Locking elements

First of all, let's look at what types of water taps can be according to the structural features and functioning of their locking elements:

Cone

Closing and opening the passage in such a crane is carried out by raising and lowering the cone-shaped plug.

At one time, this design was very widespread, but today it is practically not used due to very significant shortcomings:

-

Difficulty to use by hand

. In order to open or close such a device, a large torque is required, even taking into account the small cross section. -

Rapid wear

. The conical plug, which is responsible for the efficiency of the product, loses its accuracy of fitting to the body walls too quickly, which makes the valve unsuitable for further operation. -

Relatively high price

due to the complexity of processing the cone of the locking part, where the slightest mistake will lead to the lack of the necessary tightness.

Cylindrical

In this case, the locking function is carried out by moving the cylinder, which provides the following differences from the previous version:

- Simplified manufacturing technology, which affects the reduction in the cost of the finished product.

- There is no complete tightness.

Ball

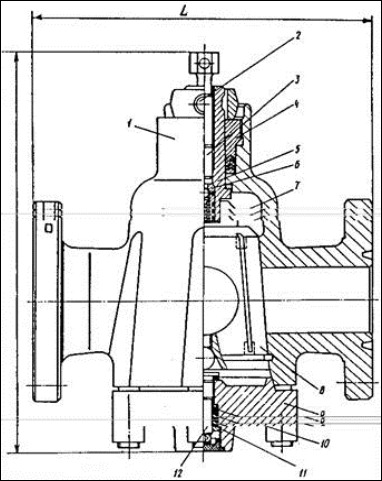

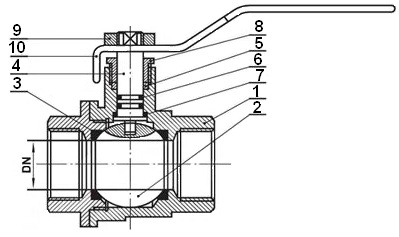

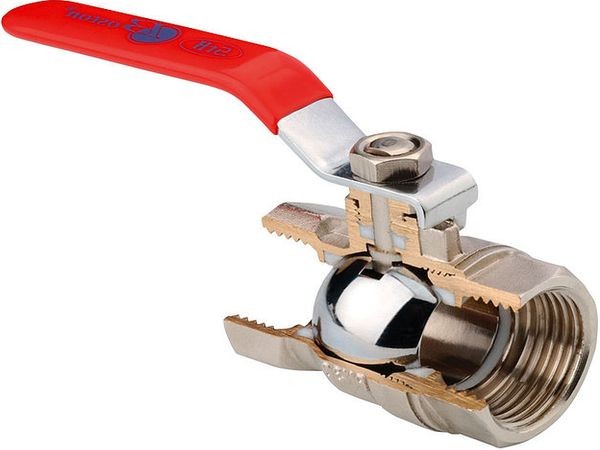

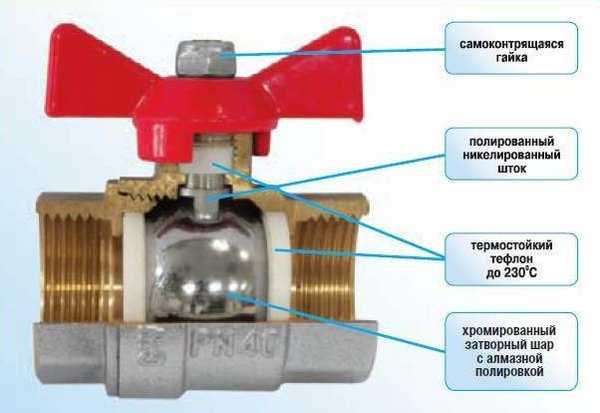

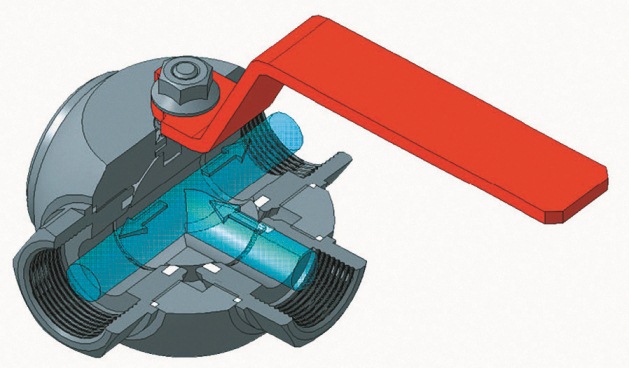

Here, the principle of operation is fundamentally different from previous variations of water taps. The locking element is a steel ball with a through hole in the middle.

By turning the handle connected to the ball by a rod, we thereby change its position:

- The hole is turned to the wall of the valve body, and the passage is completely blocked.

- The hole is turned towards the inlet pipe, as a result of which the passage is free for the movement of fluid.

Such a device provides the ball valve with the following advantages, thanks to which it is today the market leader in sanitary valves:

-

Affordable cost

provided by ease of manufacture. -

Elementary instruction manual

. It is enough to make a slight turn of the handle by 90 degrees to change the state from "open" to "closed" and vice versa.

