Introduction

For people, the environment limited by the room is of great importance. It must have characteristics corresponding to the requirements of favorable conditions for human life. These characteristics include: the microclimate of the room, the level of illumination, as well as the level of noise and vibration. In connection with the growth of industry, transport and cities, and hence the growth of noise in the world, one of the most important tasks of modern construction is to create a comfortable acoustic climate in

places of work and rest of people. Unfortunately, the low quality of construction does not always ensure the normative indicators of sound insulation in the premises. As a result, it is necessary to resort to additional soundproofing of the premises, including the use of soundproof materials. Research in the field of sound insulation began relatively recently, about 20 years ago, but the study of the sound insulation and sound-absorbing characteristics of materials has not been carried out.

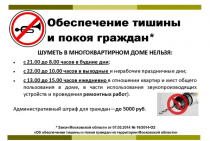

Noise is a combination of sounds of varying frequency and intensity. From a physiological point of view, noise is any unwanted sound that has a harmful effect on the human body. High noise levels lead to an increase in human nervous tension, cause irritation and aggression, reduce performance and are the cause of various diseases.

Noise sources in the human environment include: vehicles, water supply, sewerage, air ducts, technical equipment, household appliances, etc.

One of the main characteristics of the noise level is the sound intensity level L, which is measured in dB. The impact of noise on the human body depends to a greater extent on the value of this characteristic, and the higher its value, the worse the effects of this noise. Noise with a sound pressure level of up to 30-35 dB is familiar to people and does not bother. Increasing the noise level to 40-70 dB forms a significant load on the nervous system, which leads to a deterioration in well-being, and with prolonged exposure can cause neurosis. Noise levels above 75 dB can

lead to hearing loss - occupational hearing loss. Sounds whose level exceeds 120–130 dB cause pain and damage to the human hearing apparatus. Under the action of noise at high levels of 140-160 dB, tympanic membrane rupture, contusion and death are possible.

Studies show that the soundproofing properties of modern buildings do not always meet the regulatory requirements for soundproofing, which is caused not only by insufficient soundproofing capacity of building envelopes, but also by an increase in power and the number of noise sources. The acoustic climate of the premises is mainly determined by the ability of the building envelope (walls, partitions, ceilings, etc.) to reflect or absorb air and impact sound .

Sound reflection, sound insulation and sound absorption

To reduce noise by various methods (shelter, screens, acoustic treatment), materials with sound-reflecting, sound-absorbing and sound-proofing properties are used.

Sound reflection - the ability of materials to reflect the sound energy incident on them, estimated by the reflection coefficient -, which is equal to the ratio of the reflected sound energy to the incident. Dense smooth materials have good sound reflecting ability: metal sheets, textolite, glass, smooth walls, etc. The most good reflective properties are the walls finished with marble, the sound reflection coefficient of which is 0.9 (marble is called an acoustic mirror).

Sound absorption occurs through the transition of the energy of sound vibrations mainly into thermal energy due to friction losses in the porous material of the cladding or absorber.Sound-absorbing materials are divided into 4 classes:

- 1) fibrous-porous - felt, cotton wool, acoustic plaster, fiberglass, polyurethane foam, etc.;

- 2) membrane - PVC, PP and other polymer films, thin sheets of plywood or metal on the crate, etc.;

resonant - special designs based on the acoustic properties of resonators;

combined of the first 3.

Sound-absorbing materials are characterized by the sound absorption coefficient, equal to the ratio of the sound energy absorbed by the material to the energy incident on it. Sound-absorbing materials should have 0.2.

The noise reduction effect (dB) due to the use of porous sound-absorbing lining can be estimated by the formula:

L (dB) = 10lg (V2/V1), (4.9)

where in1 and B2 — permanent premises before and after acoustic treatment;

B \u003d A / (1- Wed), (4.10)

where A = i Si is the equivalent sound absorption area;

i and Si - the sound absorption coefficient of the cladding and the corresponding surface;

Wed — weighted average absorption coefficient:

n

Wed = iSi/Spov, (4.11)

i=1

where Spov is the total surface area of the room.

