Plasterboard sheets

This material is often used if you need to decide how to hem the ceiling in a private house. From drywall, you can perform the usual finishing of the ceiling or build a multi-level system with built-in lighting fixtures.

GKL sew up niches between beams or completely close them, creating a perfectly flat surface. The plasterboard ceiling is puttied and then painted with a water-based emulsion in any color. This method of finishing can, if desired, be combined with wooden elements or tension structures.

Due to the difference in thermal expansion coefficients and the large size of the GKL, they are not attached directly to the beams. They are mounted on suspensions and guides that have flexible contact with a wooden beam.

Advantages:

- low price;

- ease of processing;

- you can create designs of different shapes;

- good combination with any finish;

- the material "breathes", so condensation does not collect on it;

- easy to color.

Flaws:

- the drywall construction turns out to be quite heavy and therefore it exerts a load on the floors;

- the material is dangerous for water leakage;

- fragility.

The use of stretch ceilings

For overlapping, you can choose different types of ceilings. One of the most popular are stretch ceilings in a wooden house. However, before you finish the surface with your own hands, you must immediately think about your capabilities. These materials are very finicky in installation, so sometimes it is better to entrust the work to professionals.

Using a stretch ceiling in a wooden house, there are some advantages, since the base of the timber allows you to use it as the basis for stretching the canvases. To sew up the surface, you need to make certain cells in which the materials are stretched. To do it yourself, use the following sequence:

- For mounting cells, materials with dimensions of 100x50 mm and 200x100mm are suitable. The thickness and width of the beam should be selected based on the overall dimensions of the room in which the stretch webs will be used.

- The next step is to identify the lower point at which the base of the lathing from the timber will be made. Having selected this point, draw from it using the mark level to all corners

- First, the timber board is mounted along the length of the ceiling, and then insert shorter strips of timber to make squares

- Since tension materials have a wide color palette, you can install several colors at once that will highlight the ceiling in a wooden house in certain areas

- The ceiling in a private house in the kitchen must have moisture resistance properties. It is stretch ceilings that are most in demand in the kitchen and bathroom.

- The lighting layout should take place before the installation of the canvases, so it is better to immediately decide where the lamps will be located.

How can you hem the ceiling

The interior and style of the room largely depends on the material with which the draft ceiling will be closed. In addition, you should take into account the features of the place of repair.

You can hem the ceiling with such materials:

- Drywall. GKL has an affordable cost and is quite simple to use. On the draft ceiling, it is glued or screwed to a spatial frame made of steel profile. It should be borne in mind that in damp rooms only moisture-resistant drywall should be installed. External putty of the assembled surface is required.

- plastic panels. These products have a presentable surface and low weight. As a rule, they are fixed on a frame made of timber, steel or plastic profile.If the base is well leveled, then the panels are glued to it with liquid nails.

- Wooden lining. This type of finish has a pleasant and beautiful appearance, environmentally friendly and durable. Reiki can be attached both to a solid base and to a frame. Fixation is carried out using thin nails without a hat or self-tapping screws.

- MDF panels. The front part of these products can imitate wood, natural stone, sky or plants. Fastening is carried out using special clamps (kleimers), which press the edge of the rails to the base or frame.

- Plywood. Before installation, plywood sheets must be treated with an antiseptic and a primer. If the installation is carried out on the frame, then the joints of the sheets should be on its guides. After installation, seams are sealed and painted.

- Siding. Plastic siding is an ideal material for finishing non-residential and damp areas, such as bathrooms, summer kitchens, garages and balconies. Installation of this cover is quite simple and does not take much time.

The choice of material for filing the draft ceiling depends on the purpose of the room, the taste and financial capabilities of the owner of the building.

