Water well design basic elements

When drilling wells, measures are taken to protect the channel from shedding; for this, several basic elements are included in the device of water producing wells.

Rice. 4 Appearance of casing pipes

Casing

Casing pipes are used to strengthen and seal the wellbore, the main materials for their manufacture are metal, plastic and asbestos cement. Metal pipes are produced from ordinary or stainless steel, there are also galvanized and enameled types.

In addition to threading, pipes are interconnected by welding or by means of couplings.

Recently, HDPE pipes, which are widely used in common sand wells, have been especially popular. A plastic production string can be made up of pipes having a length of 3 or 6 meters, and their outer diameter, designed for the installation of submersible electric pumps, is usually 90, 113, or 125 mm.

Bottom filter

The device of wells producing water on sand necessarily includes a filter, which is located in the bottom of the casing string and is immersed in the aquifer. There are several types of well filters that differ in design and principle of operation.

gravel

The simplest type is created by adding fine-grained gravel to the bottom of the well. The gravel pad prevents the intake of mud solution in the well from sand and silt from the bottom, thus reducing the load on the filtering surfaces of the casing pipes and the electric pump.

Rice. 5 Downhole filters - design features

slotted

A simple device with a casing wall having transverse or longitudinal perforations in the form of thin cuts. Water passes well through narrow cracks, and small particles of sand are screened out. This design is mainly used in HDPE pipes.

Reticulate

It is a fine mesh made of corrosion-resistant materials (food grade stainless steel or fiberglass), which is highly resistant to abrasion. The main drawback of the design is its increased resistance to water flow (by 20-40%), in some cases, with a low flow rate, this can lead to a lack of water in the source.

perforated

The design is used in conditions where high strength is required, it is a pipe with a large number of clarified round holes. The perforated filter is used in sources with a small volume of supply and low pressure.

Wire

It is made of stainless wire of triangular section, wound in dense rows on a perforated casing pipe. It is distinguished by high strength and durability, directly related to the cross section of the wire used in it.

Options for distributing water in a private house

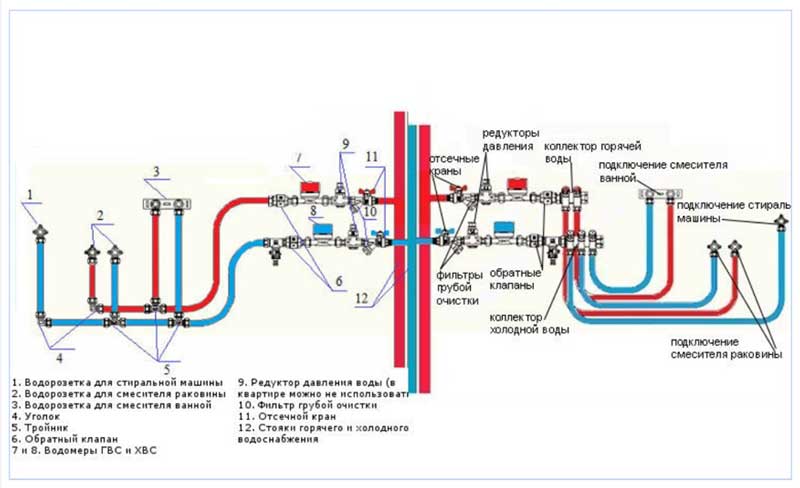

There are two main ways to connect consumers to the water supply, when choosing an option, the volume of water consumed and the required pressure in the system are taken into account.

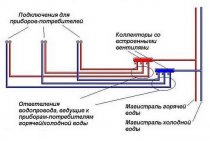

Serial (tee) connection. The scheme consists of a common pipe for hot and cold water supply, from which water is supplied to the consumer using tees, it is economical and easy to install. Its disadvantage is a sharp drop in temperature when several consumers are connected to the line, and the water pressure in the system for the last of them will be much lower than normal.

Parallel (collector) connection. With this method, pipes are laid separately from a common collector to each point of consumption. The system is characterized by uniform water pressure and temperature throughout, but requires a large number of pipes, which complicates installation and is more expensive than the previous version.

Rice. 3 Series and parallel water distribution

Principles of proper arrangement

- Around the mouth, compaction of the soil or pouring a layer of concrete must be carried out.

