The scale is selected from the condition that at operating pressure the pointer is in the middle third of the scale. The scale should have a red line showing the allowable pressure.

In electrocontact pressure gauges EKM, two fixed fixed contacts are installed on the scale, and a movable contact is installed on the working arrow. When the arrow touches the fixed contact, the electrical signal from them is sent to the control panel and the alarm is activated.

A three-way valve must be installed in front of each pressure gauge to purge, check and turn it off, as well as a siphon tube (water seal filled with water or condensate) with a diameter of at least 10 mm to protect the internal mechanism of the pressure gauge from exposure to high temperatures.

The installation of mercury thermometers without a sleeve is mainly used for short-term accurate measurements of the temperature of the medium. Installation of a direct mercury thermometer on a pipeline with a diameter of up to 80 mm: 1 - case; 2 - thermometer; 3 - boss; 4 - sleeve; 5 - expander made of pipe. Mercury thermometers are usually installed in protective (thermometric) sleeves in accordance with the following requirements.

storage tanks

2.2.18.storage tanks

must be specially made

developed projects.

For everyone again

introduced and operated storage tanks

external reinforcements must be installed

structures to prevent collapse

tanks.

2.2.19. Working volume

storage tanks, their location

on heat sources, in heat networks should

comply with SNiP 2.04.01-85 "Internal

plumbing and sewerage of buildings.

2.2.20. Application of typical storage tanks

oil products to replace existing

storage tanks are prohibited.

2.2.21.anti-corrosion

protection of storage tanks should be

carried out in accordance with the Guidelines

instructions for protecting storage tanks from

corrosion and water aeration” (M., SPO

"Soyuztechenergo", 1981).

2.2.22. Locations where they are installed

storage tanks must be ventilated and

be illuminated. Load-bearing structures of the premises

must be of non-combustible materials. Under

tanks must be provided with pallets.

2.2.23. storage tanks

must be equipped with:

pipeline

water supply to the tank with a float valve. Front

each float valve needs

install shutoff valves;

diverting

pipeline;

overflow pipe

at the height of the maximum permissible water level in

tank. Overflow pipe capacity

must be at least the capacity of all

pipes supplying water to the tank;

drain (drainage)

pipeline connected to the bottom of the tank and to

overflow pipe, with a valve (valve) on

connected section of the pipeline;

drainage

pipeline for draining water from the pallet;

circulation

pipeline to maintain if necessary

constant temperature of hot water in the tank during

time of breaks in its analysis. On the circulation

the pipeline must be installed reverse

valve with gate valve (valve);

air (vest)

pipe. The cross section of the windpipe should

ensure free flow into the tank and

free release of air or steam from it (with

the presence of a steam cushion), excluding

formation of vacuum (vacuum) during pumping

water from the tank and the pressure increase is higher

atmospheric during its filling;

equipment for

water level control, alarm

limit levels with the output of signals in

room with permanent attendance

personnel, as well as with interlocks that should

provide: complete cessation of water supply to

tank upon reaching the maximum upper level,

activation of backup pumps when

switching off the working pumps, switching

main power supply

equipment related to

storage tanks, for backup

loss of voltage at the main source;

control and measuring

devices for measuring the temperature of water in tanks

and pressure in the inlet and outlet

pipelines;

thermal insulation,

protected by a cover layer from exposure

atmospheric factors.

2.2.24. Everything

pipelines, with the exception of drainage, must

connect to vertical walls

storage tanks with the installation of compensating

devices for the estimated draft of the tank.

Structural connection solutions

pipelines to the tank should exclude

the possibility of transferring power from these

pipelines on its walls and bottom.

2.2.25. Gate valves on the water supply pipeline to each

tank and dividing valves between tanks

must be electrically driven. Electric drives

gate valves must be placed outside the zone

possible flooding in such a way that

in the event of an accident on one of the tanks, it was provided

operational disconnection from him of others

parallel tanks.

2.2.26. In

avoid uneven settlement of sandy

tank bases must be provided

devices for removing surface and

ground water.

2.2.27.Group of tanks or

free-standing tank should be fenced

earthen rampart not less than 0.5 m high and wide

top not less than 0.5 m, and around the tank should be

blind area completed. In the space between the tanks

and fencing should be organized water drainage

into the sewer system. Around the tanks

located outside the territory of the heat source

or enterprise, should be provided

fence at least 2.5 m high and installed

prohibition signs.

