When filling with coolant

There are only two situations that require the implementation of this technological operation:

- putting heating into operation (at the beginning of the heating season);

- restart after repair work.

Usually, the heat carrier water is drained in late spring for two reasons:

- Water is inevitably polluted by corrosion products (inside radiators, metal-plastic and polypropylene pipes are not subject to it). Leaving the old water for the new season, you risk breaking the circulation pump with solid contaminants.

- Non-launched flooded systems of country houses can “thaw out” during a sudden cold snap - such cases are not uncommon. In this sense, antifreeze coolant is preferable. The high-quality composition has high anti-corrosion properties, which increase the “drainage” interval up to 5-6 years. There are known cases of uninterrupted operation of heating on the same volume of antifreeze for 15-17 years. Low-quality antifreeze is recommended to be drained after 2-3 years.

Pumping antifreeze into the heating system.

Features of using water as a heat carrier

In terms of heat transfer efficiency, water is an ideal heat transfer medium. It has a very high heat capacity and fluidity, which allows you to deliver heat to the radiators in the required volume. What water to fill? If the system is closed, you can pour water directly from the tap.

Yes, tap water is not ideal in composition, it contains salts, a certain amount of mechanical impurities. And yes, they will settle on the elements of the heating system. But this will happen once: in a closed system, the coolant circulates for years, a small amount of replenishment is very rarely required. Therefore, a certain amount of sediment will not bring any tangible harm.

Water as a heat carrier for heating systems is almost ideal

If the heating is open, the requirements for water quality, as a heat carrier, are much higher. Here there is a gradual evaporation of water, which is periodically replenished - water is added. Thus, it turns out that the concentration of salts in the liquid increases all the time. And this means that the sediment on the elements also accumulates. That is why purified or distilled water is poured into open-type heating systems (with an open expansion tank in the attic).

In this case, it is better to use distillate, but it can be problematic and expensive to get it in the required volume. Then you can fill in the purified water, which is passed through the filters. The most critical is the presence of a large amount of iron and hardness salts. Mechanical impurities are also useless, but it is easiest to deal with them - several mesh filters with a cell of different sizes will help to catch most of them.

In order not to buy purified water or distillate, you can prepare it yourself. First, pour and stand to settle most of the iron. Carefully pour the settled water into a large container and boil (do not close the lid). This removes hardness salts (potassium and magnesium). In principle, such water is already well prepared and can be poured into the system. And then top up with either distilled water or purified drinking water. This is no longer as costly as the initial fill.

Basic rules for arranging heating make-up

Example of a heating system make-up unit

Example of a heating system make-up unit

What is the reason for the decrease in the volume of water in the pipes? The main source of its leakage is the excess of the operating temperature. As a result of this, a critical expansion of the liquid occurs, after which its excess in the form of steam leaves through an air vent (closed circuit) or an open expansion tank (gravitational).

The installed heating system replenishment machine compensates for the lack of water by adding the required volume to the line. But this is not the only case when it is necessary to quickly add a coolant to the system:

- Removal of air pockets. As a result of opening the Mayevsky tap or air vent, some of the liquid will inevitably leave the system. In a closed circuit, in this case, a pressure drop will occur, to which the automatic replenishment of the heating system must respond;

- Micro leaks. Loose fitting of pipeline joints and loss of sealing even at a small level will lead to a gradual decrease in the volume of water. It is difficult to identify such defects, but it is necessary. The automatic heating system make-up valve will only work after the pressure drops to a minimum level;

- Carrying out repair or maintenance work;

- The formation of corrosion on the walls of metal pipes, which leads to their thinning and, as a result, an increase in the internal volume. At first glance, this is a minor factor. But if the recharge of a closed heating system is not installed, the pressure will gradually decrease and air jams will begin to form.

What should the heating system feed device consist of? It all depends on the type of heating scheme. Also, the design of adding a coolant to the system is influenced by its characteristics: pressure, operating temperature, line layout, number of heating circuits, etc.

How to pour water into a closed heating system with and without plumbing

Arkady How to pour water into a closed-type heating system?

No heating system will function without a coolant. because it directly provides the transfer of energy to the radiators and the subsequent heating of the air in the room. So after installation and repair work, you will inevitably need to pour new water into the equipment. To many, this procedure seems overwhelming. Especially if you need to fill a closed system. Indeed, the task is troublesome, but at the same time absolutely realizable, if you do everything according to the rules - they will be discussed further.

Preparatory operations

Before you start pouring coolant into a closed heating system, prepare it for work. In particular, the following procedures should be followed:

- Hydraulic test - before filling the system, it must be pressure tested. This is done using a special device that pressurizes and fills all pipes and batteries with compressed air. Pressurization is carried out at a pressure of 25% more than the base pressure for a particular heating system.