- The sealing of the upper part of the trunk is carried out taking into account the geodetic features of the area.

- The caisson must be insulated.

- Installation of the head and sealing are carried out immediately after drilling the shaft and pumping it.

- Pumping equipment is mounted as close as possible to the mouth.

- The piping of the source is carried out taking into account its debit.

Wellhead piping is the installation of equipment for supplying water to the surface through the inlet of the mine shaft. The pump, submerged in casing or mounted on the surface, is connected to a hose passing through the head cover.

For the device of the caisson, the preparation of a solid and reliable foundation will be required. Around the mine they dig the soil and pour the ASG. On a well-packed base, concrete is poured with a layer of up to 10 centimeters. Such a foundation will withstand both a plastic caisson and a brick box. Outside, the walls must be treated with waterproofing materials. Warm inside.

Submersible pump installation and connection

To install a submersible pump, a head is usually used, placed in a caisson pit along with equipment, or an adapter is cut into the side wall of the casing. In the latter case, all automatic nodes are placed in a residential building or a separate outbuilding.

Fig.13 Scheme of connection and installation of downhole pumps in the well

When choosing automation for a pump, the main criterion is its cost associated with the submersible electric pump used. When using inexpensive electric pumps of domestic or Chinese production, it is sufficient to use the simplest automatic devices - the functions of expensive control units with such units will not be fully implemented. If an expensive device is purchased (for example, a Grundfos electric pump for $ 1000) with frequency control of the speed of rotation of the electric motor, the use of any other devices other than the native Grundfos PM2 module does not make any sense.

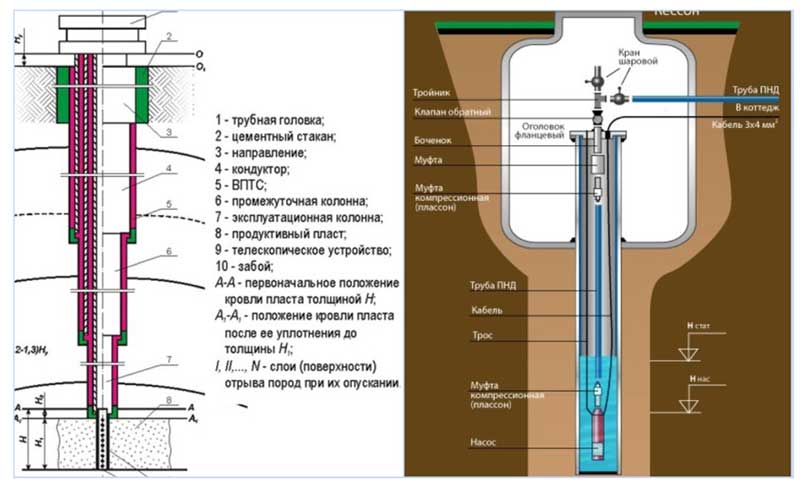

The concept of design and the main elements of the well

The design for a well is a set of elements of a soil excavation with a diameter in diameter much smaller than their length, which ensures a durable and reliable creation of a channel between the earth's surface and the exposed deep reservoir fluid. The main purpose of the borehole channel is geological exploration and evaluation of underground resources, study of the structure of the section, maintaining the pressure of the working layer, monitoring the exploitation of deposits, and the extraction of natural resources.

Wells are divided into the following components:

- The wellbore is a soil working in which casing and filter pipes are located.

- The mouth is the beginning of the wellbore from a pipe segment fixed on the surface of the earth.

- Bottomhole - the lower part of the borehole channel, the bottom.

- The cementing ring is a cement-sand mixture pumped into the space between the walls of the wellbore and the casing pipe, which performs the functions of sealing and strengthening the well channel.

Rice. 2 Well layout

- Filter - the lower section of well casing pipes, immersed in the reservoir with the resource being extracted. As a filter, a part of the wellbore without casing pipes is used, on the bottom of which fine-grained gravel or a special filtering device is placed.

- Casing string - casing pipes connected together and immersed in the wellbore are needed to isolate the borehole from the earthen rock of the wellbore. Provides efficient and reliable operation of the well, preventing soil from entering the channel and protecting it from external pressure.

