Beginning of work

Before you install a faucet in the kitchen, you should take care of the availability of the necessary working tools. As a rule, for such manipulations, a minimum set is sufficient:

- screwdrivers;

- wrench;

- containers for draining water;

- flashlight.

Before changing the faucet in the kitchen, turn off the water supply. Regardless of the type of mixer, the entire further process is divided into two stages: dismantling the old device and installing a new one.

In apartments of multi-storey buildings, valves are usually located in bathrooms.

Note. To carry out repair work, it is not necessary to disconnect the entire room from the water supply - with proper hydraulic wiring, you can turn off the water supply only to the kitchen.

For greater convenience when working on replacing the mechanism, it is advisable to remove the sink sink.

An excellent video in which the author talks in great detail about installing a new faucet on a kitchen sink. The same goes for replacing a faucet!

Types of crane boxes for mixers

The culprit of the failure of the crane box is of two types.

- In a semi-rotary mixer, this is a axle box faucet with ceramic inserts that, when turned, open and close the hole for water pressure.

- In the mixer, where it is necessary to turn the valve handwheel several times, a crane box is used, which works on the principle of a worm gear. Such a faucet box shuts off the water with the help of a rubber gasket that descends onto the valve seat.

These two types of crane boxes have many different modifications. They can vary in length, thread size, flywheel mounting method, and other parameters.

- First of all, there is a difference in the size of the thread that is screwed into the mixer body. The most common axle boxes are 15 mm (1/2 inch), rarer - 20 mm (3/4 inch) and 10 mm (3/8 inch). It would not be surprising if other sizes exist. Manufacturers prefer creativity and fantasy to “dull” standardization.

- Also, one of the main differences is the fastening of the valve lamb, which is attached to the end of the crane-box stem. The end of the stem may be in the form of a square or have slots applied to it. Usually the number of slots is 20 or 24, but there may be another number. Accordingly, on the lamb there will also be a mount either under the square or under the slots. Sometimes there are handles with a universal mount for both slots and a square.

The flywheel screw is usually suitable for all types of crane boxes, but an exception may very rarely occur.

Crane box with locknut

As a rule, bushings with a square end of the spindle are found on Russian mixers. Accordingly, worm-driven axle boxes with a rubber gasket are usually of domestic production and have a square end of the spindle. On mixers of foreign manufacturers, crane boxes are produced with slots.

- There may also be other differences on crane boxes. There may be a different number of threads. Both the one that is screwed into the mixer body, and the one on which the protective and decorative cap is screwed.

- The axle box may or may not have a lock nut.

- The length of different crane boxes may vary, as well as the dimensions between the various elements.

Therefore, before buying a new crane box, you must first remove the old one in order to have a sample. And to the plumbing store, take with you not only the old crane box, but also the lamb. The new axle box may not differ by eye from the old one, but the number of splines may be different. Recalculating slots is very problematic. It is better to immediately try on a lamb on a new crane box in the store.

On sale there are crane boxes assembled with a protective cap and lamb. Sometimes a package is sold in which both crane boxes with lambs are located at once. Such a kit is more expensive than a separate crane box.But in the event that for some reason it is impossible to remove the axle box in advance, this option may be a way out of the situation. All you need to do is to choose a set that matches the color and style of your faucet. True, in this embodiment, there is some risk that the kit still does not fit the mixer. Or it doesn't fit perfectly. For example, a protective cap can hang freely on the stem, because the thread intended for it will go too deep into the body of the mixer.

If desired, you can also repair a failed crane box. This is especially true of the crane box with a rubber gasket. In 90% of cases, it is possible to simply replace the gasket or even simply turn it over to the other side, on which there are no signs of wear. Repairing a crane box with ceramic inserts is more difficult, but in most cases it is still possible. If there is no desire to bother with repairs and with the search for the spare parts necessary for it, and also does not bother the cost of a new axle box, then in this case it is worth replacing it.