- Checking for malfunctions - after completing the pressure test, all joints of the heating equipment should be checked for depressurization and leaks. If there are any problems, they must be corrected.

- Closing valves - to avoid unplanned water consumption during filling, close the shut-off valves that remove fluid from the system.

When the preparatory work is completed, you can start pouring water. It can be run from a centralized water supply or, in the absence of the latter, from another source of water - consider both options.

Hand pump for pressure testing of the heating system

Filling water from the tap

If your house is connected to the water supply network, there will be no problems with filling the heating system. First you need to determine which fittings are closest to the heating boiler - it is through it that the coolant should be introduced.

Next, the heating boiler must be connected to a centralized water supply and a special shut-off valve must be installed between them. Filling is carried out precisely thanks to this valve: when it is opened, water begins to flow from the water supply into the boiler, which is then poured into the pipeline.

Important! Water should enter the heating system at a minimum speed - this will allow the air that remains in the pipeline to be removed without consequences through special Mayevsky taps on batteries. If the house has more than one floor, the system can be filled not at once, but in parts: starting from the lower radiators and ending with the upper heating points

If the house has more than one floor, the system can be filled not at once, but in parts: starting from the lower radiators and ending with the upper heating points.

Pouring water without plumbing

If the source of the coolant is not a centralized water supply, but a well, a well or a reservoir, auxiliary equipment will be required to fill the closed heating system. It can be a powerful pump or an expansion tank.

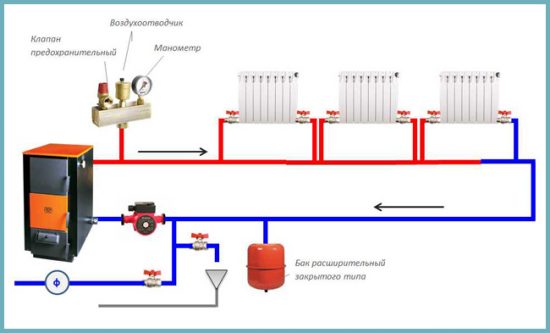

Scheme of the heating system device

In the first case, you will need a manual or electric pumping unit. With its help, the filling is performed according to the following scheme:

- Connect the pump hose to the drain pipe.

- Open the special valve on the nozzle.

- Open Mayevsky taps.

- Start the pump and start running water into the system.

In the second case, use a membrane tank with a baffle in two parts and a regular bicycle pump:

- Connect the tank to the heating system piping and fill it with water.

- Unscrew the nipple at the top of the expansion tank and bleed air from the tank.

- Connect the bicycle pump to the nipple and start pumping air into the tank, building up pressure to bring water into the system.

Advice. Pump up the tank until the pump pressure reaches 1.5 atm.

Now you know that you can fill water into a closed-type heating system both from a water pipe and without it. The main thing in both cases is to carefully prepare for the procedure and observe all the technical details of the work. So, if you follow the rules, filling the system will not be an overwhelming task for you.

Best Answers

Konstantin Sukhorukov:

Only the heating engineer did not say what would happen to the boiler heat exchanger from the effects of antifreeze. If you want to use anti-freeze, then use propylene glycol-based liquids. And you can download without using a water pump, using a conventional, automobile and closable container with two fittings.

larisa:

pump and hose

Alexander Bakushev:

open the emergency tank, and fill it up until it runs!

Andrey:

Pump a small container in the usual way and a cheap submersible pump into it, through a hose to the make-up tap, control the pressure using a standard pressure gauge, bleed air, pump and pump. Preliminarily pressurize the system with network water, check in operation with a temperature difference. Evaporation of antifreeze and antifreeze inside the living quarters, this is goodbye to health and vision. for these reasons, they are filled with an aqueous solution of drinking alcohol (vodka). Moreover, if the system is new and its volume is not very large, get a supply of a strategic product.

White Oleg:

Make two fittings in the canister, pour anti-freeze, one hose to the boiler, pump air into the other with a compressor from the refrigerator. The compressor from the refrigerator presses up to 8 bar - you will definitely have enough. Performance is just poor. But they cannot pump any electrically conductive liquids - there the windings are not protected by anything ...

Denisochka:

Where did the need for glycol coolant come from? When using it, heat transfer decreases and maintenance of the boiler is difficult, especially if the boiler is double-circuit with one heat exchanger. For almost any heating system, the best coolant is water.

Heating filling quality control

Before filling a closed heating system with water, you need to make sure that all protective elements are present.These include Mayevsky taps, bypasses, and control devices - thermometers and pressure gauges. They are necessary not only to control the pressure in the pipes during the supply of coolant, but are also the main safety measures during heating operation. This is how you can correctly fill the heating radiator with water.

