Other types of pipe piles

In the previous part of the article, we considered bored piles, but there are also other types of them. In private construction, the technology of mounting screw rods is very often used if it is planned to erect lightweight buildings. Their advantage lies in the fact that they are suitable for any soil, except for rocky, although even smaller holes can be drilled there. Moreover, such a pipe foundation is easily installed using do-it-yourself rotation levers. It can be mounted on the site of the old base and equipped with headrests, which is an indisputable advantage, because a wooden house can be lifted with jacks and installed on a new base.

Screw pile with casing

Screw pile with casing

There is a technology for extending the operating period of metal screw rods, for which they are turned into stuffed ones, and the cavities are filled with concrete, which must be rammed. This technique will help protect the supports from corrosion. Read more about foundations on screw piles.

No less often than bored ones, they arrange asbestos-cement foundations, which are additionally supplied with a recessed or suspended grillage. They are mounted where the landscape is characterized by heaving soils. Here, the technology also provides for the concreting of cavities, which gives the base strength and increases its operational period.

Summing up the material presented, it can be said with confidence that with the use of pipe-concrete piles, by adjusting the length of the rod, it is possible to solve the problem of building a foundation on slopes, watery and landslide soils. But, despite the many advantages, it is worth remembering that bored piles create high-amplitude vibration during installation, so they can cause damage to nearby buildings.

Well support during drilling

- well performance;

- Well operation time;

- The strength and tightness of the channel through which the extracted product will flow from the horizon to the day surface;

- Protection of the production channel from corrosion;

- The strength of the walls of the well in places where the rocks are not sufficiently stable;

- Tightness of separation of all permeable horizons from each other.

Fixing oil wells involves the use of special columns or packers. The use of columns is the most popular method that allows you to make the well strong, durable, and also separate the permeable horizons. Such columns are made up of special pipes called casing.

Methodology for the manufacture of some designs of a drilling rig

For the effective operation of a homemade drilling rig, it must be equipped with parts.

Small drilling rig

Casing

It is made of plastic, asbestos cement, cast iron or other metal. It begins to be installed at a depth of 4 m. To connect the individual parts, threads are cut at the ends of the pipes or welding is resorted to. If their diameter is less than 50 mm, couplings can be used.

shock rod

For its manufacture, solid steel blanks are used. To make them heavier, concrete is poured inside. Individual structural elements are connected with bolts or flanges. Threading is not allowed. With a strong impact, such a connection is destroyed, which makes it impossible to further use the impact rod.

Bailer

For the manufacture of a part with the simplest design, a pipe section with a diameter of 90 mm, a ball from a bearing, and a steel transition should be used. The last two elements are carefully rubbed with sandpaper. This ensures a tighter fit of the ball to the transition.To weight the bailer, concrete is poured into its upper part.

rope lock

A comb is installed in the upper part of the castle. In an emergency, with its help, the rope can be lifted to the surface.

The support washer is necessary to protect the body from destruction during impacts on the ground.

The end of the cable is pulled into the sleeve, disconnected into parts and fixed by pouring a light metal alloy.

Well drilling with casing

Drilling wells and installing a casing with the appropriate equipment and technology does not seem to be too complicated a process, the most common sand wells are as follows:

- A drilling rig is driven into the site, after determining the location of the well, the equipment is turned on and a drill of the appropriate diameter attached to a rod of a standard length of 3 - 4.5 - 6 m starts driving. As the rods deepen, they are lengthened by screwing the following elements onto the thread, thus immersing the drill to the desired depth until water appears.

- Almost all sinkers use the technology of hydraulic drilling, directing water from the tank of an auxiliary machine (water carrier) into the wellbore during sinking. Water is supplied to the mines through hollow rods, the second method is the construction of a small pit at the place of sinking, which is constantly replenished with water, it is used in low-budget sinking.

- After the appearance of the desired sandy or calcareous rock in the dump (depending on the type of well), the rods are removed and dismantled one by one, then the drill is removed, changing it to a downhole PVC-U filter. The filtering device is a conventional factory-made pipe with transverse slots (slotted filter), many drillers make it themselves, perforating a series of round holes in the casing pipe and wrapping the shell with a fine-mesh mesh made of metal corrosion-resistant materials (stainless steel, bronze, brass and copper alloys).