Wooden rough coating device

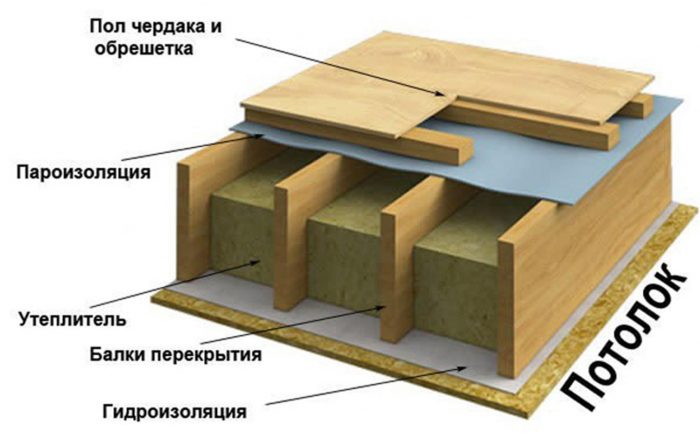

Before hemming the ceiling surface, you should understand the layers that make up the interfloor overlap in a wooden house.

Overlay layers from top to bottom:

- The topmost layer is a boardwalk, which can be the basis for a finish coating or serve as a fine finish.

- A vapor barrier membrane is a mandatory layer. Membrane fabric prevents the formation of condensation on wooden structures, prevents the formation of wet areas, mold and fungus growth.

- Thermal insulation. Fits in any case, regardless of whether the premises are residential or not above the floor. If the attic is not residential, the energy efficiency of the house increases, residential - the sound insulation of the floors increases.

- Waterproofing. The layer is designed to protect the insulation and wooden structures from moisture. If you do not lay waterproofing, moist air, hot steam, rising to the ceiling, will destroy the heat-insulating material - which will reduce the practical characteristics of the product.

- The draft ceiling is the last layer, which is finished with a finishing cladding.

Sometimes boardwalk is left unfinished, especially when good quality boards are used. If, after the arrangement of the ceilings, the flooring is to be laid on the floor above, then a layer of vapor barrier is laid on top of the insulation, then a wooden floor base can be laid.

How to make a ceiling in a wooden house DIY ceiling Draft ceiling Device ceiling

In this video I will show you how to make a ceiling in a wooden house with your own hands, I will tell you about some secrets when filing a rough ceiling, which worked well when building a bath from a bar, so I decided to use them when installing a ceiling in a house from a bar. Watch other videos on the channel dedicated to the construction of a house from profiled timber with their own hands:

Waterproofing the strip foundation with glass isolator // Do-it-yourself foundation // Laying the basement: https://www.youtube.com/watch?v=1NoDm…

Marking for laying the first row of a brick plinth//Laying a plinth with your own hands: https://www.youtube.com/watch?v=YmjAU…

Laying the first row of bricks//Single-row corner dressing system: https://www.youtube.com/watch?v=sPDY8…

We cover the vertical seams in the brickwork // Basement: https://www.youtube.com/watch?v=krW7j…

Laying the second row of bricks//Single-row corner dressing system: https://www.youtube.com/watch?v=b_oEx…

How to level the foundation//Leveling the foundation//Exhibiting angles to the horizon//Overview of the laser level: https://www.youtube.com/watch?v=87mJT…

Air in the plinth: https://www.youtube.com/watch?v=IzGe1…

Is it possible to fill the foundation in parts // Do-it-yourself foundation: https://www.youtube.com/watch?v=y7BG2…

Penoplex instead of lining board: https://www.youtube.com/watch?v=JOoDW…

Stencils for assembling timber in the “Warm Corner”: https://www.youtube.com/watch?v=Dj8T6…

Connecting a beam to a warm corner: https://www.youtube.com/watch?v=1w-Hh…

How to cut a profiled beam in the corners when assembling in a “Warm corner”: https://www.youtube.com/watch?v=dtHGk…

The simplest exhaust ventilation // Insulation of the ceiling with sawdust: https://www.youtube.com/watch?v=wbvF5…

Assembling a house from a bar for dowels: https://www.youtube.com/watch?v=fpQkF…

How to bleach wood // Hoarfrost vs Whiteness: https://www.youtube.com/watch?v=AEhlS…