-

Little weight

due to which there is practically no load on the pipeline. -

Reliability and wear resistance

. There is no such fast development as in previous models. -

External attractiveness

. The small size of the crane itself makes it almost invisible on, and the protruding handle in the form of a lever or butterfly looks quite aesthetically pleasing.

Thus, if we talk about the shutter mechanism, then the ball models definitely win.

Which faucet is better valve or ball Myths and reality

You can find opinions on the net. Both right and wrong. How can an unprepared person, who decides to clarify for himself some question unknown to him, find the truth?

There are only two ways:

– Check any information from other sources and analyze;

- Follow the recommendations of those specialists whom you already know as professionals.

Let's try to use the first method and analyze one recently appeared article in Zen with a similar title.

Quoting from a screenshot:

What can be said here? Valves appeared long before the emergence of the USSR and are still very widely used in world practice.

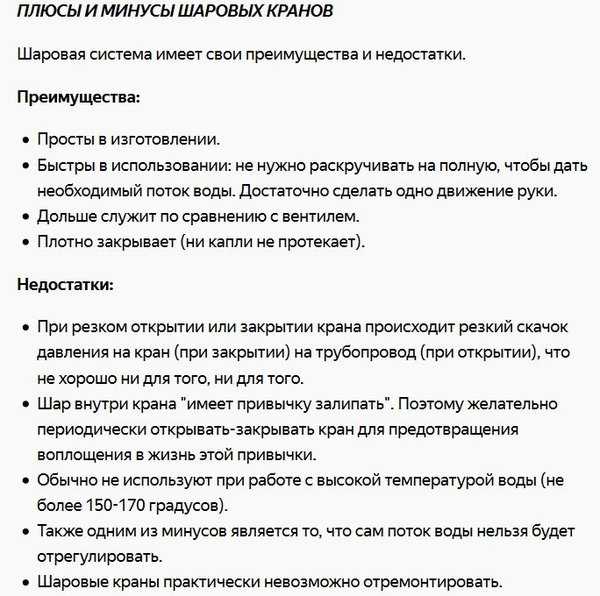

Why don't they last long? This unsubstantiated statement of the author is given solely in order to make the transition to "some kind of replacement", which is offered as ball valves. Why they are more popular, the author is silent, but gives such a list of the pros and cons of ball valves:

In fact, simplicity is not so simple, ball valves became widespread only after the advent of sufficiently high-tech materials and production processes, before that their use was quite modest due to the inability to provide the necessary tightness of the seal of the ball plug with traditional materials and surface treatment methods.

Does it last longer than a valve? Complete nonsense, the standard service life of high-quality ball valves and valves is approximately equal and is about 30 years. The actual service life of the valves is many times longer.

The occurrence of water hammer during a sharp closing of a ball valve is not significant for small diameters of valves used in everyday life.

