Mounting factors

- bends;

- Ground water level;

- Turns.

Sewerage of any type is equipped with treatment facilities.

Any sewer is placed under a slope. If it is necessary to change the slope level, then it is necessary to build on the indicators of the pipe section. In individual cases, manholes or pumps are installed.

Compound

Wells are structures that are divided by purpose. And they are: drainage, perepannye, rotary, viewing. Wells are usually equipped with brackets so that specialists can go down for repairs, as well as hatches with covers.

Outlets to water intakes are structures that provide free discharge of sewage from pipelines into a tank.

Collectors - are underground tunnels, which are made in the form of pipes of large diameter, through which wastewater moves to the final destination.

Local sewage treatment plants are installations that are used to discharge and treat wastewater. Such facilities include biological treatment plants. The number of serviced houses depends on the productivity and size of the structure.

Pumping stations are units that are installed at separate facilities that need a dosed supply of wastewater.

Pressure sewerage in a private house

Pressure sewerage in a private house is needed only in cases where it is not possible to build a gravity system. The most common factors "against" gravity pipelines:

- The house has already been built and is located below the level of the central sewer network;

- The relief of the site does not allow laying pipes with the desired slope. Mountainous terrain with complex rocky soils; steep terrain in any soil.

- Only pipes of small diameters can be used; the internal pipelines of the house have a complex configuration.

- On the way of the pipeline railway or motorway.

A situation is also possible when the owners want to arrange a Finnish bath in the basement of the house, which involves a bathroom and drainage. If the zero of the basement floor is higher than the mark of the external sewer pipe (the inlet pipe is located higher), then there is no way to divert the drains by gravity.

In any of these situations, only a specialist can calculate and design a pressure sewer for a private house. Independent work without a base of knowledge and experience is doomed to errors: the finished system will not work correctly and may fail partially or completely. In a sewer context, all this is very unpleasant, so it is better to entrust professionals with designing even a small and simple system from a pressure pipe, a pump and one well. About the design in a nutshell:

- Based on the initial data on the relief of the site, the characteristics of the soil and the occurrence of groundwater and GPG (the depth of soil freezing, reference data for the construction area), the required length of the pipeline and the necessary technical characteristics of the special equipment, as well as its type (SPS or fecal pump) will be determined.

- Simultaneously with the pipeline plan, they decide where to place a well or a special container to collect wastewater. The best option is when household drains go into the well by gravity. But a lot depends on the relief conditions, sometimes effluents have to be discharged into the well and further from the well under pressure. If the relief of the site allows gravity drainage to the tank, then there is no need to select and purchase additional equipment for internal sewage. In addition, having successfully located the container (well) on the site plan, they achieve the minimum length of pipelines.Ideally - so that there are no rotary wells, one straight pipe into the container.

Another important factor is HGG, the volume of earthworks depends on the depth of freezing. So that the pipeline does not freeze and the system does not fail, the laying of pipes is done below the freezing level, which does not always cancel the insulation of pipes. It is possible to lay even higher GPG, modern heat insulators allow this.

According to the estimated number of effluents, the elevations and pipe lengths obtained during planning, pumping equipment is selected. The main parameter is power, preferably with a margin for the future. If not a pump is selected, but an installation station, then there is no need for waste containers.

General information

Types of networks

The sewerage network is a communication with different branches, which consists of different pipes and represents one whole.

This system is necessary for transporting wastewater from users to specialized tanks in which water is processed and treated.

Sewer networks are of two types:

- internal;

- outdoor.

Pipes and treatment systems that are on the street belong to the external appearance of sewer networks. And the pipes that are inside the houses belong to the internal view.

In such communications, wastewater is transported both under pressure and by gravity.

Therefore, all sewage pipelines are divided into:

- Non-pressure;

- Pressure.

Free-flow pipelines of sewage systems are installed at an angle to ensure the movement of wastewater to the final point. For the device of free-flow sewerage, pipes made of polyethylene are used.

Pressure sewer networks operate according to this principle: the pump builds up pressure and, under its action, sewage is removed. For pressure pipelines, pipes of good strength are used, this is necessary in order for them to cope with pressure.

Also, sewer systems, depending on the purpose, are divided into the following types:

- Storm sewers (removing melt and rain water);

- Production;

- Household - household.

- Storm sewers are needed to remove rain and melt water.

Household sewerage is divided into two types:

- Autonomous (local);

- Central (main).

The central type of sewage removes sewage from houses in the area of the city or settlement, and the autonomous sewer serves only one house (in isolated cases, several houses).

