Soft walls in the interior are not a new direction, but an echo of the aristocratic chic and sophistication of past centuries, actively revived by modern designers. This little-known type of finish looks really amazing and unusual, but at the same time it performs not only a decorative function: due to its unique qualities, soft lining will certainly interest both practical housewives and caring parents.

What are soft wall panels made of?

There are two main types of soft panels for walls: do-it-yourself / design studios and factory ones. The decorative material of such a plan looks like a three-layer "sandwich". The following layers are typical for factory soft slabs:

- The basis is PVC panels. They have light weight, high strength, good adhesive characteristics.

- Filler - polyurethane foam. This is a dense porous high-volume material, characterized by fire safety, excellent heat and sound insulation properties, low weight and strength.

- The front side - eco-leather - an artificial material that is comparable and even superior in its characteristics to natural leather. Its positive properties include hygroscopicity, breathability, abrasion resistance and absolute safety for health.

If we consider soft panels made by hand or by design studios, the materials used will be as follows:

- The base of the soft panel is plywood or hardboard, which are safe and environmentally friendly. The thickness is selected depending on the size of the element.

- Filler - foam rubber or synthetic winterizer. Apply depending on the design idea and dimensions of the plates.

- The front side is leather, leatherette or fabric. The latter should have increased strength and resistance to ultraviolet rays.

The difference between factory soft panels and hand-made ones is quite significant. It is worth making out where and when it is appropriate to use such a finish.

Recommendations for use

There are three main options for using soft walls in the interior.

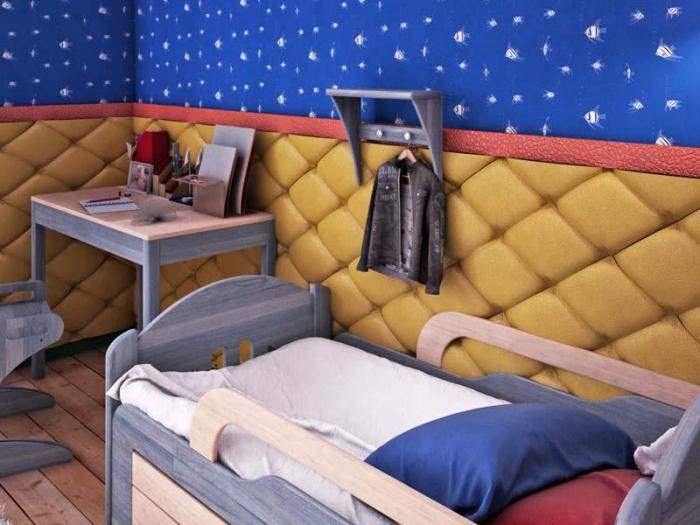

- Very often, soft walls are mounted in children's playroomsto protect children from possible injury when hitting a wall. For these purposes, not the entire wall is sheathed with soft panels, but only its lower part. It is quite natural that in this case bright colors are used. Environmental friendliness and safety of such materials meets all standards.

- The second use case is allocation of a certain zone in the interior. For example, in the bedroom above the head of the bed. The color design of the soft walls should be in harmony with the rest of the decoration and with the furniture in the room. Such a design technique will bring a feeling of softness, warmth and sophistication to the room.

- Application as a complete wall finish. In this case, you should carefully select the texture and color of the soft panels, as well as the execution, so as not to end up with a pressure effect.

With caution, soft finishes should be selected for small rooms and rooms with low ceilings. An illiterate design solution can visually reduce the space.

Advantages and disadvantages of soft walls

The main advantages of soft panels for walls include the following properties:

- Heat and sound insulation. The effect will be fully present if we are talking about a fully sheathed wall or room. If soft panels are used only as an element of decor and occupy a small area, then there is no need to talk about complete insulation.

- Noise absorption in the room. Walls with soft finishes dampen sounds instead of reflecting them back into the room.

- Ease of care.This mainly applies to panels made of leather, leatherette, eco-leather. Such materials do not accumulate dust and are well washed. Care for fabric walls will be more difficult.

- Ease of installation. First of all, this applies to purchased panels. To make soft wall cladding completely with your own hands, you will need patience and certain skills.

- The ability to hide poor-quality plastered walls or communications behind the finish.

- An interesting design decision. If you are tired of the classic renovation, soft volumetric panels can give a special flavor to any interior.

There are not so many disadvantages of soft walls:

- High price. The panels themselves and installation work will be quite expensive. Doing it yourself will reduce the cost, but you will have to spend money on the material.

- Fabric panels do not last long. If the material is not chosen correctly, then it may lose its shape and color over time.

There are significantly more advantages than disadvantages, so everyone who is thinking about repairing and updating the interior, it makes sense to consider the option of using soft walls for decorating a nursery, bedrooms or living room.

Installation of factory panels for walls

Soft finish is attached to a pre-prepared base. The plane must undergo plastering, sanding and coating with a primer. After that, the wall is marked by level. This will help to avoid distortions and shifting of decorative elements.

