How to insulate heating pipes with your own hands

The sequence of actions in the form of step-by-step instructions:

calculation and purchase of thermal insulation material;

wrapping the pipe with foil tape or foil. Foil

acts as a heat reflector;

installation of insulation around the pipe. Sectional rigid

(casing) or soft insulation is simply “put on” on the pipe. As for soft

materials, then they need to be cut into blanks, equal in width to the diameter of the pipe.

Then wrap around the pipe and fix with tape, wire or

plastic clamps. Hard insulation is the hardest part. From it you need

create a box around the pipe (or use pipe shells of the appropriate

diameter);

inspect the insulated pipe for the presence of "bridges

cold" and eliminate them;

fasten the thermal insulation material to the pipe with

plumbing or metallized tape;

if necessary, cover the thermal insulation material

protective material (film) and seal the joints with adhesive tape.

The cost of insulating heating pipes, despite their

the initial value, quickly pay off by saving on payment

home heating bills.

Insulation of water supply pipes in a private house is an important step in creating a comfortable microclimate and reducing the cost of space heating in private and apartment buildings. Consider in the article the requirements for insulation for polypropylene pipes, whether it is necessary to insulate heating and plumbing.

In private houses, communications have two vulnerable areas for freezing. These sites are located on the street when laying communications from the well to the house or in an unheated basement. If you have not done basement insulation, then it is necessary to protect the pipes in the basement of a private house from heat loss. Consider how and how to insulate communications on your own, tell you what materials to use.

Is it necessary to insulate polypropylene pipes in a private house? If you did not spend during construction, then it is simply necessary to protect communications from heat loss. If a country house is rarely used in winter, then communications can freeze, regardless of what material is used for the water pipe - metal-plastic, HDPE or galvanized steel.

How to insulate pipes in a private house with your own hands

When a cold water pipe enters a warm room, condensation will always form on it. If the pipe is insulated, then you will protect the room from the possible appearance of dampness. Heating houses also need thermal insulation in order not to waste excess heat in a given room, but to redirect it to the maximum to living quarters, reducing their heating costs.

How to insulate heating pipes on the street with your own hands

To choose the right pipe insulation, you need to know

what types of thermal insulation for heating pipes exist, and what are the features

each of them.

1. According to the installation method:

rigid sheet insulation

. These include: foam and

expanded polystyrene. Despite the high thermal insulation properties, the installation of such

insulation is quite complicated in terms of ensuring tightness

insulation;

roll insulation

. Among them: polyethylene (used in

as an additional component of insulation), foil penofol, cotton wool

(mineral and glass wool). The use of roll materials requires arrangement

their reliable fastening to the pipe;

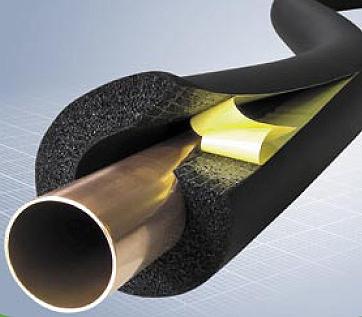

segment (casing) heaters

. There are such heaters

two varieties: rigid - shells made of expanded polystyrene, polyurethane foam (PPU) or polystyrene,

and soft - polymer pipes. The advantage of segmental materials is that they

keep their shape perfectly, are easy to install and provide the right level

tightness of the fit of the heat-insulating material to the heating pipe;

sprayed heaters, incl. thermal paint

. Penoizol excellent

has established itself as a sprayer, because it allows you to isolate even

small cracks. Thermal paint has the same property. The only downside to these

materials, they are quite expensive and their self-application is problematic.

2. By type of insulation:

polystyrene and expanded polystyrene

. Possess the best

characteristics in terms of maintaining the initial temperature of the coolant.

Their use in the form of a shell simplifies installation and provides reliable protection.

systems;

wool (mineral, glass wool)

. Can be applied as

rolled and as sectional material. Regardless of the type and configuration

cotton wool insulation for heating pipes has a significant drawback, which

is that cotton wool is hygroscopic. Those. she needs more

moisture protection. When wet, cotton wool loses its properties. Therefore, often

sections have additional protection in the form of a foil layer. But cotton wool

Great for thermal insulation of pipes in the basement or attic.

foam foil

. Due to the small thickness, it is used

mainly for the insulation of pipes indoors.