The method of installing external sewers is divided into:

- separate;

- All-alloy;

- Semi-separate.

External sewer networks

There are several types of sewer networks that are laid outdoors.

tracing. This design is installed from a point to a specialized tank. Tracing is also installed in an apartment building (observing all building rules and regulations). Pipes are laid only vertically. From the outer wall of the building to the communication, the distance should be at least three meters. Tracing is installed only when there are connections to the central sewerage network.

External sewerage is pipes, wells and collectors.

Sewerage network located on the street. This system consists of a complex system of wells and pipes. It is made on the streets of the city. Through the street sewer networks, effluents move to the central sewerage system, and then to the treatment systems.

Collectors. These devices are designed to collect sewage and redirect, if necessary. Effluent is redirected from the collector to the collector, which is located near the sewer pool or on its territory. The work of the collector is to transport wastewater by gravity or under pressure.

Wastewater treatment plants are the final destinations for sewage.In these facilities, wastewater is concentrated and treated. After the water is purified, it is dumped into reservoirs and then used for economic purposes.

The laying of sewer networks takes place in different ways because it depends on specific cases.

Installation

If you comply with all building codes, this allows you to accurately install the external sewage system, as well as the period of use of all parts. It is necessary that the pipeline has the correct slope. This slope allows the drainage of wastewater in a natural way. According to SNiP, the slope of the pipeline should be towards the well.

The slope of the pipeline is determined by the diameter of the installation of communication and ranges from two to three centimeters per meter of construction.

Important! It is necessary, indeed, to produce the diameter of the pipes that will be supplied to serve the house or area. There are diameter standards for sewers that serve a different number of houses.

There are norms of diameter for sewers that serve a different number of houses.

If wastewater is discharged from several private properties, then the diameter of the pipe must be at least two hundred millimeters. And if wastewater is removed from one house, then the diameter of the pipes should be one hundred or one hundred and ten millimeters. If pipes are installed between wells, they must be placed evenly, without any slope. When designing, you need to draw up a plan for the movement of communications, not forgetting to put a pipeline and nearby buildings on it.

It is also better to place the water collector near the roadway, but only if you plan to equip a cesspool (it is usually pumped out by a sewer machine). If the external sewer system is equipped at bends or at differences in depth, then a manhole must be built. Also, manholes are mounted in cases where the straight section of the pipeline is more than 25 meters. And such a well is called intermediate.

The pipeline along its entire length must consist of pipes of the same material. Because different materials have different thermal expansion, and for this reason, a pipeline that has pipes made of different materials quickly collapses.

So we have described the basic rules for the arrangement of external sewage. When arranging external sewerage and equipment of all types of sewerage, it is recommended to follow these rules and regulations. Because if there are deviations during installation, this can subsequently lead to accidents on the tracks and equipment failure. And this is very bad.

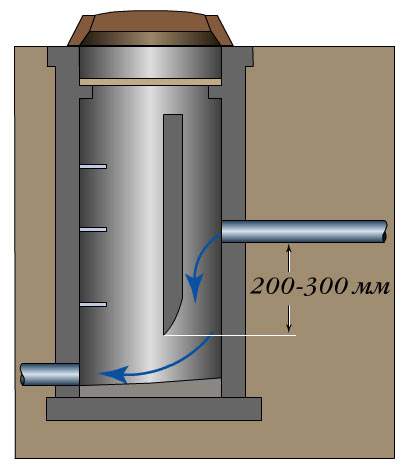

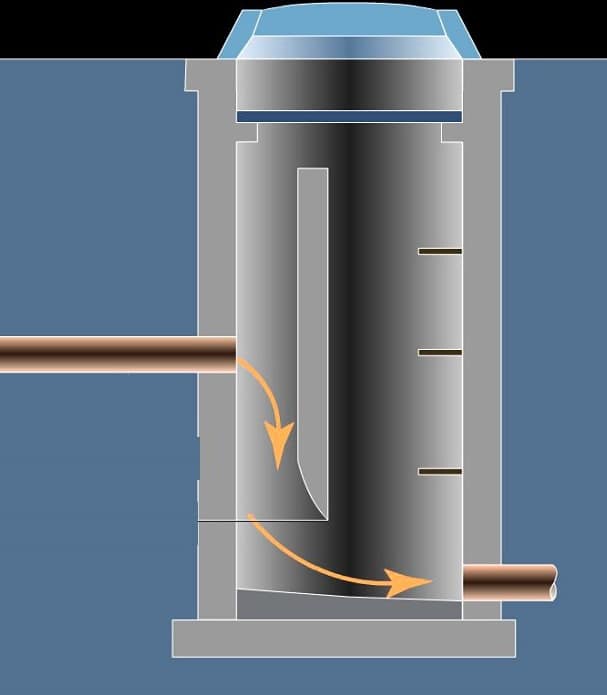

How is the damping of the speed of water movement carried out

The damping of the flow force is achieved due to the difference in the level of wastewater. The design of a standard absorber well allows to reduce the pressure by 17-20%. The deeper it is, the more the sewage flow will slow down.

