In our time, it is difficult to imagine a residential building - private or multi-apartment - that would not be connected to gas. Thanks to this wonderful substance, we can cook food and definitely not freeze. However, the gas itself cannot enter the house, and thank God, it needs a special way - a gas pipeline. And in order for it to be, it is necessary to crash into a gas pipe.

In our country, the unauthorized process of tapping into a gas pipe is strictly prohibited, but the number of those who want to do everything with their own hands and against the law does not decrease in any way. Meanwhile, this business is dangerous and often ends in death, which is why, and not because the state is greedy, unauthorized tie-in is prohibited. For home craftsmen and nonconformists who go against the system, we offer a little theory.

A gas pipeline is a means of transporting and storing gas. Depending on the mission of the gas pipeline, the designs can be different: for example, powerful networks are equipped to transport gas over long distances, and the gas flows through them under high pressure. It’s definitely not worth experimenting with him - a very large hole can be in place not only of a home-grown craftsman, but also of the connected house itself. Here it is better to contact special services that know how to work with such systems.

Smaller distribution pipes branch off from any powerful network, the pressure in which is lower than in the main ones. However, it can still vary - from low to high. You can already crash into such a pipe on your own, but still it is better to turn to special services if there is no understanding of what needs to be done and knowledge of safety precautions.

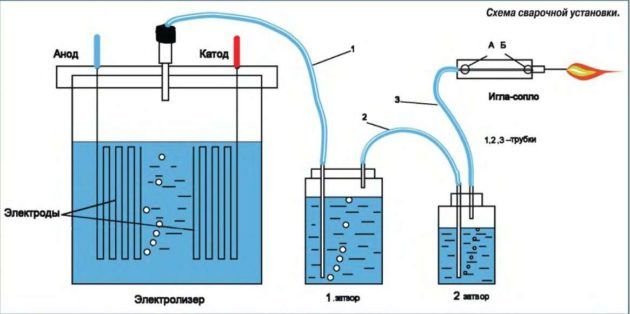

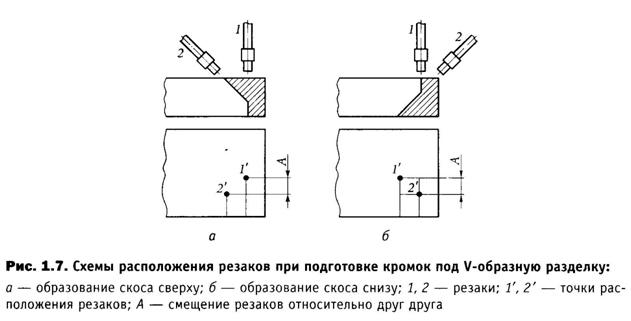

Technological process of flame cutting

In the manufacture of metal structures, not only gas welding is used, but also metal cutting. It allows you to work with such blanks:

- discs, rings;

- contour elements combining straight and curved lines made of steel up to 200 mm thick:

- details of complex configuration;

- sheets with a thickness of more than 4 mm;

- channels from No. 16;

- I-beams from No. 20.

To obtain a high-quality cut, the metal surface is pre-cleaned of dirt, paint, oil or rust. Metal cutting is a thermal processing method divided into stages:

- The heater brings the temperature up to 1100 C.

- The gas burner supplies oxygen to the working area.

- The jet, in contact with the metal, ignites. The core of the flame should be located at a distance of 1 to 1.5 mm from the surface to be treated.

- Under conditions of stable gas supply, the flow easily cuts the workpiece. The jet speed depends on the chemical composition of the material being cut.

Types of gases used

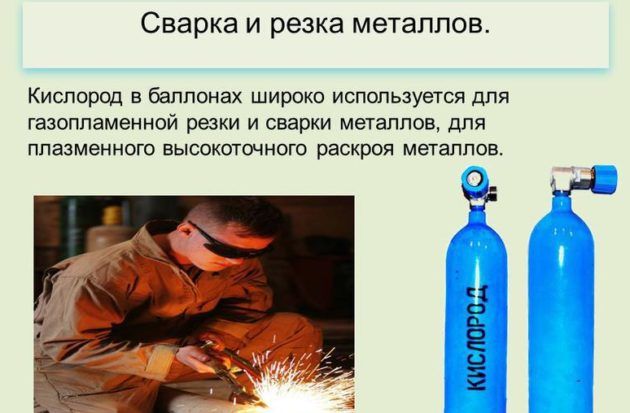

Oxygen

An essential element for soldering and cutting. It is used as a catalyst necessary to activate metal processing processes. It is characterized by the absence of color and smell, poor solubility in water and alcohol. Oxygen is an active chemical compound. It is kept in special containers under constant pressure. Three grades of technical gas are used for oxygen welding. Each species depends on the purity of oxygen. This property affects the quality of processing parts.