Ball valves are also used at higher temperatures, the difference is only in heat-resistant gaskets:

Ball valve for working with temperatures of the transported medium up to 230 degrees

Typically, ball valves are used as shut-off rather than control valves. But there are also special ball valves. It is enough to google to be convinced of this. But these are mainly industrial taps, if a regulation function is needed in everyday life, it is better to use a valve.

High-quality ball valves are maintainable:

Column 5 in the crane passport - maintainable, column 2 - standard service life - 30 years

The crane is easily disassembled and worn or damaged parts are replaced with new ones:

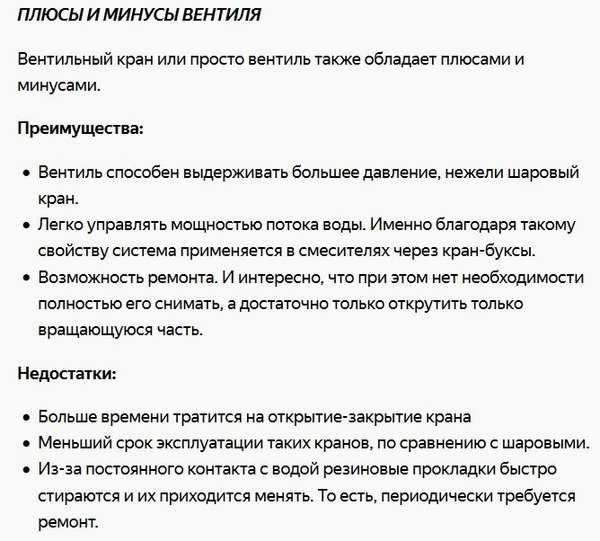

Let's move on to the valves. The author of the article in question offers us the following:

There are ball valves and valves for a variety of pressures.

Valves are indeed much easier to repair at home without the use of branded spare parts. Therefore, their repair is also cheaper.

There are valves with a ceramic locking mechanism (widely used in faucet boxes of mixers and taps). A valve with such a locking mechanism opens as quickly as a ball valve.

The rubber seals are abraded by rubbing against the faucet seat, not by contact with water. They cost a penny, the replacement is simple and within the power of almost anyone.

And now about the really important difference between ball valves and valves. The valve, due to its design features, creates greater pressure losses in the system than a ball valve

The valve, due to its design features, creates greater pressure losses in the system than a ball valve.

The diameter of the hole for the passage of the medium in the ball valve most often corresponds to the inner diameter of the pipeline on which the valve is installed (such a ball valve is called full bore). In the open position, the ball valve does not create resistance to the flow of the transported medium, and therefore does not "devour" the pressure in the system.

This is important for heating systems and gravitational water supply of country houses with limited pressure in the system. It was with full bore ball valves that I installed a gravity water supply system in my country house, which works perfectly at very low water pressure from a storage tank installed in the attic of the house

It was with full bore ball valves that I installed a gravity water supply system in my country house, which works perfectly at very low water pressure from a storage tank installed in the attic of the house.

Good luck to all!

Production material

As for the material, you should pay attention to the two most commonly used options:

Brass

High resistance to mechanical stress

. Withstands any inaccurate treatment of himself, survives the most extreme situations.

-

High resistance to temperature changes

. Calmly withstands the pressure of hot water and does not deteriorate in the cold. -

Ease of installation

. easy to assemble and dismantle. -

No corrosive processes

. Most other metals cannot boast of this property.

Plastic

Polypropylene is a relatively new material, which, despite this, has already managed to take a strong position in the field of plumbing.

Plastic faucets boast the following advantages:

- Low cost. Plastic products are always cheap, especially when compared with metal counterparts.

- Small mass. Due to this, there is no pressure on the pipeline.

- Reliability of joints. The installation of a plastic pipeline takes place using a special soldering iron, which guarantees complete tightness. Although it should be noted that there are also classic models with threaded connections.