Soundproofing is the ability of a structure to keep sound energy out of it. Soundproofing can be achieved through the use of both sound-reflecting and sound-absorbing materials. For sound-reflecting materials (casings, screens, cabins, etc., made of concrete, brick, steel, alloys, plastics, etc.), the soundproofing ability of fences is evaluated by the level of attenuation of sound energy, and for a single-layer partition can be determined by formula:

L (dB) = 20lg (mof) - 47.5; (4.12)

where mo — weight of 1 m2 of partition, kg/m2;

f is the sound frequency, Hz.

When noise propagates inside the workplace, the level (equivalent level) of sound in decibels on the “A” scale of the sound level meter (dBA) or the sound pressure levels at geometric mean frequencies of octave bands in decibels (dB) at the workplace located at a distance (r, m) from noise source, can be calculated by the formula:

L = L'+10lg10lg20lgr, (4.13)

where L'- sound level (equivalent sound levels) or sound pressure levels at the geometric mean frequencies of the octave bands of the noise source, dBA (dB);

— directivity factor, if there is no information about noise directivity, then =1;

is the spatial angle of sound emission, sterads. If the distance from the noise source to the workplace is greater than the maximum size of the source, then it is considered a point source, and then = 2.

Airborne and impact sound insulation examples

The main characteristic for materials that isolate from airborne noise is the sound insulation index. In order for you to get rid of neighborly conversations, this figure should reach at least 50 dB. If during the construction of a house this problem can be solved by increasing the thickness of structures or using ready-made blocks, then in an apartment where every centimeter counts, this method is completely irrelevant.

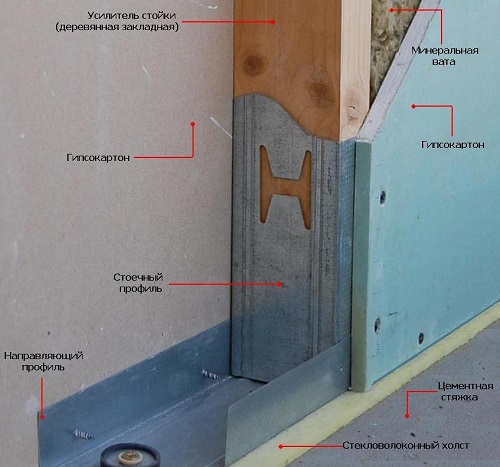

An acceptable option is a combination of different materials in a multilayer structure, alternating soft and hard products with varying degrees of density. Drywall can be hard, it will be responsible for soundproofing. Soft materials, such as glass wool or mineral wool, will take over the sound absorption. The effective thickness of wadded products in such structures is not less than 5 cm and at least 50% of the internal space of the structure.

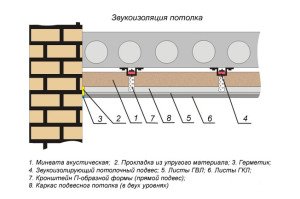

Increasing the sound insulation index of the ceiling is possible by arranging an acoustic ceiling. Since the height of most rooms is already small, manufacturers and consumers are trying to save as many centimeters as possible. Semi-rigid and rigid materials for soundproofing in this case will help create the first layer of soundproofing, the second can be drywall or stretch ceiling. The stretch ceiling membrane itself has a good degree of sound insulation, but it is even better to purchase special acoustic stretch ceilings that have a multilayer perforated structure that perfectly reflects sound.

Porous materials stop impact sound waves. Their elastic structure repels sound vibrations, as a result of which they lose their strength. One of the brightest examples of such elastic materials is technical cork sheets and polyethylene foam.Most often, they are used in the arrangement of floating floors, substrates for laminate and parquet, and for sealing joints.

When performing sound insulation, the thickness of the floors should be taken into account - if plates with a thickness of at least 200 mm are used in elite housing, then in panel houses they are much thinner. In the first case, it is enough to lay a layer of technical cork on the floor with a sound insulation index of 25 dB, in the second case, you will have to make a multi-layer structure using cotton and semi-rigid materials.

Soundproofing refers to the attenuation of noise provided by a fence.

Measures to achieve soundproofing:

sufficient soundproofing qualities of the fence;

space-planning solutions;

Calculation of walls and partitions is carried out according to the indicator of sound insulation from airborne noise Iv, and interfloor ceilings - from air Iv and shock Iat noise.

The airborne sound insulation index is determined by comparing the design frequency response curve of airborne sound insulation with the standard. Figure 30 shows the characteristic frequency response curve for airborne sound insulation.