At the installation stage, two important factors should be considered:

- Panels are not recommended to be cut to fit the walls. This will affect the appearance not for the better. You can sheathe the wall, starting from the middle and leaving the same gaps in the corners. This will look much more aesthetically pleasing than the cut material.

- It makes sense to start work from the top. In the case of cutting to height, the bottom edge can be hidden plinth.

For gluing, you will need liquid nails, acrylic glue or PVA. The latter is applied to the entire surface of the plates, other materials dotted or in a narrow strip along the edge. Soft panels are applied according to the markup and pressed for a while to set.

Important! Trimming of plates is done with a hacksaw. Previously, the skin or fabric is detached from the desired side, the desired part is cut off, the upholstery is stretched and fixed with a stapler from the inside.

The process of installing a factory product is quite simple, making soft walls and fixing them with your own hands will be more difficult. But the second option provides more opportunities: there are several options for creating and attaching home-made soft walls.

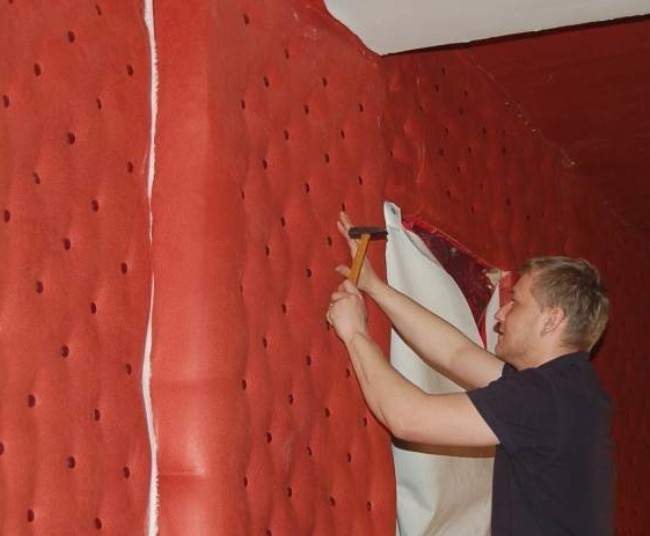

Wall cladding

This method is based on the installation of a wooden rack frame, between the planks of which the filler is placed, and leather or fabric is stretched on top.

Important! The fabric is cut with allowances from 50 to 100 mm on each side. It is not recommended to choose a material with lines or a large pattern: during the installation process, image elements may shift, which will negatively affect the overall appearance of the finish.

The fastening of the upholstery starts from the top, having previously made 2-3 folds. This will avoid tearing the fabric. Work is carried out using a furniture stapler. The tension should be monitored so that wrinkles and sagging do not form in the future.

Tip: to simplify the process, a rail is fixed on the bottom edge of the fabric from the inside along the entire length, which, under its own weight, will give a natural tension in the vertical direction.

After that, the sidewalls are fixed. The lower part is attached last. To achieve an original decorative effect, additional tightening elements can be used: slats, furniture buttons, etc.Doing this method with your own hands will require the accuracy of observing the technology, but the effect of the work is worth it.

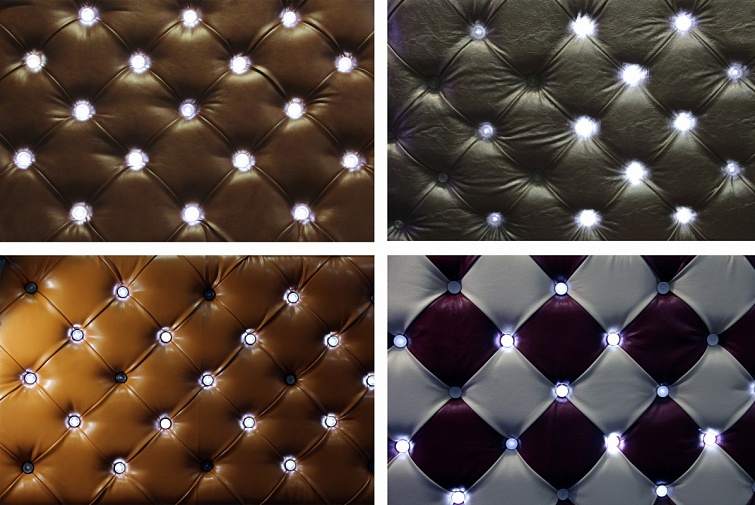

Production and installation of soft walls in the style of Capito

For this do-it-yourself cladding option, it is not a rack frame that is used, but a base in the form of plywood or hardboard. In this way, you can decorate the entire wall or make individual plates of various configurations.

- They start with markings: places for holes are marked, through which the tightening will then be made. Traditionally, they are arranged in a checkerboard pattern.

- Holes are drilled, and then a soft material is mounted on the glue - foam rubber or synthetic winterizer.

- After that, with the help of a furniture stapler, the upholstery is attached in a taut state.

- At the final stage, tightening is done with buttons, usually covered with similar material.

Important! Threads are selected of special strength, as a rule, nylon.

After the Capitonné-style soft slabs are made, they are fixed to the wall. For such soft walls, it is better to provide fastening on dowel-nails along the edge, and then close the fasteners with decorative strips.