- Neutrality to the aquatic environment - does not rust and does not change the taste of water.

- Durability. Polypropylene decomposes no earlier than after 200 years.

But there are some difficulties that you need to be aware of when choosing valves from this material:

- Weak resistance to mechanical stress. Plastic can crack under strong physical exertion.

- Fear of high temperatures. Polypropylene begins to deform already at +95 degrees Celsius.

Therefore, depending on the conditions in which your plumbing will serve, choose which of the materials is more suitable.

The use of radiators in autonomous heating systems

When it comes to connecting housing to small autonomous boiler houses, special meters are installed to account for the heat consumed. In order to use resources efficiently and not overpay, it is recommended to install control valves in apartments during the installation of heating radiators and underfloor heating systems.

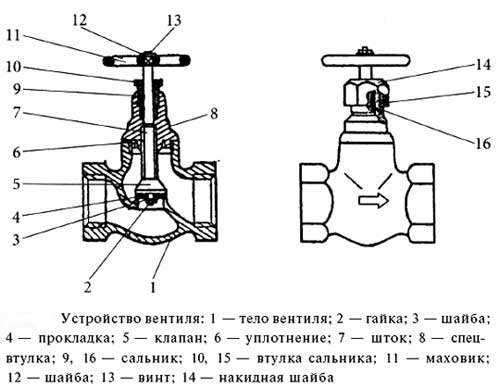

Shutoff and control valves are of two types - valves and gates.

When using a valve for bimetallic radiators, the preliminary setting is performed manually, and the further operation of the system occurs automatically. The valve is controlled by a thermostatic head that reads the room temperature. If the battery is supposed to be installed in a recess in the wall, or heavy complex curtains are located nearby, a remote sensor is mounted for the convenience of controlling the valve.

As a rule, the battery is connected using two locking devices. A valve with a thermal head is installed on top, and a shut-off valve for the heating radiator is installed on the bottom. The shut-off stem of the valve is usually covered with a special plug.

Please note that closing the tap for the lower connection of heating radiators is performed only in some situations. In this regard, the shut-off valve stem is always raised to the maximum height, and it can only be moved with a hexagon

Features of buying a ball valve made of polypropylene

Before purchasing a polypropylene faucet, it is necessary to carefully inspect it; there should be no damage on its surface. When rotating the stem, you need to make sure that it turns with little effort.

And yet, it does not make sense to purchase a ball valve in markets or obscure stores. Practice shows that it is really possible to save money there, but there are no guarantees of quality and cannot be.

A valve made by a serious manufacturer is sold only through specialized outlets.

When choosing a faucet made of polypropylene, you need to remember a few simple things:

the thread on the valve body must match the thread on the nozzle;

the purchase of a used valve can lead to leaks, with all the ensuing consequences, in the form of flooded neighbors.

brand is important. The fact is that many European manufacturers transfer their production to third world countries, but they do not always perform quality control. It is advisable to invite plumbers to install a tap

Self-installation of valves can end sadly. It must be remembered that the working pressure is up to 8 MPa

For the installation of the crane, it is advisable to invite specialists - plumbers. Self-installation of valves can end sadly. It must be remembered that the working pressure is up to 8 MPa.

Which pipeline valve to choose

Therefore, when deciding which ball valve to choose, follow a few simple and useful rules:

Find out in advance which cranes from which manufacturers are considered the most reliable and durable, and, if possible, purchase just such products. For example, Bugatti ball valves have a deservedly high reputation all over the world. Of course, such products are not cheap, but the money spent will more than pay off due to the long service life.

Try to purchase faucets with a brass body, as this is a durable and reliable material that is resistant to corrosion and can withstand heavy loads. You should not buy ball valves made of silumin (an alloy of aluminum with silicon), even in order to save money, since silumin is less durable and does not tolerate sharp fluctuations in loads (and this often happens in plumbing systems during water hammer). Silumin can be easily distinguished from brass: it is much lighter and has a different color.