In the oil and gas industry, intermediate casing strings are used to separate incompatible geological zones that require different modes of drilling a well channel.In the drilling industry, the following intermediate well strings are used:

- Solid. Completely cover the entire trunk, regardless of the location of the main interval.

- Shanks. Columns intended for casing only the open hole interval with partial overlapping of the main one.

- Flyers. Special intermediate casing strings that serve only to close the defective gaps of the main string, excluding the following casing strings.

Rice. 3 Well section

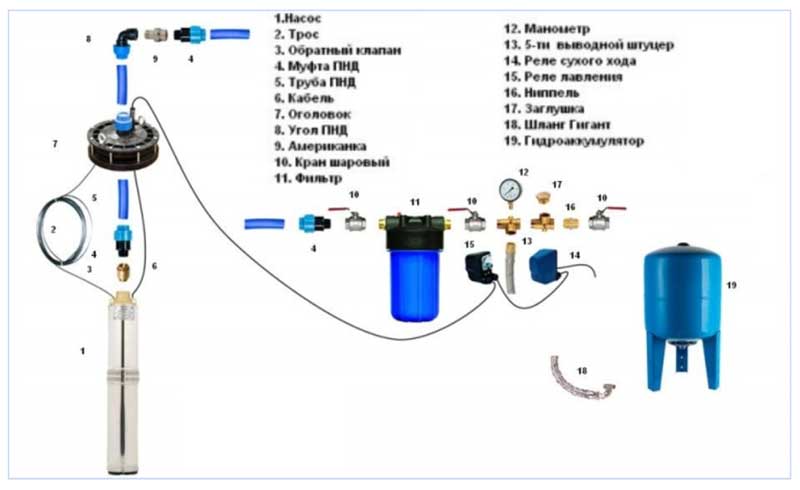

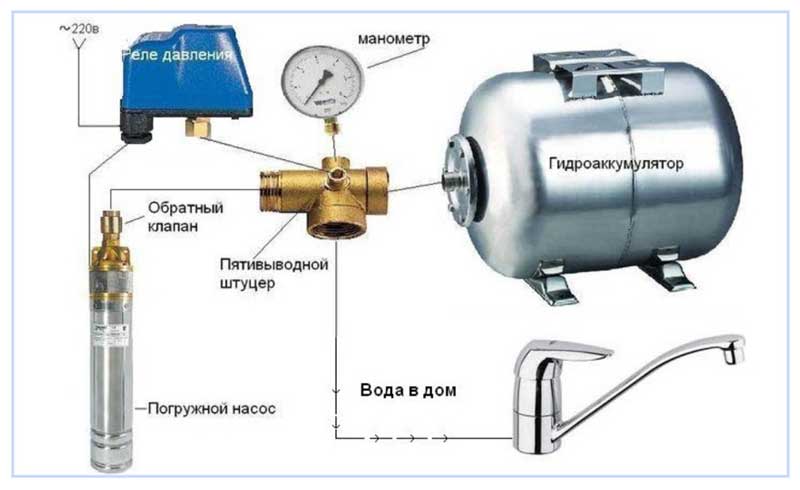

Connection diagram and piping of the accumulator

For reliable operation of the pump, it is connected to an automatic control system, consisting of a relay, a pressure gauge and a hydraulic accumulator. The hydraulic accumulator is the most massive element and performs the following functions in the system:

- Prevents water hammer during pump on/off cycles.

- Reduces the turn-on time of the electric pump, thereby increasing its service life.

- Maintains constant pressure in the system.

- Creates some water supply in the absence of water supply.

The choice of equipment for water intake implies the use of a hydraulic tank of the required volume, which is calculated taking into account water consumption; when buying, balloon-type devices are more often preferred.

During installation, the accumulator must be located next to the main automation devices, which are connected directly to the inlet fitting of the hydraulic tank, or a branch is made to connect it in the form of a flexible reinforced pressure hose of the required section.

Fig.10 Installation of a submersible pump

Well piping is a prerequisite for the optimal functioning of the water supply system. The most popular type is the use of a caisson - such a system protects the water main from freezing in winter and it is possible to install pumping equipment from a volumetric hydraulic tank and automatic control system devices into it.