Logs for the floor in a house made of timber: https://www.youtube.com/watch?v=uXKKe…

A simple do-it-yourself septic tank // Sewerage for a private house: https://www.youtube.com/watch?v=MJRxU…

Installation of shrinkage compensators (aka adjusting lift (jack): https://www.youtube.com/watch?v=nAoDM…

Floor beams//Installation of floor beams: https://www.youtube.com/watch?v=CxIoh…

Installation of studs during the construction of a house from a profiled beam//Shrinkage of a house from a beam: https://www.youtube.com/watch?v=S1Nuz…

The simplest exhaust ventilation in a private house. Part 2//How to get rid of condensate in ventilation: https://www.youtube.com/watch?v=SH_PY…

Preservation of a house from a bar for the winter // Preparing an unfinished house for winter: https://www.youtube.com/watch?v=CI6mE…

Heating a private house // Breneran solid fuel boiler// Leningradka// Single-pipe heating system: https://www.youtube.com/watch?v=VpkPf…

Spring knot strength. Start of the 2017 construction season: https://www.youtube.com/watch?v=tL6AF…

Mauerlat// House from profiled timber//Use of the “Strength” knot.: https://www.youtube.com/watch?v=tXq_2…

House from profiled timber//Do-it-yourself house//Gables: https://www.youtube.com/watch?v=SpB2-…

Installation of the rafter beam // Lay down with chopped gables: https://www.youtube.com/watch?v=kCSia…

Mounting the ridge of a house from a bar // Ridge beam: https://www.youtube.com/watch?v=8pKMV…

Splicing rafters along the length: https://www.youtube.com/watch?v=PXBFx…

Roof with your own hands. Part 1//Gable preparation: https://www.youtube.com/watch?v=rAsAk…

Roof with your own hands. Part 2//Installation and fastening of rafters: https://www.youtube.com/watch?v=Zu6XK…

Roof with your own hands. Part 3//Installation of slippers//Roof lathing//Banner instead of roofing material: https://www.youtube.com/watch?v=mHj79…

Do-it-yourself pigtail // Preparing the opening // Making a casing: https://www.youtube.com/watch?v=JRKqm…

Water well//Do-it-yourself well//How to drill a well//Zhelonka: https://www.youtube.com/watch?v=M2l9Y…

Cellar in the house//Filling the floors in the underground//Basement of a private house: https://www.youtube.com/watch?v=3Jfxt…

Laying sewer pipes underground // Do-it-yourself sewerage in a private house// Sewer slope: https://www.youtube.com/watch?v=6Nscs…

What happened to the house after the winter // House from profiled timber//Overview of the house from timber: https://www.youtube.com/watch?v=JGC4C…

Aligning a wall in a wooden house//Bent a wall out of a bar//How to align a wall: https://www.youtube.com/watch?v=0O87Q…

Draft ceiling finish

There are many durable materials for filing a draft ceiling, the embodiment of a conceived interior, a special design of a room, even without cladding, antique. Depending on the purpose of the interior of the room, decoration and decor are selected.

Draft ceiling lining

For example, for a rough repair, interior, when designing, decor in a bath, you can not use the following elements:

Various wooden ceiling panels: chipboard, fiberboard, plywood, because they will deform in high humidity.

Plastic, they can finish the rough base, the ceiling under wood and antiquity, emphasize the design even without cladding, but it has poor thermal insulation properties, condensation will form, and then mold on the finish.

Timber containing resins that will drip down when heated

It can be a rail and MDF, it is important to clarify before purchasing .. https://www.youtube.com/embed/LeOoQZaFNc0

False ceiling installation

For a qualitative solution to the question of how to make a false ceiling, experts recommend following a certain sequence of actions:

- First of all, you need to prepare the hemming material. At this stage, the lumber is treated with an antiseptic compound to protect against fungus and mold, as well as a means that prevents the material from igniting. After processing, the boards are well dried in natural conditions.

- At the second stage, the finished lumber is brought into the room where the installation work will be carried out. If you have equipment for lifting loads, you can immediately lift all the material up and lay it on the floor beams.But it is better to use this method if the building is under construction.