In multi-stage wells, water moves along planes located at different levels. In this case, the next plane is lower than the previous one, like steps. The flow rate decreases repeatedly as the water moves through the cascade.

The flow rate is slowed down by the water column in the tank (pool) into which it strikes. Installing an additional baffle (water baffle) further reduces the flow rate. Instead of a partition, a special lattice can be fixed.

The pressure is reduced by a 90º swivel elbow mounted on the incoming pipe.

If large debris comes across in the wastewater, the well is equipped with a trash basket (grid). It will trap floating objects and prevent clogging of pipes. The trash basket also reduces the speed of wastewater movement.

The choice of pipes for sewer systems

Pressure sewer system

The main parameters that pipes should have:

- tightness;

- ease of installation;

- strength;

- resistance to corrosion;

- resistance to chemically aggressive environments;

- resistance to electrocorrosion caused by the presence of stray currents;

- universality;

- elasticity (resistance to water hammer);

- preservation of properties during the service life.

PVC-U sewer pressure pipes have all these properties. The connection of the system with the help of sockets, in the grooves of which sealing gaskets are inserted, allows installation without expensive equipment, ensuring tightness. These pipes are resistant to UV radiation and aggressive chemical waste. The range of fittings makes it possible to connect with pipelines made of other materials.

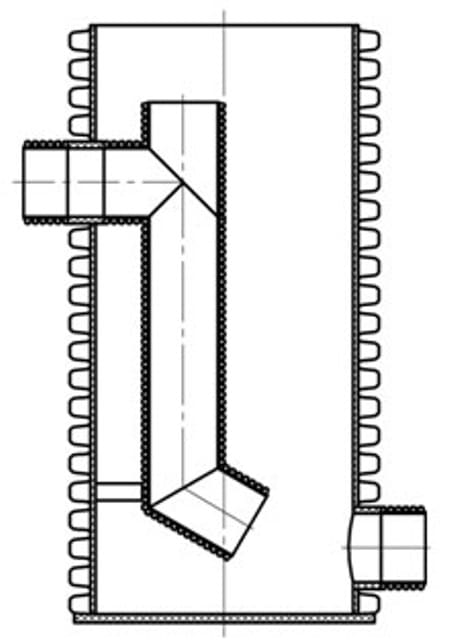

PVC-U pipe and tee with metal flange for connection to metal pipeline

The reliability and tightness of the external pressure sewer eliminates the possibility of a breakthrough and avoids the negative consequences of sewage leakage.

Non-pressure sewerage system

Non-pressure sewer pipes transport wastewater with a temperature of up to 45 ° C by gravity. Pipes are divided according to ring stiffness (classes from SN2 to SN8). Orange color. The pipes are equipped with sockets with rubber seals. The non-pressure sewage system made of PVC pipes and fittings has all the necessary hydraulic and chemical parameters. Pipes for non-pressure sewerage are made from high-quality raw materials on automated equipment and comply with certificates for this type of product.

Pipes for non-pressure sewage PVC

Materials and drawings how to make an absorber

Self-assembly and assembly of the structure can only be performed when installing a simple turn or overflow well in a private sewer. Complex designs of wells for pressure absorbers of local, connected to the central, sewerage are installed according to a standard project after agreeing on technical specifications.

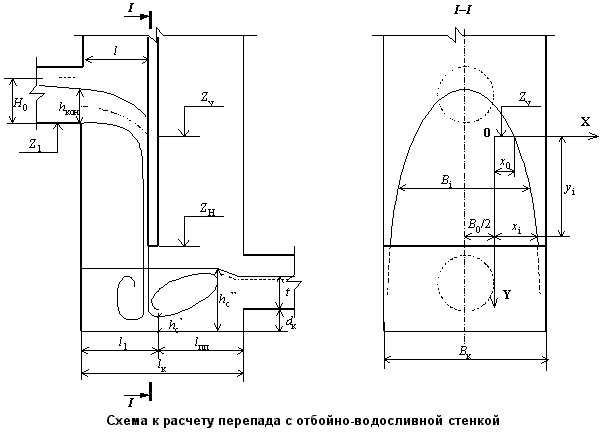

Preliminary scheme for calculation

The layout of the shaft, the diameter and thickness of the walls, the location and size of the openings for the entrance, are designed taking into account the characteristics of the local pipeline and pressure indicators, flow rates and height differences.