Crane replacement

Fig.5. throughput valve

We recommend the procedure for sealing water meters. Important information: registration, terms and cost

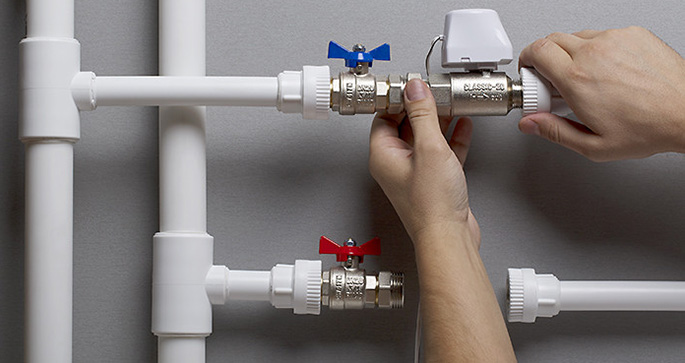

It is possible to change the bushing valve in the mixer only for an identical one. To do this, you need to disassemble the mixer. Before disassembling it, it is necessary to shut off the water in the pipe to prevent a small flood. To do this, close the valve. It is located in front of the mixer and may look like this.

These are modern ball valves. In this position, water flows freely in the pipe. To block the water, its petals must be rotated 90 degrees.

Fig.6 Ball valve

If there is no such valve on the supply pipe, then it is necessary to look for a shut-off valve on a pipe of a larger diameter. It may look like this.

To shut off the water, the handle must be rotated 90 degrees. If there is no such valve, then it is necessary to turn off the water on the riser, which goes from bottom to top from the first to the last floor.

Good advice: Do not repair the faucet without shutting off the water. This is fraught with a scandal with the neighbors below.

How to fix a leaky faucet

Water is dripping from the faucet spout and it is impossible to completely shut off the faucet valve? What to do in such a situation? How to fix this water supply problem?

In the event that this happens with a two-valve mixer, this is usually the case. in the breakdown of the crane box.

And it doesn’t matter if it’s a kitchen faucet or a faucet installed on a bathroom or bathroom washbasin. node

This also applies to a two-valve bath or shower faucet if water drips from the spout of the faucet or from the shower head, depending on the position of the selector switch. This applies to both a semi-rotary valve mixer, and one in which the opening and closing of the water flow occurs with the help of several turns of the valve knob.

How to buy and not be mistaken

Before buying, you need to find out which axle box crane is to be replaced. Ours or imported? Imported ones have slots on the stem in the amount of 20 or 24. The domestic axle box crane for the mixer does not have such slots. Their stems are made in the form of a square. All plumbing items are measured in inches. They come in 0.5 and 3/8 inch sizes.

Choice of axle box crane - Photo 05

- when buying an imported bushing faucet, you need to make sure the quality of the water. To do this, you need to collect water and let it settle. If there is sediment, then you need to either buy a spare part with a rubber gasket or put a fine filter in front of the mixer,

- in order not to confuse anything when buying, you need to take the bushing crane with you to the store and show it to the seller,

- faucets with rubber gaskets to shut off the water make 2-4 turns of the flywheel.

- faucets with ceramics to shut off the water make a half turn.

The design of the plumbing fixture

The body of the two-valve mixer is made of brass, less often steel.On the front part there is one faucet (spout) designed to supply water, at the end of which a sprayer is installed.

On the back there is a threaded pipe for attaching to water pipes.

Inside the structure there are crane boxes (valve heads). They are responsible for the pressure and temperature of the supplied water.

Faucets with a shower with separate taps are of two types:

- Tee (herringbone). This type of device is equipped with two valves and is connected to the pipes by means of a tee. For this, two channels are pre-made in the case.

- Branch pipe. This type of plumbing fixture is connected separately from the body, using special flexible or rigid pipes. The pipe mixer is considered the easiest to install.

Most often, faucets are supplemented with a shower hose, at the end of which there is a watering can. Between the hose and the tap, the water is switched by means of a special lever in the form of a flag or button.

Repair secrets how to disassemble a faucet in a two-valve bathroom

No matter how high-quality the faucet in the bathroom is, sooner or later it will need to be repaired or completely replaced. Regular operation of valves and hard water disable the plumbing fixture. But before replacing, you need to study the device and understand how to replace the shower faucet yourself.

The main problem is leakage, the cause of which is the wear of the gaskets, and replacing them is much cheaper than changing the mixer. Disassembling the mixer is not difficult, but you still have to spend a little time and prepare certain materials and tools. But do-it-yourself replacement will significantly save the budget.