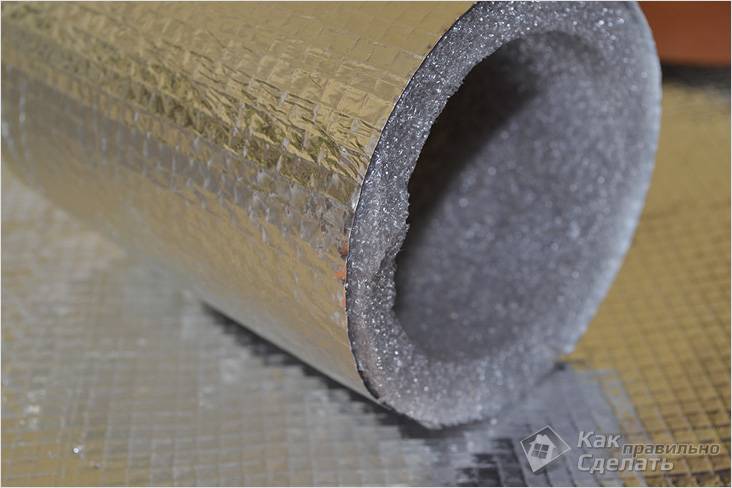

polyethylene foam

– (EPE, PPE) polyethylene foam for pipes.

Foamed polyethylene

This is a flexible insulation, which is produced in the form of pipes of various sizes, with a cut in the middle (this is done for ease of installation).

When the pipeline is insulated with this material, pieces of insulation are applied to the pipes along the entire length, and pulled together with construction tape. The joints or joints of pipes must be covered with insulation of a thicker diameter. Therefore, before starting work, you need to roughly calculate the required amount of insulation of different sizes.

The insulation of this brand is very convenient, it can be easily cut, and the remaining pieces can be used elsewhere, making up one long part from several segments.

Styrofoam

Such a heater is made in the form of two shells of different sizes, they are fastened with special grooves, but for the reliability of the connection they must be additionally fixed with special glue or tape.

When connected on pipes, the halves of the insulation are interconnected and the two parts are displaced in different directions by several centimeters. The next link is also connected, and the remaining ends are joined together, it turns out a kind of "overlap" of one connection to another, which provides a better bond.

For warming uncomfortable areas and turns, curly shells are used, which are of unequal sizes.

In order to carry out high-quality insulation with this material, it is necessary to calculate in advance the length of the pipeline, the number of joints and bends. This is necessary to purchase the required number of connecting parts.

What to consider when performing thermal insulation

Before proceeding with the insulation of a structure located in the basement of an apartment building, you should learn the basic requirements in order to get the expected result and avoid numerous problems.

- Maximum service life.

- The ability to self-extinguish.

- The presence of water repellency.

- Ease of installation.

- Low cost.

- Environmental friendliness.

- Low thermal conductivity.

Thermal insulation in an apartment building

What materials are preferred?

To date, the variety of materials with which you can easily and quickly insulate the plumbing in the basement is impressive.

Among the most effective and most popular are the following:

1. Mineral wool

Elements made on the basis of mineral wool will cope with temperature changes. With its help, it is possible to insulate not only pipes in the basement of an apartment building, but also those that are outside or in the ground. What the mineral wool looks like can be seen in the photo below.

2. Polyurethane foam

Ideal for insulating basement plumbing and attics. In fact, it is the outer shell of the water pipe. This design minimizes heat loss and adds strength. This heat insulator is not afraid of chemical influences, does not rot. But it has one drawback - high cost.

3. Styrofoam

This material is characterized by a high level of rigidity. Expanded polystyrene insulation is sold in the form of a pipe part, which has protrusions for fastening.

This heat insulator is best suited for internal insulation of a heating system.

5. Styrofoam

Styrofoam is good for insulating heating and water supply systems on the basement and basement floors. It has a low level of moisture absorption. Also, the foam is very durable, can be used for more than two decades.

6. Foam rubber

The thermal insulator has a number of advantages. It is elastic, resistant to temperatures and is not afraid of fire. Due to the fact that it is resistant to fire, it is suitable for the insulation of outdoor pipelines.