Downhole pumping units and automation

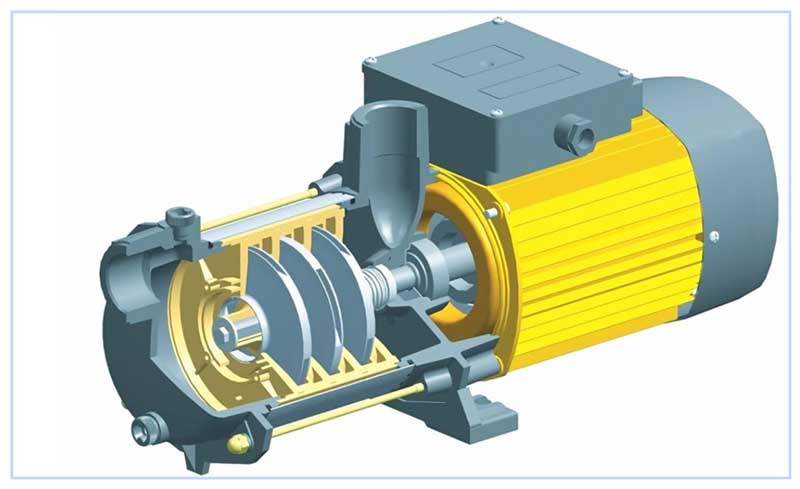

For water intake from wells, surface and submersible electric pumps of the centrifugal principle of operation are mainly used. The advantage of this design is the possibility of creating a high pressure in the line, thanks to the use of units with a large number of impellers, which allow increasing the pressure in each subsequent stage.

Household submersible electric pumps can lift water from very great depths (about 200 meters), while surface types are used in sources with a water mirror at a depth of up to 9 meters from the surface of the earth. To increase the sampling depth of surface models, built-in or submersible ejectors are sometimes used, although their efficiency drops significantly.

Rice. 11 Centrifugal electric pump

Hydraulic accumulator, relay and pressure gauge

To automate the operation of water intake pumping equipment, well automation or a pumping station is used, consisting of the following devices:

- Hydraulic accumulator. It is a volumetric metal tank with a rubber pear inside, which, when the electric pump is turned on, is filled with water. The device avoids water hammer in the system and optimizes the operation of the electric pump, reducing the number of its on and off cycles.

- Relay. The main element of the automatic control system is a pressure switch, which is connected to the line using a fitting. When the pressure in the system rises above its settings, the built-in membrane inside the relay housing, through the mechanical system, interrupts the supply voltage to the electric pump, and it turns off. After water consumption, when the pressure in the system drops, the relay closes the contacts and turns on the electric pump.

- Pressure gauge. The device is one of the main elements in any plumbing system, it allows you to control pressure and set up equipment.

Rice.12 Automation in the control system of electric pumps

The design of water wells is not very complicated, the main internal elements that are installed during drilling are casing pipes and a filter in the bottomhole area. For water intake after well installation, additional equipment and engineering systems (caisson, head, adapter) are used to effectively connect the electric pump to the source, taking into account its location and type.

This is interesting: Moisture-resistant laminate: consider together

wellhead equipment

The casing pipe is made of metal, plastic or polyethylene. Depending on the material of manufacture, the head is installed using different technologies. A flange is welded to the steel casing. A response is attached to it, on which all the equipment will be located. The cover must be deaf. A thread and a distribution unit are mounted in the upper part if a station is used, and not a submersible pump. A pipe or water supply hose is threaded through the cover.

The head for a polyethylene or plastic pipe practically does not differ from steel. The same flanges and bolts, but the gasket between the joints is rubber, not paronite. In the factory version, the head cover has holes with a collet clamp for a hose or pipe that is immersed in the shaft. The cable is entered through a rubber sealed spigot. For ease of installation and repair, hooks are fixed on the flange on both sides.