- Fastening of hemming material starts from one of the walls. 2-3 boards are placed perpendicular to the beams and fixed to them with nails or self-tapping screws. Accordingly, use a hammer or screwdriver. Boards can be placed close to each other or with a small gap. It depends on the type of insulation used or, if necessary, to save hemming material.

- Next, the thermal insulation material is laid. Styrofoam or mineral wool fills the gaps between the floor beams.

- In this order, the entire area of \u200b\u200bthe ceiling is hemmed.

Ceiling installation

For work, you will need, in addition to the selected building materials:

- goats or a stepladder (it is recommended to take two stepladders, because the help of at least one person is needed);

- hammer;

- drill;

- screwdriver (if there is a need to fix it on self-tapping screws);

- pencil and long ruler for marking;

- construction roulette;

- a knife, jigsaw or other cutting tool (drywall can be cut with a knife, but a hacksaw or jigsaw is required for a board).

It is recommended to prepare all the necessary tools in advance.

There are two mounting options.

First way

A draft wooden ceiling is made from a board or lining (the planks are nailed to a wooden beam close to each other), and then decorative trim is fixed on them - siding, plastic or decorative plywood - using glue or self-tapping screws.

For those who do this work for the first time with their own hands, this method is the most convenient, because errors in attaching wood will be hidden during decoration. But at the same time, extra time is spent on rough sheathing and the consumption of building materials increases. Also, a rough ceiling base made of boards or lining is done when it is planned to make a suspended or stretch ceiling below.

Second way

A frame made of metal profile, wood or plastic is fixed on a beam base made of wood. Selected finishing building materials are screwed to it. Such repairs can be done with your own hands much faster. Of course, drywall will need to be further finished, but plastic, siding and MDF boards will become both a draft ceiling and a beautiful decorative finish.

This method is not recommended when a vapor barrier has been previously installed. Experienced builders advise placing boards impregnated with flame retardant between vapor barrier materials and decorative finishes.

A rough ceiling covering will help hide ugly, but necessary building elements, such as electrical wiring or a beam base. But before you start creating a draft ceiling, you should carefully consider all the nuances of using the room. Perhaps it will be possible not only to hide the wooden ceiling beams and other building elements, but also to make a decorative finish at the same time. Combining a rough and decorative ceiling will help save money.

Sheathing board or panels

In order to hem the ceiling with fiberboard or plastic along the beams or along the counter-lattice, they begin to do work from the most noticeable wall in the room.

There is a certain procedure for how to hem the ceiling in the house with a board:

- The material is measured with a tape measure or in place and cut off with an electric jigsaw from the wrong side.

- It is attached to nails or screws. The first of the boards is fixed at the points of its intersection with the counter-lattice.

- The lining or tongue-and-groove board is knocked out with a wooden hammer or bar until a complete tenon-groove connection is made and fixed to the extreme elements of the crate. To intermediate bars are fixed through one in a checkerboard pattern to avoid damage to the cladding.

- After the completion of the sewing of the entire ceiling surface, the points of contact with the walls are covered with skirting boards made of wood or polymeric materials.

- The boards are coated with a water-based wood impregnation or a coloring composition.

When fiberboard is planned to be used only for sewing niches between beams, the finishing material is attached to pre-nailed bars. At the same time, the filing technology is similar. In the same way, they finish with plastic panels or MDF, but to prevent the appearance of chips, experts recommend pre-drilling holes of small diameter in the products at the attachment point.

Plasterboard and plywood ceilings

Finishing the ceiling with plasterboard

The choice of drywall and plywood for the ceiling is one of the most sought-after design options for subsequent decorative finishing. In order to to do the work with your own hands, you must first assess the condition of the ceiling. This is especially necessary for old wooden houses.