7. Liquid heat insulator

High quality material that can compete on equal terms with the rest. For example, one coat of paint can replace a 5 cm layer of polyurethane. In addition to insulating properties, liquid thermal insulation is able to protect the metal from corrosion and gives pipes a good appearance. But it is not used for thermal insulation of plastic pipes.

Regardless of the material you choose, the main thing is that the thermal insulation is effective, and on cold days there are no problems with tearing or other damage. More detailed instructions for installing a particular heat insulator can be viewed on the video on the Internet. It is worth noting that working with heaters is not difficult, you can easily do it yourself.

If you find an error, please highlight a piece of text and click Ctrl+Enter

.

7901

Hello. Today I want to talk about how to insulate heating pipes inside and outside construction sites with your own hands

. The topic is of considerable interest, since proper thermal insulation can reduce the level of heat loss during the transportation of the coolant from the thermogenerator to the heater. I hope you find the instructions in this article interesting and helpful.

How to insulate pipes in the basement with your own hands

glass wool

Fiberglass insulation Isover, Knauf and Ursa. The material is most often used for the insulation of pipes made of metal-plastic. A positive characteristic is the low density of the material, its use requires additional insulation using rolled waterproofing materials (fiberglass or roofing material), which requires additional financial and time costs.

Basalt insulation

Basalt insulation in the form of cylinders made of basalt fiber. The shape allows you to mount the insulation without the construction of special trays, due to its cylindrical shape, while the cost of the insulation can be high. The upper protective layer of waterproofing can be made of foil isol or glassine.

Foam insulation

Styrofoam is the most common material. Expanded polystyrene shells can be used to insulate pipes without an outer coating; it does not require laying trays. The insulation can be used repeatedly, and the performance characteristics of expanded polystyrene satisfy all the requirements for the insulation of water pipes.

Is it necessary to insulate heating pipes and what it gives

Thermal insulation for heating pipes allows you to:

reduce heat loss in places where pipes pass through

ground, mounted by air (ground) method or located in

unheated room;

prevent freezing of the liquid that is the heat carrier

(freezing is fraught with a pipe break);

reducing the likelihood of corrosion on the pipe surface

(for metal pipelines);

saving money on home heating.

Thus, the more reliable the system will be insulated

heating, the more heat will go to the user (higher efficiency), and the less

will have to pay for gas for heating (or for electricity, if

electric boiler).

Due to the fact that the coolant moves through the heating system,

the task of pipe insulation is reduced to minimizing heat loss and preventing

rupture of the system due to its freezing.

A popular solution in this case is to use

thermal insulation materials. This is the most budgetary and simple in terms of

self-implementation of the method of insulation.

Who should pay for the replacement of pipes in the basement

Hello, I live on the ground floor, the apartment is divided into three rooms, a hot water pipe burst in our basement (that is, there is no water only in our apartment, there is water in the whole house), the management company says that the tenants must replace it themselves. Such a question, should we pay money for replacing the pipe, or should the management company do it?

Victoria Dymova

Support Officer Pravoved.ru

Similar questions

- Who should, after replacing the pipes of the in-house heating system, eliminate the consequences (if the wallpaper was damaged during gas welding)? 23 August 2016, 14:56, question #1354083 5 answers

- Replacement of pipes and mixers in a communal apartment June 14, 2015, 20:38, question No. 871057 2 answers

- At whose expense should there be a replacement of the pipe from the central water supply to the column in the private sector? July 28, 2017, 13:34, question #1708933 1 answer

- Who should pay for the repair of heating pipes? 10 February 2017, 21:20, question #1534698 1 answer

- Do we have to pay for the replacement of the pipe or should the housing department replace it for free? 16 July 2016, 13:56, question #1316494 1 answer

We insulate communications in the basement of the heating pipe

The problem of insulation of communications in the basement, as a rule, is not familiar to ordinary city dwellers. But it is very often encountered by all those who live outside the city or have a dacha (or a private house) of seasonal residence. Insulation of pipelines is not only a useful, but often necessary measure that protects the entire building from many potential problems.

Materials for thermal insulation

Today, a variety of materials can be used to reduce heat loss and insulate heating pipes. The choice of one or another heat insulator for basement pipes will depend, first of all, on the specific requirements of the owner of the house, operating conditions and pipe dimensions.

A huge number of heat-insulating materials are presented on the modern market, but not all of them are suitable for heating pipes.

This point must be foreseen before purchasing one or another heat-insulating material.

