Expert opinion

Which is better - foam or foam? Experts give an unequivocal answer to this question. According to its characteristics, penoplex significantly exceeds the performance of foam plastic. Therefore, this material was able to win its place in the market. Even at a much higher cost, extruded material is often purchased for various construction work.

Penoplex inherited some of the disadvantages of foam. It is a vapor-tight and combustible material. However, it fully copes with its thermal insulation functions. This allows us to talk about the high efficiency of penoplex. Polyfoam has a rather limited scope. This is also a shortcoming of the presented material.

The house should be not only beautiful and comfortable, but also warm.

Therefore, it is very important to choose the right insulation.

There are many different heaters on the construction market. This article will talk about such modern heaters as Technoplex and Penoplex, how they differ and which one is better to choose.

Let's start with what they are made of. Both insulations are made of extruded polystyrene foam (EPS). XPS is a heated polystyrene (the familiar white Styrofoam balls) and a foaming agent.

What to choose

After the construction of the building, the owners always wonder what kind of insulation is better to use for, in fact, the thermal insulation of the home.

And this question is quite reasonable, since the construction market has a huge number of different heaters, which, as it seems to many, only specialists can compare in terms of efficiency.

And given that Penoplex and Technoplex are now the most popular as a heater, this article will be devoted to which of these heaters is better, and what is the difference between them.

Differences between Isolon PPE and NPE

The differences between these two types of Izolon are visible to the naked eye, in addition, they have different areas of application. Externally, Isolon NPE has larger cells and is less elastic to the touch. It is undesirable to use it with a point load, since cells filled with air can burst, depriving the material of its noise-absorbing and heat-insulating properties. Large cells contribute to the formation of a rather uneven surface of the material, which can complicate the process of gluing and subsequent leveling of the surface.

Most often, this type of Izolon is used when carrying out packaging work, as well as when it is necessary to create a shock-absorbing pad. Thanks to a simpler production method, CPE costs an order of magnitude cheaper than polyethylene foam with a cross-linked molecular base.

PPE costs a little more, but its technical characteristics benefit in many ways. It is more durable and elastic, better adapted to changes in ambient temperatures and mechanical stress, and it is also more durable. This material has a perfectly smooth surface, making it easier to install. When gluing the material, several times less glue is used than when installing the NPE.

Extruded polystyrene foam

Penoplex has a bright and recognizable orange color.

Penoplex has excellent chemical resistance, but it is important to know that it absolutely does not resist gasoline (however, like Technoplex). Due to its good strength characteristics, Penoplex can be used for external insulation.

In the Penoplex line there are different types of it (their names speak for themselves):

- roofing (insulation of attics and roofs of various configurations);

- wall (insulate basement, walls, partitions, facade);

- foundation (used as a heater for the basement and the floor of the first floor);

- comfort (can be used for any work, but is especially well suited for warming apartments, balconies);

- 45 (has the best performance of all types, used in road construction and bridge building).

The manufacturer of Penoplex is Penoplex. Penoplex is produced in standard width and length - 600 mm by 1200 mm, respectively. But the thickness is different - from 20 mm to 150 mm.

Penoplex is operated at temperatures from -50 0 C to +75 0 C. Water absorption - 0.4% - is slightly worse than that of Technoplex, but still a very high figure. The thermal conductivity is 0.03 W/(m*K).

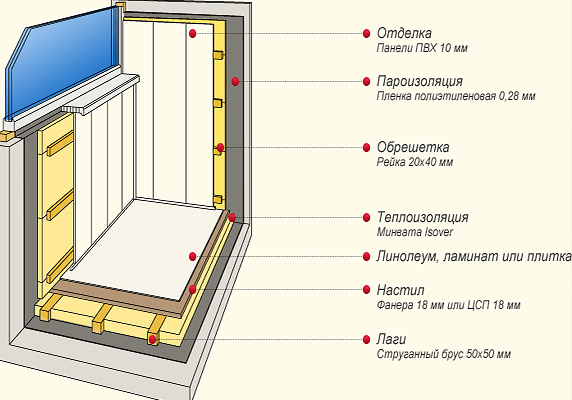

Complex insulation of the balcony with Izolon

In the photo, the balcony is ready for finishing.