- A conical plug is attached to the end of the filter using threads or self-tapping screws, after which it is lowered into the borehole channel. Before installing the columns, crushed stone and river sand are sometimes poured to the bottom of the well to organize additional filtration.

- As it lowers, the next pipe is screwed to the filter and so on until the desired mark is reached.

- After installing the column, the upper pipe is cut off and the well is pumped, supplying water under pressure into its channel for some time, after which the muddy water is pumped out by a submersible electric pump until a clear liquid appears at the outlet.

- A complete pumping procedure can take several days, but experts tend to do their job in a few hours, counting on the sedimentation of suspended particles to the bottom over time.

Rice. 16 Do-it-yourself drilling examples

For well construction, casing pipes made of unplasticized polyvinyl chloride PVC-U are currently widely used, which have high physical and chemical characteristics, a long service life, and a lower cost compared to metals. The use of PVC-U casing makes it possible to effectively equip all types of wells with a depth of 5 to 300 m with convenient placement of water intake submersible electric pumps of any models in them.

Well on site

- availability of aquifers available for drilling;

- physical properties of ground rocks;

- type of drilling tool;

- the length of the casing, depending on the depth and direction of the well shaft.

After a geological survey of the area, the owner makes one of the following decisions:

- rent a cable drilling rig from UKB and do the work on your own;

- hire a specialized team.

For independent actions, you can make a tripod of your own design. The triangular pyramid is made from improvised materials - wooden beams or a metal profile. You will need to stock up on a lifting mechanism for lowering the casing into the well and manipulating the projectile. The height of the drilling tower is determined by the size of a single casing fragment.

Connection types

When arranging the casing, the pipes are connected to the column in the following ways:

Threaded socket. The method is used when joining polymer or metal thin-walled pipes, while an internal thread is cut in the socket, and an external thread is cut in the section of the outer shell of the connected pipe.

Threaded. They are used in thick-walled metal and polymer pipes, the connected elements have external and internal threads, when they are joined, the walls are smooth from the outside and from the inside.

Coupling. The tubular elements to be connected have an external thread, they are screwed into a butt joint with an internal thread until the ends are connected.

Electric welding. Welding can be useful in thin-walled steel pipe applications where the cut threads would be too weak. The welding method is often used when installing steel casing - although it takes some time and requires good welder skills from a specialist, it can be cost-effective (no need to purchase expensive heavy pipes with threads and thick walls).

Rice. 13 Steel and HDPE casing pipes

Advantages and disadvantages of the method

The technology of percussion well drilling has many advantages over other methods:

- using this method, it is possible to qualitatively open the aquifer and exploit it. The life of the well exceeds 50 years;

- percussion drilling does not require the use of water or special drilling mud. This is very practical;

- using this method to form a well, you can even drill a rock that absorbs flushing fluid very easily;

- the operation of the well can be started immediately after the completion of the entire complex of works;

- impact drilling does not pose a threat to the aquifer. After carrying out the whole complex of works, its clogging is excluded;

- do-it-yourself impact drilling of wells is carried out with the formation of a hole with a large initial diameter;

- with the help of this drilling rig, it is possible to carry out exploration work. The excavation of the rock is carried out throughout the depth.

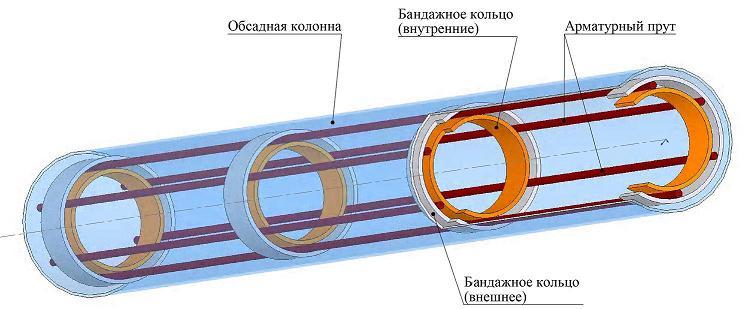

Installation of casing bored piles

Installation and arrangement of the pile foundation is carried out directly on the construction site. In principle, the do-it-yourself installation technology of such a design is quite simple: it is necessary to lower the pipe into the well, reinforce it and concrete it. In length, such structures can be up to thirty meters with a diameter of up to one and a half meters, although with the improvement of technical support, the length can be doubled, and the cross section increased to 3.5 m. With such parameters, the bearing capacity of bored supports will be 500 tons.

