Welded gutter pipe bracket

A gutter system with reinforced gutter brackets will ensure that water drains from roofs safely for the home.

When choosing a gutter system, you should pay attention to the fact that galvanized materials will cope with any weather. Such a downpipe bracket is used to provide resistance to severe loads on the downspout system.

The mount with a reinforced holder is made taking into account these influences, therefore it contains additional stiffening ribs in its design. Such ribs help to withstand additional loads from strong gusts of wind, heavy rainfall and snow. In the cold season, you can often observe the freezing of water inside the pipes, and reinforced bracket options will help here. They will allow you to hold the weight of frozen water that is unbearable for conventional fasteners.

Why a reinforced bracket?

The drainage system must be reliable and practical. Experts note with regret that in rare cases in our country the drain is properly arranged. When creating these systems, few people care about the thermal expansion of the material, significant loads from incoming water. But if you act decisively and purposefully, all the troubles with the drain can be avoided.

In any scenario, a good gutter pipe bracket is always needed. A worthy choice would be a reinforced welded bracket, capable of holding structures with increased weight on the facade. Success in the construction of a drain largely depends on its quality. With a large weight of the system, the facade is strongly affected. This means that you need to be more careful in choosing mounting hooks.

Downpipe brackets from our factory

Galvanized materials provide excellent metal protection against corrosion and rust. For greater protection of galvanized products, we offer a polymer coating that increases the service life by 2 times or painting in any color of the RAL catalog

Please note that we produce both drainage systems and additional elements for buildings. Therefore, all products painted in one place will completely match in color.

Dowels or anchor bolts are used to attach the reinforced downpipe bracket to the wall. Reinforced pipe fasteners are attached to the wall at an increased distance. The service life of the gutter system is largely dependent on the correct construction and fastening. Therefore, follow the installation instructions for the fasteners, and your drainage system will be a long-term assistant and protector of the house from the effects of precipitation.

Types of brackets and holders for fixing gutters

The gutter is fastened to the roof, building facade, cornice or any base using fixtures. There are several types of them, they have different functions. The type of bracket has an impact on the sequence of installation of the roof. There are brackets that are attached before the roof is laid, and there are those that can be installed at any time.

The gutter is fastened to the roof structure using a holder (bracket) or hooks. There are two types: long and short. It is desirable to use a metal mount, it will provide high reliability of the structure.

The shape of the bracket should repeat the design of the gutter. Fasteners for the drain are selected depending on the material of the walls. To assemble the structure, you will need different options for brackets:

- long;

- short;

- universal;

- downpipe holder.

Long brackets

Subject to power load, since the entire mass of the gutter with water rests on them

You should pay attention to the choice of this element.It is mounted along the perimeter of the facade before laying the roofing material.

Its fastening sets the necessary slope of the entire system.

Short brackets

They serve as an auxiliary support for the parameters of the horizontal structure. Short brackets can be used at any stage of construction.

Universal brackets

Perform the functions of both long and short brackets. The size of the holder itself is adjustable. If they are used as a long one, they should be mounted before laying the roofing material, if as a short one, then at any stage of construction. They are attached to any surface, even on pins hammered into the wall.

downpipe holder

There are special types for gutters that are designed for roofs with non-traditional coatings:

- Holders that reinforce and align the edges of the roof (they are in the form of a bracket or clothespin).

- Holders with which you can adjust the slope of the mounting base.

Helpful Guidelines When Installing Pipes

The gutters of the drainage system must be attached either to the walls with self-tapping screws using special brackets, or screwed to the frontal boards. The method of installing the gutter to the frontal boards can be used if the catchment system is made of plastic materials. In addition to screws, metal anchors or ordinary nails can be used to fasten the drain to the walls.

If you decide to mount the catchment system already during the construction of the roof, then the mounting brackets can be screwed to the rafter supports located at the bottom of the roof batten system. Do not forget that when marking out the place for fastening the brackets, it is worth considering the slope of the gutters to the drain funnels. The slope of the drainage system must be at least 5 degrees so that water can flow into the vertical collection pipes by gravity.

Polymer pipes, located vertically, must be firmly attached to the outer surface of the walls of the building. It is advisable to use special brackets made of metal or at least having metal fittings for this. Usually in the construction markets and in stores you can find a wide range of modifications of the fastener brackets, so you can choose the option that suits the size, quality and cost.

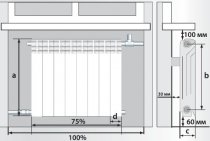

The bracket for fixing the drainage system must be installed in the wall of the house using anchors or self-tapping screws to a depth of more than six centimeters

It is important to understand that this indicator is calculated for the bearing surface, and not for the heat-insulating layer or decorative cladding.

When choosing a bracket for mounting downpipes, make sure that the size of the fastener is slightly larger than the diameter of the system. In this case, it will be possible to avoid deformation of the gutters and pipes due to temperature surges.

Metal constructions

The drainage system must meet the following requirements:

- mechanical strength;

- chemical resistance;

- light weight;

- low cost;

- ease of installation.

Metal ebbs of drainpipes, regardless of the composition of the alloy, have a common drawback - a high noise level.