Of course, fibrous heaters, including mineral wool, can be attributed to the most common and traditional heat insulators that are used everywhere.

It can be used in a variety of conditions, and almost always thermal insulation will be quite effective.

Materials based on mineral wool can potentially withstand extremely high temperatures, so they can be used in basements and boiler rooms.

Mineral wool.

What can be distinguished from the main advantages of this heat insulator?

- high level of resistance to chemicals;

- safety for humans and the environment;

- minimal water absorption (but with a serious impact of water, the insulation will lose its properties);

- small price.

Basalt wool.

Mineral wool, according to experts, is great for thermal insulation of external pipelines, as well as heating systems in the basement of a private house.

In recent years, derivative materials have been increasingly used: basalt wool and glass wool, which also have good operational and performance characteristics. Materials of this type are suitable for most suburban homeowners.

Insulation with polyurethane foam

Recently, more and more people began to pay attention to modern heat insulators. And one of the most popular and effective is polyurethane foam (PPU)

This type of material is great for pipes and is, in fact, the outer shell for a water pipe (“pipe in pipe”).

Polyurethane foam significantly reduces heat loss.

This type of construction not only minimizes heat loss, but also gives the pipes a high level of strength.

Positive characteristics of polyurethane foam:

- the material does not contain any compounds hazardous to humans;

- high level of resistance to climatic influences;

- increased mechanical strength;

- neutrality to electricity and biological influences.

Insulation materials based on polyurethane foam will not rot or break down when exposed to chemicals. The only obvious drawback of the material is its high cost. In fact, only this can be considered a reason to abandon the thermal insulation of polyurethane foam in the basement of a private house.

Ready shells PPU.

It should be noted that it is not so easy to do the insulation of pipes with polyurethane foam with your own hands, so it is better to hire specialists for this work. In the basement of a private house, the use of polyurethane foam often does not look like a very profitable measure: the cost of a single installation (for example, for one or two pipes) will be quite high, so there is no urgent need for this.

Basalt cylinders

The heat-insulating material is a hollow product made of stone basalt wool, having a cylindrical shape. They are available coated with aluminum foil or uncoated. There are different diameters and thicknesses, 1-1.2 m long. You can find basalt cylinders with a tongue-and-groove lock or an even joint that needs insulation. The material is resistant to aggressive environments, bioresistant, easy to install. Because of hygroscopicity requires isolation.

Interested in insulation for heating pipes? Its price will depend on the characteristics and properties of the heat-insulating material. The estimated cost of the most commonly used products in the construction market is as follows:

basalt cylinders - from 50 rubles per linear meter;

polyurethane foam - from 10 rubles per linear meter;

heat-insulating paint - from 230 rubles per 1 liter;

energy flex - 10 rubles per linear meter, and more;

foam shell - 30 rubles per linear meter and more.

Remember that you should not save on thermal insulation material. To keep your home always warm and cozy, use quality products from trusted manufacturers.

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world This girl's name is Melanie Gaidos, and she broke into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

Unforgivable Movie Mistakes You Probably Never Noticed There are probably very few people who don't like watching movies. However, even in the best cinema there are errors that the viewer can notice.

15 Symptoms of Cancer Women Most Often Ignore Many of the signs of cancer are similar to those of other diseases or conditions, so they are often ignored.

Pay attention to your body. If you notice

7 Body Parts You Shouldn't Touch Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch. Display research.

Our ancestors slept differently than we do. What are we doing wrong? It's hard to believe, but scientists and many historians are inclined to believe that modern man sleeps in a completely different way from his ancient ancestors. Initially.

10 Mysterious Photos That Will Shock Long before the advent of the Internet and the masters of Photoshop, the vast majority of photos taken were genuine. Sometimes the pictures got really unbelievable.

Why insulate pipelines

To begin with, let's take a closer look at whether it is necessary to use the material for insulating heating pipes or for thermal insulation of heating networks, and if necessary, then why and where exactly.

The heating system of any building is arranged as follows: indoor air heats the coolant (water) circulating through pipelines to radiators.

Giving off its heat through the walls of the pipes, the water returns back to the boiler, which again heats it. This is if in general terms.

However, heat transfer is not necessary along the entire length of the pipe. For example, if the boiler room in your house is located far from residential premises (or even in a separate building on the street) that need to be heated.