In a private sewer system, differential and rotary tanks are equipped to minimize the load on the pipe. Use ready-made and prefabricated structures:

Made of plastic, PVC, fiberglass.

Composite industrial dampers

From reinforced concrete.

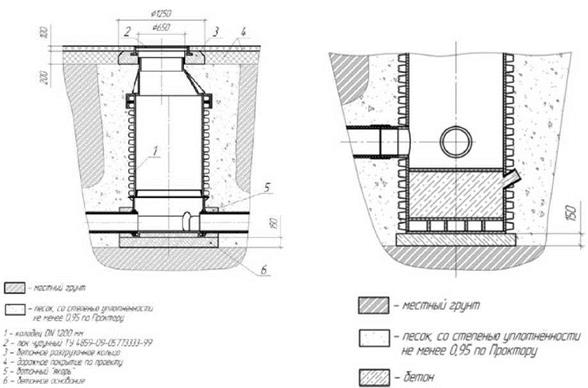

Schematic drawing of a simple pressure absorber well for installation at the site of a change in the height of the sewerage.

Schematic drawing of a simple well

According to the scheme, the main indicators are calculated: the height of the drop, the diameter of the shaft, and the tie-in points are determined.

The main requirement for the material of manufacture is tightness and the ability to withstand the load. For the manufacture of extinguishing wells, reinforced concrete factory parts and rings equipped with a sealed bottom are used. Products are made from a special solution with a low degree of permeability. The material is reinforced.

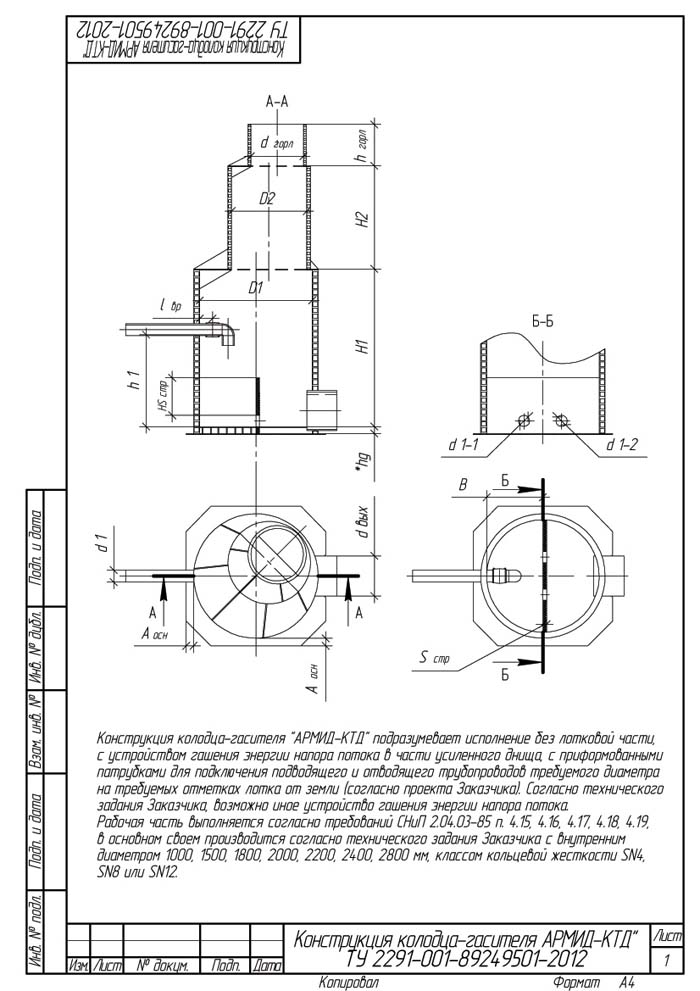

Drawing of a prefabricated damper well

The advantage of assembling a tank from rings is that compatible parts of different diameters are available. If it is planned to install a shaft with a tapering neck, a cover with a hole is installed at the junction of structural parts.