The insulation of the balcony with Izolon, as well as the loggia, should be carried out in a complex manner. This means that thermal insulation must be fixed everywhere: on the floor, ceiling and walls. Please note that without good, energy-saving windows, no insulation will help. The lion's share of the heat goes through the glass (this is if everything is sealed). We have already written about how to check heat loss. High-quality insulation of a balcony with only one Izolon is nonsense, thick heat-insulating materials are needed. The best option is foam with a density of 25 kg / m. cube

We present to your attention the fastest and easiest way to comprehensively insulate a balcony:

- foam plastic is glued to the walls and ceiling with glue-foam;

- guides are laid on the floor according to the level;

- between the guides, you can simply put the foam in two layers with a gap in the joints, all the cracks are foamed with the same adhesive foam;

- the entire balcony is pulled in with foil insulation with a shiny side into the middle of the room, the joints are glued;

- logs are placed on the floor guides, and everything is sewn up with an OSB slab - the floor is ready;

- wooden bars are drilled into the walls and ceiling through the foam plastic - this is a crate;

- trim is attached over the crate.

This method minimizes the use of an impact drill, and there is no need to dilute universal construction adhesive. It saves time and nerves, and the result is excellent. Everything will hold securely and will never fall off, you won’t even be able to tear it off on purpose.

Now let's sum up the brief results of our today's article about Izolon. Insulation for floors, walls and ceilings without foil works more as sound insulation, protection against steam and moisture. Often used as a lining under a laminate or even linoleum. The thermal insulation properties of foamed polyethylene are quite high (0.037 W/m*C), but with a small thickness the effect is insignificant. Foil materials serve IR rays, which is very useful, especially in the bath. A gap of 15 mm or more must be maintained between the foil and the trim.

2 Types of heaters

Question: "Which insulation to choose?" it is very multifaceted, moreover, each individual case requires an individual choice, and it is impossible to say exactly which insulation is objectively the best. Let's look at the basic requirements that a really high-quality insulation must meet.

Comparison of different types of insulation

thermal insulation properties. The higher the thermal insulation characteristics of the material, the thinner the lining layer will be, as a result of which both finances and free space will be saved.

Hydrophobicity From how much the heat insulator absorbs moisture, the life span of the ego directly depends. The presence of internal moisture contributes to the accelerated destruction of the insulation

It is important that the material has water-repellent properties.

Fire resistance. High-quality insulation should not undergo combustion and be self-extinguishing.

Lifetime

It is important that over time the insulation does not decompose, does not lose its thermal insulation properties, microorganisms, midges and rodents do not start in it.

Safety. This factor acquires maximum significance when it comes to materials for thermal insulation of a country house from the inside. The insulation should not have any negative effect on the human body;

Soundproofing. High-quality heaters, as a rule, have good soundproofing properties. We are talking about foamed foam and mineral wool products.

Price. How much insulation costs is often one of the leading factors when choosing a thermal insulation material. It is important that the cost of the insulation is optimally correlated with its functional characteristics.

Let's figure out which insulation is best used to insulate a country house with your own hands. The following materials meet the above requirements:

- Mineral (basalt) wool;

- Expanded polystyrene foam;

- Foil penofol;

- Liquid penoizol.

Warming the walls of the house with liquid penoizol

If you are not limited in funds, then mineral wool is the best option for warming the cottage with your own hands. In terms of thermal conductivity, this material is one of the best heaters. It does not burn, does not rot, has excellent soundproofing properties and vapor permeability, which helps to maintain an optimal indoor climate.

Mineral wool can be used to insulate walls with your own hands, both inside and outside the house. The weak side of mineral wool insulation is unsatisfactory moisture resistance.

Manufacturers are trying to solve this issue with the help of a variety of hydrophobic additives that impregnate mineral threads at the creation stage, however, in order to be completely sure that the insulation does not collapse due to moisture gain, it is necessary to equip a high-quality waterproofing layer.

If you do all the work yourself, then an important factor is the maximum simplicity of the insulation. The best option in this case is foil penofol, or foamed polystyrene foam.