Acetylene

The most common type, as it provides a high temperature compared to other flammable substances. It is formed on the basis of calcium carbonate with water. The chemical substance absorbs moisture from the atmosphere and breaks down under its influence, so the compound is stored in closed drums. Acetylene is explosive. However, this quality disappears if the mixture is dissolved in a liquid.

Hydrogen

Has no smell and color.Becomes explosive on contact with air. The chemical element is stored in steel cylinders under pressure.

coke oven gas

Formed through the processing of coal. It is a colorless mixture of combustible substances with a pronounced hydrogen sulfide odor, which is transported through pipelines.

Used on the basis of methane, extracted from the bowels of the Earth.

Gasoline and kerosene

Products of the oil refining industry. They have the appearance of colorless liquids with an odor that evaporate easily. The gas burner feeds them through evaporators to form steam.

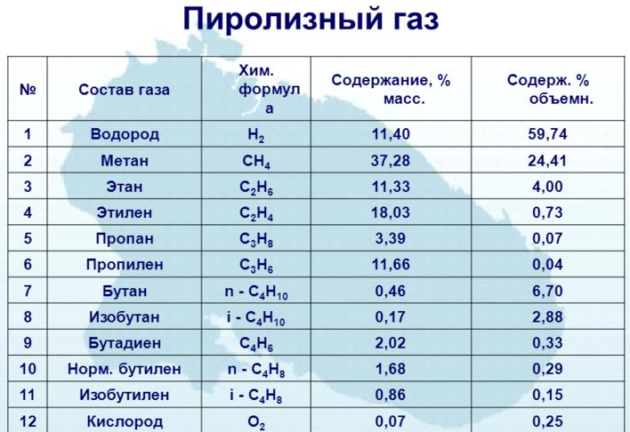

pyrolysis gas

It undergoes cleaning, as it consists of hydrocarbons and carbon monoxide. It is a by-product of oil refineries.

Process description

Naturally, the work begins with the preparatory phase, regardless of whether you will crash into the system yourself or choose a specialized service. If the latter, then you need to contact the appropriate authority, fill out an application, perhaps provide a package of documents prescribed by law. Decided to connect a new pipe with your own hands? This means that you need to buy the appropriate materials, prepare the system and yourself for the planned work. So, if the preparatory stage is completed successfully, we start the sidebar.

Connection of metal systems

- Surface cleaning. Remove from the place where you planned to make a frame, paint, debris, rust.

- Markup. Determine where the connection will be, put the marks.

- Making holes (with the coil method - 1, with the tee method - 2).

- Well treatment. Slots should be treated with clay, and it is recommended to start this process even during the cutting of the surface in order to minimize the risk of burning / igniting the leaked blue fuel. Ready holes should be closed as quickly as possible with a special (made of asbestos and clay) plug. The treated area must be cooled.

- Installation of the disconnect device. When the metal has cooled, the plug can be opened to remove a fragment of the cut pipe from the structure. After removing a piece of metal, a disconnecting device is placed in the slot, which is a set of disks made of wood and rubber, as well as small bowls with viscous clay. If you stick to the tee method, then there will be two such slots.

- Pipe installation. When the disconnect device has covered the gap, it's time to start making the main hole - under the attached (new pipe). Check the correct diameter, it is possible that the markings will have to be corrected. Make a hole, install a pipe. Weld the joints of the pipe on both sides, then close the valve on it.

- Closing the hole. So, the pipe is welded, now you need to weld a new pipe. To do this, first remove the remains of the metal that appeared as a result of making the main slot. Put them in their place, work with clay, and brew them too. Check if the welding seam is leaking gas (using soap).

- Attaching a new pipe.

Cutting into a plastic pipe

Increasingly, plastic structures are used for the installation of engineering networks. If you need to connect to such a system, what should you do? First, be glad that the process will not be more complicated than in the case of metal. Secondly, strictly adhere to such recommendations.

