

Knowing the functional features of certain types of valves and the rules for their installation, you can choose the most suitable device and install it on the plumbing system with your own hands.

Shut-off valves are installed

- At the input and output of supply and return pipelines from settlements.

- On pumps with nozzles.

- In places where the pipeline branches to the nodes of the risers, as well as indoors.

In all other cases, the use of stop valves, as well as coal in Moscow, is justified by the project and terms of reference.

Rules for the installation of valves

When installing shut-off valves, several rules should be followed. And the first thing to do is to clean the pipeline. Cleaning can be done by hand or by blowing air, water or steam. Then you need to carefully check the flanges. They should be straight, without any bends.

An important point is protection against hydraulic shock. The high pressure that can occur upon impact can significantly reduce the service life, as well as lead to breakdown of pumping equipment and valves. That is why it is necessary to install a check valve that ensures the stability of the water flow. Do not close the shut-off valve too much or twist it. When welding fittings made of stainless steel, it must be kept in the open position.

How to install shutoff valves

The pipeline in which the shut-off valves will be installed must have a check valve that ensures a stable flow. Installation of shut-off valves is possible only in straight sections. Before starting work, all internal surfaces are cleaned of foreign objects and contaminants. In addition, they must not show any damage. When mounting the butterfly valves, the disk must be one quarter open. Valve and piping flanges must have equal diameters. When installing fittings, the use of additional gaskets between the flanges is not required.

Installation of ball valves involves the use of a connecting nut

When performing work, care must be taken not to damage the thread. The ball valve during installation must not be subjected to force

When installing valves, it is impossible to transport them using a steering wheel as a rigging. The valve should be protected from falling from a height, as this entails the risk of mechanical damage and corrosion.Before installation, the valve should be positioned according to the direction of movement of the working medium.

Shut-off valves, like technical salt, are cheap, so they are available to all consumers. Installation is carried out in stages, and stable operation depends on how accurately the installation rules were followed.

Valve requirements

Locking devices in terms of prevalence make up about 80% of pipeline valves. Their main purpose is to completely block the flow of the medium, however, they can perform protective, distribution and other additional functions. Depending on the field of use of the devices and the nature of the liquid or gas being transferred, special requirements are imposed on shut-off valves, especially for chemically aggressive, as well as flammable and explosive environments. However, most often pipeline fittings of this purpose are used for arranging heat and water supply systems.

General requirements

- The tightness class of shut-off valves must be maintained after at least 2500 cycles.

- Duration of operation - from 50 years.

- The drive of the mechanism must be carried out with a maximum force of not more than 250 N/m.

- Tightness of drives and connecting pipes.

- Correspondence of connecting dimensions to the diameter of pipes, threads or flange connections.

- Reliability of operation of shut-off valves of heat and water supply networks at temperatures from -10 to + 80 °С for underground placement, from -40 to +60 °С - for ground ones.

- Availability of graphic symbols of boundary positions and direction of movement.

Hydraulic resistance

One of the requirements for shut-off valves is efficiency, which is achieved by minimizing the hydraulic resistance of devices, and, accordingly, saving electrical energy by pumps that transfer the working medium

Hydraulic losses, to a greater extent, take place in the radial direction of networks, therefore, special attention is paid to the resistance of section reinforcement

Valve tightness

The tightness level of shut-off devices is determined by the tightness class of the flow shutoff. If the nominal diameter is 1000 mm, the following leakage volumes are allowed: for classes B, C and D - 18, 180 and 1800 cm 3 /min, respectively. Class A implies a tight fit of parts and no leakage.

The following requirement is imposed on the shut-off valves of the water and heat supply system: the absence of gaps on elements such as air vents and drains (class A), minimal leaks in sectional networks and branches (class B).

Structural reliability

The operating pressure of heat and water supply systems is 1, 1.6 and 2.5 MPa. Shut-off valves in the process of operation must withstand the values of this indicator. In the process of operational testing, the network is supplied with a pressure 1.5 times higher than the calculated one. When the devices are used at higher values of this parameter, special requirements are imposed on the fittings: significant structural strength, branch pipes and a thicker body. Design pressure of devices from 4.0 MPa.