In most cases, the structure is buried by 5–12 m with a diameter of 25–40 cm. Do-it-yourself assembly of metal structures is carried out according to the following scheme:

- A well is filled with concrete mortar per meter;

- tamping of the solution is carried out;

- the casing gradually rises to the level when the concrete drops by 35 - 40 cm;

- this process must be repeated until the rod is completely filled with mortar.

The walls of the leader well for the casing during drilling become rough and loose due to the collapsed soil, therefore, a gap is formed between the hole and the metal structure, which is compacted with mortar, and the concrete, in turn, seeps into the soil structure and makes it more durable.This technology has one disadvantage, and it is that you cannot control the density of the concrete pour inside the long shaft. This minus can lead to erosion by groundwater of unset areas of the mixture, if such, of course, will be.

The well for the foundation of pipes is reinforced only in the upper part, while the reinforcement cage is buried in fresh concrete by 1.5 - 2 m. Along with the casing, a dry method is also used, suitable for stable and dense soils that withstand the load without destroying the walls. The frame is installed in the well with your own hands, and then the mortar mass is filled. If bored wells are sunk into weak watery soils without casing, then their walls must be reinforced with clay coating, the density of which should be at least 1.2 g / m3.

Application for water wells

When drilling water wells, three types of casing pipes are used: plastic, steel and asbestos-cement. In order to save money and simplify installation, it is recommended to use a plastic casing (PVC or PVC-U).

Installation of a casing pipe is carried out when arranging water wells to any depth. Casing immersion is performed upon completion of cavity drilling. Compound pipes are used, joined by means of a threaded connection.

The diameter of the casing pipe and the well itself is selected based on the required productivity of the source. The cross section of the casing must be such that it can accommodate a drainage pump. The lower sections of the casing string are made of perforated products, the openings of which are blocked by a mesh filter.

There is a lot of controversy about which pipes for casing water wells are better to use - steel, asbestos-cement or plastic. The key disadvantage of metal products is the tendency to corrosion, which can cause a characteristic taste of rust and the presence of sediment in the water, for the purification of which you will have to buy expensive filtering equipment, and the iron products themselves are much more expensive than their counterparts.

Asbestos cement casing pipes are a budget solution, the disadvantages of which are a large wall thickness, which reduces the useful volume of the well, as well as dubious sanitary suitability (there are studies indicating that asbestos cement is a carcinogen).

In general, asbestos-cement products can be used for casing wells under the following conditions:

- when arranging an artesian well (such a pipe cannot have perforations, which makes it impossible to equip a filter column in sand wells);

- in the presence of a hygienic certificate for the product.

In terms of performance, plastic casing is best suited for water wells. Such products are easy to install, cheap, resistant to corrosion and durable (service life up to 50 years).

Plastic casing for water wells

For the manufacture of plastic casing pipes, four types of materials can be used:

- PVC - polyvinyl chloride;

- nPVC is an unplasticized variety of polyvinyl chloride;

- HDPE - low pressure polyethylene;

- PP - polypropylene.

The most popular are products made of PVC-U. Unlike standard PVC products, PVC-U pipes are classified as pressure pipes - they have greater mechanical strength and resistance to deformation, which allows them to be used in wells up to 300 m deep.

PVC and UPVC plastic casing pipes for water wells are produced in the following sizes:

- Diameter 90 mm, wall thickness 5 mm;

- DU 110, thickness 6.3 mm;

- DU 125, thickness 7.6 mm;

- DN 140, thickness 10 mm;

- DU 165, thickness 12 mm.

Most often, pipes with a diameter of 90 and 125 mm are used, since most modern borehole pumps are produced for this size.

Pipe sections (length 3-12 meters), depending on the design features, can be joined into the casing in two ways - using a thread or a socket. The threaded connection, which is easy to assemble with your own hands, provides the greatest reliability and tightness of the casing, however, threaded products are more expensive than analogues with a socket.

The leading domestic manufacturer of PVC and PVC-U polymer casing pipes is Cormell, which supplies the market with products of all common sizes. In addition to the Cormell company, the products of the SPT, Bix and Omega companies have also proven themselves well.