Figure 22 - Standard frequency response of airborne sound insulation

To plot the design frequency response curve for airborne sound insulation, the surface density of the structure P is determinedn, kg / m 2:

(45)

where g is the density of the material of a single-layer fence, kg / m 3; d is the thickness of the fence, m.

According to the graphs (Figure 22), the airborne sound insulation P is determinedv, and frequency f are the coordinates of point B.

Figure 23 - Name

Point B is drawn on the coordinate grid (Figure 23). From point B, straight line BA is drawn to the left, straight line BC is drawn to the right with a slope of 7.5 dB per octave. At the same time, airborne sound insulation RC (coordinate of point C) is 60 dB.

A curve with standard indicators is plotted on the coordinate grid with the calculated partial characteristic of insulation from airborne noise (see Figure 24).

Figure 24 - Name

Indicators located below the standard curve refer to unfavorable deviations. The average unfavorable deviation, equal to 1/15 of the sum of all deviations, should not exceed 2 dB. With a deviation less than or equal to 2 dB, the sound insulation index is 0 dB.

If the average unfavorable deviation of the sound insulation index turns out to be more than 2 dB, then the standard curve should be shifted towards unfavorable deviations by an integer number of decibels in order to fulfill the condition Dcf. £2 dB. This displacement value is an indicator of the sound insulation of the structure with a minus sign.

Calculations can be clearly presented in tabular form (Table 9).

Date added: 2016-02-20 ; views: 1471 ; ORDER WRITING A WORK

Payment

The main requirement for profitable and reliable sound insulation is the correct calculation. Using laser measuring equipment, you can make the calculation with maximum accuracy so as not to buy extra material. Of course, if there are no skills and knowledge, then it is better to entrust it to specialists who will calculate everything quickly and efficiently.

You can make soundproofing with an isover yourself if you have an idea about the product and how it is installed. As for the choice of sizes, it is necessary to select based on the characteristics of not only the room, but also the insulation layer. If possible, then for installation work it is better to invite a professional who, in just a few minutes, will calculate the thermal and sound-proof qualities of the house and the insulation itself.

From what size of the processed surface is needed, the same amount of material is selected

It is important to bear in mind that during installation, the plates must not be pressed too much. They should fit snugly, but they also don't need to fall out.

If the width of the soundproofing plate is 60 centimeters, then the distance between the lags or structural elements will be 56-58 millimeters.

1 Scope and features

Isover soundproofing materials are produced in the form of mineral wool boards, including high-quality fiberglass.

The long strands of glass wool, from which the sound insulator is made, not only dampen the sounds that enter the room from the environment, but also guarantee effective room insulation, since air is retained between the fibers, which helps to reduce heat transfer.

Soundproofing Izover can be used for the following purposes:

- Sound insulation of inter-wall partitions. These boards are excellent for installation between layers of drywall inside false walls, which, with an internal layer of soundproofing material from Isover, are comparable in sound absorption to thick brick walls.

- Soundproofing and insulation of pitched roofs and mansards. In this case, you will almost completely eliminate all external sounds that enter the house through the roof, and ensure the optimal microclimate inside the attic, due to better thermal insulation of the room, and maintaining the optimum temperature in it.

- Sound insulation of brick and concrete walls. For wall cladding, Isover soundproofing is fastened with special profiles and hidden behind a facing layer of drywall or any decorative material.

- Sound protection and insulation of wooden lag floors using, among other things, Izorok thermal insulation. By laying a layer of Isover soundproofing material under the lag floor in an apartment building, you will forget that someone lives below you.

Soundproofing walls with Izover Soundproofing

Isover soundproofing, as mentioned above, is available in the form of plates, the width of which is 610 and the length is 1170 millimeters.

13. Roofing and waterproofing materials

TO

roofing materials include

roofing steel, asbestos-cement

corrugated sheets, asbestos cement

flat slabs and

also big

a group of bitumen and tar, which

are also waterproof.

bituminous

materials consist of petroleum bitumen

or alloys of petroleum and natural

bitumen, tar - from coal

and shale tar. Roofing and

waterproofing materials for

based on bitumen and tar binders

have been most widely used in

industrial construction. To bituminous

include: roofing material, glassine, borulin,

waterproofing, etc.

Ruberoid

- roofing and waterproofing

material. There are two types of ruberoid:

armored with large and small

sprinkles. Rolls have a width of 650-1050 mm

and an area of 10 and 20 m2.

