Classification by additional parameters

Each product has an open section and is designed for the gravity flow of water.

The straight gutter accepts liquid along its entire length. Its design is in the form of I and M. In the first case, installation does not require a foundation. In the second - your own foundation is needed.

The box version has the shape of a rectangle in section and a removable grille. The product prevents penetration of large objects into the throughput channel.

Slotted - with a round through hole that provides a path to the sewer.

The curb view has a ledge at the top.

Concrete trays with gratings collect and transport wastewater. Systems with covers are used only for drainage.

Bandwidth:

- Telescopic gutters are suitable for slopes.

- Marginal - remove excess moisture from roads to ditches.

- Drainage divert groundwater.

- Stormwater collects rainwater from a specific area.

Additives used:

- Reinforced concrete.

- Fiberglass.

- Polymer concrete.

Materials for installing concrete sewer trays

For the correct drafting and installation of storm sewers, special efforts or special technical skills are not required.

For work, you need to prepare the following materials:

- Pipes;

- Gutters;

- Trays;

- Pallets;

- sand filters;

- Storm water inlets.

The number of listed structural elements of the sewer system is determined depending on the developed design plan.

The most effective stormwater drainage should consist of ground and underground parts.

For different types of coatings, special schemes are being developed, in accordance with which it is necessary to install the trays:

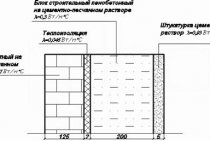

- Concrete coating. Trays of class C250 are suitable for this. In this case, the width of the adjacent seam should be 100 mm, the thickness of the concrete base under the tray is at least 150 mm;

- High-strength products for asphalt pavements. The thickness of the base is at least 150 mm, the adjacent seam is 20 cm;

- For asphalt pavement, products of class C250 can also be used. Screed at least 150 mm, seam - 100 mm;

- For tile flooring, trays of class C250 and D are suitable. With a screed width and a joint thickness of 100 mm.

Before installation, it is imperative to complete all preparatory work.

What are drainage trays made of?

For the production of concrete trays, various types of fiber-reinforced concrete are used. Chopped polypropylene fibers are introduced into the finished solution, which can reduce the shrinkage of products, as well as increase their resistance to bending forces. Metal fibers can also be added to concrete.

Reinforced concrete drainage trays are also common, which are produced using cement grades of at least M 500 and additional reinforcement.

All channels, including those with a vertical spillway, are equipped with gratings. This is necessary to protect them from leaves and other debris. The choice of material for gratings used depends on the location of the line and the expected load. Lattices fasten to concrete by means of special screws. They can be removed for cleaning.

Types of concrete trays for sewerage

There are 4 main types of concrete trays:

- Concrete, characterized by the greatest strength;

- Reinforced concrete products retain their integrity better, pass water less;

- Polymer concrete combine the qualities of concrete and plastic products;

- Polymer sand, compared to other products, is quite flexible and has an unlimited service life.

The latter are considered the most advanced development.

Only some models of concrete trays are available for sale that can withstand really high pressure. Therefore, when choosing, you need to take into account the strength class of the product.

There are several types of concrete trays:

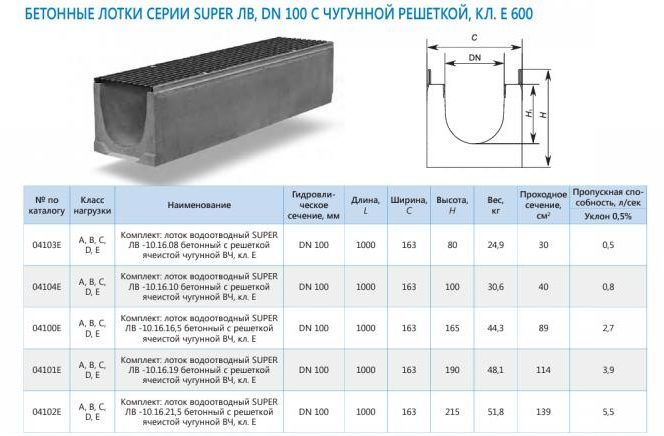

- Reinforced with built-in cast iron grate with strength class ABCD. Models SUPER DN 100 and SUPER DN 150.

- Lightweight channel with ABC strength class. Model DN 100.

Polymer concrete products have the following distinctive features:

- Solidity and sufficiently high strength of the product;

- Rigidity;

- Not amenable to chemical attack;

- High operating period.

Trays are created from a composition that includes quartz sand, as well as granite chips. Polyester or epoxy resins are used as a hardener. Due to the replacement of cement with a polymer, the product is not exposed to various chemical influences. Since the composition of the mixture from which the tray is created includes plastic, the product is much lighter than the concrete structure. Such trays are installed in various urban construction projects.

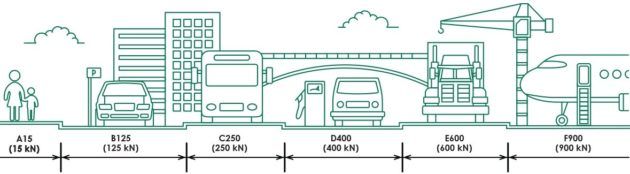

There is a classification of concrete trays for storm sewer equipment:

- Class F900 the most durable products are used in airports, large logistics centers, airports;

- E600 is used in the design of highways, equipment of large industrial facilities;

- D400 trays are installed on high traffic highways, gas stations, large garage complexes, small industrial areas;

- Class C250 is used for equipping small and medium-sized highways, small parking lots for light vehicles.