Important! Drywall sheets can be installed in several ways. Before you make a ceiling in a wooden house, you should know that the use of glue for installing tiles is unacceptable

Finishing with drywall slabs consists in installing the material on a crate made of wood, metal profiles or on the very base of the ceiling. All types have their advantages and disadvantages, but the best is mounting on a frame made of metal profiles. The advantages of fixing drywall in this way:

- Long service life, as the material is not subject to deformation and the influence of negative factors

- Between the crate of the profile, you can fix the heat-insulating layer

- The easy do-it-yourself installation process means you can save on costs and sheathe the surface with minimal effort.

- Using the profile, you can make multi-level ceilings

The disadvantages of using drywall include only the price of the material and the need to use improvised tools. However, if you are used to doing repairs yourself, then you will not have problems with the availability of tools for installing drywall.

You can also finish the ceiling with plywood. If we take into account the possibility of acquiring laminated elements, then clearly subsequent finishing is not required. But if you sheathe the ceiling with low-grade plywood, then the following work should be carried out:

- In order to paint the plywood base, it should be treated with special compounds. For painting, you can use water-based paint

- Coloring can be done with a brush or roller. For structural paints, special rollers are required

- If you decide to paint the plywood in two layers, then wait for the first to dry completely and only then apply the second

- The ceiling finished with plywood dries in an average of 24 hours

Sheathing with a board or clapboard design options and installation technology

Before you make a ceiling in a private house, please note that for its cladding in a wooden structure, it is better to choose a board, wooden lining or MDF. Plastic panels in this case will be inappropriate

For an original design, you can choose a laminate, and a block house looks great in a house made of timber.

Advantages:

- Environmental friendliness. The panels, like the board on the ceiling in the house, are made of wood material without the use of resins and harmful phenol.

- Design. The color, texture and width of the skin can be chosen for each specific interior.

- Water resistance. The material is not afraid of moisture, which makes it possible to install it in bathrooms, saunas, and kitchens.

- Easy care. To clean the lining, it is enough to wipe it with a damp cloth, without using cleaning agents.

- Functionality. All the necessary communications are easily placed inside the design of such a ceiling.

Technologically, the installation process is practically the same and includes several stages:

- Ceiling frame device. In wooden houses, for this, a crate is made of bars. In rooms with possible sudden temperature changes (bathroom, kitchen) and a high risk of deformation of the wooden base, it is better to use metal profiles.

- Before you hem the ceiling with a board or clapboard made of wood, it needs to be kept in a room for several days for acclimatization.

- The material is cut along the length of the room. In this case, it is necessary to provide a gap of 3-5 mm. It is needed for the possibility of free expansion of the rails with a possible change in temperature and humidity.

- Laying the first ceiling element starts from the wall opposite the entrance to the room or from the window.

-

The board is nailed to the bars, or with self-tapping screws, if the base is a metal profile. The lining, which is fastened by the tongue-and-groove method, must be fixed into the groove every 20 cm. From the side of the groove, the panel is attached to the frame by means of clamps. This metal plate is attached to the frame with screws or a nail on one side, and its second part has a recess into which the panel enters. Thus, all subsequent slats are assembled.

- The last bar must be cut not only in length, but also in width, while not forgetting to leave gaps from the walls. In addition, it must be fixed by analogy with the first.

- Holes for spotlights can be made before or after installing the panels on the ceiling.

- Finishing work on finishing includes the installation of lamps and a skirting board, the function of which is to embellish the interior of the room, as well as to hide the seams between the ceiling and the wall. If desired, the material can be coated with a colorless varnish.

Preliminary preparation

It is necessary to calculate all the costs necessary to build a rough foundation.

- Ladder;

- Construction trestle;

- Self-tapping screws, screwdriver;

- Sheathing material, heat and vapor barrier;

- Construction level, clerical knife;

- Antiseptic, construction adhesive, fire-fighting composition.

First, I inspect the beams for defects: cracks, chips, curvature, mold, cover the cracks with putty, clean suspicious places, treat them with an antiseptic, primer, after which they can be painted, if necessary, done once and for centuries.