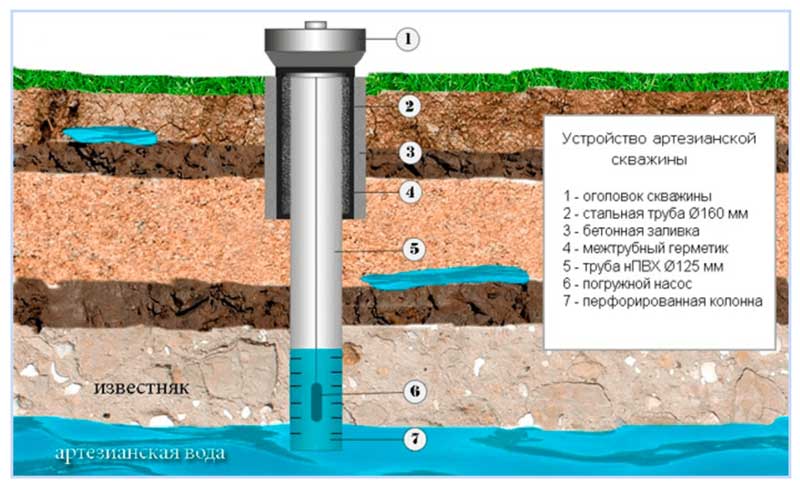

Arrangement of an artesian well for a country house

On a suburban area, it is necessary to establish in advance the location of the future well. The owner carefully studies the project, although a well located in the basement is the most appropriate, because it provides reliable protection for pumping equipment and pipelines.

Wells with a depth of 20 m are equipped with the following materials:

- deep pump;

- sensors that capture the upper and lower indicator of the presence of water;

- a device that provides stable pressure in the water conduit, hydrophore.

For a drilling depth of less than 20 m, an automatic pumping system is installed. Its main components are a hydrophore and a deep pump.

The device of a pumping station for an artesian well assumes the presence of tools for work:

- thin nylon cord;

- coil for loamy soils;

- bailers for the aquifer;

- auger drill;

- shovels;

- couplings;

- drill spoons.

Using a cord, the owner measures the total distance from the water level to the surface of the earth. Before drilling, it is necessary to purchase a diagram showing the geological section of the working section of the well.

For a well less than 20 m, a pumping station is installed, in which the following important components are required:

- suction line;

- water intake;

- pump;

- relay;

- water accumulator;

- motor;

- pressure gauge.

When using pumps for arranging a water well, their positive qualities should be taken into account, namely:

- conformity of performance with real indicators;

- profitability;

- minimal maintenance;

- possibility of operation at low temperatures.

For other modifications of pumping stations, more serious defects may occur during operation:

- relay failure;

- freezing of water at low temperatures;

- high power consumption.

https://youtube.com/watch?v=uAUMmgUgqpQ

A balanced approach is required to the choice of a pumping station for an artesian well. Its depth should be taken into account.

For a well with a depth of less than 10 m, a single-pipe installation is purchased, which reduces the installation time. For deeper drilling, it is necessary to mount a two-pipe station. The deepest wells require the installation of other expensive equipment.

As external work, when constructing a well, it is necessary to install a pumping station.The casing pipe protruding above the ground to a height of 1 m is covered from freezing in winter. To strengthen the pumping station in the basement, they acquire tools and materials such as:

- welding machine;

- steel square pipes;

- corner;

- anchors;

- bolts;

- brick.

The station is installed on a light table or brick elevation. The welded structure is fixed with bolts. For installation of lines it is necessary to use an ejector.

The device of all connections in the ejector must be tight.

For a two-pipe station, a head or outlet of the required diameter is installed, welded to the casing. In the well, the catchment area is joined to a vertical pipe extending from the main. The connection is fixed with a key, and the ejector is mounted in the well. At the point where the water exits the pumping station, filters are installed to purify the water.

A properly created water well equipped with a pumping station will provide a high-quality supply of drinking water to a country house for many years.

Basic methods and equipment for well construction

For water intake from wells, submersible and external electric pumps, pumping stations are used, surface pumping equipment can be located near the wellhead or at some distance from it. To connect electric pumps to a downhole source, various methods and equipment are used, designed for different types of electric pumps.

headroom

If it is necessary to resolve the issue of fixing a submersible electric pump and protecting the borehole channel from the penetration of dirt and sediments, a head is used, which is installed over the casing. The device is designed for a standard diameter, can be made of plastic, steel or cast iron, can withstand the weight of suspended pumping equipment up to 250 kg. in plastic version and up to 500 kg. when using metal. The standard design provides for the placement of a carabiner for hanging the electric pump and an outlet through which the pressure pipe passes when connected to the line.