Ruberoid with coarse dressing is used

for the upper layers of rolled roofs, and

also for waterproofing, and with fine

sprinkle - for the lower layers.

glassine

differs from ruberoid in that

the surface of the layer is free of bituminous mastic.

Rolls are produced with a width equal to

roofing material, the area of one roll is equal to

20 m2.

It is applied to the lower layers

multi-layer roll roofs, as well as

for steam and waterproofing. Ruberoid and

glassine glued to the surface

hot or cold bituminous mastic.

Borulin

- waterproofing roll material,

milled

bitumen with dry asbestos fiber

followed by rolling into a sheet.

Due to the high plasticity

it is used to insulate surfaces

with a complex profile (pipelines,

equipment, etc.).

Hydroisol

– waterproofing roll material

- this is asbestos cardboard impregnated

oil bitumen. Used for

waterproofing in underground structures

and on flat roofs, as, unlike

from roofing material and glassine is not exposed

rot-resistant, flexible, waterproof and durable.

To tar materials

include: roofing and non-covering

tol etc.

roofing

only receive

impregnation of roofing paper with tar

compositions and dressing from one or both

sides with wood.Roll width 750-1050 mm,

area 10 and 15 m2.

They cover the irresponsible

structures. Good waterproofing

material.

Bloodless

only

made without sprinkling and used

as underlayment under roofing

only for sticker

tar roll materials are used

tar mastics. Tar materials

less resistant than bituminous.

2 Advantages of sound protection from Izover

Soundproofing Isover, among similar materials on the market, stands out with a number of significant advantages that make its use preferable to any other soundproofing material.

Having mentioned expensive materials, it is worth noting that the cost of Isover soundproofing is more than adequate. The price of one package of Isover 100, consisting of 10 plates with a total area of 7.14 m², is about 750 rubles, which is more than acceptable for a material with similar characteristics.

Optimum density, elasticity and elasticity of the material allow it not to be afraid of deformations, unlike Izospan windproof membranes: after any short-term external compression, the sound insulation will return to its original shape.

This is an extremely important characteristic for noise protection products, since even the slightest gap between it and the wall leads to the fact that not muffled sound waves pass through the free space, from which the overall efficiency of the sound insulation of the room deteriorates greatly.

Plates Izover Sound protection of different thicknesses

Isover soundproofing is made of mineral wool interspersed with fiberglass, which ensures complete fire safety of the material.

2.1 Soundproofing technology

When arranging soundproofing a room and soundproofing a ceiling with your own hands, it is important not only to choose the right sound-absorbing material. An extremely important factor is the noise isolation technology itself, since even the slightest inaccuracies made during the performance of work can have an extremely negative effect on the effectiveness of the final noise protection.

If you want to equip your home with high-quality soundproofing with your own hands using Isover 100, follow the recommendations given in this section of the article.

First of all, it is worth understanding that eliminating noise from the environment into an apartment is a matter that requires an integrated approach. The completed wall or floor cladding will certainly bring certain results, however, it is powerful to achieve really effective sound insulation of a room only as a result of working out all the factors.

For example, the lion's house noise from the street enters the house through the windows, therefore, it makes sense to take care of installing high-quality, best double-glazed windows using additional polyethylene products.

The next most effective part of the system approach is wall cladding with sound-absorbing material, which is perfect for the Isover 100 discussed in the article.

The process of facing soundproofing Izover drywall

Installing Isover soundproofing is extremely easy as the boards have a width that fits perfectly to the dimensions of a standard drywall frame and do not need to be further cut.

This ensures that there are no voids in the baffle, thereby effectively reducing incoming sound waves.

So that you can get a complete picture of the effectiveness and rationality of using Isover Soundproofing material, we bring to your attention the reviews of consumers who have a positive experience with this product.

Nikita, 28 years old, Moscow:

As a result, realizing that I need to create high-quality working conditions myself, I decided to completely soundproof a separate room in the apartment.As a noise-absorbing material, after a long weighing of all the pros and cons, Soundproofing Isover 100 with ultra-thin thermal insulation Bronya was chosen.

I can say that all the positive reviews have been confirmed, it is really good. To be honest, I don’t notice the difference between the professional insulators with which the studio and Izover are lined, but it costs an order of magnitude cheaper.

