Ways of trenchless laying of pipelines

Trenchless pipe laying can be carried out in various ways. The most common of all existing ones include:

- Horizontal directional drilling;

- Methods of punching (driving) and piercing;

- Sanation.

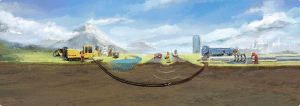

Consider each of the above methods of trenchless laying of pipelines. At horizontal directional drilling (HDD) special drilling rigs are used, through which, it turns out, excavation for laying pipelines at great depths.

At the same time, the length of this method of trenchless laying can be hundreds of meters, and the diameter of the laid pipes can be up to 1500 mm. HDD is one of the most effective ways of trenchless pipe laying, since the savings on the implementation of work here reach 40 percent or more.

Renovation - includes several separate methods of trenchless pipe laying: relining and renovation. In relining, the existing pipeline (the old line) is cleaned, after which it is used to lay a new pipeline.

During renovation, the pipeline is also updated, only without preliminary cleaning of the line, but by laying new pipes according to the previous design.

As for the methods of punching and piercing during trenchless pipe laying, they are used exclusively in the construction of new underground tracks. The disadvantage of these methods of trenchless laying of pipelines is the limited length of the section, as a rule, no more than 100 meters.

Trenchless pipe laying and its advantages

Trenchless pipe laying has a lot of undeniable advantages. Well, firstly, work on the arrangement of underground routes for the pipeline can be carried out at any time of the year. At the same time, to perform trenchless laying, a minimum of labor is required (there is no need to dig pits, etc.).

Well, thanks to the latest equipment, all of the above methods of laying pipes allow you to increase the speed of work many times over. So, for example, depending on the complexity of the work and the terrain, the speed of laying pipes in trenchless laying varies from 4 to 40 meters per hour.

But the most important advantage of this technology is that the integrity of the site is not violated when laying pipes. All roads, buildings and vegetation already existing on it remain intact and unharmed.

At the same time, the usual rhythm of life is preserved, since trenchless pipe laying does not affect traffic flows in any way, which is very important when carrying out this kind of work in densely populated regions of our vast country. https://www.youtube.com/embed/KlYvUBNZgZk

HDD drilling

Trenchless laying of pipes and gas pipelines, as well as other services related to drilling, have long become common practice, because it is an economical, fast and modern way of conducting communications. The rapid development and improvement of trenchless technologies led to the formation of several branches in HDD methods.

A distinctive feature is the absence of trenches in the working areas from the start to the final penetration. The digging of ditches, their arrangement, the restoration of structures, paths and green spaces after the completion of work - all this is a thing of the past. Today the world chooses HDD (Horizontal Directional Drilling) technologies.

Basic Methods

For trenchless pipe laying, the following most popular and popular methods are used:

- sanitation,

- punching,

- horizontal directional drilling,

- soil puncture.

It should be remembered that, just as with open laying, it is imperative to adhere to the distance between pipes in the trench established by SNiP, so with the trenchless method, these rules must be observed.

Trenchless pipe laying technology can be viewed here.

Sanation

Translated from Latin means recovery, treatment. This procedure is used only on an existing section of the pipeline and consists in replacing old pipes with new ones. This can be done in two ways - relining and renovation.

Relining is a common renovation method in which a new polyethylene pipe of a smaller diameter is laid into an old, for example, steel pipe. At the same time, it is necessary to carefully examine the internal state of the old pipe, choose the right diameter for the new one, and attach a hydraulic calibrator to the end of which, which will move forward along the old line, making room for the new pipe.

Renovation is used if the old pipeline has become obsolete, so it is completely destroyed, and a new one is laid in its place.

Punching

This method is used for laying large diameter pipes. At the same time, they are pressed into the ground using a hydraulic jack and a vibro-impact mechanism. The soil, preferably sandy and loose, is removed by compressed air to the outside through the pipe itself.

