Mounting methods

When laying water pipes or communications for other purposes using stainless steel pipes, several types of connections are possible, namely:

- welded;

- the use of flange-type connecting elements;

- crimping.

To connect with the help for arranging water supply and heating networks, you will need not only special equipment, but also a qualified specialist. Such a process, as a rule, is carried out, and the welding itself is performed in an inert gas environment. Plasma welding is the most modern method, which allows high-quality joining of stainless pipes, which also requires the use of special and expensive equipment.

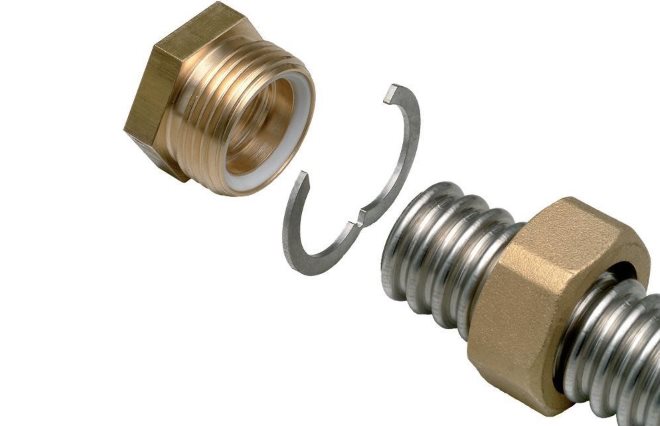

Press fittings provide a quality connection and quick installation, but are expensive and require special tools

In domestic conditions, it is not always possible to use welding, since for this it is necessary not only to have special equipment at your disposal, but also to attract a qualified specialist to manage it. In this regard, in such cases, threadless flange or threaded fitting connections are used.

Flanges are, in fact, two ring elements connected to each other using studs or bolts. To achieve tightness when using flanges, a special sealing element made of rubber or other soft polymeric material is used. Parts such as flanges, which are quite large in size, are used mainly when pipeline elements need to be periodically dismantled and serviced, spending a minimum of time on this. The disadvantages of connections of this type is that they react rather poorly to temperature changes and pressure surges in the pipeline.

The service life of fittings for corrugated pipes is practically unlimited, you only need to change the seals, which can last up to 30 years

A more reliable option are fittings, which are designed with a silicone gasket to ensure tightness. You can dismantle such connections repeatedly and at the same time not worry about their reliability.

Specifications

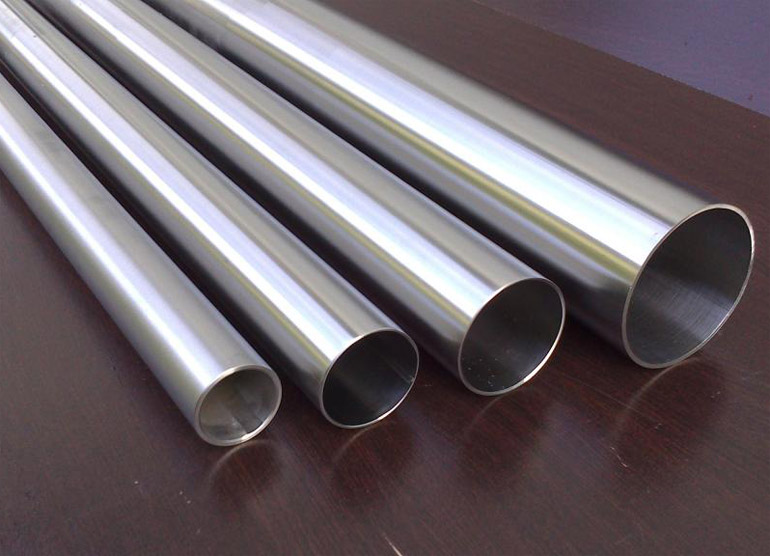

Seamless stainless steel pipes compare favorably with indicators of strength and resistance to rust formation. The absence of welded seams is guaranteed to protect products from near-weld corrosion.

In comparison with electric-welded counterparts, a number of advantages can be distinguished:

- The pipe does not have a welded seam - the most vulnerable part of the product.

- It has the same strength throughout.

In addition, such pipes are effectively operated at high carrier pressures, and are able to withstand destructive external influences. This makes it possible to use them in conditions of high humidity, high and low ambient temperatures. The threshold temperature for a simple carrier is 800°C, for aggressive chemicals - 350°C.

Other important features include:

- The tensile strength of the material is not less than 529 N/sq.mm.

- The relative elongation index is not less than 40%.

- The sulfur content in steel is not less than 0.02%.

The permissible curvature of products is also strictly regulated and should not exceed the following values:

- Pipes with a wall thickness of more than 0.5 mm - 1 mm per 1 m of length.

- Products with a wall thickness of less than 0.5 mm and a cross section of more than 15 mm - 2 mm per 1 m of length.

When buying, you should give preference to large hardware stores and products of popular brands. Perhaps the final cost will be slightly higher, but the buyer is guaranteed to receive a quality product with the required characteristics.