Locks with seals

Ready-made wells are equipped with factory locks: such fasteners will eliminate the need to fix the connections with metal brackets and mortar. Holes for the inlet of pipes and outlet pipes are made according to the diameter of the sewer pipes.

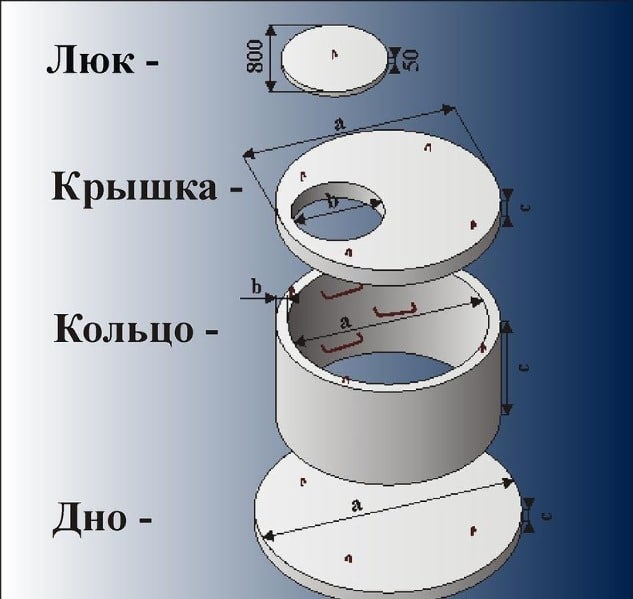

Elements of a reinforced concrete well

The neck rings along the inner wall have protrusions - steps along which the descent is carried out to monitor the condition of the tank.

From finished parts, you can assemble the damper barrel of any required height, diameter.

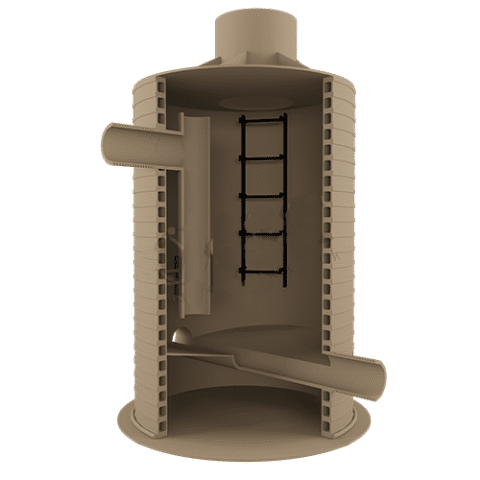

Drawing of a plastic damper device

Factory dampers made of plastic - lightweight construction with the ability to install in difficult conditions. For the manufacture of polypropylene, PVC, fiberglass. Composite artificial materials are durable, the smooth surface of the walls does not allow moisture to pass through and does not absorb pollution.

Plastic damper: inner space

The material is resistant to chemicals, mechanical damage. Installation at depth is carried out without additional thermal insulation.

Polymer factory containers

Plastic dampers are available in different sizes. There are ready-made solutions for all types of sewer systems.

The installation of dampers in the local branch of the sewer is carried out according to the scheme:

At the planned point, they dig a pit that exceeds the size of the well by 20 - 30 cm.

Pit with a plate under the bottom

After thorough compaction of the soil, a reinforced concrete slab is laid on the bottom (if a plastic tank is planned to be installed), gravel and sand are added (if a concrete well with a bottom is installed).

Instead of installing on the stove, the bottom can be filled with mortar

Carry out the installation of the structure.

Check the conformity of the tie-in and pipe outlets.

If there are no factory holes, they punch the entrance at the tie-in

Connect pipes with nozzles and seal the connections.

Joint insulation

The outer surfaces of the concrete walls must be insulated with waterproof sealants, the parts are insulated above the freezing point.

Wall coating

Perform backfilling.

For home sewage, it is preferable to use plastic wells for installation in problem areas. With proper installation, such a container will last forever. Reinforced concrete structures are less durable, but are better suited for use in difficult rocky ground at great depths. The most correct choice is to order a home sewerage project with installation. Experts do not recommend installing differential and pressure absorber wells on their own. In order for the design to fulfill its functions, before starting work, it is necessary to accurately calculate its parameters. The consequences of an incorrectly working differential can be unpleasant - from a pipe burst to a reverse overflow of sewage.

Pressure absorbers in different types of sewer systems

Pressure control wells are installed in different types of sewer systems:

- Livneva. The need to change the pressure arises due to the large length of local straight branches laid before entering the urban system.