Choose high pressure faucets

This will help extend their life and avoid unpleasant consequences in the event of the same water hammer.

Please note that the ball lock is smooth, free from corrosion and damage, and that it rotates easily. It is better that the ball is not made of steel (you can check with a magnet), because even "stainless steel" gradually deteriorates in a humid environment.

It is advisable to purchase a faucet with metal handles, as plastic handles can break easily.

Types of ball valves

Cranes differ from each other primarily in their purpose. Some of them can be used for cold water, others for hot water. The purpose of cranes determines their design features. Some models of cranes are collapsible, others are detachable. PP cranes with a detachable design are mounted where the question of disconnecting it from the network may arise. By the way, the connector can be installed on one or both sides of the valve body.

When connecting a collapsible faucet, union nuts are used. They are installed in systems where fittings made of metal are used, in steel pipelines and next to heating radiators.

Collapsible propylene taps have two designs - straight and angled. If everything is clear with straight taps, then the advantage of corner taps is that they are connected to the main line directly, without the help of auxiliary couplings. This design not only facilitates installation, but also increases the maintainability of the product. Thanks to the design of the valve, it can be quickly disassembled and repaired.

Manufacturers produce valves of different colors. Moreover, at the manufacturing stage, a color marking is applied to the body, which can tell what this or that crane is intended for. For example, a blue stripe indicates that this product is designed for cold service.

Batyanya Secrets of repair Ball or valve valve

21.07.2014

Shutoff valves on water pipes - an inattentive attitude to this thing can cost you a significant amount.

Just imagine: breaks the tap on the pipe of cold water supply. Of course, there is a fountain in the apartment. And if you are on vacation, then the fountain quickly turns into a lake and all this flows to the neighbors below. And if they are also on vacation / at work or something else? Another floor below. Well, and so on. The financial side of this business can be estimated independently.

A faucet is just the place where a leak is most likely to occur. Pipes are welded securely.If not, it will be noticeable immediately, but problems with the crane accumulate gradually. So let's try to figure out which of them is more reliable in operation.

Ball or valve?

For an apartment, only two of these options are possible. Available at any plumbing store, there is an assortment for pipes of different diameters. Let's look at the pros and cons of each.

valve

The main plus is maintainability. And this is the main disadvantage. Such a crane is a little more complicated both in device and in operation. It needs to be twisted and unscrewed, you often don’t want to mess around with this, and besides, gaskets and seals regularly wear out, the stuffing box begins to leak. Changed the gasket — for the time being all is well again.

The valve cock can be used as shut-off and control valves. Ball only shut-off. This iron rule - the ball valve has only two positions: open and closed.

ball

Easier to set up and operate. Turn the flag and you're done. There are compact flags (butterflies). They are convenient because they do not take up extra space (the butterfly does not protrude beyond the dimensions of the pipe).

But it is inconvenient to open taps on pipes of large diameter with a butterfly. Here it is better to take with a flag-handle.

Due to the simplicity of the design, the durability of the ball valve is higher. With the same (and sufficiently large) number of closing / opening cycles, the valve will leak much earlier. But! At home, you are unlikely to open them so often. It's not a kitchen faucet. And this is where the main problem of ball valves opens.

The ball turns sour during operation. And it's not that easy to close it. Therefore, it is impossible to leave the ball valve in a half-open state. The harder the water, the faster the mirror of the ball will “overgrow”. As a preventive measure, you can periodically (every two to three months) open and close the tap, thus erasing scale. The only question is not to be lazy.

Well, and most importantly, it is impossible to repair a ball valve. Complete replacement only. Unlike valve.

comments powered by HyperComments

Which ball valve is better to choose so that it works for a long time and reliably

Ball valves have long been widely used in pipeline systems, due to the simplicity of the device and ease of use. However, they must have another valuable quality: reliability. After all, if the crane is made of insufficient quality materials, it can fail prematurely, or even cause an accident. It is not uncommon for buyers, when deciding the question: “which valve to choose?”, In pursuit of savings, purchase ball valves made of cheap aluminum-based alloys, made by some unknown company. And this can turn into big troubles and losses - for example, if the tap breaks under the pressure of water, and the apartment of the neighbors below is flooded.