These materials have good thermal insulation properties, and, at the same time, they are quite inexpensive. Penofol with double-sided foil is great for internal insulation of the walls of the house, while expanded polystyrene should be used for external wall insulation. To the menu

Material features

An important indicator for building materials is their ability to ignite. Styrofoam belongs to the category of normally combustible, while foam plastic is a highly combustible material. To reduce its flammability, at the production stage, the material is treated with flame retardants. The result was achieved, but only the penoplex began to emit dangerous toxic gases into the atmosphere.

Manufacturers of both types of materials claim their unlimited service life. But such a statement is appropriate in the absence of ultraviolet radiation on the surface of materials. Therefore, it is possible to talk about durability after covering the foam and polystyrene with protective materials.

This material has high moisture resistance and airtightness. Polyfoam loses in these parameters, since it is not a reliable barrier to air circulation, and less protected from moisture.

The difference between foam plastic and foam plastic is due to the following parameters:

- strength;

- moisture resistance;

- air tightness.

Penoplex has the following advantages:

- the high density of the material reduces its thermal insulation properties;

- in the absence of additional processing, it is inferior in combustibility to foam;

- low coefficient of environmental cleanliness;

- high degree of moisture resistance.

Styrofoam has the following properties:

- minimum density, but the best degree of thermal insulation;

- lack of sound insulation;

- minimum moisture resistance.

These are the main important properties of both building materials for insulation, according to which they are selected.

Both materials are easy to install and process, but when choosing a material for insulation, it is important to take into account such a factor as its scope.

Comparison of types of heaters

To avoid problems in the future operation of housing, you must first familiarize yourself with the technical characteristics of the insulation materials and their relationship with the main structures. Only after receiving complete information about the properties of various heaters, you can safely decide what type of appropriate material you can insulate a house with.

Currently, for external insulation, min-plate, foam plastic and polystyrene are used.

When analyzing the comparative characteristics of these materials, the main attention is paid to such properties as:

- thermal conductivity;

- density;

- vapor permeability;

- water absorption;

- combustibility and so on.

It is necessary that all of the above properties meet the required standards. This, in turn, will help ensure the safety of the house, the formation of its internal climate and a long service life.

In this matter, the type of the main material of the house structures is important. As you know, it is customary to build housing in a suburban area using wood material, block or brick. The technology of house insulation directly depends on the main types of materials that were used during the installation of the structure structure.

For example, for a wooden house, the best option for insulation would be, of course, a mine stove. Foam insulation of wooden walls is unprofitable for many reasons. First of all, due to the fact that wood is a breathable material, and in the case of using foam, all the important useful properties of the insulation will simply come to naught.

Minplita, in turn, is suitable not only for sheathing external walls, but also for internal partitions, floors and ceilings. Since, together with heat-conducting qualities, it is an excellent noise-absorbing material.

Styrofoam, unlike plate mines, is in excellent contact with wet ground. Therefore, it is more often used as insulation for foundations and various engineering networks passing underground. Due to its internal properties, the foam is able to protect structures for many decades.

In addition to polystyrene, many people think of using polystyrene foam. Conducting a comparative analysis of the properties of materials and finding out their data on thermal conductivity, strength, water absorption, and so on, the majority comes to the conclusion that penoplex is somewhat better. The main disadvantage is the cost.

Insulation with foam plastic will cost one and a half times more than using foam plastic. It is for this reason that it is often rejected, preferring to deal with cheaper insulation. Such reasoning, when the price becomes the dominant component in the choice, can lead to negative consequences.

It is always better to think well in advance, what is better, to conduct insulation cheaper, but worse, or overpay, but end up with a high-quality insulating, protective coating?

However, polystyrene has its advantages over polystyrene. The latter, for example, due to insufficiently good adhesion, is not suitable for mounting on walls above the level of the plinth. Here, preference is given to foam plastic or mineral wool, which is even more acceptable, since, unlike mineral plates, foam plastic and foam plastic are combustible.

Recently, there have been trends in Russia aimed at refusing to use polystyrene foam in the construction of houses. It should also be noted that many European countries have already banned the use of such materials due to their toxicity at the time of combustion.