Scheme of the correct design of the soundproofing layer

Pavel, 45 years old, Rostov:

Choosing between materials, I gave preference to Izover, since its characteristics, in my opinion, are an order of magnitude better than those of other analogues, and the price is quite adequate. In addition, from neighbors who performed soundproofing before me, I heard only laudatory reviews.

As a result, I can say that the noise really became less, and much less. If you are looking for a soundproofing material with an optimal price-quality ratio, then you will not find an option better than Izover 100.

Varieties

The product from Isover is made from fine fibers of mineral raw materials in the form of basalt rock and broken glass products. As a result of heat treatment and fiberization technology, thin, almost microscopic fibers are obtained from molten raw materials. The fibers are combined into a single web using various resins. It is worth noting that the manufacturer offers its products in mats that are folded into compact rolls, as well as plates of certain sizes. The material can have different thicknesses and sizes. Depending on the intended area of application and installation, the optimal solution can be selected.

One of the latest innovative products of the brand is a panel made on the basis of wood fibers. This product is distinguished by its versatility and a lot of advantages due to which it becomes popular. Wood fiber panels have the following qualities:

- weatherproof;

- breathable;

- resistant to mechanical stress;

- lungs;

- convenient in installation.

In addition, the material has high rates of heat and sound insulation. The company offers a high-quality product for various construction, including wood. In the list of products there are exactly those that can be used for insulation in wooden structures, providing effective, heat and sound insulation.

Fiberglass material improves the insulation performance of a house or apartment by several times, which in turn makes it competitive in the international market. Speaking about the advantages of the isover product, it is also worth mentioning its protection against fire, because the material belongs to the NG material group, that is, non-combustible. You can use this insulation in a residential building and premises of increased fire risk.

Using this insulation option, you can get not only a well-insulated room, but also save time on transportation and installation. Due to the lightness of the product, it can be transported and independently laid in accordance with the requirements of the owner and the characteristics of the building.

Isover material can be divided into two groups, where the first is chosen according to the field of application, and the second is universal.

Isover materials by scope include products

Universal soundproofing from isover is represented by the following product options:

Misconceptions and facts in acoustics and soundproofing

- Mineral wool, ecowool or glass wool between the plasterboard frame is an effective soundproofing. In general, noise isolation with this approach grows by only 3-6 dB. They should be used, but only in combination with acoustically decoupled structures and cotton wool with a density of 35-40 kg/m3. Sound absorption coefficients of various materials in the form of a table Sound absorption of materials.

- Sound absorption and sound insulation are one and the same. This is not true.It is inefficient to use only sound-absorbing materials in soundproof structures. It is necessary to increase the mass of fences, apply acoustic decoupling and GIS materials along with the RFP.

- Polyfoam well absorbs sound and soundproofs. Unfortunately, this is only a heater that can be used in the floor cake as an impact sound absorber. But the expediency of its use even for this purpose is doubtful - 4-5 cm of polystyrene are equivalent to 0.3-0.5 cm of special soundproof membranes. Styrofoam is acoustically hard and would rather make things worse, plus it's windproof, and you need a porous or fibrous material to isolate the sound. The same unsuccessful building materials include: sheet cork, GKL on glue, plywood, OSB, soft fiberboard, polyethylene foam, foam propylene. Theoretical calculations on this topic can be found here.

- "Nanotechnologies" of ultra-thin structures 2 cm thick solve the problem of sound insulation. The reality is that an effective soundproofing structure does not fit two centimeters, as it must include at least three levels of mass-elasticity-mass: soft, thick, elastic material with a high sound absorption coefficient between two sound-reflecting layers. 4-5 cm is the required minimum. There are no miracles in physics.

- The effectiveness of sound insulation depends on the number of layers of fencing. In fact, the thinner the air gap between the partitions, the worse the sound insulation, especially at low frequencies. The most effective soundproofing partition wall is the single air gap design. Proper assembly is more important than acoustic building materials as such.

The advantage of sandwich constructions with a large air gap

Main part

Let us consider the main properties and characteristics of porous-fibrous sound-proof and sound-absorbing materials.

Table 1. Main properties and characteristics of porous-fibrous sound-proof and sound-absorbing materials.