How to install a thermometer on aogv-23.2-1

In your quote, we are talking about a mercury thermometer, does this also apply to liquid ones? Designer of the OV subsection (Minsk, Belarus) Dmitry Dmitrievich Forum member Not currently available Quote: Nkassandra on November 09, 2012, 10:27 am Your quote refers to a mercury thermometer, does this also apply to liquid thermometers? Maybe I don’t understand something, but it seems like a mercury thermometer is a kind of liquid one? I don’t know if this applies to alcohol thermometers, but one can argue: they have the same principle of operation, there is a can of alcohol, for a correct measurement it is necessary to ensure good thermal conductivity of the layer between the frame and the thermometer - which means you also need to fill it with oil. So far I decided to install bimetallic thermometers.

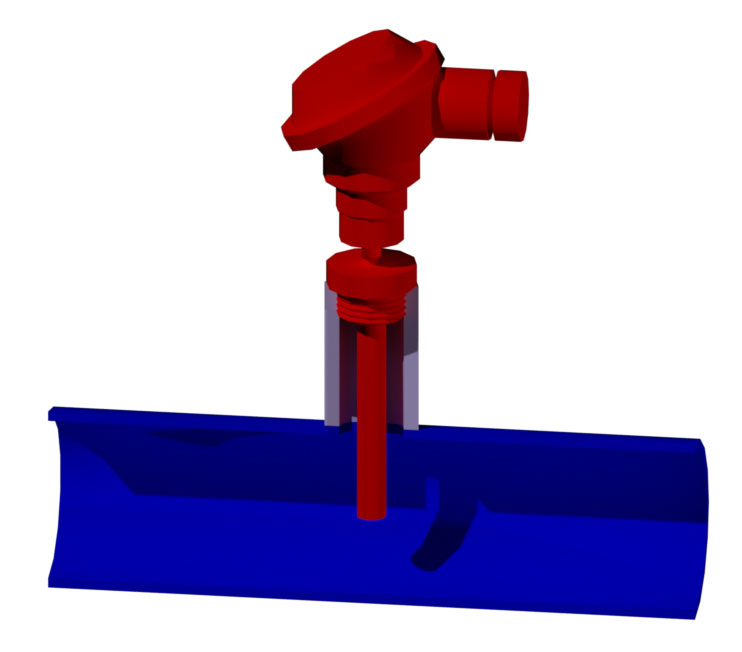

Resistance thermal converter

3d resistance thermometer

A resistance thermocouple from VZLET was chosen. For measurement accuracy, it is necessary to select the sleeve and the boss in such a way that the sleeve is immersed in the pipeline to a distance of ½-2/3 of the inner diameter. Then, a resistance thermal converter is selected under the sleeve. In our case, it did not work out to pick up the boss and the sleeve in this way (they didn’t get 1mm), but for our system this is not critical.

The following equipment has been ordered:

- Resistance thermocouple TPS VZLET Ltps=140 mm

- Protective sleeve basic version VZLET L=57 mm

- Boss No. 7 BP-BT-30-M20×1.5 (for BT thermometer) ROSMA L=30 mm ∅29

In our work, we did without the installation of thermometers: a thermometer, a boss and a sleeve are placed. All this can be viewed at the company ROSMA.

Instrumentation

Do not close both taps when the purge valve is open, as the glass will cool down and may burst if hot water gets on it. If, after purging, the water in the glass rises slowly or takes a different level, or does not fluctuate, then it is necessary to repeat the purging, and if repeated purging does not give results, it is necessary to clean the clogged channel.

Info

A sharp fluctuation of water characterizes abnormal boiling due to an increased content of salts, alkalis, sludge or the selection of steam from the boiler more than it is produced, as well as the ignition of soot in the gas ducts of the boiler. A slight fluctuation in the water level characterizes a partial “boiling” or clogging of the water tap, and if the water level is above normal, “boiling” or clogging of the steam tap.

Thermometers for heating boiler types and installation

If the task is to determine the temperature indicator as accurately as possible, then experts advise making a choice in favor of submersible devices.

- It must be taken into account whether the repair of appliances is difficult.

- Working range. This indicator also affects the accuracy. If the device is chosen incorrectly, then it may show the temperature incorrectly, or stop working.

- Method of taking readings. The inertia of the device, that is, the speed of bringing readings to the real level, should be taken into account.

About Remote Instruments If a remote temperature instrument is selected, the length of the lens must be considered. For a radiator, a device length of 120 millimeters is considered an excellent indicator.

The sleeve length can reach 160 millimeters. It is necessary to look at the distance over which information can be transmitted, the possible error.

How to properly install a mercury thermometer on pipes in a boiler room

When the temperature rises, the pressure in the system increases, and the spring through the lever system sets the arrow in motion. Indicating and self-recording manometric thermometers are stronger than glass ones and allow transmission of readings over a distance of up to 60 m.

The action of resistance thermometers - platinum (TSP) and copper (TCM) is based on the use of the dependence of the electrical resistance of a substance on temperature. The operation of a thermoelectric thermometer is based on the use of the temperature dependence of thermoelectric power of a thermocouple.