Horizontal Directional Drilling

The most expensive, but at the same time the most versatile method of trenchless pipeline laying, since it can cope with soils of any density, even rocks, and lay a pipeline up to 100 meters long. The drilling process is carried out using installations for trenchless pipe laying - drilling machines. At a depth of up to 15 m in a given direction, a small well is drilled. The drilling head is connected to a drive rod, therefore it is able to bypass underground obstacles, clearly adhere to a given trajectory. The resulting well is expanded and a working pipeline is dragged through it.

Ground puncture

This method is effective on clay and loamy soils, when laying pipes with a diameter of up to 15 cm is required. The essence of the method is that a steel pipe with a cone is pushed through the thickness of the soil. The earth is not brought out, but compacted with the help of hydraulic jacks. A polyethylene pipe is then introduced into the formed well.

Soil piercing method

Soil piercing method

Trenchless pipeline laying is the future. We hope that we will soon forget about the unpleasant traces that remain from repair work on heating mains and other city communications.

Add a comment

Consider the classification of the main methods.

A group of unmanaged methods. Drilling can be carried out:

Tunneling machines making hauls:

- washing;

- screw;

- with suction.

Wash drilling.

Occurs by flushing with bentonite. The probe is controlled.

Pilot drilling followed by:

- dry or wet extensions;

- expansion in rocky soil.

Let's take a brief look at the key principles and moments of laying pipes using trenchless methods.

Auger drilling (or GSB) is widely used in industry and construction. This is especially true in cramped conditions. The case is pressed through simultaneously with the removal of excess rock. It also prevents collapses.

The advantages include the integrity of the soil surface and the environment, performance in various rocks and in any weather, the creation of a channel of the desired length and diameter, there is no subsidence of soils.

The simplest drilling rigs will do. Their basis is a drill head with augers located along behind it. The motors can be electric, hydraulic or pneumatic.

The price of HDD of this type allows you to minimize costs.The estimate includes a miscalculation of each stage and takes into account the conditions.

Pilot drilling. It is resorted to in cases of laying routes, routes for laying pipelines for industrial purposes. In installations for this type of operation, the drill heads are beveled. Can be equipped with special bentonite nozzles. A special sensor located in the head part determines the trajectory of movement.

Any trenchless pipe laying has a number of its own special, undeniable advantages that distinguish it favorably from others:

- versatility for any type of tasks: from a pipeline in desert areas to densely built-up urban areas;

- high-precision technologies guarantee the accuracy of laying any type of communications;

- the length of the tracks is up to hundreds of kilometers, the diameter is from 12 m and above;

- heavy equipment and many workers are not needed, therefore, labor costs are minimized. One installation and no more than four employees is all that is needed;

- GNB pricing policy allows you to save up to 50% of finances and terms up to 20 times;

- the possibility of damage to nearby networks is minimized;

- at the same time, the walls of the shaft are laid and strengthened. This is facilitated by special solutions in combination with soil compaction;

- mountains, rivers, house foundations, etc. - no problem;

- no dependence on weather conditions;

- environmental friendliness: the upper layers of the soil are absolutely not damaged.

It is better to entrust such an important and responsible task to highly professional specialists, since a number of conditions are required: the availability of special installations, trained employees with appropriate qualifications. Also possession of legal documents, conducting geological exploration studies

We have everything you need from the above list, most importantly - vast experience in this industry, we undertake the coordination of all technical documentation. And this is the best guarantee of quality and durable, trouble-free operation.

HDD price. As for the payment for work, in each case, the estimate is made taking into account the characteristics of your order, and the price is determined individually. The final account is affected by the type of soil, the required length of the mine, materials.

Our masters and the wide range of unique technologies of trenchless pipe laying will solve all your difficulties and save you from unnecessary headaches in the shortest possible time. And at this time you will live in your usual rhythm.

Modern construction companies involved in laying pipelines and other communications are gradually minimizing the use of the trench method, which is losing its relevance, preferring new, time-tested, unique developments. Thanks to new technologies, today it is possible to carry out complex construction work without causing harm to surrounding objects, without large financial investments.