Scheme 1

(Side or diagonal connection, unconstricted unbiased bypass)

This scheme provides the supply of coolant to the upper part and the release of the cooled coolant back to the riser from below. Circulation through the heated towel rail is provided only by the gravitational pressure of the water cooling in it.

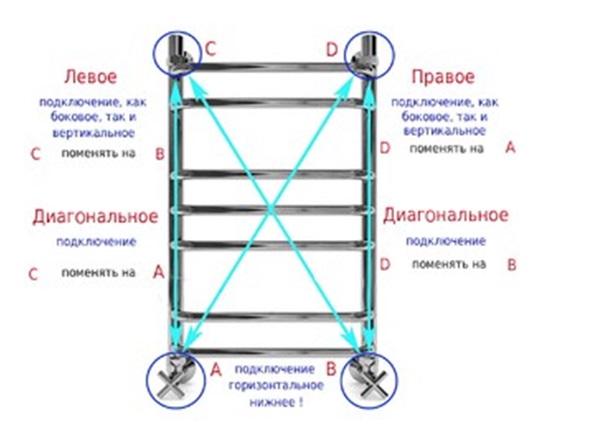

Ladder side connection, working on natural circulation, without constriction and without displacement of the bypass

Diagonal ladder connection, running on natural circulation, without constriction and without displacement of the bypass

The diagonal option for connecting a heated towel rail does not have any advantages over the side one.

Lateral connection of the U/M-shaped heated towel rail, running on natural circulation, without constriction and without offset bypass

This wiring diagram is universal:

- Works with any direction of supply in the riser.

- Does not depend on the circulation rate in the riser.

- It is not required to bleed air from the heated towel rail after turning off the water.

- Distance from the riser - up to 4-5 meters.

Conditions for the scheme to work:

- The lower outlet of the riser must be below the bottom of the heated towel rail or on a par with it, and the upper outlet of the riser must be above the top of the appliance or on a par with it.

- With a bottom feed, there should definitely not be any narrowing between the taps. It will interfere with the operation of the heated towel rail up to complete inoperability! At the top feed, it is permissible to narrow the bypass by one step of the diameter of the riser (this option will be discussed in detail a little later), but it is not required for the operation of the device.

Connection according to this scheme with bottom feed in the riser is very critical to the quality of installation. Any narrowing between the taps, which, for example, occur when the polypropylene welding technology is violated, harms its work. These are nozzle overheating, exceeding the heating time of the pipe and fitting, pushing the pipe into the fitting with excessive force without depth control. Narrowing can occur if there are welds on the riser between the bends or if there are displacements of the riser pipe relative to its axis between the bends.

Why narrowing / offset between taps at bottom feed interfering with the towel warmer? Because it creates an additional pressure drop due to the movement of water in the riser (at the lower outlet - more than at the top), which counteracts natural circulation, which pushes water back into the riser through the lower outlet.

Important note: since natural circulation is provided by cooling the water in the appliance, with this connection there will always be a temperature difference between the top and bottom of the heated towel rail. However, in a well-mounted device, it is only 3-4 ° C, which cannot be felt by hand - above a certain threshold, the temperature is perceived as “equally hot”

If the difference is greater, then either an installation error was made, or the temperature of the hot water supply system was overestimated. Try to measure the temperature of the hot water in the system, as well as the temperature of the top and bottom of the heated towel rail.

Permissible options for the execution of scheme No. 1

Lateral connection (correct example)

The entire heated towel rail is vertically placed strictly between the outlets, the correct slopes of the supply pipes are observed, and no working conditions are violated.

Lateral connection (example of a conditionally permissible design)

The heated towel rail is located above the top outlet. You will need to bleed air from the upper left corner of the instrument. An ordinary radiator will not allow this to be done without very inconvenient tricks (for example, loosening the union nut of the upper water outlet), air will stand above the dotted line, and the device will not work.

For the full operation of this option, it is mandatory to install an air valve strictly in the upper corner for water supply. Only a few models of heated towel rails allow you to do this, in particular, the Sunerzha brand of the “+” series (“Bohemia +”, “Galant +”, etc.).

The air valve in the opposite corner from the water connection point cannot bleed all the air out of the appliance!

Scheme 2

(bottom connection)

Slightly less effective than the side, but has its advantages.

The distance between the branches is any, in order to normally weld the pipes and screw on the taps so that their handles do not interfere with each other during rotation. For example, 15-20 centimeters.

Bottom ladder connection, running on natural circulation, without constriction and without offset bypass

Lower ladder connection operating on a combination of forced and natural circulation, with bypass offset

The lower connection of the ladder, working on a combination of forced and natural circulation, with a narrowing of the bypass

Benefits of the scheme:

- Works with any direction of supply in the riser.

- It is possible to run pipes discreetly under the bathroom, without chasing the walls.

The disadvantages of the scheme:

- It is required to bleed air through Mayevsky's taps.

- Slightly less efficient than side connection.

Conditions for the scheme to work:

- The top outlet of a riser with an offset or narrowed bypass must be lower than or level with the bottom of the appliance. This guarantees the independence of the heated towel rail from the direction of supply. For top feed, the top outlet can be positioned above the lower edge of the appliance.

- The lower outlet must be lower than the heated towel rail in all variants of this scheme so that a dirt pit does not form from the supply pipe and the device itself.

Bottom connection (example of conditionally permissible design)

The bottom of the device is between the taps. With a bottom feed in the riser, a low height of the heated towel rail, or a large distance between the taps, this circuit may not work or be unstable.

Installing a water-type heated towel rail

The water type of heated towel rail, the installation procedure of which will be described below, can be easily installed by hand.

Scheme of the correct connection of the heated towel rail.

Installation of any heated towel rail is always carried out according to a given scheme:

- Removing an old towel dryer.

- Installation of cranes.

- Installation of a new dryer.

- Installation quality check.

If everything is done according to the scheme described above, the procedure will not take more than a few hours. Each of the steps above will be discussed separately.

Before connecting a new water heated towel rail, be sure to get rid of the old one.

This is done by hand in this way:

- the supply of hot water to the pipe to which the heated towel rail is connected is blocked (this can be done either with your own hands or by contacting the necessary authority);

- dismantling of heated towel rails with side contact and any of those that are not part of the hot water pipe (in this case, the threaded connections are simply unscrewed);

- in the event that the thread is “sticky” or the device is strongly welded to the pipe, it should be cut using a grinder.

Important! In the process of dismantling the heated towel rail, trimming is carried out with the calculation of a pipe section sufficient for threading. The dismantled device must be removed from the brackets

Then you can safely proceed to the installation of cranes. In the case of cutting off the old device, a new thread can be cut on the remnants of the pipe using a die of the required diameter. If the thread on the pipes remains, it must also be removed to improve the quality of the thread connection.

After putting the threads in order, it is necessary to mount the valves of the shut-off type, that is, taps.

This is necessary in order to:

- adjust the intensity of the device by opening or closing its taps;

- in case of need for repair (for example, when the heated towel rail is leaking) or in replacing the device, shut off the water and perform all the necessary actions for this.

https://youtube.com/watch?v=vC4heReuh7E

If you want to install a jumper, you should provide for its installation at the current stage.

Depending on the type of heated towel rail used, you should choose fittings - angled or straight.

Each threaded connection should be sealed with a special linen winding with your own hands. For conical connections, FUM tape is used.

Next, the device is connected to the fittings, the fasteners are tightened (at the same time, care must be taken not to damage the thread).

The heated towel rail is attached to the wall with your own hands or with clamps, or using specialized telescopic holders.

It is very important to correctly measure the distance from the wall (cladding or plaster) to the pipe axis of the device. https://www.youtube.com/embed/kUI7G-SW8Mo

https://youtube.com/watch?v=kUI7G-SW8Mo

With a careful study of all the information, the user should not have any questions about how to properly mount the heated towel rail. At the same time, he will definitely cope with the installation with his own hands.

How to choose a water heated towel rail

The first step to installing a towel dryer is choosing the most optimal model.

When choosing a heated towel rail, you should pay attention to the following parameters:

- material of manufacture;

- shape and dimensions.

What materials are heated towel rails made of?

For the manufacture of heated towel rails are mainly used:

- black steel. The material is characterized by low resistance to pressure drops and corrosion, as well as low cost. Due to the susceptibility to water hammer, the devices are recommended to be installed exclusively in private homes;

- stainless steel. The stainless steel towel dryer is characterized by a low level of susceptibility to corrosion, resistance to changes in temperature and internal pressure, as well as a pleasant appearance. The cost of such equipment is higher than analogues made of black steel, but the costs are paid off by the duration of the period of use;

- copper, brass, bronze and so on. Products made of non-ferrous metals are distinguished by their originality, durability and, at the same time, high cost. However, high susceptibility to water hammer significantly reduces the scope of equipment use.

Varieties of towel dryers depending on the material of manufacture

Before purchasing a heated towel rail made of any material, it is recommended that you carefully read the characteristics indicated in the passport.

The choice of the shape and overall dimensions of the heated towel rail

The next selection options are the shape of the heated towel rail and its dimensions.

Currently, devices of various configurations are being manufactured: from standard ones in the form of the letters “M” and “P”, to complex ones, which are multi-stage ladders or convex vines.

Variety of towel dryer shapes

Some models of dryers are available with a shelf designed for vertical drying or drying shoes. The most popular representative is the Trugor towel warmer.

Towel rail with shelf

Which is better? When choosing a shape and size, consider:

- bathroom dimensions. The heated towel rail should not take up much space and interfere with free movement around the room;

- design. Drying can be both a separate design element and elements that fit into the general trend. Selection by this parameter is purely user preference;

- installation method: diagonal, side, top, bottom. By design, the heated towel rail must fully comply with this parameter. Otherwise, additional refurbishment of the bathroom will be required.

Selection of drying by type of connection

The most polar brands

Every year in the Russian Federation, a rating of the most popular models of heated towel rails is developed. According to data for 2018, the leaders are towel warmers of the following brands:

- "Siena", manufactured by the company "Terminus" in the form of a multi-stage ladder (34 steps). The dryer is made of stainless steel and has a bottom connection method. The equipment is suitable for a large bathroom;

Towel dryer from the company Terminus

- Sunerzha High-Tech G. The device is made of stainless steel and can be connected both horizontally and vertically. The main distinguishing feature is the presence of a unique flow distribution system, which, with small overall dimensions, significantly increases the efficiency of the device;

Heated towel rail with vertical and horizontal connection

- Nika LD. The features of this heated towel rail are the presence of a protective chrome coating, which allows you to extend the life of the equipment and give the device an aesthetic appearance, as well as the ability to withstand pressure up to 40 bar, which allows you to connect the device to a heating system or hot water supply system;

Chrome towel rail

- Dvin WW. A standard snake-shaped heated towel rail, characterized by low cost and a high level of reliability. Installation can be made both in the central water supply system and in the heating system;

Reliable and original heated towel rail at a low cost

- An analogue of the Dvin WW heated towel rail is the Boheme model from the Russian company Tera. The device is distinguished by low cost and durability, as well as the presence of additional equipment - a Mayevsky crane, which allows you to eliminate problems with the circulation of the carrier.

Types of cable heater

The heating cable is of two types:

Resistive. Has a low cost. Quite easy to install. It is usually used in everyday life for heating pipes with a diameter of up to 40 mm and for equipping a floor heating system. The principle of operation of this element is to lay special sensors and wires along the entire length of the pipeline. Sensors react to any temperature changes and periodically connect and disconnect the heating system.

You can lay the wire in a spiral and tape way. With the help of aluminum tape, it is attached to the pipes. Under no circumstances should it be overstretched during installation. For even heat distribution, you can wrap the wires and pipes with aluminum foil. You also need a reliable thermal insulation system. Mineral wool is suitable for thermal insulation.

If the air temperature rises, then this process goes in the opposite direction. The self-regulating heating cable has a long service life. Cost-effectiveness and safety of the cable is ensured by reliable insulation.

Advantages of self-regulating cables

- A self-regulating cable has a higher resistance to voltage surges. If the voltage is increased for a long time, the cable will not burn out for a while.

- The self-regulating cable can be cut into pieces of the desired size. But resistive ones have a fixed length.

Photo of installing a heated towel rail

We also recommend viewing:

- Long burning boilers

- Do-it-yourself potbelly stove

- How to clean a chimney

- Heat accumulator for heating

- Heating water pipes from freezing

- Chimneys for gas boilers

- solar collector

- Heating of a private house

- Do-it-yourself oven

- Storm sewer

- Sewerage in a private house

- Plumbing in the country

- Pipes for heating

- Water to the house from a well

- DIY fireplace

- well pump

- Chimney installation

- DIY sewerage

- Heating radiators

- Swede oven

- Warm floor do it yourself

Please repost

What to buy

Wiring diagram for a heated towel rail.

To install a universal electric type of heated towel rail for the bathroom, you should first stock up on a new plumbing fixture. At the same time, you need to be careful and not choose any device, because the usual snake, inherent in many designs, will not be appropriate. It would be most rational to choose a heated towel rail, created according to the type of ladder and equipped with four contact points.

In addition, you should purchase the following tools:

- a special electric heating element equipped with a thermostat;

- Mayevsky's crane;

- 1-2 m of a pipe made of polypropylene or plastic (with all the turns and limit switches necessary for a heated towel rail).

How to choose the right size towel warmer

The specifics of choosing the size of equipment for drying towels is to determine the thermal power of the device, which is directly dependent on the dimensions. The larger the dimensions and the number of intertwined pipes of the structure, the better the ability to heat the room in which the installation is required.

Heating area

- the number of weaves or jumpers;

- construction material;

- diameter of the main and auxiliary pipes;

- coolant temperature (hot water);

- coolant supply mode (frequency of hot water use);

- plumbing area.

It will take a long time to learn and understand all the components that affect the heat dissipation of towel drying equipment. Relying on the rough calculations of experienced specialists, they take the heat output of the coils, with an overall size of 500x1000 mm, equal to:

- 0.5 kW, when connected to the heating system;

- 0.2 kW - to hot water supply.

Based on the existing rules for the selection of heating equipment (1 kW per 10 sq. M), it is clear that such a plumbing fixture will heat the bathroom up to 5 sq. m. m, when connected to heating. Connecting to the hot water supply will allow you to heat the room up to 2 square meters. m. Most of the individual bathrooms of apartment buildings have this area. The above figures make it possible to understand the difference in thermal power with different methods of connecting to communications, and to determine the required size of the heated towel rail.

When choosing a size, take into account the length and height of the wall space on which the plumbing fixture will be installed. The wishes of the consumer for the convenience of using the equipment are also important. The upper part is placed within reach without much effort, and the side dimensions should recede from walls, door frames or furniture by 10–20 cm, for ease of use.

The thermal power, which is taken as calculated, is taken for a conventional M-shaped device. If the coil is supplemented with auxiliary pipes, or the structural ladder has a large number of frequent partitions, then the heat transfer of the device will be approximately 1.5 times greater than the calculated one.

When choosing an electric heated towel rail, it is necessary to clarify its thermal characteristics with the seller. The size of the electrical equipment is not fundamental in determining the heating power. The efficiency of heating a room of electrical appliances is usually directly proportional to the current consumption. If the device consumes 500 W, then it will heat a room up to 5 square meters. m.

Having studied the features of the choice of sizes and connections of heated towel rails, you can safely go in search of the required equipment for the bathroom.

Typical errors for connecting a heated towel rail

Bottom connection (incorrect execution example)

Lateral connection (incorrect execution example)

The heated towel rail is located below the lower outlet. A device connected with such a violation works until a certain height difference “lower outlet - bottom of the heated towel rail” is exceeded, then the circulation stops.

It is undesirable to lower the device below the taps for two reasons:

- The water that has cooled and descended is trapped by the lower part of the device and the pipe (the stagnant zone is from the bottom of the heated towel rail to the lower outlet) and is poorly pushed back into the riser, as lighter hot water presses on it.

- In the resulting "pits" from the pipes, dirt from the riser will accumulate. In the future, with low water quality, you can get a clogged pipe, as well as under-sludge corrosion, if the dirt collector falls on a section of a metal pipe or on the device itself.

Lateral connection (incorrect execution example)

Lateral connection (incorrect execution example)

The top tube forms a rise (above the dotted line in the illustrations) in which air stands. The circulation in the device stops. Theoretically, operation is possible if there is an automatic bleed valve for air at the highest point of the pipe (however, they regularly leak) or a Mayevsky tap.

Lateral connection with offset bypass (example of incorrect design)

Lateral connection with reduced bypass (incorrect design example)

The performance of the side connection with an offset or narrowed bypass and bottom delivery depends on the circulation rate in the riser.

At a low or normal circulation rate, the device does not work, since the pressure in the lower outlet due to displacement / narrowing of the bypass is greater than in the upper one. The circulation pump tends to supply water through the lower outlet, and the "gravity pump" inside the device tends to lower the water cooled in the heated towel rail down. Mutually opposite flows decelerate each other, and the circulation stops.

If the riser has not yet been mutilated by neighbors, and there is a powerful circulation pump in the basement, then it happens that the pump wins, and circular circulation starts in the device. Hot water rises along the left collector, while cooling water descends along the right collector, gradually mixing with the hot water in the left collector through horizontal bridges. However, as soon as someone puts, for example, a barbarian tap on the bypass or connects a forbidden warm floor to the riser, the circulation rate may drop so much that the heated towel rail will stop working. Or it will work unstably - depending on the time of day and the water intake from the riser.

A diagonal connection in this situation is no better than a side connection.

Bottom connection with reduced bypass (incorrect design example)

One of the most common mistakes is that it is so tempting to run pipes in the floor screed without tiring wall chasing…

A device connected with such a violation can only work with a very good circulation rate in the riser. But, as a rule, such a connection is inoperative, because the circulation pressure first needs to raise the water from the pit up into the device, and then raise the cooled and heavier water from the same pit up to the riser outlet.

Also, in the resulting pits, dirt from the riser will accumulate. In the future, with low water quality, pipes clogged with sludge can be obtained.

Rules for installing a heated towel rail common to all schemes

The slope of the supply pipes must be observed (the direction is shown in the figures).For definiteness, you can take a difference of 3-30 mm per meter. With small distances from the riser (several meters) and a large diameter of the supply pipes (PPR 25-32 mm), strictly horizontal laying is permissible.

There should be no "humps" in horizontal sections! Air will accumulate in them and circulation will stop. Dips are allowed only within small limits, deep "pits" will interfere with circulation and become dirt collectors.

Pipe diameter to ensure efficient circulation: at least DN20 (3/4” for galvanized steel pipe, 25 mm for good reinforced PPR, 20 mm for stainless steel pipe), ball valves – at least 3/4”.

The use of pipes and valves of a smaller cross section is only allowed on supply pipes of short length.

It is highly desirable to place the supply pipes in thermal insulation. This is a prerequisite for installation when embedding any plastic pipes: thermal insulation provides their mechanical protection and compensation for thermal expansion. It also improves the performance of the heated towel rail, which receives hotter water.

It is strictly forbidden to install any taps on the bypass - this is vandalism and sabotage to yourself and your neighbors. Closing or excessively narrowing the bypass slows down circulation throughout the riser. Wherein:

- The temperature of hot water drops, as it has time to cool down, reaching the consumer.

- The water pressure in all apartments located further in the direction of supply is drastically deteriorating. And with a certain location of the hot water outlet - and at the very owner of the heated towel rail. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as much.

- The effectiveness of the above schemes does not improve.