Drywall is often used for self-repair. It is used for covering floors, constructing arches and multi-tiered ceilings, niches and other interior elements. Obtaining a smooth and uniform surface is impossible without pre-treatment of the GKL structure, which consists in sealing the seams and finishing putty. When strengthening the joints, you can not do without a reinforcing tape for drywall. We will find out what it is for, how to choose it and glue it correctly.

Why you can not do without reinforcing tape

The fact is that drywall is subject to certain fluctuations under the influence of moisture and temperature. This will manifest itself in the weakest point of the drywall construction - at the joints of the sheets. If you do not use a special tape for the seams when puttying, cracks form there over time. Such a product will help prevent their occurrence and facilitate surface leveling.

The process of sealing GKL seams is very important: any flaws made at this stage will surely remind themselves over time and lead to substantial financial costs. Therefore, it is necessary to treat it as carefully as possible.

The main types of tapes used for sealing seams

To strengthen the joints of sheets of drywall structures, two types of tapes are more often used:

- sickle, consisting of fiberglass;

- paper reinforcing tape.

In addition, when finishing drywall joints, the following types of tapes can be used:

- Non-woven or bandage - to reinforce the corners.

- With metal strips - for reinforcing external corners other than 90 degrees.

- A wide piece of fiberglass to reinforce the drywall-to-wall joint, such as when building an arched structure in a doorway. It can have a width of 10 cm or more.

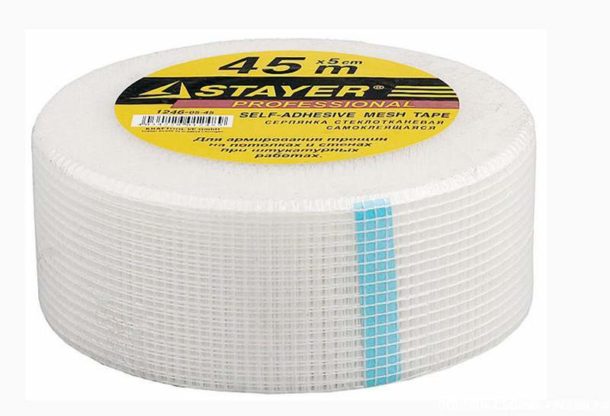

Serpyanka

Serpyanka is sometimes called a construction bandage: they are really very similar. It is a thin fiberglass mesh, one of the sides of which is covered with a special adhesive composition. It must be stored in a bag to prevent the glue from drying out.

In cheap analogues, there is no sticky layer; such a sickle is fixed with a construction stapler or directly on the putty. The strip width is 4.5, 5 or 10 cm, the roll length is 20, 45, 90 or 150 m.

The material is easy to use and ideal for beginners.

Important! It is not recommended to use sickle when reinforcing longitudinal joints or internal corners. Despite its strength, it is prone to stretching even under a layer of putty. There is a high probability that cracks will still appear at seams with increased load when using fiberglass mesh.

paper tape

Tape for drywall joints is made of special durable paper with longitudinal and transverse fiberglass reinforcement. For convenience of processing of internal corners on it there is a special fold. Suitable for all types of seams, both longitudinal and transverse. Available in rolls 50, 76 or 153 m long with a standard width of 52 mm.

Note! It is more difficult for beginners to work with paper tape; if there is not enough putty, air will accumulate under it and form bubbles. To avoid this, it is better to choose a product with microperforation.

Reinforced paper tape is inferior in ease of use to serpyanka, but surpasses it in a number of other parameters:

- The material is affordable.

- Due to the minimum thickness, it is possible to use even ready-made surfaces for strengthening.

- It goes well with putty and drywall, practically making up one whole with them after drying. This gives the seam a special strength.

Seam technology

Before as putty the seams, it is recommended to prepare them in advance:

- If there were no chamfers on the drywall sheets, then you need to make them using paint knife.

- The seams must be treated with sandpaper to remove all burrs, and then thoroughly cleaned. It is recommended to blow them with a jet of air.

- Joints are primed. For drywall, an acrylic-based interior mortar is ideal.

In the future, the technology will differ depending on the type of reinforcing material chosen.

sickle laying

Most often, such a tape is glued to putty, but in some cases it can also be attached to a dry surface.

In the first option, the algorithm of actions will be as follows:

- Putty is mixed. When buying, choose special composition designed for processing drywall joints, for example "Knauf Uniflot". You need to prepare the mixture in small portions, this will allow you to use the material before it dries and deteriorates. The consistency of the finished solution resembles thick sour cream.

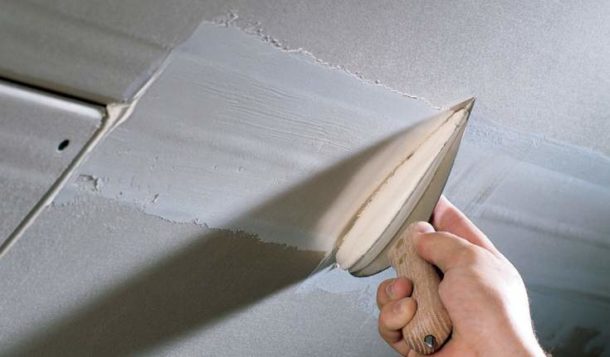

- Putty is pressed into the seam with a narrow spatula. A thin layer of it should also fall on the drywall on both sides of the seam at a distance slightly greater than the width of the tape.

- Serpyanka is laid from top to bottom, slightly sunk into the putty solution. If you have to fasten several pieces, then their edges are overlapped. Cut off the excess with scissors.

- With a spatula, the tape is sunk into the solution, while smoothing it out. Do not press hard on the tool: this can break the sickle. Or wrinkles may form. The mesh should be completely immersed in the putty. At the same time, excess solution is removed.

- It is necessary to wait for the composition to dry. This will take 8-12 hours.

- A thin finishing layer of the mixture is applied. Its main goal is to remove all minor flaws.

- After drying, the seam is polished with fine sandpaper. The next step is priming and puttying the entire surface.

When fastening dry, a self-adhesive sickle is pre-mounted on the joint, and then covered with a putty solution.

Using paper tape

The procedure for attaching perforated paper tape will be as follows:

- As with the installation of sickle, the prepared seam is filled with putty. Then a thin layer of the mixture is applied, slightly exceeding the width of the tape. The composition should not contain even the smallest lumps: thin paper will not be able to hide them.

Important! It is necessary to apply the solution to small areas of the joint, since the putty dries quickly.

- The tape is applied exactly in the middle of the seam and, when taut, is slightly sunk into the putty mixture. Then it is smoothed with a spatula from the center to the edges. The pressure should be sufficient for high-quality gluing, but not too strong. Do not try to squeeze out all the putty, otherwise the tape will have nothing to hold on to. The optimal thickness of the mixture layer under the tape in the center is 1.5–2 mm, along the edges it is slightly less, 0.8 mm.

It is important to avoid the formation of air bubbles under the tape. Therefore, it is more convenient to use paper reinforcing material with small holes (perforations). Air will come out through them.

- Excess putty squeezed out from under the paper is immediately removed.

- After drying, after 12 hours, a layer of finishing composition is applied. When it dries, the puttied strip is sanded. Only after that you can start puttying the entire surface.

A useful video will tell you about an interesting device for applying putty on paper for perfect seams.

What to choose: paper or sickle?

The experience of many experts shows that paper tape provides more reliable protection against cracking at the seams than sickle.

The conclusions are as follows:

- For longitudinal joints, only paper reinforced tape is suitable. Ideally - with perforation.

- For cross joints and short seams with minimal stress, an easy-to-use serpentine mesh can be used.