The rough base, together with the beams, can be treated with an antiseptic with the addition of a teaspoon of building universal glue so that the mixture does not drip and creates a stronger film.

Assembly of hydro and vapor barrier

First you need to decide what the room will be used for, if there is another heated room on top, then there is no point in installing heat and sound insulation on the draft ceiling, wooden surfaces spread noise and heat quite well.

The vapor barrier is mounted along the entire perimeter of the ceiling, it is especially well stretched in the corners, it lays with an overlap, the boards are mounted along the overlaps. This will help protect the rough base and wooden ceiling from rotting and mold.

Ceiling vapor barrier - effective and high quality

The subtleties of laying insulation

If the insulation is not laid correctly, skirting boards and decor can be destroyed, the draft ceiling can even cause a fire, for which you should slowly study the instructions so as not to confuse the sides, because the markings of different companies may contradict each other.

It is enough to cut circles of about 20 cm in the material around the planned lamp, this will create good fire safety, which is extremely important for a wooden house, and wooden decor elements. It is important to establish these places even during the installation of the material - we measure the places from the wall, then put a mark on top, in the form of a circle with a diameter of 20 cm

Comprehensive thermal insulation reduces the energy loss of the building

The same applies to vapor barrier, although the material is strong enough, but unstable to high temperatures, it can melt and cause a fire, especially if the rough, cladding and decor are made with untreated clapboard.

Thus, an underlined design can lead to sad consequences for the interior and the integrity of the room. But since the lamps and decor are not mounted to the draft ceiling, like the wiring, it is enough from below, at the attachment points, to install heat-reflecting foil on the vapor barrier, squares of 20 by 20 cm. It will not be visible, but it will help preserve the interior of the room and not damage the plan decor design.

Installation of thermal insulation in a wooden ceiling

As we see a wooden ceiling with our own hands, it is quite possible to do it quickly and efficiently. In addition, you can hem the rough base yourself, faster, better than many workers.

sledcomspb.ru

chudesniydom.ru

kvartblog.ru

pootdelke.ru

materials

You can hem the ceiling on wooden beams with various materials. Designs that combine original finishes from several panels look beautiful, as a result, the coating is completely or partially even. Such a surface can be additionally pasted over with foam tiles, textured wallpaper or painted with paint.

In addition, in modern design, a variety of materials are used for ceiling cladding.

Fiberboard. The sheets of the product are cut in such a way that their end parts are placed in the middle of the beam. The fiberboard is attached to the structure using wooden beams 20 × 40 mm in size or fixed with special lags. To do this, recesses are cut out in the boards and an additional corner or beam is inserted.

With this type of finish, it is important to ensure that the fiberboard panels do not sag. Therefore, they are nailed and laid with a seam offset or in a checkerboard pattern.

Plywood

If the texture of wood is not important for the interior of the room, then the ceilings are sheathed with plywood, it is attracted with self-tapping screws and nailed

In this case, you need to pay attention to the thickness of the beams, since this material is heavy. The thickness of the sheets is chosen depending on the distance between the lags

At the end of the sheathing, the seams are sealed with putty on wood or mastic. Then the surface is well primed and covered with a finish.

- OSB boards (OSB). This material is considered inexpensive, easy to install and well amenable to processing. OSB slabs can be sheathed in ceilings in any room. The only drawback of the product is the presence of resin in its composition, but if the material is made with high quality, then during its operation the emission of formaldehyde will be small. The plates are assembled quickly, since in their design they are similar to lining and have special grooves. After such sheathing, the ceilings acquire a smooth and seamless surface.

- Drywall. It is the most common material for surface cladding, it is easily attached to both wooden and aluminum frames. With it, you can create beautiful multi-level systems or simply insert between wooden beams. After installing drywall, it is necessary to seal all joints, for this they apply a special construction mesh and cover it with putty.

- Sandwich panels. They are an excellent insulation, which is easily joined using a special connection. The panels are screwed to the beams with self-tapping screws, after which they are painted. The material is available with a matte and glossy surface, does not require additional processing. They can either completely cover the ceiling, or make separate inserts vertically or horizontally.