In the process of transportation from the boiler to the area requiring heating, the water will lose some of the heat. As a result, more energy (fuel) will have to be spent on heating the air for living rooms, which means more money.

Often, boiler rooms are located in basements, where the temperature is significantly lower than for a living room. So the Energoflex insulation for heating pipes in the basement will give a serious result in fuel economy.

But thermal insulation for heating pipes for an apartment is no longer so important and indispensable. The only caveat is that the insulation of heating risers is relevant: in this case, more heat will reach the battery

In addition, the pipeline also needs mechanical protection - from possible damage. First, this applies to sections that run along the street - it is their isolation that needs to be thought about first of all.

How to insulate pipes in a private house

You should think in advance how to insulate water supply pipes in a private house, how to insulate a columnar foundation and what kind of heat-insulating material to use for various materials. The requirements for the materials used should take into account the ease of installation of insulation, long service life, water-repellent characteristics, environmental and fire safety of the material.

You should not have any difficulties in your work, anyone can cope with this issue. No special skills or special tools for pipe insulation are required. Check out the video instruction at the end of the article on this topic, and you will understand

Insulation of heating pipelines is an important aspect in the creation of energy-saving technologies, and this issue is acute today.

At the moment, a large number of insulating materials and methods for their optimal use in various industrial fields have been developed.

But, it is necessary to rationally use energy not only in industry, but also in everyday life. Insulation of heating lines is not only desirable, but also turns into a vital necessity.

In general, the process of thermal insulation is aimed not only at maintaining the temperature regime at a stable level, but also at protecting the heat carrier from freezing during the cold period.

Thermal insulation materials are of the following types:

- piece;

- in rolls;

- combined;

- for filling;

- casing.

Depending on the technical characteristics and insulation parameters, these materials are used in the following networks:

- ventilation;

- supply of cold and hot water;

- technical equipment;

- steam heating.

The choice of protective material must be approached with great responsibility, because it is a guarantee of warmth and comfort in people's homes.

The types of the most effective insulating material are as follows:

-

Thermal insulation paint

. It is attributed to the achievements of Russian science. One layer of this coating can be a replacement for several centimeters of polystyrene foam and mineral wool. At the same time, this material does not harm the environment and is resistant to high temperatures. This type of pipeline insulation is used in difficult production conditions. - . This material is characterized by low heat conductivity and fire resistance. For these reasons, it has found extensive use in the protection of heating systems. But, this type of protection refers to expensive building materials.

-

Insulation with polyurethane foam

. They began to use it for thermal insulation recently, but they have already managed to evaluate its practicality. -

Styrofoam

. This is practically the same pinoplast. This option is distinguished by affordable cost and simple fasteners. - . It is a shell resembling a pipe in shape.

Heating pipe insulation technology

The choice of pipe insulation and the method of its installation has

influence of the location of the pipeline.

Insulation of heating pipes on the street

External thermal insulation of pipes is the most difficult method of insulation,

because in the open air, not only pipes need protection, but also the

insulation. Non-hygroscopic materials are used for outdoor installation, or

others, but reliably protected from moisture by a film, a casing.

In addition, on the street it is advisable to use the most dense and

thick insulation. Another requirement is the use of material

resistant to UV radiation, bad weather and mechanical damage.

Insulation of heating pipes in an unheated room

Basement, cold attic, boiler room - a feature of such

the room is the lack of heating radiators. But since the pipes

filled with coolant and located in an environment with minimal humidity, here

there are no special requirements for either the heat-insulating material or its thickness.

Insulation of heating pipes underground

The specifics of installing heating pipes underground is that

that they must be laid below the freezing level of the soil, and this

depth of one and a half to two meters. If you do not adhere to this requirement, the coolant

will be strongly cooled until it passes through a heating main located in the ground.

In order to reduce heat loss, you need to take care of quality

insulation of the underground pipeline.

Masters say that the best solution in this case

there will be a cable heating system for pipes. But due to the high

cost, users prefer reinforced pipe insulation

heating.

Good insulation of heating pipes underground involves

fulfillment of requirements:

isolation of the insulation from the moisture that is in the soil;

exclusion of the possibility of deformation of the insulation, tk. in that

case, its properties are reduced. This is especially true for soft

thermal insulation materials;

According to reviews, the best solution is the thermal insulation of heating pipes

via .