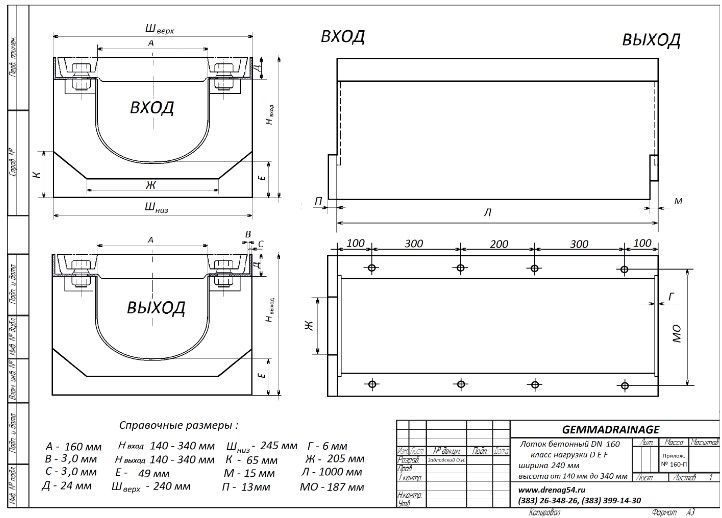

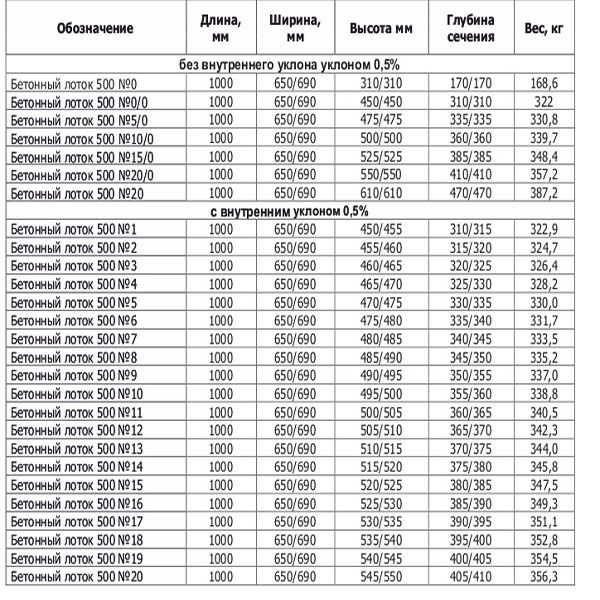

Concrete trays are classified not only by strength, but also by other parameters. Today, trays are manufactured with a standard length of 1 m. The internal section can be from 100 to 500 mm.

Advantages of concrete trays over plastic ones

In order to assess the advantages of concrete products over plastic ones as objectively as possible, it is necessary to compare the main qualitative characteristics.

Features of concrete trays:

- High strength and reliability allows you to withstand the continuous destructive effects of the environment. Concrete products are recommended for use in areas with the most severe climate conditions;

- Good resistance to high and low temperatures;

- The high duration of the operational period is ensured through the use of special technological innovations in production;

- The quality of the equipped structure is always due to the observance of all the rules during the installation process;

- If it is planned to move heavy trucks over the area equipped with a drainage system, strong concrete trays are installed that can withstand systematic high physical exertion.

Transportation of concrete trays must be carried out under special conditions. If the product is hit too hard, damage may occur. For this reason, it is desirable to allow only highly qualified specialists in this field of activity to transport and install such trays. Concrete trays are considered the most suitable products for arranging a drainage system. This is especially true for areas with adverse climatic conditions.

Features of plastic trays:

- Dirt and debris residues are easily removed from plastic trays, the smooth surface of the product prevents clogging;

- The production technology involves the use of a durable plastic alloy that can withstand a sufficiently high mechanical pressure;

- Lightweight plastic products can be transported to any convenient place without any special difficulties;

- Easy to install;

- Performance characteristics allow you to mount drainage systems from plastic trays in different places;

- Compared to concrete trays, plastic is not sufficiently resistant to low temperatures, so they are not recommended for use in regions with harsh climatic conditions;

- Plastic trays are subject to deformation under the influence of the environment.

Concrete trays are more resistant to environmental influences. Therefore, the operational period of such products is the highest.

Characteristics of different types of concrete trays for sewerage

There are several varieties of concrete trays - pressed, metal-concrete and foam concrete. Each product has individual characteristics.

Pressed fine-grained concrete trays have a smooth texture with minimal air bubbles. Thanks to these properties, the gutters are indestructible and can withstand large flows of water. They have many advantages:

- water resistance;

- low thermal conductivity;

- fire resistance;

- special strength.

These are universal devices that cope with any construction tasks. They can serve for decades.

Metal concrete structures are highly efficient. They are made on the basis of a metal body, which is filled with a mixture with the addition of binder particles of various metals of artificial and natural origin. The metal matrix is particularly durable and suitable for heavy loads. It has the following positive characteristics:

- resistance to biological and chemical influences;

- durability;

- heat resistance;

- high resistance to deformation, heavy loads.

Foam concrete sewer trays are porous. Such a structure is formed as a result of the hardening of the solution, to which high-quality cement, sifted sand, water, and a foaming agent are added. It is expedient to apply products in places with low air temperature. They have such positive qualities:

- good thermal performance due to air bubbles;

- performs well in winter;

- light weight;

- ease of installation;

- increased strength;

- environmental friendliness.

Preparing to install trays

Preparatory work is carried out in several stages:

- Development and approval of project documents, which contain descriptions of the main structural elements and locations of storm sewers.

- Taking into account the design documentation, marking is carried out at the installation site of the trays.

- Preparation of all structural components and auxiliary materials and tools in the required quantity for subsequent use.

- Preparation of cranes for moving heavy concrete structural elements.

Installation can be carried out after all preparatory work has been completed.