During the correct filling of a closed system with water, the following parameters must be monitored:

- Pressure. Pressure gauges must be installed at key points in the system - extreme heating radiators, and the highest point. After the final release of air, the pressure on all gauges should be the same;

- No leaks.

This is the only way to achieve stable pressure. However, the main verification process occurs when the boiler is turned on. The thermal expansion of water at the maximum operating mode should not affect the integrity of the pipelines of the heating elements.

Selection of pressure values in the system and expansion tank

The higher the operating pressure of the coolant, the less likely it is that air will enter the system. It is necessary to remember about limiting the operating pressure to the maximum permissible value for the heating boiler. If, when filling the system, a static pressure of 1.5 atm (15 m of water column) was reached, then the circulation pump with a head of 6 m of water. Art. will create a pressure of 15 + 6 = 21 m of water column at the entrance to the boiler.

Some types of boilers have an operating pressure of about 2 atm = 20 m of water column. Be careful not to overload the boiler heat exchanger with unacceptably high coolant pressure!

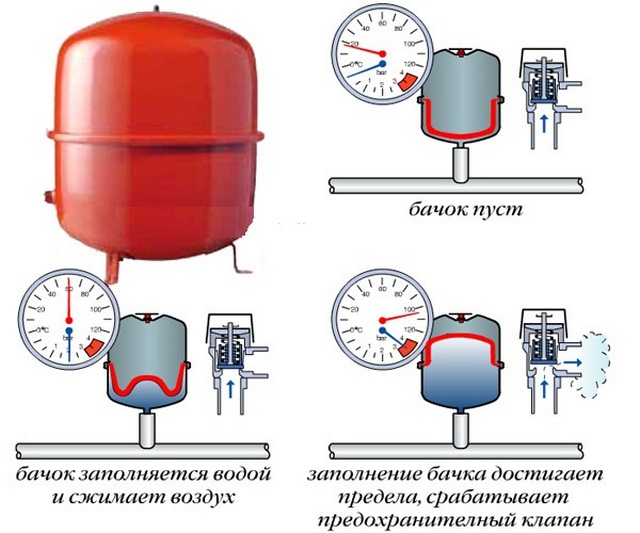

The diaphragm expansion vessel is supplied with a factory set pressure of inert gas (nitrogen) in the gas cavity. Its common value is 1.5 atm (or bar, which is almost the same). This level can be raised by pumping air into the gas cavity with a hand pump.

Initially, the internal volume of the tank is completely occupied by nitrogen, the membrane is pressed by gas to the body. That is why it is customary to fill closed systems to a pressure level not higher than 1.5 atm (maximum 1.6 atm). Then, by installing the expansion tank on the "return" in front of the circulation pump, we will not get a change in its internal volume - the membrane will remain motionless. Heating the coolant will lead to an increase in its pressure, the membrane will move away from the tank body and compress the nitrogen. The gas pressure will increase, balancing the coolant pressure at a new static level.

Expansion tank pressure levels.

Filling the system to a pressure of 2 atm will allow the cold coolant to immediately compress the membrane, which will also compress nitrogen to a pressure of 2 atm. Heating water from 0 °C to 100 °C increases its volume by 4.33%. The additional volume of liquid must flow into the expansion tank. A large volume of coolant in the system gives a large increment during heating. Too much initial pressure of the cold coolant will immediately use up the capacity of the expansion tank, it will not be enough to receive excess heated water (antifreeze)

Therefore, it is important to fill the system to a correctly defined coolant pressure level. When filling the system with antifreeze, you need to remember about its higher coefficient of thermal expansion than that of water, which requires the installation of a larger expansion tank

Conclusion

Filling closed heating systems is not just a standard final operation before commissioning. Performing this step correctly or incorrectly can seriously affect the performance of the system, in the worst case, even disable it. Compliance with filling technology is the key to obtaining stable heating.

How to implement alternative heating of a private house

Two-pipe heating system of a private house - classification, varieties and practical design skills

One-pipe and two-pipe heating distribution in a private house

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until the moment when water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the filling valve of the system open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

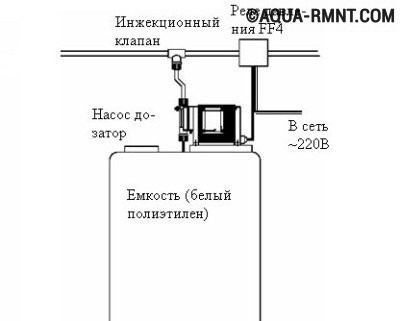

Example of an automatic make-up system

There is a lot of equipment on the market for solving the issue of feeding heating systems. Do you want an automatic, trouble-free, reliable installation? It can be "assembled" from the following elements:

- containers with screw caps;

- dosing pump;

- pressure switch;

- rigid suction line with level sensor;

- air valve for air release;

- fitting for filling the coolant into the container, complete with a plug (prevents solid particles from entering the container);

- injection valve for connection to the circulation system;

- flexible tube;

- low level sensor for signaling the absence of liquid in the make-up tank;

- electric stirrer to prevent possible separation of the coolant into fractions.