How to choose a heater for a loggia or balcony correctly

The balcony is a special design, and it is not recommended to make it heavier. And if you take into account that before the insulation you will need to install double-glazed windows, which will entail strengthening the fence, then the insulation should be made of minimally lightweight materials.

To begin with, it must be said that all materials for insulation have a different structure and installation method. Some, such as isolon, are sold in a roll, others - polystyrene and foam, have a solid, porous structure, others are soft and elastic like cotton wool. It is easiest to work with those materials that are harder, but they do not fully meet the requirements of insulation. For greater thermal insulation, they have to be supplemented with isolon.

Basic requirements for heaters:

- Low thermal conductivity;

- Resistance to deformation from temperature changes;

- Ecological cleanliness;

- Strength under mechanical action;

- Ease of installation;

- Resistance to dampness, water, heat;

- Durability;

- Compatibility with other materials.

When doing repair work, it must be borne in mind that some materials, such as polystyrene, have disadvantages. Almost all of them are destroyed when exposed to solvents, can crumble and break under load.

Wall insulation with Izolon

It is important to lay the sheets butt-to-butt and glue the gaps. As we have already found out, ordinary polyethylene foam does not give the expected reduction in heat loss, therefore, insulation of walls with Izolon from the inside must be carried out with foil materials

A shiny surface will serve the rays of heat back into the room. If the foil is glued onto a polyethylene base, then the ability to absorb sounds and vibrations, as well as retain water and steam, is added to the reflective properties. All this is necessary when you need to insulate a bath, or rather a steam room.

As we have already found out, ordinary foamed polyethylene does not give the expected reduction in heat loss, therefore, insulation of walls with Izolon from the inside must be carried out with foil materials. A shiny surface will serve the rays of heat back into the room. If the foil is glued onto a polyethylene base, then the ability to absorb sounds and vibrations, as well as retain water and steam, is added to the reflective properties. All this is necessary when you need to insulate a bath, or rather a steam room.

Consider installation methods with additional insulation with mineral wool:

- we attach wooden bars to the wall - in random order, the main thing is that later it would be convenient to stuff the counter-lattice;

- mineral wool is placed between the bars, you don’t even have to glue it to the wall;

- on top of the bars with a stapler, the Izolon foil insulation is nailed with a shiny side into the middle of the room;

- rolls are spread end to end, and the slots are glued with aluminum-coated tape;

- the second tier of the crate is nailed (counter-crate);

- any finish is attached.

It is important to strictly follow the installation recommendations, especially with regard to the gap between the foil and the trim. It must be 15 mm or more

This is necessary so that the material can realize its full potential at 100%. After all, the foil beats off IR rays, and they are transmitted only through the air, if there is no gap, then the radiation in this case is impossible. Temperature will be transferred from one material to another, and aluminum conducts heat very well. Therefore, instead of warming, you can get the opposite result.

If we are talking about a sauna, then in addition to infrared radiation, there is plenty of moisture. It will condense on the foil insulation and, in the absence of a gap, will certainly be absorbed into the finish.Dampness has not yet gone to the benefit of any material, the service life in such conditions is catastrophically reduced.

The difference between expanded polystyrenes

As mentioned above, the use of liquid and powder blowing agents is better, so the products obtained using this technology have stable thermal insulation characteristics. Although, it is impossible to call this the only reason why Freon is not included in the Technoplex and Penoplex. There are two more:

- Sealed cells of new material that has not yet been used have freon residues. Formally, it is called safe, but in reality it is better not to deal with it. It can cause lung problems in children.

- Over time, the gas will be forced out of the cells by air and moisture. And if dirty raw materials with the inclusion of styrene were used in the manufacture of the material, then the contents will penetrate into the external environment.

And if technical grades of EPPS, such as Penofol, are used to process the foundation, highway, basement, then the presence of freon in the composition does not affect the material in any way. But for home insulation it is better to use safe products. Therefore, the answer to the question: Penoplex or Penofol, which is better, can be answered - the first option.

And how do you know which is better Penoplex or polystyrene foam? Indeed, many recommend performing insulation with foam plastic, because it has a low price and excellent characteristics. To answer this question, you need to find out how penoplex differs from polystyrene foam. Let's start with production technology.

