When erecting any drywall structures, preparation for fine finishing plays an important role. Its main part is the sealing of seams between the fragments of the plasterboard, for which putty and reinforcing tape are needed. Let's find out how good drywall sickle is for these purposes and in what cases it is better to refuse it.

What is a serpyanka and why is it needed

Serpyanka is a thin tape made of fiberglass in the form of a grid with rectangular cells. The standard width is 45, 50 and 100 mm, the footage is 20, 45, 90, 150 m. Usually, the manufacturer applies an adhesive on one of its sides, due to which it is attached to the surface in the same way as masking tape.

Serpyanka is needed for reinforcing drywall joints on walls, ceilings and any structures. Without gluing the joints, cracks will inevitably appear on them, which means that the finish will be damaged. A special paper tape or fiberglass cut into strips can replace such a mesh for seams.

Advantages of a reinforcing mesh for drywall:

- Easy to use: glued without problems, cut with ordinary scissors.

- Resistant to aggressive environments.

- Improves the strength characteristics of the surface. Fiberglass tape is not subject to shrinkage, tolerates vibration and displacement of individual elements well.

- It interacts well with putty, in combination with it provides a reliable connection.

- Cheap and available material.

In addition to strengthening the seams in drywall, self-adhesive reinforcing mesh is used:

- When sealing cracks in walls or ceilings.

- When finishing door or window slopes.

- When processing the places of adjunction to the wall of the door frame.

Which is better: sickle, paper tape or fiberglass?

Let's compare the advantages and disadvantages of these materials.

Serpyanka

Pros:

- Beginners are advised to use fiberglass mesh for sealing seams: it is easier and faster to glue it onto the drywall surface.

- The mesh structure allows you to effortlessly remove excess putty that protrudes through the holes.

- Serpyanka does not bubble and does not exfoliate.

Minuses:

- The strength of the fiberglass mesh is not always enough. So, it cannot guarantee the absence of cracks.

- It is not recommended to use it for reinforcing transverse joints and corners: it tends to stretch.

paper tape

Pros:

- Reduces the risk of cracking even at the most difficult joints and internal corners.

- Forms a very strong, monolithic seam using any type of putty.

- Thin, so you can apply the solution in a small layer.

Minuses:

- With a lack of experience with the tape, there is a risk of bubbles due to the small amount of putty under it. This can be easily avoided by purchasing micro-perforated tape.

- More labor intensive installation.

fiberglass

Pros: superior in strength to tape and sickle.

Minuses:

- Uncomfortable in work, prickly.

- Bubbles may form.

- Not suitable for corners as it cannot be bent.

ibuilder.decorexpro.com/en/ recommends: if the quality and durability of the result is more important to you than ease of use, choose paper tape from a well-known manufacturer (Knauf, Gyprok, Sheetrock) or cut glass canvas. Experienced finishers do not use sickle! The probability of cracks with it is much higher: look at the video.

Read more about the difference between sickle and paper tape, features of choice and application is written here.

Price, consumption

Serpyanka is an inexpensive material.

- The cost of a roll of 50 mm × 90 m is 125–265 rubles;

- 100 mm × 45 m - 120–270 rubles.

In the well-known Leroy Merlin hypermarket, you can buy a mesh for GKL joints at the following prices:

- 45 mm × 20 m - for 36 rubles;

- a larger roll - 45 mm × 45 m - for 67 rubles;

- 45 mm × 90 m - for 130 rubles.

The standard consumption of sickle per 1 sq. m. - 1.2 m.

How to properly seal drywall seams with sickle

Any beginner can handle this simple procedure. To learn how to properly reinforce and putty the seams, just read the instructions carefully.

Making chamfers

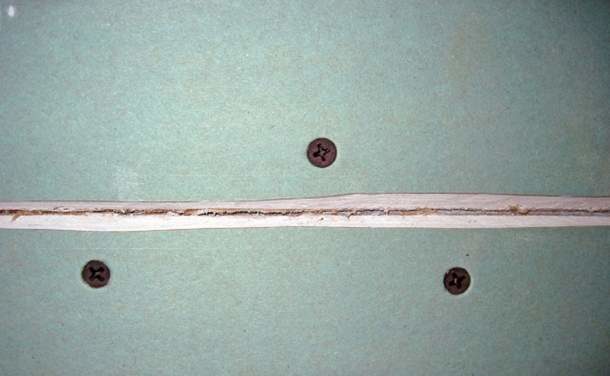

At the joints of drywall elements, chamfers must be made in advance. Most standard sheets already have a special thinned edge. But during the installation process, you often have to cut them into pieces, which results in raw ends. You can make a chamfer after fixing the drywall with a paint knife, but it is much more convenient to form them with a planer before fixing.