Note. Users recommend for pipes that

laid above the level of soil freezing, use a combined system

insulation, namely: a combination of cotton wool and a rigid PPU shell with a protective coating

fiberglass. Ideally, even at the laying stage, use factory multilayer ones.

polyurethane foam

This insulation is applied by spraying. A specially prepared composition is sprayed onto the mounted pipeline. It reliably adheres to the surface and, foaming, forms a dense protective mass with high strength.

Due to the fact that this insulation does not tolerate exposure to sunlight, the insulation of pipes located in the open air with it must be accompanied by their protection: winding with roofing felt or aluminum foil.

For high-quality insulation of pipes, heaters can be combined. For example, in the boiler room and on the street they can be covered with mineral wool or basalt insulation. And in the house there are places for connecting to radiators - with foamed polyethylene, which looks more aesthetically pleasing.

Thermal insulation for outdoor heating pipes

A variety of heaters provides an opportunity to choose

exactly the one that is best suited for a specific application

(on the street, in the ground, in the basement, in the attic) and the budget.

The selection of a heat insulator is carried out taking into account the following factors:

diameter of the pipe of the heating system;

operating conditions (location of the heating

systems);

average heating temperature of the coolant;

the thermal conductivity of the insulation (the lower, the

it is better);

water absorption index. Shows ability

insulating material to perform its functions in a humid environment;

resistance to combustion, biological and chemical

activity, exposure to ultraviolet radiation and other environmental factors;

life time;

ease of installation (provided sufficient

tightness);

price.

Do I need to cover the pipes from the cold

The coolant that enters the radiators of our apartments comes with a temperature slightly lower than it was in the boiler room. If the boiler room is located at a remote distance from the house, this heat loss is even more noticeable. According to statistics, a quarter of the total amount of heat that comes from the boiler room to the radiator is lost along the route of the pipeline. Most of the pipeline is in the open air and is not always insulated. Street heating is undesirable for any consumer. Therefore, protecting the pipeline from the cold is a vital necessity.

The warm water that flows inside is able to protect the pipeline from freezing, but the heat loss is significant. Pipe insulation will help maintain the temperature of the coolant inside the pipe, heat loss will be significantly reduced, and the pipes themselves will be protected from atmospheric influence: temperature and humidity changes. Corrosion processes in insulated pipes will be insignificant, which will lead to long-term use.

It will be especially important to carry out thermal insulation work in areas where the pipeline runs along the street, or in basements. Timely insulation will reduce the financial costs of heating an apartment or house.

Installing your own boiler house in a multi-storey building will not solve this problem, because the pipeline is located in the basement, where cold air is present, and heat loss is inevitable.

The use of high-quality thermal insulation materials will allow the consumer to obtain a comfortable air temperature in the apartment, regardless of which radiators he has: cast iron, aluminum or bimetallic.

So, the purpose of warming the heating pipeline is as follows:

- increase the temperature in the consumer's room;

- save money on the purchase of this coolant;

- exclude pipe freezing and, as a result, repair work;

- protect pipes from adverse environmental influences.

thermal insulation requirements

The efficient operation of the heating system depends entirely on the material that the consumer chooses.

When choosing a heat insulator, it is necessary first of all to pay attention to thermal conductivity.Thermal conductivity is the ability to maintain or lose the temperature of the carrier inside the pipe for a certain amount of time.

In addition to the thermal conductivity of the material, the insulation must meet the following criteria.

- The pipeline must be protected from the ingress of moisture and the formation of condensate inside. Good moisture resistance will not allow corrosion to form on the heating pipes.

- The insulating material must be resistant to high temperatures, and in some cases be fireproof - resistant to fire, smoldering and fire. Some industrial productions operate in a dangerous fire mode.

- The insulation material must not be attacked by aggressive chemicals.

- The heat insulator should not rot, deform and collapse.

- Installation of material on the pipeline should not cause difficulties.

- The service life of thermal insulation is necessary for a long time: the more durable the material, the better.

- When performing heat-insulating work on the pipeline, it is necessary to exclude gaps at the junctions of the material.

- The insulation should not accumulate electrical energy and have a high electrical resistance. Nearby electrical wires will cause electrical corrosion, which is unacceptable.

- It is good if the insulation is easy not only to install, but also to dismantle. In case of repair work, the insulation material can be reused.