Buy high-quality - factory-made, GOST-compliant connecting elements (fittings), ideally - metal. Use a socket joint and special glue to increase the reliability of the seam. Make sure that the junction is perfectly sealed, has a maximum density. Before installation, treat the insert with an anti-corrosion compound.

How is the tie-in itself carried out in the case of plastic networks? The connection is made by creating inserts perpendicular to the working system. The length of the inserts can vary between 70-100 cm.The extension should take place with the help of plastic pipes - on the basis of a socket-contact connection. What is this technology? The steel insert is heated (approximately to the level of 60 degrees). And a plastic structure is already being put on it, moreover, instantly and with force. If you crash into a system with medium pressure, experts advise connecting powdered polyethylene to the “case” in order to make the connection as strong as possible.

Crashing into a gas pipe is certainly better with the help of professionals, however, knowing the theory, you can experiment, meanwhile, it's up to you.

Safety regulations

The connection of the main gas pipeline to the centralized system is carried out taking into account the rules to ensure maximum safety during the performance of work. These rules include:

- tapping into the low-pressure pipeline is carried out in the range of this parameter 20 - 80 mm of water column. If there is a pressure below or above these indicators, the work is performed only after the stabilization of the parameter;

- insertion into the pipeline of medium and / or high pressure is permissible only after the indicator has decreased to the parameters indicated above. If pressure reduction is unacceptable or impossible for any technical reasons, then the work is carried out with the involvement of specialists with the appropriate permit and specialized equipment;

- if the pressure in the gas pipeline is higher than 40 - 150 MPa, then it is forbidden to use equipment for welding and gas cutting when performing work.

The place of work on tie-in into the central gas pipeline should be limited by warning signs with the inscriptions "Caution, gas", "No passage" and so on. It is unacceptable to make fire near the place of work, including smoking.

Signs warning about work on the gas pipeline

Cold tie-in to the main gas pipeline

Tapping of branches into main pipelines is carried out using a device that allows work to be carried out without stopping pumping at a working pressure in the pipeline up to 6.4 MPa.

A complex of works on tie-in into an existing gas pipeline under pressure using hot work is performed by a specialized team. Preparation of the gas pipeline for tie-in is carried out by a subdivision of the enterprise operating the gas pipeline. For hot work under pressure, an order is drawn up - a permit. A specialized team must be trained and certified to perform welding and tapping work using special equipment.

Prior to the start of tie-in work, it is necessary to conduct a survey of the gas pipeline section where the tie-in is planned. The laying depth of the gas pipeline is determined, the location of the longitudinal axis, marked with pegs installed every 50 m, and signs 1.5-2.0 m high indicating the actual laying depth, installed within sight on straight sections of the route no more than 50 m apart, in points of intersection with a branch. Determine the position of the gas pipeline in the vertical (laying depth) and horizontal (in plan) planes.

Work on tapping under pressure using welding on gas pipelines is only allowed if the chemical composition of the pipe metal at the tapping point is known. At the place of installation of the tie-in unit, the presence of surface and internal defects (laminations, cracks, shells, etc.) is not allowed.

Before carrying out work on quality control of the metal, clean the surface of the pipe under pressure for the entire length of the tie-in section of the gas pipeline in the pit from soil residues and insulation. Cleaning should be carried out only by hand, or by sandblasters, scrapers, brushes, or other non-impact tools. Determine and mark with chalk the location of the tie-in and the installation of the tie-in nodes.

Perform quality control of the pipe metal at the installation site of the tie-in unit using the ultrasonic method.

Measure the pipe wall thickness at a distance of about 100 mm on both sides of the weld circumference.

Assembly and welding of joints is carried out in accordance with the requirements of SN 111-42-80 and VSN 006-89.

Requirements for welded joints made on a gas pipeline under pressure:

circumferential welds when welding lining, split tee, coupling and main pipe are performed with the obligatory position of the deposited weld layer on the pipe body.

the penetration depth of the main pipe wall at the position of the root and deposited layers of the weld should be 2.4 mm, but not more than 40% of the pipe wall thickness.

at the position of the longitudinal welded seams of welding the floorboard of the split tee (coupling) between themselves, the depth of penetration should be equal to the wall thickness of the tee (coupling).

Penetration of the wall of the main pipe is not allowed.

The parameters of the welding process are set in accordance with the basic requirements for ensuring safety and quality of work:

preventing burn-through of the pipe wall;

prevention of metal cracking in the heat-affected zone due to flow and gas cooling and hydrogen cracking.