Work order

It is recommended to start with preparatory activities. The first stage is the formation of a platform for mounting a tripod. It is necessary to dig a small pit with a size of 1.5x1.5 m and a depth of up to 2 m. A home-made drilling rig is subsequently installed in this pit. Panel board structures, fixed on the walls of the pit, prevent collapses of loose rocks contained in the surface layers.

The next step is to install a do-it-yourself tripod on the prepared site. At the top of the triangular pyramid, a winch with a cable is mounted, on which a percussion instrument is fixed. A prerequisite is the vertical orientation of the structural parts of the drilling equipment. The slightest deviations will not allow the installation of a casing pipe in a drilled mine.

Subsequent work on drilling wells by the shock-rope method is carried out according to the following algorithm:

- from a height of two meters, a home-made driving glass is immersed into the ground with the help of a shock rod, destroying it;

- with a winch or a well gate, the working body rises to the surface, removing crushed soil particles;

- the projectile is released from destroyed soil fragments, and the procedure is repeated cyclically;

- depending on the characteristics of the rock, the drilling tool is replaced by a bailer or a chisel.

In some cases, the surface layers are moistened by watering the mine with water. In other situations, dry soil is poured into the face.

Criterias of choice

For arranging the casing, it is necessary to have the following information: the depth of the well, the volume of water supply, the diameter of the submersible electric pump, and the financial means of the consumer also influence the choice quite strongly. To determine which pipe is best for a well, consider several options for well sources for water supply.

- For water intake using a submersible electric pump from a shallow well (up to 30 m) of the Abyssinian type, it is best to use a PVC-U polymer pipeline. Depending on financial capabilities, thin-walled products with a threaded socket connection or thick-walled products with versatile external and internal threads are chosen.

- For wells in sand up to 60 m deep, thick-walled PVC-U is a good option, with further depths up to 100 m, various double-cased polymer casing methods can be considered. A good option is to use a rigid pipeline made of PVC-U on the outside, and inside a shell made of flexible and less resistant HDPE.

- For depths above 100 m, it is rational to use a rigid metal casing string, inside which an elastic HDPE or rigid PVC-U pipeline can be placed.

Rice. 14 Appearance of PVC-U pipes

- In any case, when choosing a single-pipe or two-pipe casing, one should take into account the composition of the soil, geological factors, and the level of groundwater. It does not hurt to listen to the reviews of highly qualified specialists on the issue of casing.

- When buying HDPE products, you should be careful due to the fact that recycled technical polyethylene and food primary material are sold in the distribution network.Their main easily distinguishable difference is the color: the pipe from the secondary granule usually has a dark blue or deep blue color, sometimes there is a green tint. HDPE products made from primary raw materials, in accordance with GOST, have a bright blue or light blue color.

- Another criterion for determining a low-quality HDPE product is the smell of plastic. Un can be reminiscent of the aroma of confectionery, detergents, washing powder, etc. - all this indicates the material of manufacture from recycled granules. Pure primary polyethylene is odorless and can be used in drinking water systems without harm to human health, while polyethylene from recycled materials can be used in water intake systems for technical needs.

- When choosing the diameter of the string, they are guided by the flow rate (productivity) of the source and the dimensional parameters of the electric pump; with large volumes of water intake, they try to increase the diameter of the casing string. The pump is selected in such a way that its diameter is not less than 5 mm of the inner size of the wellbore, if a soft HDPE pipeline is used or water intake is carried out at great depths, a larger inner diameter of the column is selected, taking into account the deformation of the channel when squeezed by soil.

- The quality of a PVC-U threaded connection is determined as follows - a pipe is screwed into another or its branch pipe by three turns and then one of the parts is moved to the sides - a large backlash indicates a weak fastening. Such a connection has low tightness, and if it is necessary to dismantle the casing and remove the string from the wellbore, the thread will most likely be torn off.