Features of connecting seamless stainless pipes

The main competitive advantage of such products is the absence of welds, which are the most vulnerable point of any welded pipe. For this reason, increased requirements for quality and reliability are imposed on the connection procedure.

Pipes are joined only by welding, and the process can be carried out in manual, semi-automatic or automatic mode. One of the following technologies is used:

- TIG. Welding is carried out in an inert gas environment, which protects the treated area from oxidation. The heat source is an electric arc formed between the tungsten electrode and the welding point. Subject to the technology, the seam turns out to be even, uniform and not inferior in strength characteristics to the material of the pipe itself.

- HF. Less expensive technology, which, however, does not provide such strength indicators. Welding is carried out using high-frequency current.

- laser. Laser welding is not inferior in seam strength to TIG technology, while allowing you to reduce the melting zone and make the seam less noticeable.

Thus, seamless stainless steel pipes can be safely called one of the most practical, strong, durable and environmentally friendly pipe materials that allow you to implement any project: from the installation of industrial pipelines to the manufacture of elegant furniture. The only disadvantage of such pipes is the justifiably high cost.

Choice of stainless steel chimney

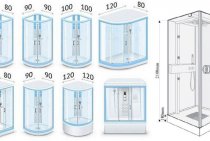

The design of the stainless steel chimney includes cylindrical sections with a length of 1.0 and 0.5 meters, as well as numerous additional elements:

- turns at an angle of 90, 120, 135 and 150 degrees;

- adapters for connecting pipes of a different size;

- adapters for connecting sandwich and single-wall pipes;

- tees for connecting connections;

- dampers or internal dampers for draft adjustment;

- clamps for strengthening the joints of pipe sections during installation;

- brackets for attaching the external chimney to the wall of the building;

- transitional glasses for crossing ceilings and roof structures with a chimney.

In the delivery set, sellers offer various fasteners for mounting and installing the chimney.

In addition to the above, you must definitely purchase a head for a pipe or deflector. For solid fuel units, in some cases it is necessary to use a head with a spark arrester.

If the chimney is intended to remove products of combustion of wood, it can be equipped with a protective cap with a mesh spark arrester

The listed accessories for the chimney allow you to assemble a channel of any configuration. In doing so, the following requirements must be taken into account:

The total length of the chimney must be more than 5 meters. Only under this condition can we count on normal traction.

If necessary, a horizontal transition device on the chimney must not exceed one meter in length.

The use of more than two turns at shallow angles in the design is undesirable. This can negatively affect traction.

When crossing interfloor floors and roofs, a fire crossing device is required. The design of the roof penetration depends on the angle of inclination of the slope

It is important to ensure not only fire safety, but also tightness.

The chimney inside the boiler room is made of single pipes without insulation, all its parts located in the cold room and the external component need thermal insulation, for example, using a sandwich pipe.

When buying materials, pipes and components must be checked with a magnet. Good quality stainless steel is not magnetic. It belongs to the austenitic class, resistant to heat and aggressive media.A similar material in the ferritic or semi-ferritic grade will corrode even though it belongs to the stainless steel family.

The internal size of the chimney pipe is always indicated in the technical documentation for the heating unit. If a home-made boiler or stove is installed, then the cross section of the chimney is selected in a ratio of approximately 1:10 to the size of the furnace compartment. In private houses, pipes with a size of 140-150 millimeters are usually used.

The given data will be useful in the selection of material and completeness of the device.

Our advantages

Our company has chosen the installation of stainless pipelines as the main activity. The highest requirements are imposed on such works, and we fully comply with them. We have everything you need to carry out high-quality installation, namely:

- a permanent staff of qualified specialists who hone their professional skills by installing stainless steel pipelines at numerous facilities both in the CIS and abroad;

- modern high-tech equipment designed for the installation of process pipelines made of stainless steel, which meets the high requirements of the market;

- the desire to become the best among competitors;

- the confidence that our many customers, having appreciated the installation of stainless steel pipelines produced by our company, will contact us again and again, and also recommend us to their partners.

Often, Customers face a dilemma: to install a stainless pipeline with the involvement of a company that has rich successful experience in such work, or to entrust the work to a little-known company, which is also ready to perform these works a little cheaper. At the same time, Customers should not forget that by entrusting the installation of a stainless steel pipeline to unskilled performers, they run the risk of facing serious problems during the commissioning of equipment and in the production of the final product. Therefore, we recommend entrusting such responsible work to companies whose specialists have real experience in the installation of process pipelines.

Another confirmation of the high professionalism of the company is the number of its staff. Our company, unlike some of our competitors, has its own large and permanent staff. This confirms our focus on high professional training of our specialists, who are always ready to perform the installation of stainless pipelines for you with high quality and in the shortest possible time, regardless of the amount of work, the remoteness of the facility and the complexity of the tasks.

Our goal and main priority is customer satisfaction with the result of cooperation with PUE “RViMA”. Installation of stainless pipelines, performed at a high professional level, is the key to positive feedback on our work and contributes to the dynamic development of our company.