Welding of tie-in units on an existing gas pipeline under pressure should be carried out with mandatory preheating of the surfaces to be welded.

Preheating is carried out before applying the root weld, as well as each of the subsequent layers, if the temperature of the weld area to be welded has fallen below the minimum limit.

The preheating temperature of the surfaces to be welded is controlled using contact thermometers and thermal pencils.

The temperature of preheating of the surfaces to be welded for welding the tie-in unit to the body of the gas pipeline must be 100ºC, not more than 250ºC.

Preheating is done using a gas burner or electric induction heaters.

Deviations from the nominal dimensions of the outer diameters and ovality of the pipes should not exceed the limits that provide the allowable gap when welding the tie-in unit to the surface of the gas pipeline.

If the deviation limits are exceeded at the intended tie-in location, the tie-in location is shifted.

It is forbidden for the period of production to work on a gas pipeline with a mortise under pressure rise in pressure on parallel and crossing gas pipelines.

The opening of a gas pipeline under pressure and the excavation of the pit by an excavator should be carried out provided that the cutting edges of the bucket teeth approach at a distance of not closer than 0.5 m to the generatrix of the gas pipeline from all sides, while the undercarriage and supporting elements of the excavator should not move directly above gas pipeline.

Connecting the system to the gas pipeline

To tie into a common highway, you will need to carry out the following activities:

- Clean the joint of debris, rust or paint.

- Make a markup, mark the place of the tie-in.

- Make holes, of which there will be two - in the case of the tee method, and one - with the coil.

- Close the cracks with clay. Processing must begin at the moment the surface is cut. This will reduce the risk of gas fire. Close the holes made immediately with a plug made of clay and asbestos, after completion of work, cool the surfaces.

- Mount the disconnecting device after the final cooling of the metal. To do this, pull out the plug and remove the part of the cut pipe. After that, insert a disconnecting device into the resulting gap - it looks like viscous clay sacks and several rubber and wooden discs. In the case of using the tee method, there will be two slots.

- Now you need to mount the pipe through which the gas pipe is connected to the main. But first, check the diameters match.If nothing needs to be corrected, then make a hole and mount the pipe, then weld the joints and close the valve installed on the pipe.

- We close the holes and weld a new pipe. To begin with, get rid of all the remnants of metal formed during the creation of the main gap. After that, connect the pipe to the nozzle, process with clay and weld. The quality of the weld is checked with a soap solution.

If no leaks were found, then you can proceed to the finishing work - that is, backfilling the trench. Despite the fact that the work may seem very simple, they must also be carried out in compliance with regulatory documents.

As a rule, such documents contain the following information:

- Soft soil no more than 20 cm thick is poured around the mortise unit, pipe and tap, followed by compaction.

- At the very end of backfilling the trench, heavy equipment should not be allowed to run into pipes, mortise units and a ball valve.

Upon completion of construction work, it will be necessary to sign an agreement with the local gas service to start supplying blue fuel. In addition, the gas service will be required to carry out technical and emergency dispatch services. The same organization will deal with the acceptance of the finished gas pipeline system. After the start-up and adjustment work, it is imperative to draw up an act, as well as seal the gas control system.

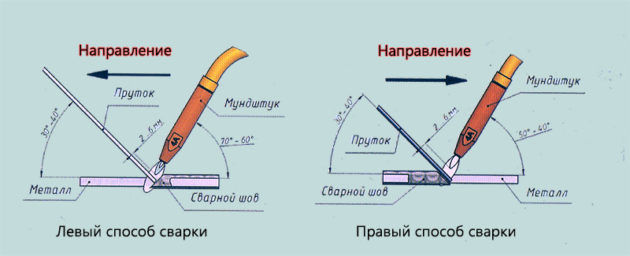

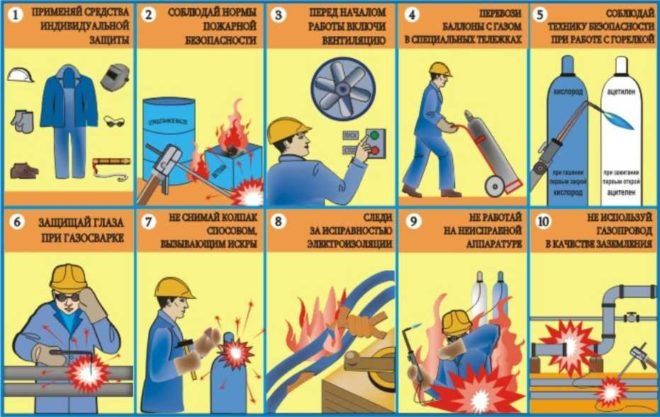

Safety

Gas welding and cutting are not complete without observing safety regulations. During work, the welder is exposed to all sorts of potential hazards.