Types of ball valves

The crane device described above and the principle of its operation are the same for all types of products. Varieties of ball valves arose as a result of adding various useful elements to the design that expand the functionality of the crane. The only exception is a three-way ball valve, in which the body has not 2 outlets, but three. This element does not just block the coolant, but redistributes its flows and can serve as a mixing unit.

All other functional elements that complement the design of the crane are given in the list:

- fitting for draining water;

- connection with a union nut (American);

- Mayevsky crane (needle valve);

- mesh filter;

- various types of actuators for stem rotation.

It should be noted that the term "ball valve with a fitting" also means a conventional valve with the possibility of attaching a watering hose.

To remove air plugs from problem areas of the network, a needle valve for the heating system is used in the scheme. This is the well-known Mayevsky valve for manual air release, combined with a ball valve. This is not to say that this product is often used, but in some cases it is simply irreplaceable. For example, when air locks occur on horizontal pipelines laid at the highest points of the system.

When in complex heating schemes it is required to automate the operation of shut-off valves, they use a product such as an electric ball valve. Its task is, at the command of the electronic control unit, to open or close the fluid flow, or direct it in a different way. In such cranes, a platform for mounting a drive designed to rotate a stem with a ball is structurally provided.

In mixing units, where it is necessary to ensure the separation or combination of flows in the required proportions, three-way valves with a servo drive are installed. Their difference from electric mechanisms is that the device can slowly turn the stem and stop at the required position at the command of the controller or thermostat. Then the streams partially overlap, merging into one at the exit.

Now that we have figured out what this or that type of ball valve is intended for, we can begin to choose it. It should be remembered that this type of fitting is not used to regulate the amount of water, but only performs locking functions. The exception is devices with servo drives. It is better to make a specific choice of a crane, knowing the operating parameters of the coolant. If there is no such information, then it is enough to know that fittings in a coupling version with a working pressure of up to 10 Bar and a temperature of up to 120 ºС are quite sufficient for systems of private houses.

If we are talking about centralized networks, then for heating it is better to use ball valves with a working pressure of up to 16 bar and above. With the selection of fittings for central heating, you need to be more careful and provide for a decent pressure margin. The reason is unpredictable parameter jumps due to water hammer.

Separately, we will give a warning about fakes, with which all plumbing markets are filled. A cheap Chinese faucet is made of silumin, it is very fragile and often cannot even withstand a tightening with a wrench. In addition, the material is subject to electrochemical corrosion, which destroys it in a couple of years. At the same time, it became very difficult to recognize a fake. The only recommendation on this topic: buy fittings from trusted people or trusted stores, even if you choose a small faucet for heating radiators.

Where to buy a ball valve

If we talk about the Bugatti brand, you will definitely not find these products in the market near the house. Real ball valves from an Italian manufacturer are sold only in specialized stores.

There is nothing worse than paying a lot of money for a supposedly real Bugatti crane, bought at a local market or in a nearby shop. The chance of buying a counterfeit there is very high. After a breakdown, you are unlikely to be able to return the money back - as a rule, neither checks nor certificates are provided on the market.

We conclude: regardless of the brand chosen, it is better to buy valves in a certified store or at least in construction hypermarkets. To dispel all doubts, do not be too lazy to ask for a certificate confirming the quality of the chosen model.

Selection tips: what to look for when buying?

In addition to certificates, you can simply pick up the crane and inspect it visually. If you have a genuine Bugatti or an original ball valve from any other well-known company, it definitely should not have incomprehensible sags and bumps. The applied marking should have even letters that are easy to read and distinguish.

Brass marking is another point that you should pay attention to at the time of purchase. For example, Bugatti make their products from brass material marking CW617N

Be sure to look inside and find a ball there. If it is mirror-like and polished to a shine, this is a good sign of quality. Feel free to scratch the case a little - the yellow metal will indicate brass. Fakes are most often made from silumin or steel.