A thermocouple as a sensitive element of a thermometer consists of two dissimilar conductors (thermoelectrodes), one end of which (working) is connected to each other, and the other (free) is connected to the measuring device. At different temperatures of the working and free ends, an EMF occurs in the circuit of a thermoelectric thermometer.

If it is not provided in the system initially, then you can always buy it in addition. Checking the device It is not enough to choose a suitable measuring device, you also need to check it after purchase. Experts say that it is best to check the accuracy of the readings before installation. This is necessary in order to be sure that the products are a source of accurate data. If a cheap device is selected, then one can suspect that its readings will be inaccurate.

Attention

You should not save on the purchase of products, because a low-quality device can lead to a distortion of the real picture, a decrease in the efficiency, and reliability of the system. It is quite easy to check, for this you need to take a device and a sensor with an external spike for water

Engineer-technologist, engineer of the 2nd category Design Bureau (Dnipropetrovsk, Ukraine) Nkassandra Curator of the subsection "Heating" Quote: Dmitry Dmitrievich on November 08, 2012, 14:50 Wrote a letter to the manufacturer. I'm waiting for an answer. Even it became interesting, unsubscribe later. I just never thought about this topic, I assumed that if there is an angular frame, then everything is automatically provided for in it.

- 1 Bimetal

- 2 Manufacturers

- 3 Spirits

- 4 Manufacturers

The optimal mode of operation of any heating equipment is regulated using measuring instruments that play an important role in this process - after all, according to their indicators, the mode of operation of the boiler changes. In modern heating appliances, thermometers are almost always included in the mandatory package.

There are two main types of devices for measuring the temperature of the coolant:

- Visualization of current indicators.

- Communication of the thermometer with the boiler control unit. When a certain temperature level is reached, the system adjusts the power level.

Such systems are included in the mandatory set for all gas heating boilers.

For classic solid fuel devices, the first type of thermometer is used.

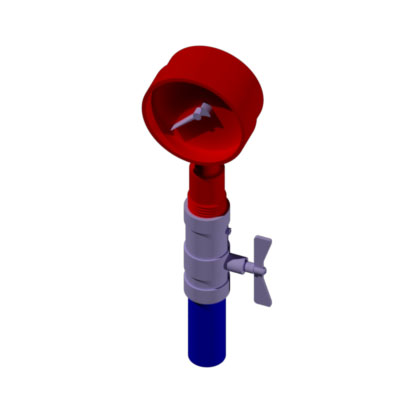

pressure gauge

manometer in 3d

It was decided not to use expensive three-way valves (accordingly, we refused to check on the control pressure gauge), but to install an ordinary valve with the ability to release pressure to zero.

A standard manometer from ROSMA TM-310R.00 (0-0.25 MPa) G1 / 4 2.5 with a diameter of 63 mm, accuracy class 2.5, was chosen. The measuring range is 0-0.25 MPa, the working pressure lies in 2/3 of the scale.

Also ordered:

- Crane DN 15, VILN.491812.015-12 (11B41p30) of the Penza Valve Plant

- Adapter Nr G1/2 Vn G 1/4 L=30mm ROSMA

- Boss No. 4 BP-KR-40-G½ (for taps) ROSMA (it was possible to order a fitting and weld a piece of threaded pipe to it).

Big encyclopedia of oil and gas

Important

HEAT GENERATORS OF BOILER ROOMS Instrumentation and automation (I&C) are designed to measure, control and regulate temperature, pressure, water level in the drum and ensure the safe operation of heat generators and heat power equipment of the boiler room. one

Temperature measurement. To measure the temperature of the working fluid, manometric and mercury thermometers are used.

A stainless steel sleeve is welded into the pipeline, the end of which must reach the center of the pipeline, it is filled with oil and a thermometer is lowered into it. The manometric thermometer consists of a thermocylinder, a copper or steel tube and an oval-section tubular spring connected by a lever transmission with an indicating arrow.

The whole system is filled with an inert gas (nitrogen) at a pressure of 1...1.2 MPa.

Thermometers for measuring water temperature in heating

The pressure gauge is checked in the following sequence: 1) visually notice the position of the arrow; 2) connect the pressure gauge with the atmosphere with the handle of the three-way valve - the arrow should be at zero; 3) slowly turn the handle to its previous position - the arrow should return to its previous (before checking) position; 4) turn the valve handle clockwise and put it in a position where the siphon tube will be connected to the atmosphere - for purge; 5) turn the tap handle in the opposite direction and set it to a neutral position for several minutes, at which the pressure gauge will be disconnected from the atmosphere and from the boiler - to accumulate water in the lower part of the siphon tube; 6) slowly turn the tap handle in the same direction and put it in its original working position - the arrow should return to its original place.