Comprehensive precautions:

Protection against electric shock requires:

- Grounding the device.

- Insulation of conductive parts of equipment.

- Dry, undamaged clothing.

- Exclusion of work in wet weather.

Eye protection requires the use of a special mask with light filters.

Gas welding is a threat of burns, fire explosions. To help avoid an emergency:

- Outfit in overalls.

- The absence of open combustible, flammable substances in the places of work.

- Availability of fire extinguishers.

- Compliance with the technological regime.

Against poisoning with toxic vapors use:

- Respirators.

- Efficient ventilation in the room.

- Masks similar to gas masks.

Illegal tie-in and its consequences

Most often, illegal tie-in is carried out by individuals who are disconnected from the gas pipeline for non-payment, or who want to connect a house, garage or any outbuilding without coordinating the project and paying for both the connection itself and the subsequent use of gas. Depending on how severe the damage was caused to the gas pipeline during the tie-in, the amount of gas used, as well as the consent or disagreement of the guilty person to resolve this issue peacefully and pay all the due fines, administrative or criminal liability may be applied.

In the event of causing particularly large damage and unwillingness to compensate for it, as well as revealing the fact that such tie-ins are not being carried out for the first time, articles of the Criminal Code of the Russian Federation 158 (Theft with open access) and 165 (Causing damage by deception) can be applied to the guilty person ). Therefore, it is better not to take risks and obtain all the necessary permits and conclude an appropriate contract.

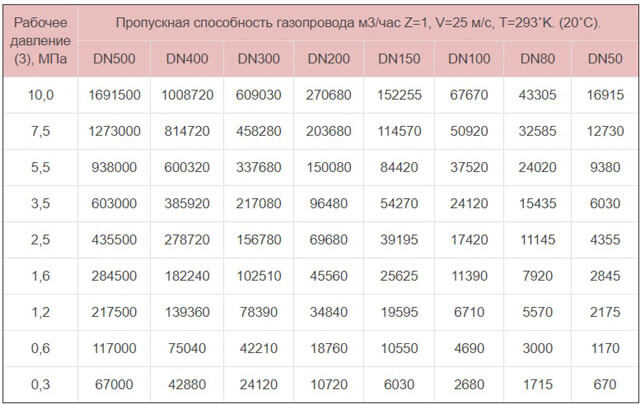

Specifications

Uninterrupted gas supplies to consumer homes directly depend on the throughput of gas pipes. In this regard, the calculation of this parameter is made especially carefully. Moreover, this process is mandatory regardless of the material used products - polymers or steel.

To determine the maximum throughput of each specific pipe, the following formula is used:

Q max \u003d 196.386 T × (P / Z) × (D y / 2),

where P is the value of the constant working pressure in the gas pipe, increased by 0.1 MPa; D y - the size of the conditional passage of the pipe; T is an indicator of the temperature of the gas passing through the pipe in degrees Kelvin; Z is the compression factor.

Based on the formula, we can conclude that the higher the temperature of the gas transported through the pipes, the greater their throughput should be in order to prevent leaks, loss of tightness or even explosions.

Although in their professional activities, masters often use more complex formulas for calculating throughput, nevertheless, the above calculation method is more than enough for self-selection of pipes of the desired diameter.

Insert Features

What is a notch? In professional terms, this is the connection of a new pipe to a working "relative" - already transporting blue fuel. Often, systems are connected without shutting off gas, even trunk lines, but there are important nuances in this process. So let's look at how to crash into a pressurized gas pipe.

Work rules

Remember the basic rules for handling these systems:

- it is permissible to make a tie-in into a low-pressure network at pressure indicators not exceeding 80 mm of water column, but not lower than 20;

- connection to highways or networks with high / medium pressure is possible only after its level has been reduced to an acceptable level;

- if it is impossible to reduce the pressure, you will have to find special equipment that allows you to make a tie-in under unusual circumstances;

- work without reducing pressure by law is allowed to be carried out only by relevant organizations that have permission for this type of activity (sometimes even receiving a special outfit);

- gas welding and cutting can be carried out in areas with a pressure of 40 to 150 kg / cm (moreover, this corridor must be observed throughout the entire process).