Rice. 15 Downhole filters and cone plug

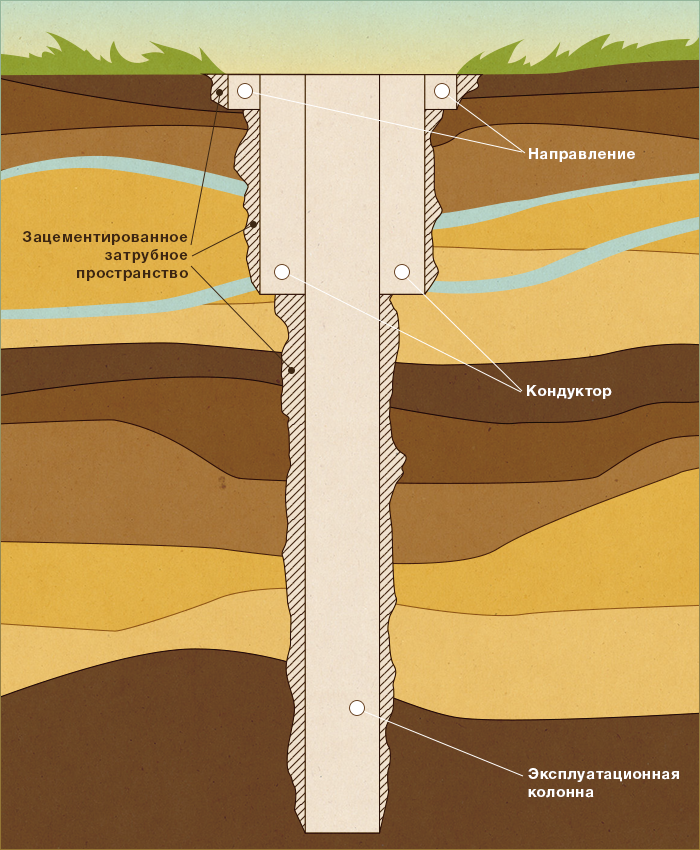

Fixing wells with pipes

Casing pipes are special pipes manufactured in industry with a clear purpose of its use, which is to prevent collapse of insufficiently stable rocks in the walls of various wells.

So, in order to fix the well with the help of columns, casing pipes are immersed in the well, after which the annulus is cemented.

Due to the presence of casing pipes in the well, the well is completely protected from complex stresses, namely:

- External pressure that rocks form;

- Internal pressure resulting from the flow of working agents through the pipes;

- Longitudinal stretching;

- Bending that may occur under its own weight;

- Thermal elongation, the probability of which in some cases is very high.

All this is tested by pipes, thereby protecting the well and ensuring its integrity.

Before the casing pipes are driven inside the well, the internal diameter of the well is determined using a caliper, and the volume of cement slurry required for cementing the annulus is calculated.

This process is mandatory, since it is thanks to the quality of the cement slurry and its pouring that success in mining will be determined. After all, cement mortar not only provides complete tightness of the well, but also is an excellent protection for pipes from exposure to aggressive environments, such as salt solutions and groundwater.When the process of casing the well with pipes is completely completed, the well is left to "rest" for a period of 16 to 24 hours. This is done so that the cement is completely frozen. However, the rate of setting of the solution can be controlled by applying various chemicals. So, the hardening time can either be increased or decreased.

Also, a very important point is the fact that during the preparation of cement mortar for fixing wells, pipes do not use fresh water. This is due to the fact that cement on fresh water does not provide proper sealing of the well due to the formation of a loose boundary layer. The reason for the formation of such a layer is the interaction of excess fresh water in solution with rocks. A much higher quality of the interaction of cement with clay, for example, is provided by a saturated aqueous salt solution.

During the casing of the wellbore with pipes, a sufficiently concentrated solution of sodium chloride is used to flush the wells before cementing, as well as during the displacement of cement. In the latter case, for the correct distribution of cement in the annulus, the velocity of the supplied saturated salt solution must be at least 1.2 m/s.

Well before operation. Trial

The casing of the wellbore is considered completed only after the well test, which involves two stages.

The casing of the wellbore is considered completed only after the well test, which involves two stages.

The first stage is carried out immediately after the cement mortar has hardened. If the well is not deep, then the string is tested at a pressure 2-3 times greater than the pressure that the working agent has directly during development. The strength test of deep wells is carried out at a pressure of 600-1000 MPa.

The second stage of testing oil wells in the pipe and under the casing string after the cement shoe is drilled out. In this case, the optimal pressure for testing is one that is equal to twice the pressure of the working agent.

Carrying out all the necessary tests allows you to determine in time the presence or absence of damage and all sorts of malfunctions that could harm the well, and eliminate them in time.