- Wooden lining. It is one of the most popular types of material that looks beautiful in the cladding of private houses; a wood product is environmentally friendly and has a pleasant aroma.The ceiling decorated with a board maintains a certain microclimate in the room, absorbs excess moisture. If you install such a structure correctly, it will last for many years and act as good sound and heat insulation. Most often, lining of cedar, alder, pine and oak is chosen for ceiling cladding. Its width is from 30 mm to 150 mm, and the length can reach six meters. Of course, such sheathing is considered expensive, since, in addition to installation, the boards must be additionally coated with varnish, which, when dried, creates a protective film and makes the coating resistant to moisture.

Installation

It is quite possible to sheathe the ceiling on wooden beams with your own hands. To do this, you first need to prepare all the tools, finishing material, as well as glue and mixtures for woodworking. In the event that the beams will act as the basis for the floor, they should be carefully checked for the presence of fungus and mold. If there are defects, then the logs must be treated with an antiseptic solution, and cracks and chips must be puttied.

After the completion of the preparatory work, you can perform the installation, which consists of several stages.

- First of all, you should create a vapor barrier and close the beams. This is best done with plastic wrap or parchment, which can be easily stapled. Then the logs should be lined with any draft material, most often a cut board is used for such purposes. If the ceiling turned out to be crooked, and the floors have differences in levels, it needs to be leveled.

- The next step in the work will be the laying of thermal insulation, it will keep the heat in the room and will not let cold air flows from the roof or interfloor ceiling. This is especially true for the cladding of the first floor in apartments. Mineral wool or polystyrene is used as a heater.

- After installing the thermal insulation, an additional layer of vapor barrier is laid. To date, there are many materials with which it is possible to provide structures with natural air exchange, but membrane polyethylene is considered the main one.

- The final stage is the device of the rough base. The coating is sheathed with plywood or profiled sheet.

In the event that the work is carried out in a private house, then the finishing should be done, taking into account the functional purpose of the attic. In many buildings, it can serve as a residential attic, or simply act as a non-residential space. For an attic that will accommodate a full-fledged room, it is necessary to add aluminum foil to the floor layer, it will help to avoid heat loss in the house. In addition, when decorating the attic, a layer of sound insulation is laid, consisting of sawdust and mineral wool.

The ceiling sheathed in this way should not only be beautiful, but also maintain the microclimate of the room. The aesthetic appearance of the entire structure will depend on the correct installation of the finish coating. Therefore, work must be done slowly and adhere to all plating technologies. To simplify installation, it is recommended to first draw up a ceiling diagram, indicate in it the laying of heat, steam and sound insulation.

Stretch ceiling

With the help of stretch ceilings, it is possible to completely close the beams or niches between them, while the structures are fastened to the walls. Stretch ceilings are rich in textures, shades and shapes, allow you to install built-in lights and hide ceiling defects. You can use them in combination with other types of finishes.

With the help of stretch ceilings, you can completely close the beams or niches between them

It is not easy to mount stretch ceilings on your own, therefore, for a quality finish, it is better to resort to the help of professionals. They will help you choose the material and design, as well as mount the lighting.

Important! When installing stretch ceilings, ventilation of the subceiling space must be ensured, otherwise condensation may occur.Advantages of stretch ceilings:

Advantages of stretch ceilings:

- richness of textures, shades and shapes;

- durability and strength;

- the material is not afraid of moisture and leaks;

- does not require painting and finishing, it is easy to clean;

- goes well with types of finishes.

- rather expensive material;

- installation requires skills and special equipment.

Ceiling tiles

The cheapest, but short-lived option. The tile is lightweight, easy to mount with glue, but due to its small size, it may require the installation of an additional crate.

Important! Ceiling tiles burn well, while emitting toxic substances and acrid smoke. Do not use it in houses with stove heating!

- light weight;

- low price;

- not afraid of water;

- simple installation.

- fire hazardous;

- breaks easily;

- looks pretty cheap.