Technoplex, Penoplex and even that Penofol are created in the process of extrusion. This allows you to get a very dense linear structure, which affects the resistance of the material to water and humidity, as well as strength. Therefore, foam plastic is somewhat worse than materials created by extrusion methods.

Thermal insulation of the ceiling with mineral wool

Before proceeding to the description of the installation, it should be noted about the significant drawback of mineral wool. In conditions of high humidity, the insulation accumulates condensate, which gradually deprives it of its qualities; in other cases, the surface of the room is affected by fungus or mold. True, this drawback concerns the uppermost floors of high-rise buildings (ceiling) and partially lower ones (floor insulation).

https://youtube.com/watch?v=Z-f0YLbXzqA

Lay mineral wool as follows:

We eliminate all the irregularities of the ceiling.

We tightly fix the hydro and vapor barrier material (oilcloth or membrane).

We prepare, and then we install a suspended wooden frame.

We fix the required amount of mineral wool under the main ceiling (by making a constriction from a nylon thread) or by passing the insulation through U-shaped suspensions.

Mineral wool can be laid in the bosom between the ceiling and the frame

When using this method of insulation, it is important that dust does not penetrate through the lining. https://www.youtube.com/embed/Vg2OtJl1nDQ

The quality of insulation depends on the thickness of the insulation. In this case, you can use thermal insulation in both 2 and 20 cm, it all depends on the design of the loggia and your preferences.

Thermal insulation with foam

Laying insulation on the ceiling is not always carried out as the final element of the installation of the loggia. Sometimes it is completely absent, which is why the owner of the room loses in coziness, comfort and quality of heat.

The simplest way, which does not require a lot of time for thermal insulation, is considered to be laying with penofol. The installation looks like this:

- We make accurate measurements of the length and width of the surface.

- We transfer the dimensions to a roll of building foam foam, after which we cut off the required amount of material.

- We install the first layer of thermal insulation using transverse wooden slats (3-4 pieces are enough).

- We clean all recesses and joints with a special sealant or mounting foam.

- We wait until the surface is completely dry.

- We carry out the installation of the second layer of insulation, using already longitudinal rails. The finished ceiling structure must be connected without defects to the thermal insulation of the walls.

- You can fix the finish using external slats that form a flat surface.

Thermal insulation of the ceiling of the loggia with penofol, including high-quality insulation of the floor and walls, will retain a significant part of the heat of your apartment in the winter. And self-installation of loggia insulation will save you a good amount of money, because. penofol is one of the easiest materials to process and relatively inexpensive.

What thermal insulation is better for a balcony

Thermal insulation of a balcony or loggia is a mandatory procedure if you need to attach additional square meters to the main living space. It is not difficult to create comfortable conditions here with your own hands (unless you have to entrust the replacement of windows to specialists). We offer an overview of the most popular and effective materials that are suitable for these works.

It is a slab or soft loose rolls of the finest mineral fibers, randomly intertwined and fastened with synthetic resins. It is made by melting basalt rocks, silicates (cullet) or blast-furnace slag.

Mineral wool is widely used in construction, but it is rarely selected as an internal insulation for a balcony. All because of the large thickness of the effective layer, which must be laid under the skin. If the area of \u200b\u200bthe loggia is small, and every square centimeter counts, you have to think seriously about the appropriateness of its use.

- Good thermal insulation at the level of 0.04 W/m °C.

- Ease of installation.

- Environmental friendliness and fire safety.

- High breathability.

- Excellent absorption of airborne and impact noise if it is basalt wool (from 80 to 98%).

- Average price.

- Too light and inexpensive mineral wool gives noticeable shrinkage. Its ability to keep its shape is inversely proportional to the density and thermal insulation characteristics.

- It absorbs moisture well, which is why it noticeably loses its effectiveness, that is, it itself needs a hydro- and vapor barrier device.