Thus, a well, formed with all the subtleties, is a durable and strong tool for oil production.

Well construction from scratch

A person involved in the arrangement of wells with water flushing from a to z must take into account that all known drilling methods have their advantages and disadvantages, which will be discussed below.

- screw method.

This option is deservedly considered simple and budget. The vast majority of units used today are developed on the basis of auger equipment. In this case, the Archimedean Screw, rotated by hands or an electric motor, takes out the earth. A significant disadvantage of this method is that the depth of the well will not exceed 10 meters. Flushing is not required for such work.

- rotary method.

If the desired depth exceeds 10 meters, then the deepening is carried out using a rotor. In fact, this process looks like this:

- The column structure, which has already been discussed above (a hollow product with a rotor and a chisel inside) is immersed in the ground. The rotating rotor creates a channel of a given depth, while flushing is carried out in a direct way (the solution enters through the pipes and exits outside the structure) or reverse (the solution is pumped outside the part and removed using a pump) method;

- Optimal opening of the aquifer is more easily achieved by the second type of flushing. At the same time, the result is guaranteed through the use of sophisticated equipment, the use of which inevitably entails impressive costs.That is why, most often - to the detriment of efficiency, direct washing is used, the result is satisfactory, and costs are significantly reduced.

- Percussion-rope drilling.

Despite its own moral and technical obsolescence, as well as labor intensity, this option continues to be very popular. This state of affairs is due to the high quality and impressive operational life of the well. This method is implemented as follows: a projectile is repeatedly dropped onto the ground surface from a certain height, punching a depression. Most often, this process is automated using a winch.

The need to use the solution in the process of performing work does not arise, which should also be considered a positive feature of the method under consideration.

The uncontrolled method is relevant provided that the depth of the channel does not exceed 10 meters. As in the case of other methods described above, when equipping wells with PVA machines, it is necessary to use a drilling mixture that helps to remove waste from the well and form reliable supports (walls) of the channel. In addition, the composition under consideration significantly contributes to the softening of the soil, which in itself simplifies the work performed and reduces the load on the equipment.

The method under consideration is more often used on an industrial scale than for creating aquifers in the areas of private houses, since the use of the system involves the delivery and installation of complex equipment, which is not always appropriate and rather inconvenient.

Video about the features of choosing pipes for drilling wells:

Drilling technology

Do-it-yourself drilling rig is installed only on a site prepared for work. Installation of a home-made apparatus takes place in a small pit - a pit. It should have a depth of 2 m and dimensions - 5x1.5 m. This will prevent the collapse of loose soil, which is usually located on the surface itself. The walls of the pit are reinforced with plank shields.

Only on the prepared site is the installation of a tower operating on the principle of UKB. At the same time, the verticality of the installation of the main structural elements is carefully checked. The slightest curvature of the trajectory of the driving projectile will make it impossible to install the casing pipe and further operation of the created structure.

The destruction of the soil begins with the help of a home-made glass from a pipe trim. With a shock rod, it is sharply lowered to the surface from a height of 1.5 m. With the help of a cable with a winch, the glass is pulled out and the process is repeated from the beginning. If necessary, the driving projectile is changed to a bailer or a chisel, the soil is moistened or a little dry rock is added.

Video: Rope percussion drilling

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Device

High-quality arrangement of the mouth has several goals:

- Ease of installation of the pumping mechanism and its subsequent operation.

- Permanent access to the devices of the mine shaft.

- Prevent dirt and impurities from entering drinking water.

- Reliable sealing of the casing.

- Prevention of freezing of the trunk in the cold season.