Structurally, the head is made of two parts, which are connected after the electric pump is immersed in the well. To do this, a flange is put on the casing, pressing it to the surface of the earth, a rubber ring is installed and a second flange with a suspended electric pump is placed on top, fixing it motionlessly with bolts.

Rice. 7 Heads

Adapter

The adapter allows you to connect a surface centrifugal electric pump or pumping station to a well through a pipeline if they are located at some distance. At the same time, the pipes are located underground, which excludes their freezing in winter, the second advantage of this connection is the increase in the depth of immersion of the pressure pipeline into the well by lowering it below ground level, which in surface pumps does not exceed 9 meters.

The adapter is made in the form of two parts, one of which with a pressure pipeline connected is located in the borehole channel, and the second with a water main connected to it is located outside. Both parts are connected through the walls of the casing pipe using threads and an insulating rubber gasket.

Rice. 8 Adapter - structural device

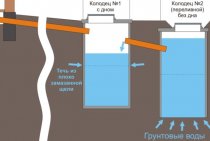

caisson pit

A caisson pit is used in cases where the electric pump and pumping equipment for automating its operation are located near the wellhead. Usually the pit is made in the form of a concrete ring, deepened into the ground, sometimes plastic or welded metal structures are used, covered with bituminous waterproofing. To avoid groundwater penetration into the bottomhole along the wellbore, the bottom of the pit is covered with a cement-sand screed.

Usually, a pumping station or automatic control of a deep electric pump is placed in the caisson wells: a hydraulic accumulator, a pressure and idle speed switch, a pressure gauge. In addition to isolation from groundwater, the caisson provides protection against freezing not only of the wellhead, but also of the entire water main, which, when used, is located underground.

Rice. 10 Caisson well

Principle of operation and varieties

The principle of operation of automation for a downhole electric pump is based on a change in the physical parameters of the water in the line and the water intake source. The pump for a well with automation is turned off and on when the pressure changes, the height of the water column in the source, the speed of the fluid through the pipeline or its disappearance in the line.

When using submersible electric pumps, separate control units and a hydraulic accumulator are installed in the pipeline; in more modern modular models, all devices are combined in one unit.

When using surface units, all control elements are mounted on one frame, the module is called a pumping station - it is much more convenient to use it than to independently install all the elements in a line.

What factors affect the design of a water well

The correctly chosen design of a water well for water determines its most important characteristics, which include:

- Water well price.

- Carefulness of the work performed, their quality.

- Maintainability.

- Composition and properties of produced water.

- Device debit.

The factors on which the design of the structure depends include:

- Hydrogeological features of the area where the device is being built.

- Required debit.

Dependence of hydrogeology on the design of a water well

Depending on the hydrogeology, there may be such device options:

A water intake well with a single casing, where the casing string is also operational. It is used for construction in stable rocks, shallow, not more than 35 meters, sandy. To reduce the cost of the device, it is possible to use plastic casing pipes. The casing string is lowered into the aquifer by two meters.

- Single case device with open hole section. It is most often used for small wells in limestone. In this case, the casing runs through loose rock and then abuts against limestone. After that, an open shaft goes to a depth of up to ten meters from the beginning of the limestone layer.

- Artesian well with plastic production pipe. By design, it is the same as the second. It is used in buildings where the water level is high.

- Artesian well with double casing. One steel casing goes through all the layers that lie above the aquifer, the other goes deep into the aquifer. Used when the water level is low.

- Artesian well with several casing pipes and a conductor. It is done in the case of difficult geology, when there are unstable layers, quicksand. The first pipe is made with the largest diameter, and the guide for the remaining pipes is the casing.

Casing strings

The casing is a system of special pipes. Such elements can be the first and last. They are distinguished by functionality. Casing strings are intended for one purpose - to isolate the walls of the well during drilling from various external influences. First of all, the pressure on the well is taken into account. In order for the annular space to be reliably isolated, it is necessary to fill the gap between the casing strings with a liquid concrete solution.

There is a special division of casing strings by purpose. Each type of such products is worth considering in more detail. They have certain advantages and disadvantages that should be considered.