- Drainage pipes made of galvanized steel are not subject to corrosion, have a relatively light weight and low cost.

-

Pural, or galvanized, coated with a polymer, is gaining popularity due to the possibility of choosing the color of the coating. Pural products have high chemical resistance. Care must be taken during transportation and installation, as polymer coating is quite fragile. Damage to the protective layer contributes to the formation of rust pockets.

- Aluminum ebbs of industrial production are varnished or resistant paint. They have sufficient resistance to negative natural influences. The elements are connected with rivets using a sealant.You can save money by assembling a drainage system from metal sheets, bending them at the installation site.

- Copper gutters are beautiful, durable and expensive.

- Titanium-zinc gutters are considered the most durable, their service life exceeds 150 years. Due to the extremely high price, they were not used in mass construction.

Installation of a drainage system

The calculation of the total length of the drainage system and its diameter is based on the area and slope of the roof. A specialist shop consultant will help you choose the right size brackets and fittings. Unified structural elements speed up the assembly process.

Installation of a horizontal section

Before starting work, it is necessary to mark the horizontal section of the catchment area. For the natural movement of water, it is necessary to withstand a slope in the range from 5 to 20 mm per linear meter. Depending on the roof structure, the brackets are attached to the rafter legs or to the windboard.

- Calculate the height difference given the length of the roof slope.

- Fasten the first bracket so that there is at least 3 cm between the roof overhang and the top of the gutter. Failure to do so will cause the gutter to break during an avalanche.

- Mark the place of attachment of the last bracket at the calculated level, but do not fasten it rigidly, later you will need to adjust the height.

- Pull the thread between the first and last bracket, mark the places where the intermediate brackets are attached.

- Lay the gutters, leaving between them 3-4 mm for linear expansion. For docking, use the connecting elements provided by the manufacturer.

- Fasten the end caps along the edges of the gutters.

The funnel of the drain pipe is located at a distance of 40-70 cm from the end of the gutter, so the last bracket must be raised 0.5-1 cm from the calculated height to ensure the movement of water to the funnel.

Gusset

vertical section

The vertical part of the drainage system is assembled from pipes. Elbows must be used to move from the horizontal to the vertical part of the system. The fewer bends, the less chance of clogging. Pipes are fastened to the wall using brackets. It is necessary to strictly maintain the vertical, checking the correct installation using the building level.

Drainage mark

Lastly, the drainpipe is installed. The height of the drain hole varies from 20 to 40 cm above the soil or blind area. The water discharge distance must be at least 50 cm from the wall of the building. It is possible to bring the mark into a storage tank, into a storm sewer, a filtration well, a drainage system or into the nearest body of water.

https://youtube.com/watch?v=6hoBj9WXiQQ

Plastic structures

PVC products are distinguished by high consumer qualities, combining:

- low cost;

- wide color spectrum;

- light weight;

- ease of installation;

- chemical resistance.

Unlike metal pipes, PVC pipes do not create noise during the drainage process. The mechanical strength of PVC sills is quite high, subject to the rules for installing the system. A wide range of connecting and fastening elements, the presence of pipes and drains of different diameters, allow you to collect drainage systems of complex configuration.

Varieties of drains

Distinguish between internal and external drains. Internal are used in buildings with a flat roof.All types of pitched roofs are equipped with an external drainage system. The area of the roof, the bearing capacity of the foundation, the purpose of the building and its number of storeys affect the choice of material for the outflow of the downpipe. The industry produces metal and plastic systems, which consist of the main elements:

Distinguish between internal and external drains. Internal are used in buildings with a flat roof.All types of pitched roofs are equipped with an external drainage system. The area of the roof, the bearing capacity of the foundation, the purpose of the building and its number of storeys affect the choice of material for the outflow of the downpipe. The industry produces metal and plastic systems, which consist of the main elements:

- Gutters serve to receive melt and rain water along the perimeter of the roof overhang.

- Connectors are designed for joining gutters horizontally.

- External and internal corner elements are necessary for installation of the ebb in the corners of the building.

- The funnel serves as a transitional element between the horizontal and vertical parts of the drainage system.

- Gutter caps are used to prevent water from draining around the edges.

-

Brackets are a fastening element for hanging the gutter system in the under-roof space and fastening the pipe to the facade of the building.

- A pipe is a vertical part of a drain. Designed to receive water from the gutter and drain the liquid down.

- A downpipe bend, or elbow, serves to change the direction of the pipe. The detail is used when bypassing the protruding parts of the facade. There are knees with corrugated or fixed angle bends. The most common angles are 45, 60 and 90 degrees.

- Drainpipe mark - a kind of knee, designed to remove water from the base.

- Protective elements. The gutter net and funnel cap keep leaves and other debris out of the system, preventing clogging.

How to fix drainpipes to the wall

Drainage structures are not only an element of the decor of the building, in addition, they perform the function of collecting water falling on the roof in the form of precipitation, and removing it from the foundation and walls of the building. This allows you to protect the structure of the building from getting excess moisture on it.

Often, professional roofers are hired to install gutter systems, but this process cannot be called very complicated, so almost any owner of a private house with little technological skills and the necessary knowledge that can be obtained in this article can handle it.