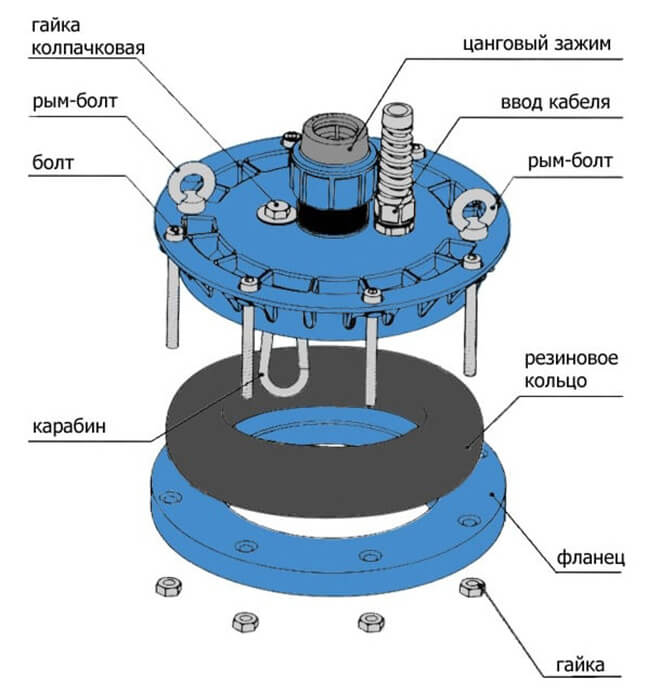

Wellhead fittings

The first is the headline. It is installed directly on the casing and fixed with special bolts. A rubber o-ring is placed on the outside to prevent leakage.

The second is the unloading harness.A complex element of the water supply unit from the mouth. On the upper section there are tees, ball valves, check valves, coarse filters. All components and assemblies work in interaction with each other. The arrangement of the units depends on the number of intake devices and the volume of water consumption. Each project is calculated individually.

The third is a caisson. To protect the source from the ingress of clay, soil, perched water into it, as well as to prevent freezing, the equipment is covered with a caisson. This is a box made of plastic, brick, concrete or any other durable material that completely covers the casing along with all the units. The caisson can be bought ready-made or assembled independently.

Fourth is the pump. The most important element of the extraction of fluid from the bowels. The shorter the distance from the water surface to the pumping station, the easier it is for the impeller to draw in and direct the water. That is why it is better to put the device near the head.

Fifth - equipment for automatic troubleshooting, alarms, sensors for the correct operation of the water supply system. Automation is mounted next to the pump, which allows all units to work almost autonomously.

Scheme

A casing pipe that comes out of the ground to the surface per meter. Head, all equipment is hung on it. Submersible, cable, hose, water distribution unit. Pumping station for deep artesian mines. Electronic sensors of autonomous operation of the source. The exit is completely closed with a protective box or caisson.

Design features of the equipment used

Percussion-rope drilling of wells implies the sequential destruction of the rock by crushing it. To perform the work, a Schitz drilling tool is used. It consists of a complex of parts.

Cup. When drilling wells by the shock-rope method, it is this tool that is used, which is formed from a pipe segment of a suitable diameter. Its end is sharpened, which improves the cutting of the soil during operation. Also at the end of the pipe may be sharp teeth. This facilitates the process of resolving soil that is formed from wet clay or a mixture of clay and sand. As a result, the soil sticks to the walls of the glass and is removed outside.

Bailer. It is a piece of pipe equipped with a valve. It allows the soil to penetrate inside, but does not let it out. This allows you to clean the well from the rock destroyed during drilling.

Bit. It is used for do-it-yourself percussion-rope drilling of wells when it is necessary to destroy rocky soils.

Winch. It is installed to facilitate the descent of the impact glass, which ensures the drilling process.

Frame with shock bar. It looks like a tripod. For effective operation, the height of the structure must exceed the length by 1.5 m or more.

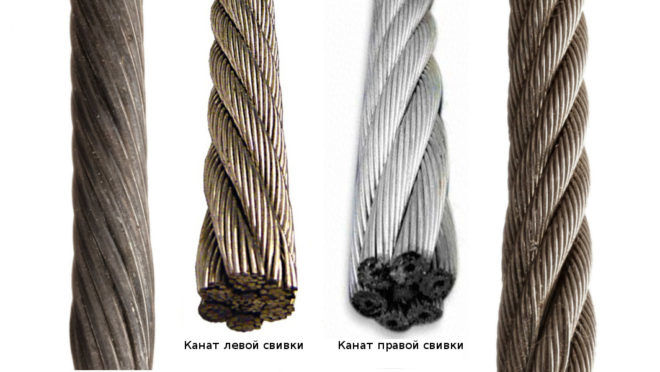

Cable. Provides movement of the cutting glass to the required depth. The cable is usually made of steel. It must have a diameter greater than 12 mm. This provides a sufficient margin of safety. The cable must withstand loads of non-standard sizes that may appear during the drilling process.