- Local household. The number of extinguishing points and the type of well design are selected depending on the number of problem areas and the characteristics of a particular network.

The main task of installing a pressure absorber well in the sewer is to restore the operating pressure, flow rate and fill level of the pipe in difficult sections of the pipeline.

Functions of adjustment devices:

Pressure drop. Installing a large volume tank reduces excessive fluid pressure on the walls that occurs inside the pipe.

The stream crashes against the wall

- Increasing pressure. With a sharp change in the level of pipe laying, it becomes necessary to create more pressure for the gravity flow of the fluid. Such containers are installed when arranging a pressure sewer type.

- Reversal of flow direction and pipe protection. To avoid damage to the pipe wall in the turn from the impact of the flow at high speed, containers are installed that accumulate liquid. In the next section of the pipeline, the drain is supplied at a lower pressure.

Change of direction schemes

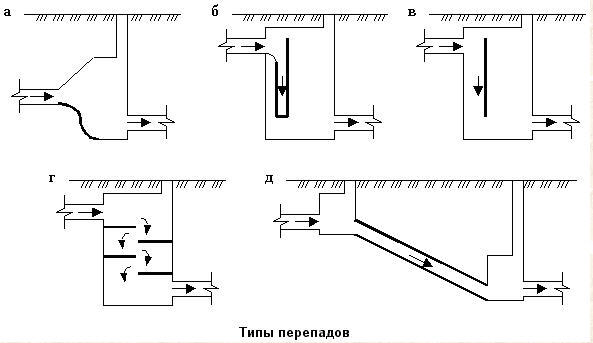

Wells designed to extinguish excess pressure are made in several forms. The type of construction is selected after studying the main parameters that require adjustment. All structures are tubular or shaft type. Internal organization of absorbers:

Standard drop tanks: used when speed needs to be reduced at the point of a sharp change in pipe height.

Overflow reservoir

Dampers with a baffle system: vertical walls are installed inside the shaft to dampen the impact of the falling liquid.

Vertical baffle wall

Wells with cascading water: equip multi-stage chippers in the form of plates inside the trunk. Mounted in areas with a significant excess of the flow rate.

In addition to quenching tanks, sewerage systems use fast currents with the function of increasing the pressure inside the system. The well is filled with liquid from the supply pipe to build up the required pressure inside the next section. Such systems are installed when it is necessary to lay a private branch on the rise of the terrain before connecting to the city network.

In private sewer pipelines, adjustment points are installed in long sections. If the total length of the branch in a straight line exceeds 30 - 40 m, then it is advisable to install at least one sewer pressure absorber well. On a straight line of a pipe laid at an angle, the drains develop too much speed. If there are no bends, splitters or damping points, then as a result of excessive load, the wall of the sewer pipe will break.

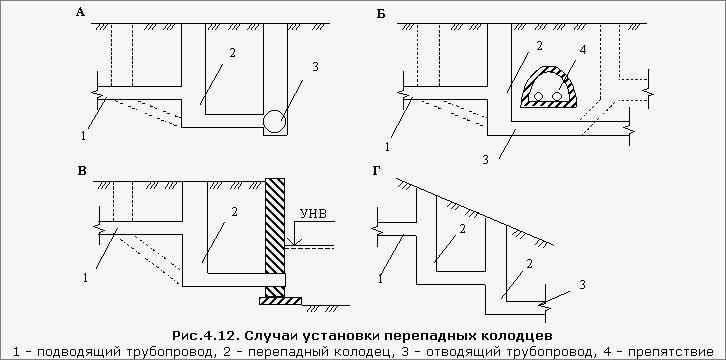

Places for installing drops and dampers

In places where the direction of the pipeline abruptly changes direction, if it is impossible to increase the angle of rotation, rotary wells are installed to reduce the risk of a breakthrough from a water hammer at the point of rotation.

Installation of damper in turn

In difficult areas, the pressure in the pipe is reduced by installing differential wells. The type of internal arrangement of the mine is chosen depending on the height of the drop and the pressure force at the inlet. The tank is a shaft with an inlet in the upper part and an outlet in the lower part of the side wall.

For storm pipelines, quenching wells are used with the installation of filters. Together with rainwater, leaves, stones and small debris get inside the pipe. A mesh basket installed at the entrance to the well acts as a mechanical filter.

Types of overflow wells

High-speed currents in pressure networks are equipped with electric pumps, if it is impossible to raise the pressure inside the system to operating levels in a natural way.

In places where a pressure local network is connected to a common gravity network, a pressure absorber must be installed.