Insert types

You can connect a new network to a working system using the following technologies:

- Cold tie-in, in which the main pipeline operates without changes (the volume of blue fuel in the structures and the supply pressure remain the same - working). According to this “scenario”, gas networks of new users are often connected to the main. Many craftsmen know how to crash into a gas pipe without welding, since this technology is relatively simple.

- Welding, popularly called the “traditional method”, is a reliable, time-tested technique, however, requiring certain qualifications and special access from the performers involved in the connection.

As for the methods of tie-in itself, they are divided into:

- reel, implying attachment to the end of a working system;

- tee, when the insert is made with the intersection of the axes of the networks.

Basic requirements for high pressure pipelines.

Welding of a high-pressure pipeline is distinguished by a number of special requirements for it. The main difficulties in carrying out such work are related to the fact that we are talking about pipes that are characterized by a large wall thickness and, at the same time, a relatively small diameter. In addition, it is necessary to take into account the peculiarities of the media passing through such pipes - they can have both very low and very high temperatures, therefore, especially high requirements are placed on the weld, which must have ideal strength and tightness, and besides, it must not succumb to corrosion.

That is why special attention during the installation of high-pressure pipelines is paid to quality control of the weld, for which special compositions and equipment are often used.

Varieties of tapping and preliminary actions

The preliminary preparation stage is mandatory in any case, whether you are a beginner or an experienced master.If you yourself do not know how to crash into a gas pipe without welding or otherwise, contact an office that specializes in such work.

When contacting a contractor, when applying for a tie-in, you may be asked to present a whole package of documents prescribed by law for such cases.

When carrying out the initial tie-in into the gas main of communications of a newly built house, the following documents will be required:

- permission for a tie-in into a gas main from an architectural and planning institution;

- a topographical image of a specific area, certified by the gas industry. In addition to gas pipes, all communications connected to the building should be marked on it: water supply and sewerage, heating;

- technical passport or its copy, certified by a notary, a number of other documents.

But those owners who understand the intricacies of tie-in work into main gas pipelines, and are also quite sure that they can cope on their own, should only purchase the necessary materials. However, be careful, as crashing into a gas pipe is illegal, not entirely safe. In the event of a violation of technology, damage to the main line can be provoked, which can threaten not only harm to life and health, but also administrative and criminal liability.

There are two ways to connect a working gas pipeline to a new branch.

cold tie-in

In this case, the main pipe continues to operate normally without changes in the volume and pressure of the transported gas. They prefer to use this method for the initial connection of new subscribers.

Those who prefer to do their own tapping into a pressurized pipe most often prefer this technology, as it is the easiest to perform.

welding method

But the method of connecting gas pipes to the main lines can be reel or tee. With a coil connection, the ends of the pipes and the operating system are joined, and with the tee method, the axes of the pipelines are crossed.

Standards for safe tapping into gas pipes

Before crashing into a gas pipe, you need to take care of safety at the facility. There should be no open sources of fire near the gas pipes, so the place of work must be isolated from smokers, and indeed strangers in general.

In addition, on the way to the tie-in point into the gas pipeline, warning signs should be placed with the inscriptions “Caution, gas!”, “No passage!”, “No smoking!” and others with similar content. Such requirements are obligatory for execution, in order to avoid accidents.

When making a tie-in into a gas pipe, it is also necessary to follow certain standards for working with them.

The most significant rules are:

when connecting to a gas pipeline with low pressure, it must be ensured that its value does not rise above 80 mm Hg, but also does not fall below 20 mm Hg;

if work is planned in networks with high or medium pressure, then before starting the tie-in, this indicator must be lowered to an acceptable level;

gas cutting or welding of pipes can only be carried out on those sections of the pipeline where the pressure fluctuates between 40-150 MPa

Moreover, it is important to ensure that this indicator is within acceptable limits during the entire time of work. The standard is legally fixed, according to which only enterprises that have received a special permit or even an order can perform tapping into gas pipelines without reducing the pressure level in them.

The standard is legally fixed, according to which only enterprises that have received special permission or even an order can perform tapping into gas pipelines without reducing the pressure level in them.