Properly assembled from the above components, the unit will be highly effective in maintaining the required pressure in the heating circuit, and also fully compatible with the air conditioning circuit. The installation will automatically "eliminate" all regular losses in the systems: along the connections, along the pump seals, on the fittings. It is not at all “capricious” in relation to the coolant: it works well with both water and glycol-containing liquids.

This node operates according to the following principle:

- Water / glycol and water in the appropriate proportion / ready-made solution are poured into the container through a fitting or neck.

- The make-up pump is connected to the network and pumps the coolant into the system with low productivity, thereby ensuring its uniform filling.

- When the pressure in the system reaches the set value, pumping stops automatically.

- When the pressure drops, the relay turns on the pump, which returns the system to stability.

Replacing water with antifreeze

If the system has already used water, and you want to switch to antifreeze, then two things should be considered.

Secondly. It is never possible to completely remove water from the heating system. Some of the water remains. If you fill in simply prepared diluted antifreeze, then its concentration will be insufficient for reliable protection against freezing. Thus, you need to apply a concentrate. I usually mix concentrate with diluted antifreeze in a 1:1 ratio. After filling the system, you need to start the circulation pump (for a system with forced circulation) or turn on the boiler (for a system with natural circulation) so that the coolant mixes well. Then you need to pour a little coolant and measure its density. To measure the density there is a device that is sold in most car dealerships. This device is used to prepare a car for winter (checking the properties of antifreeze in the engine cooling system), but it is also perfect for our purposes. If the device shows a freezing temperature lower than necessary, for example -50 degrees, it's okay, but if the temperature is higher than we need, then we will have to drain part of the coolant and replace it with a concentrate. The drained coolant must be disposed of carefully, it is poisonous, it should not be poured into septic tanks and ditches.

I also want to draw your attention to the fact that different antifreezes may be incompatible with each other. There is an opinion that it is impossible to mix a red composition with a composition of a different color.

This is true, but in fact there are other undesirable combinations.Additives of different brands may react with each other or simply reduce each other's effectiveness. Unfortunately, manufacturers do not report which other antifreezes their product can be mixed with. My advice is to pick one brand and stick with it. If, nevertheless, there is a need to mix, then mix liquids of the same color and before pouring, drain a little coolant from the heating system, mix it in a jar with a new composition and see if a precipitate falls out, if the liquid becomes cloudy, if it loses uniformity.

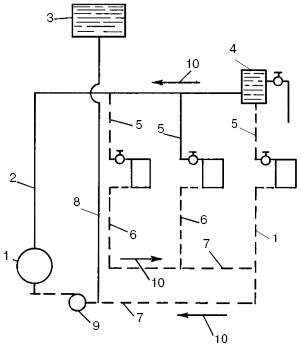

How can I fill the heating system in an apartment building

Scheme of water heating with associated water movement: 1 - boiler; 2 - main riser; 3 - expansion tank; 4 - air collector; 5 - supply risers; 6 - reverse risers; 7 - return line; 8 - expansion pipe; 9 - pump; 10 - pipe slope direction.

The water valve located in the house should be closed, and the water discharge is gradually opened on the coolant supply pipeline. At this time, the discharge on the return line is blocked. Then you need to very slowly open the shutter on the return pipeline until it is fully open.

Caution must be exercised, because if the high pressure water supply of the general heating system is abruptly opened, this can lead to sudden pressure drops that cause water hammer. The push can be so powerful that one will be enough to break the system in the most vulnerable places.

It will take some time for the heating system to fill up. Reset should be constantly monitored. When water flows without the admixture of air bubbles, and this can be understood by the cessation of the characteristic hissing sound, the discharge valve is closed. Now it's time to open the valve for supplying water to a particular room. At the final stage, it remains to bleed air from all heating circuits. This method of filling the system with water is provided for heating with lower wiring.

A system with top piping looks much easier to handle.

In this case, simultaneously, with the same caution, both dampers should be opened at once, while the discharge should be closed. To bleed air, go up to the attic of the building and open the air valves provided for by the design