Finally, a few more tips:

Take Bugatti "reinforced" type cranes. They have a 6xx serial number and a PN 40 stamp. This figure indicates a valve operating pressure of 40 atm (a very good indicator).

Reliable faucets have higher cleanliness, thicker walls at the threads, and more weight.

Try to avoid buying faucets that have plastic handles. The slightest effort will break the spitz, the handle will begin to scroll. Most often, such "pseudo-faucets" are placed on a washing machine, a toilet bowl and an eyeliner to a mixer.

The crane, even when buying, should spin freely enough (with minimal effort). If you managed to scroll only with a gas key, and at the same time you also rested your feet against the wall, it is better to refuse to buy

The thing is that the ball valve is never lubricated.

Pay attention to the size of the ball itself. The size of the "hole" in it must match the size of the attached pipe.

http://provanny.com

Where is the best place to buy ball valves

If you decide to purchase a Bugatti crane (or products from another well-known manufacturer with a worldwide reputation), in no case look for this product at the "flea market". There, with almost 100% probability, you will be slipped a fake. You can buy low-quality counterfeit products under the brand name of these manufacturers even in small plumbing stores. Therefore, so that money is not thrown to the wind, it is better to shop in construction hypermarkets, and even better - in special stores that have a certificate for the sale of such products. Make sure that the faucet body is free of bumps, sags, and contains clear, legible markings. Also note that the check ball is perfectly smooth and polished.

LLC TD Arma - supplier of ball valves

LLC "TD Arma" is the official dealer of factories producing ball valves from st.20, 09G2S and 12X18H10T:

Chelyabinskspetsgrazhdanstroy LLC

CJSC "Khimpribor"

ADSA-ADL

PEKOS VALVES S.A. (Spain)

NAVAL

other. Ball valves of these manufacturers are used in the chemical, oil, gas and food industries. This product has a "Certificate of Conformity", Permission of Rostekhnadzor" and "Hygienic Certificate".

Batteries connected to central heatingUsing radiators in autonomous heating systemsUsing heating batteries in a private houseHeating system with polypropylene componentsConnecting batteriesVariety of locking elements - straight and angledVideo

Modern efficient heating equipment is used, as a rule, in closed-type systems with forced circulation of the coolant. In order for such heating to function correctly, it is equipped with all kinds of locking elements. This article will discuss which taps are best placed on heating radiators, depending on their material and type of system. In this case, the type of stop valves is determined by the conditions in which it will be used.

It should be noted that obsolete and inefficient heating systems with steel pipe piping are used less and less.They assume a natural type of water circulation in the heating circuit, that is, the coolant moves through the pipes due to gravitational forces. No locking elements are installed in such systems, and if it is necessary to reduce the flow rate, then pipes of a smaller diameter are installed in a specific area.

Both described heating systems are most often equipped with elements such as radiators. Their task is to increase the heat-releasing surface and improve the heating of the room.

Heating radiators are used in the following cases:

- in private houses;

- in multi-storey buildings connected to an autonomous boiler room;

- in apartments heated from a centralized city heating system.

Ball valves or valves which is better

When choosing shut-off valves, the following must be considered. A polypropylene crane can operate without interruption for several decades. According to the statements made by the manufacturers of these products, they can work up to 50 years. Cone valves, unlike them, in that scale is concentrated on the surface, and you can be sure that sooner or later this scale will become an insurmountable obstacle when closing or opening the valve. In addition, it is impossible to compare the overall dimensions of ball and cone products. And yet, cone valves require regular inspection.

Polypropylene ball valves do not suffer from such shortcomings. In addition to their low weight and high reliability, they look much nicer than other types of valves. For the production of ball valves, materials such as:

- steel;

- cast iron;

- polyethylene;

In view of the foregoing, a simple conclusion can be drawn - ball products exceed cone products in all respects.