Soundproofing of airborne noise |

|||

Material |

Glass wool - fibrous heat-insulating material, manufactured on fiberglass base. Thanks to the great the number of voids between fibers that filled with air glass wool has good sound-absorbing properties. |

Mineral wool - fiber material, wadded and made from rock melt, metallurgical slags and their mixtures. Chaotic arranged fibers at various angles to each other provide good sound absorption. |

Multi-layer panel - it's multilayer construction structures that are from one or two cover layers and insulation. They are composite construction construction in which properties are combined all used materials. |

Coefficient sound absorption |

0.8–0.85 |

0.87–0.95 |

0.7–0.9 |

Dynamic hardness, MN/m³ |

20 |

10–20 |

10–20 |

dynamic module elasticity, Pa |

1.24 |

1.26 |

18*104 at a load of 2 kPa |

Insulation index air level noise, dB |

47 |

55-56 |

47-65 |

Density, kg/m³ |

13–85 |

35–160 |

110–140 |

combustibility |

NG |

NG |

G1 |

Notes |

Has a high vibration resistance, causes corrosion in contact with her metals, elastic, non-hygroscopic. |

Does not cause corrosion in contact with her metals, has biological and chemical resistance to aggressive substances, environmentally friendly, durable non-hygroscopic. |

durable, has low moisture absorption eco-friendly, no response to impact chemically aggressive substances or biological factors. |

Impact sound insulation |

|||

Material |

Polyethylene foam is universal heat-insulating material, which is also functions waterproofing, vapor barrier and soundproofing. |

cork rubber substrate - mixture granular cork and synthetic rubber. Reduces drum noise character, and also extinguishes vibration electrical appliances. |

bituminous cork substrate - made based on kraft paper bituminous impregnation and cork sprinkling crumb. |

Coefficient sound absorption |

0.5 |

0.85 |

0.7–0.95 |

Dynamic hardness, MN/m³ |

25 |

- |

- |

dynamic module elasticity, MPa |

0.5 |

- |

- |

Insulation index air level noise, dB |

54 |

37 |

63–65 |

Density, kg/m³ |

20–80 |

250 |

200–250 |

combustibility |

G2 |

G2 |

G1 |

Notes |

Good contact with unstable to |

Required additional waterproofing otherwise. under the substrate mold will form. |

No need for waterproofing, as cork surface removes unnecessary moisture, high fire safety. |

Structure-borne noise isolation |

|||

Material |

Fiberglass - ecologically pure the material that made from mineral fiberglass and organic resins. |

vibroacoustic sealant is anti-vibration material, intended for joint sealing and compounds in soundproof structures. |

Elastomeric materials - designed for noise reduction and vibrations, as well as protection of premises from structural noise, coming from outside. |

Coefficient sound absorption |

0.85 |

0.9 |

0.8 |

Dynamic hardness, MN/m³ |

10–20 |

- |

- |

Insulation index air level noise, dB |

55 |

55-65 |

55 |

Density, kg/m³ |

25–50 |

30 |

89–100 |

combustibility |

G2 |

G1 |

G1 |

Notes |

Resistant to UV rays, not causes corrosion metal. |

Easy to change shape elastic. |

We will summarize the main indicators of soundproof materials in a table for ease of comparison, identifying the advantages and disadvantages of each material. The table will help you choose the material according to the required criterion.

Table 2. Comparison of characteristics

|

Material type |

Type of noise |

α |

RW, dB |

Density, kgm³ |

combustibility |

Cost 1m2 (m3), rub |

|

glass wool |

Air |

0.8–0.85 |

47 |

13–85 |

NG |

1800–2000 |

|

Mineral wool |

Air |

0.87–0.95 |

55-56 |

35–160 |

NG |

1500–3000 |

|

multilayer |

Air |

0.7–0.9 |

47–65 |

110–140 |

G1 |

1200–2600 |

|

Polyethylene foam |

Shock |

0.5 |

54 |

20–80 |

G2 |

105–120 |

|

cork rubber |

Shock |

0.85 |

37 |

250 |

G2 |

70–80 |

|

bituminous cork |

Shock |

0.7–0.95 |

63–65 |

200–250 |

G1 |

122–140 |

|

fiberglass |

Structural |

0.85 |

55 |

25–30 |

G2 |

210–240 |

|

vibroacoustic |

Structural |

0.9 |

55–65 |

30 |

G2 |

193–220 |

|

Elastomeric |

Structural |

0.8 |

55 |

89–100 |

G1 |

63–75 |