This photo shows a chamfer cut with a knife after the GKL was attached. She's not as neat.

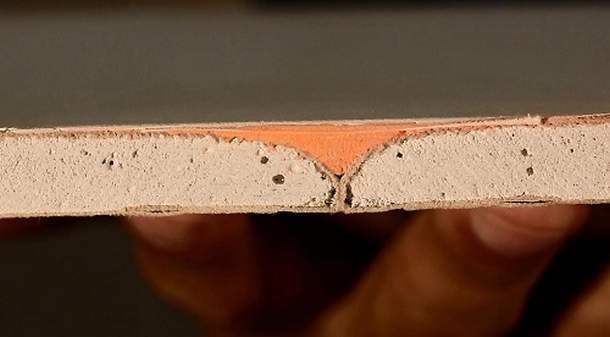

This V-shaped recess is necessary so that a sufficient amount of putty gets into the seam. Without a chamfer, even a reinforcing tape will not protect against cracks.

Preparing the seams

Before gluing the reinforcing tape, the seam must be processed:

- Clean the seams with sanding paper and remove dust from them. It is most convenient to use a directed air stream for this purpose.

- Prime the recess formed by the chamfers with an acrylic-based compound.

We close the seam with sickle and putty

Method number 1, simpler and less reliable:

- Glue the self-adhesive serpyanka on the seam. Do this from top to bottom, gently unwinding the roll. carefully smooth the mesh.

- If the joint is long, it is more convenient to reinforce it with several pieces so that the tape does not warp. Lay them overlapping each other by 1-2 cm. Cut off the excess with scissors.

Be sure to ensure that the tape is located symmetrically with respect to the seam. With uneven laying, its ability to withstand vibrations of drywall fragments is sharply reduced.

- Gently apply putty to the glued joint, pressing it into the mesh.

- Wait for the mixture to dry (8-12 hours). Then apply a finishing coat that removes the flaws left by sealing the seam.

- Sand the joint with fine grit sandpaper.

- Prime the entire drywall surface twice with a universal compound. Apply the second layer only on the completely dry first.

If the serpyanka does not adhere well or lags behind, clings to a spatula, or simply does not have an adhesive layer, you need to use the second, more reliable method - mounting on putty.

ibuilder.decorexpro.com/en/ recommends: do not try to glue the sickle with PVA glue. Putty does not adhere well to it, and the screws with which the sheet is screwed can rust, which will cause stains to appear on the finish.

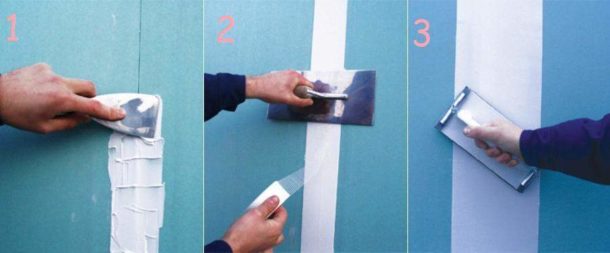

Method number 2:

- Apply the solution to the joint. The putty layer should protrude slightly beyond the boundaries of the recess, and its width should exceed the size of the tape.

- Unwind the mesh and smooth it with a spatula, gently pressing into the putty. This must be done carefully so as not to tear the sickle and not to make wrinkles. Excess composition will come out through the grid, after which they need to be leveled or removed.

- Wait for the solution to dry, putty again, as in the previous method. Then sand and prime the seam.

Tip from ibuilder.decorexpro.com/en/. When mounting a sickle on putty, all the convenience and simplicity that self-adhesive gives are lost. Therefore, we again recommend abandoning the sickle in favor of paper tape. Working with it is not much more difficult, and the result will be better.

After completion of all work, the surface is ready for painting, wallpapering or other fine finishing.

Proper use of reinforcing tape will avoid the appearance of cracks on the drywall surface caused by the displacement of individual elements. If, nevertheless, it is decided to choose a sickle, a video lesson will help to understand the technology of working with it.