Features of two-valve mixers

The task of a mixer with separate taps is to combine hot and cold water and supply it to the tap in a single stream of a certain temperature.

Despite the fact that many consider this type of faucet obsolete, it does not lose its position in the market. At a price less than that of a single-lever, a two-valve one is not inferior to it in terms of technical characteristics, and sometimes even surpasses it.

A distinctive feature of such a device is the presence in its body of two valve heads (faucet box). They serve as a locking mechanism.

Valve heads can be of two types:

- With elastic gaskets made of rubber, silicone or leather;

- With ceramic discs.

Regardless of what type of head, both rubber gaskets and ceramic discs will work equally well in the same housing, since they are interchangeable.

Expert answers

ser5779:

They haven’t come up with a better blowtorch yet - you heat the connection to a loud click - this will mean that the threads of the connections have parted and can unwind freely

Arisha Maronchuk:

Automotive stores sell rust removers for bolts and screws.

Constantine:

take the brake fluid and drip it so that it gets into the threaded connection and slowly try to unscrew it. but in general, invite a man whose hands grow from the right place

Grigory Glazunov:

call the men, swear smokers

Comte de Wall:

Weaklings. Suffocation. Ants. A hefty gas key is taken, put on the valve so that the sponges work in compression, and a metal pipe of a suitable diameter is put on the tail of the key. It makes a huge leverage. Then you resist, you say - Oh, mother, what a bad task for you .... and it moves slowly.

YALKO:

Using two gas keys. With one key we hold the pipe (from scrolling), and with the second key we unscrew the valve. OR cut along the grinder, then he will turn away. or heat it up with a blowtorch.

Sergei Chistyakov:

Moisten the exit of the thread with kerosene around the entire circumference for two hours. If not enough, repeat. Kerosene has a high penetrating power and loosens rust.

Vasily Kuzminykh:

Heat up with a blowtorch

Andrey Volkov:

two gas keys - clamp and unscrew

Alexandra Poleshchuk:

Buy a WD40 at a car dealership, process and unscrew ...

Grandfather Au:

try "whiteness" to remove the oxide

Belogurov Nikolay:

and why should a bronze valve be unscrewed at all, make an audit of it and it will work for a hundred years, by the nature of its activity, I realized that there is nothing better than Soviet bronze valves

Natus'k@:

Try Milam only gel! Eat everything!!!

Vyacheslav Koshelev:

It’s better to just warm it up, otherwise you can break off the carving. liquid products are unlikely to soak inside. and with dope, you can not only break a pipe, and not only a rusty one ... .

k190 :

cut in half with a file, jigsaw, needle file and take out the halves

Vlad:

... let's take pictures))) ... then we'll tell you !!!! P.S. There are many options!

Sergey Dmitriev:

If there was an adapter (from a larger diameter to a smaller one), then it goes under the hexagon (diameter 16, or just pliers are possible). And so little information. If on the mixer - just drive the pliers (one sponge) and twist)

Nikolay Pavlukhin:

firstly, this is not an adapter, but an eccentric ... you can carefully cut the inside of the metal with a metal blade in two or three places, but not deep, and then knock down the thread with a chisel or a screwdriver, we do this all the time

Vladimir Zavorotnyuk:

Take a 4-sided file of a suitable size, grind off the notch and hammer tightly into the thread with a hammer. Unscrew with a wrench. Good luck.

vic:

If silumin or brass, make small indentations along the entire length of the break with a round file, then use a thin screwdriver next to the recess to hammer in like a wedge between the pipe and the break, when you break the wall of the fragment, it can be twisted inward further easier, hammer the wedge without deforming the pipes. in place of the file, you can use a drill with a drill to drill through with a recessed drill.

foreman:

car dealerships sell fixtures for turning out torn studs, buy and try 100% turn it out, pre-drill a hole if there is none and then insert the fixture there and unscrew it (they will not break very strong !!!)

Irirna:

I recently had a master solve this problem with a gas key. Both knobs stuck in there and unscrewed.

Dim-Dim:

gas wrench large and twist pshtykni vd heat than a thread and unscrew make notches with a file and unscrew

Valentin Zhavoronkov: