Operational period of cast iron pipes

Cast iron pipes are often used for the construction of external networks and the wiring of a sewage disposal system. Elements of sewer networks are manufactured by centrifugal casting. The raw material that is used for this is #8211 gray cast iron.

When installing sewer networks, cast-iron pipes are often used. They are excellent for laying outdoor pipelines.

A bitumen-based coating is applied to the inner and outer surface of the pipe, which protects them from corrosion and increases the service life of cast iron sewer pipes. But such a coating serves not only to protect the metal from corrosion processes, but also to make the inner surface smooth. This improves throughput.

Advantages and disadvantages of sewer cast iron pipes

Let's start with the benefits. Today, cast iron pipes made using modern technologies are distinguished by high strength and reliability of use. They can withstand long-term exposure to high temperatures, are immune to frequent temperature changes and are more resistant to corrosion. The undoubted and important advantage of cast-iron sewers is that they are more affordable than steel ones. With all this, they are more durable in use, their service life is approximately 80-100 years. The operation of cast iron pipes is environmentally friendly.

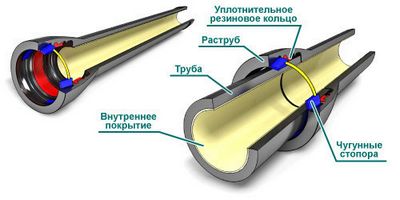

Scheme of the device of cast-iron pipes.

Cast iron pipes are most often used if it is necessary to install a sewerage system that must operate in a constant high load mode.

Due to their severity, cast iron pipes are transported on special equipment.

The disadvantages of using it include the complexity and cost of installation. Transporting cast iron pipes #8211 is not an easy task. This material is heavy, it can only be translated with the help of special construction equipment. Joining parts made of cast iron #8211 is a rather complicated and time-consuming task, on which their effective service depends.

There are two main methods for connecting sewer pipes. The first #8211 is the caulking of the seams. For caulking joints, a cable or other materials are used. In this case, the joints are connected with a cable impregnated with a self-expanding cement mortar. The second method #8211 is to flood the compound with molten sulfur, but you need to be extremely careful when using this method.

Installation of sewer cast iron pipes

To date, manufacturers produce various cast-iron pipes for sewage. Such a diverse choice helps to make sewer systems of various configurations and simplifies their use.

Cast iron pipes are connected using a special coupling.

The service life of cast iron pipes depends largely on the correct installation, so you should trust only proven specialists. Installation is carried out in a certain sequence. First, the tail of the cast-iron pipe is inserted into the socket of the previous part. Then the gaps in the socket are sealed with tow. To seal the gap, it is necessary to use a layer of wound flax tow, which is hammered into the socket. Tow is hammered using a wooden stick, which is hit with a hammer.

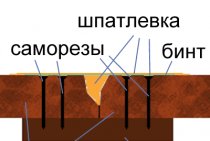

When caulking the bell with tow, care must be taken that sealing material does not get inside. This can lead to the formation of blockage, then the life of the pipe will be reduced.

It is necessary to hammer in the sealing material until 2/3 of the socket is filled. Then it is necessary to fill the socket with cement mortar grades M400 or M300. The solution is diluted 9:1. A wet cloth should be placed on the poured solution so that it dries gradually without cracking.

The described method is used to connect sewer cast iron elements to each other. If you need to connect a cast-iron structure with a plastic one, for example, then adapters should be used. Such parts help to connect pipes of different diameters. For reliability and a longer service life, the adapter with the inside of the socket must be treated with silicone sealants. After that, the adapter is inserted into the socket.

Despite all the difficulties of transportation and installation, they are in demand. This can be explained by their reliability, long service life and low cost. Sewerage made of cast-iron pipes is eternal.

Ceramic

Even the ancient Romans used baked clay to produce ceramic pipes, from which they built systems for draining rainwater and domestic wastewater. Today, ceramic products have successfully competed with cast iron and plastic. According to research results, these materials are less hardy than ceramics.

For ceramic pipes it is characteristic:

- minimum roughness of the internal (working) cavity. Due to this quality, a high flow rate is ensured, which eliminates the possibility of delaying various kinds of precipitation on the walls of the system;

- high mechanical strength;

- resistance to sudden temperature changes;

- chemical inertness. Thanks to a special glaze covering the inner and outer surfaces, special joint designs, sealing materials, not only abrasive wear is completely eliminated, but also the impact of alkaline and acidic environments (pH = 0-14);

- high environmental friendliness, which is expressed in the reliable protection of the contents of the sewer from contact with the environment.

Plastic

When buying plastic pipes, the first question that arises for a buyer may be: “What is the service life of such products, what advantages do they have?” In addition, a potential client is interested in the scope, the main working, linear parameters of the pipes.

Plastic pipes are different:

increased resistance to corrosion processes

Therefore, they are not afraid of moisture, they do not rust, do not rot, which is very important when using products in heating systems and water pipes;

environmental friendliness, since they do not contain chemically hazardous and harmful substances;

low coefficient of thermal conductivity, which contributes to long-term preservation of heat, which cannot be said about metal products;

high resistance to sudden changes in temperature and pressure;

complete absence of noise during the flow inside the water. Due to the internal smooth surface, the possibility of lime and other mineral deposits is excluded;

ease, which is very convenient for loading, transportation, installation;

ease of installation, the connections in which are performed by soldering;

external accuracy and aesthetics;

low cost, which is important for many consumers.

Are applied to installation of water pipes, sewerages, horizontal distributing of systems of heating.

metal-plastic

Metal-plastic pipes are devoid of many of the shortcomings that are typical for products made of pure metal or plastic. The structure of such a pipe is quite simple: the aluminum layer from the inside and from above was covered with layers of polymer origin.

The service life of metal-plastic collectors is significantly affected by:

- ultraviolet radiation;

- the value of the working pressure;

- installation method;

- temperature constancy. This means that it is impossible to first run hot water through the same pipe, and then immediately cold water. Such a procedure, if it becomes regular, can lead to pipe delamination, since aluminum and plastic have different heat expansion coefficients.

If you adhere to these conditions, then metal-plastic collectors can last up to 40-50 years.

Polypropylene

The answer is tritely simple:

- they are not affected by corrosion;

- they are chemically passive to working liquids and gases;

- are distinguished by the simplicity of connections in a single pipeline;

- have a huge range of locking and connecting fittings.

If necessary, they can be easily repaired, replaced, embedded in a different line.

Products do not need to be painted, because they already look quite aesthetically pleasing.

Water supply, automatic fire extinguishing systems, structures for supplying air and other gases, irrigation systems in agriculture, heating networks - this is not a complete list of applications for polypropylene pipes.

The term of service of polypropylene pipes depends on:

- temperature indicators of the carrier;

- working pressure;

- the quality of the source material from which the pipes are made;

- on the operating conditions of the collector and the mounted units.

There is a special table of the service life of polypropylene pipes, which indicates the dependence of the operating terms on the pressure and temperature limits of the carrier:

| Operational period, years | Operating temperature, ⁰ С | MAX pressure, kgf/cm² | ||

| PN 10 | PN 20 | PN 25 | ||

| 10 | 22 | 13,5 | 21,7 | 33,8 |

| 25 | 13,2 | 26,4 | 33,0 | |

| 50 | 12,8 | 25,7 | 32,4 | |

| 10 | 50 | 13,9 | 23,6 | 21,7 |

| 25 | 8,1 | 16,1 | 20,0 | |

| 50 | 7,3 | 14.7 | 18,4 | |

| 10 | 72 | 5,3 | 10,7 | 13,3 |

| 25 | 4,5 | 9,1 | 11,9 | |

| 50 | 4,3 | 8.5 | 10,8 |

Dimensions

The size is classified by inner diameter: standard parameters range from 50 to 110 mm. For example, marking DN 100 means that the inner diameter is 100 mm, and the outer diameter is 110 mm. Standardized markings for cast iron pipes - from DN 50 to DN 400.

Cast iron pipelines for sewer lines have a length of 750 mm to 2200 mm. Pipes without expansion, with polished ends, have increased strength and are made in lengths of 3 m, detachable options can be from 15 cm or more.

The wall thickness of cast-iron pipes practically does not differ from plastic options and is 4-5 millimeters. But the weight of metal and plastic structures is significantly different: 1 meter of a cast iron pipe with a diameter of 100 mm weighs 14 kg, and plastic equipment with the same parameters has a mass of about 1.5 kg.

Standardized sizes of cast iron pipes:

- conditional pass: 50 mm; 100 mm; 200 mm; 260 mm; 350 mm; 600 mm; 800 mm; 1000 mm;

- outer diameter (mm): 81; 118; 274; 378; 635; 842; 1048;

- wall thickness (mm): 7.4; 8.3; 11.0; 12.8; 17.4; 21.1; 24.8;

- length (mm): 750; 1000; 1250; 2000; 2100; 2200.