- If it is glass wool, then during processing and further operation without dense sheathing, it will produce a large amount of allergenic dust.

| Specifications | glass wool | Basalt wool | ||

| Izover Classic + | Heat Knauf | Rockwool Light Butts | Izovol L-35 | |

| Thickness, mm | 50 | 100 | 50 | 100 |

| Density, kg/m3 | 15 – 17 | 16 | 35 – 37 | 35 |

| Thermal conductivity, W/m °С | 0,038

0,041 |

0,037

0,044 |

0,036

0,041 |

0,035

0,042 |

| Air permeability, mg/m h Pa | 0,55 | 0,55 | 0,30 | 0,30 |

| Water absorption by volume, % | 1 | 2 | 1,5 | 1,5 |

| Price per package, rubles | 750 | 680 | 440 | 310 |

Mineral wool for mounting on vertical balcony structures should be moderately rigid so that uninsulated air pockets do not appear inside from its subsidence over time. Such properties are possessed by basalt slabs with a density of 35-40 kg/m3. And for the ceiling and the unloaded layer between the floor joists, it is better to choose light glass wool of the Izover type with high performance.

Insulation of the ceiling and floor with Izolon

Metallized lavsan film Izolon.

The easiest way to insulate the floor with Izolon is to use it as a lining under the laminate, although it is also possible to lay linoleum over foamed polyethylene. In addition, this material can be used in the structural elements of the building, for example, on the ceiling and wooden floor laid on the logs. The installation technique in both cases is very similar, so we will consider them together.

Naturally, Izolon thermal insulation as an independent insulation gives an insignificant result, since its thickness is too small. Therefore, in order to get a high-quality heat-insulating cake, you need to use more solid heaters, for example, mineral wool. In this case, in addition to auxiliary protection against heat loss, polyethylene foam can act as a vapor barrier.Mineral wool, especially glass wool, tend to absorb moisture from the air, especially if it is laid on the ceiling. Therefore, the insulation of the ceiling with Izolon in some cases is not only desirable, but necessary.

The correct method of warming:

- mineral wool is laid between the lags of the floor or ceiling;

- Izolon is tightly attached along the lags;

- the counter-lattice is stuffed;

- finishing is being applied.

It is quite possible to lay this material directly under the finish, as sound insulation. To do this, it is enough to fix the material with a construction stapler on the working surface butt-to-butt and glue the joints with adhesive tape. If there is a technical possibility, it is better to leave a gap between the foamed polyethylene and the finish. Even if there is moisture on the insulation, it will successfully evaporate and will not be absorbed into the finishing materials, which will significantly extend their service life. Many are interested in the question of whether it is possible to insulate the floor with Izolon in a wooden house. This is allowed, but again, as an independent thermal insulation, it almost does not give a result.

Rigid heat-insulating cylinders made of mineral wool are used to insulate communications.

You can read about which non-combustible roofing insulation is best.

Conclusion

An attempt to compare the characteristics of which insulation is better, foam or technoplex, can only be accepted as a preliminary assessment of materials. Most of the foamed polystyrenes have very similar characteristics, so in order to get the full picture, you need to take into account the feedback on the practical use of different brands of insulation.

Today, a large number of different heaters are presented on the building materials market. They differ in performance, cost and scope. Also, heaters can be made from natural and artificial components. Both groups of materials are popular.

Many buyers are interested in which is better - foam or foam? They belong to the category of fully synthetic substances. These materials and their differences will be discussed below.

Considering which is better - foam or foam, you should consider the features of each of the presented heaters. They have a lot in common, as they are made from the same material. However, its processing is significantly different.

Both presented materials are characterized by low weight. Heaters of this type do not absorb moisture. Also, artificial materials are not subject to decay, which allows them to be used in almost any weather conditions. These artificial heaters are afraid of exposure to solvents (acetone, gasoline).

It is very simple to use foam plastic and polystyrene in construction work. They do not weigh down the structure. Also, the cost of the presented materials remains invariably affordable for all categories of buyers. This makes both presented heaters popular among buyers.

However, foam and polystyrene have a number of differences. Some buyers think that these are completely the same materials. However, this is not the case.

Conclusion

Insulation is an important part of creating a comfortable home that is a pleasure to live in. Materials made from extruded polystyrene foam have excellent characteristics. They are safe, durable, effective, do not interact with moisture in any way and retain heat in the house. As far as comparisons of species are concerned, there is no single best material to be noted here. All of them are good in something of their own, have the same characteristics and are used for a particular situation. You can consider reviews of materials. They complete the overall picture.